-

Posts

939 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by garyshipwright

-

Thanks Albert and for the likes to. Hope that the next update won't be as long in coming. Gary

-

Hi Kurtis. The part that you talk about the runs completed through the ship is the keel. It did in fact taper from the middle to both ends being 18 inches squared in the middle,14" at the gripe and 12 1/2" at the forward edge of the rudder. The area where the crew took care of their business was a small deck which had seat's of ease, better known as toilets, and was called the beakhead . As far as finding out what the gripe in todays dictionary, does not exist so what you need is a dictionary from the 18th century like Falconer Universal Dictionary of the Marine. Can't remember other one's but there out there. I took a picture of the 74 gun ship Bellona which shows the parts of the knee of the head along with the other parts that make up the knee. Some thing about figure B3/2 at the top is the stem at it widest at the top and shows that it also get's tapered going down to the keel(item 1) . In front of the stem is the knee of the head once it has been tapered. Photo B3/2 show's a head on view of the taper from the stem- (item 3) to the seat of the figure head ( item 16) . the taper also goes from the Gripe (Item 6) at the bottom of the knee to the seat of the figure head( item 16) I also added another couple of photo's showing how the rail's was done. The photo's should help you and if you need any more info or just what a word means just let me know. When I started building them the biggest hurdle was figuring out what word went with what item of the ship. Thought I was going to go bonkers trying to figure them out. Gary

-

Hi Kurtis. Am not sure what information you have on the knee of the head but the place where the figure head set's is only 5". It tapers from the stem which is 1' 4 1/2" down to the 5 inch's. It also tapers from the Gripe which is a part of the whole knee and is the lowest part which is attach to the front of the keel and is taper going up from 14"down to 5 inches where the figure head sit. If you don't show the taper it probably throw off the placement of the rail's. Hope am not stepping on any one toes but just wanting to help were I can. She looks great and wish I could do this type of work on the computer but am sort of the drafting table type guy. Do hope this is some help to you. Gary

-

Well hello Mike. Been a while since we last talk and wonder what you been up to. You know you been working on Agamemnon as long as I can remember. Hoping with Chuck making a lot of the part's maybe just maybe I just might get her finish in a couple of years. Of course that also depends on the time invested in working on Montague which may take just a little bit longer. Have been keeping a eye on this build, waiting for Chuck to get far enough a head and a lot of the bug's worked out. I must say he has done a heck of a job on this ship. Am sure that there are really great kits to build out there but have settled on this one. Another thing is the price of the build is broken down over time which makes it a lot easier to pay for with out the misses making me walk the plank. It's like comparing it to buying a set of expensive plans, cost a lot but when you break them down for the amount of time it take's you to build it it like pennies on the dollar, It should be interesting and lot of fun to build.

-

Well good sir's I just about have the forward capstan completed, just need to add a few more items to the upper capstan and then I can get started on the main one. Gary

-

Thank you very much Steve. She is my baby thats for sure . Why else would one spend 20 years with her. 😊 She doesn't have a stain good sir just a couple of coats of bee's wax mixed with turpentine. Welcome to the site, you couldn't find a better place any were on the internet. Allan if you need to steal my log to welcome a new member you go right ahead and look forward to your next update. Gary

-

Looking good Glenn. You planking job is outstanding and really look's good. Gary

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I took a look Ben and must say am impressed. You building board reminds me of the one on my 74 as far as the outside rail's. I didn't have them for the longest time and if I had them when I started her, would of come in real handy. Think it was 19 years ago, maybe a couple of year's after I finished Richard up which I believe it was 98. Probably spent the in between time to figure out what I wanted to build next.

-

Scratch Builders Reply

garyshipwright replied to Dave_E's topic in Modeling tools and Workshop Equipment

Hi Richard. I have the dewalt scroll saw, and three table saws. A ten inch cabinet saw from grizzly, Jim saw with a new 18"x 10" table top and a Preac saw for cutting grating and other parts. My Jim saw get's a lot of use compared to the other two and really enjoy using it. I would recommend the dewalt scroll saw and the Jim saw. Can't do with out them that's for sure. Also have the sherline lathe and mill which the mill gets the most used between the two. Gary -

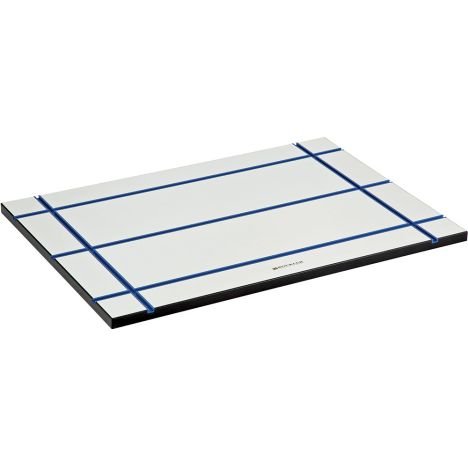

Thanks JJ, working on the progress part as we speak. Was wonder what other's such as your self was using and what size's. That's one of the thing's that I wish I did with Alfred's build board and made the build table 4 to 5 inches longer. I purchased a Rockler T-Track table top, which is 28"x 40" and was wonder if the length would work. Had it for awhile and couldn't figure out what to use it for untill now. Been sitting on the work bench so hopeful I won't have to go out and buy another build board. With the track's built in should be a big help with keeping it all squared up. Also thanks for the welcome.

-

Thanks Trussben and Chuck. Don't mind using your size Trussben but what thickness is it? Chuck this will come in very handy and very helpful. Also, was wondering where I can find some good photo's of the Stern before any planking is put on. Hope that some of the member's show me the way. Very curious about how you or other member's built it up. One thing about the stern it can make you have a really bad day. Seems am like a fish out of water and if you must know have never really built a plank on bulkhead model. Tried once but that ended up in the round file. Thanks. Gary

-

Well I have finally pulled the plug and decided to start a build log on building the Winchelsea while also working on my 74. Why some will ask, some times it's nice when you don't have to make all the parts and piece's, but she still have a lot of parts and pieces to make along with the ones that Chuck makes for her. Some call her a kit but I would say 50 50, and to me it still takes as much skill and understanding to build her as well as a 74. May take a little time to get her up and running but am working on that. I can't seem to find the answer to how long , wide and thick does the build board need to be? I came across that the hull length which is 38 inches so a length of 42 to 46 inches would be just about right. Tomorrow I plan on going to have the plan's blown up to a 100 percent which should help me figure out the size of the build board along with other question I have, and then I can start cutting and make the bulkheads along with the her Bulkhead former. Glad to be aboard. Gary

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.