-

Posts

3,315 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Hubac's Historian

-

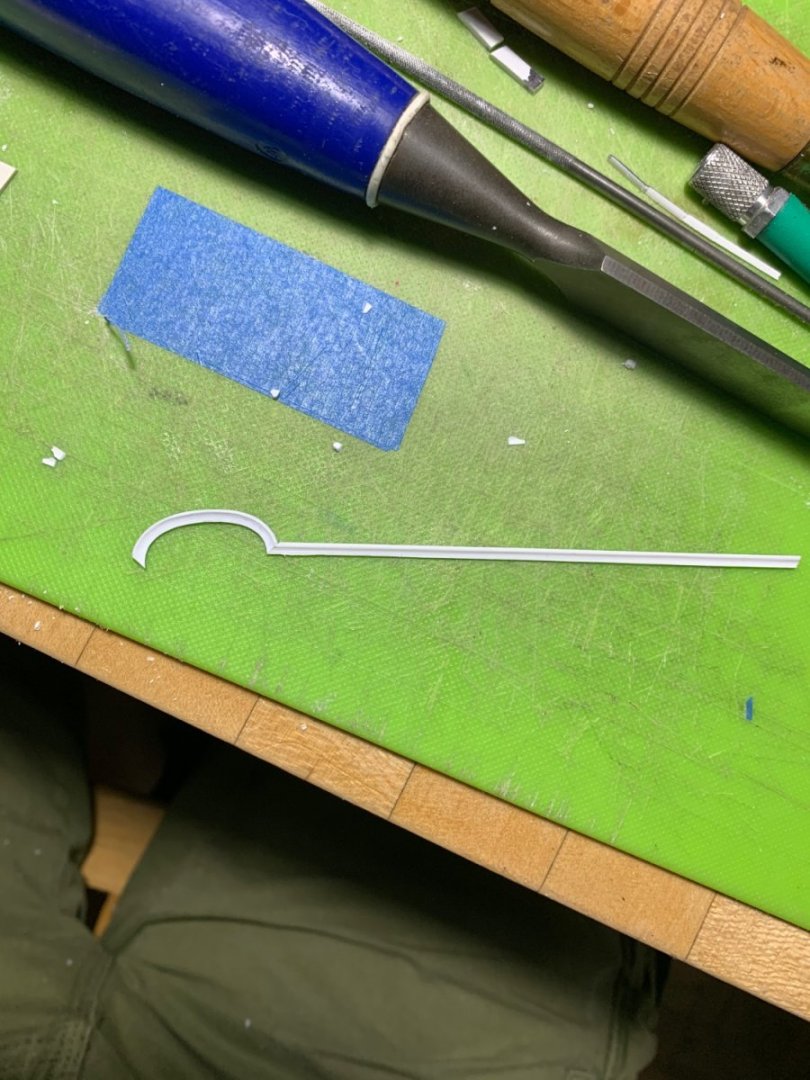

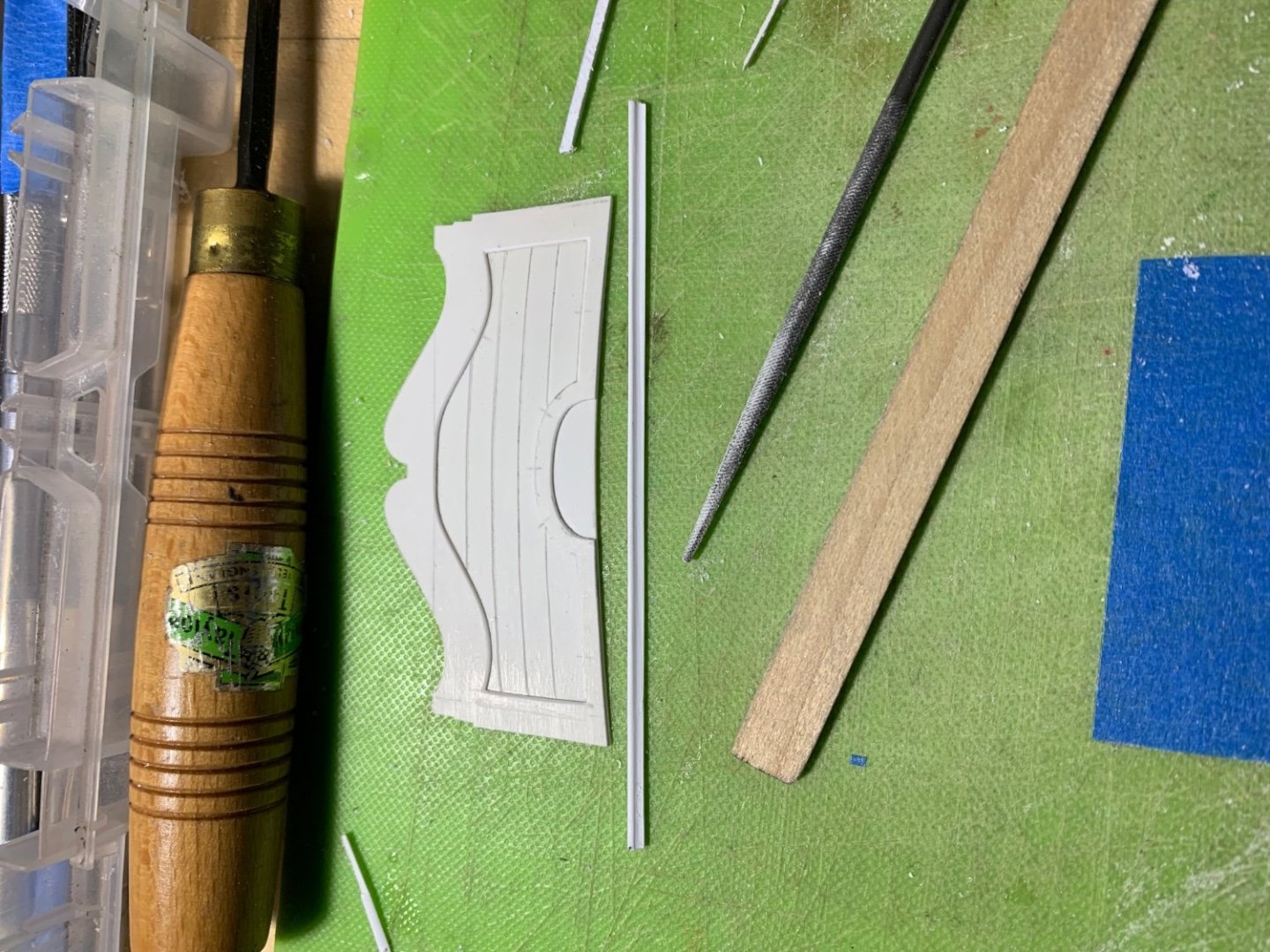

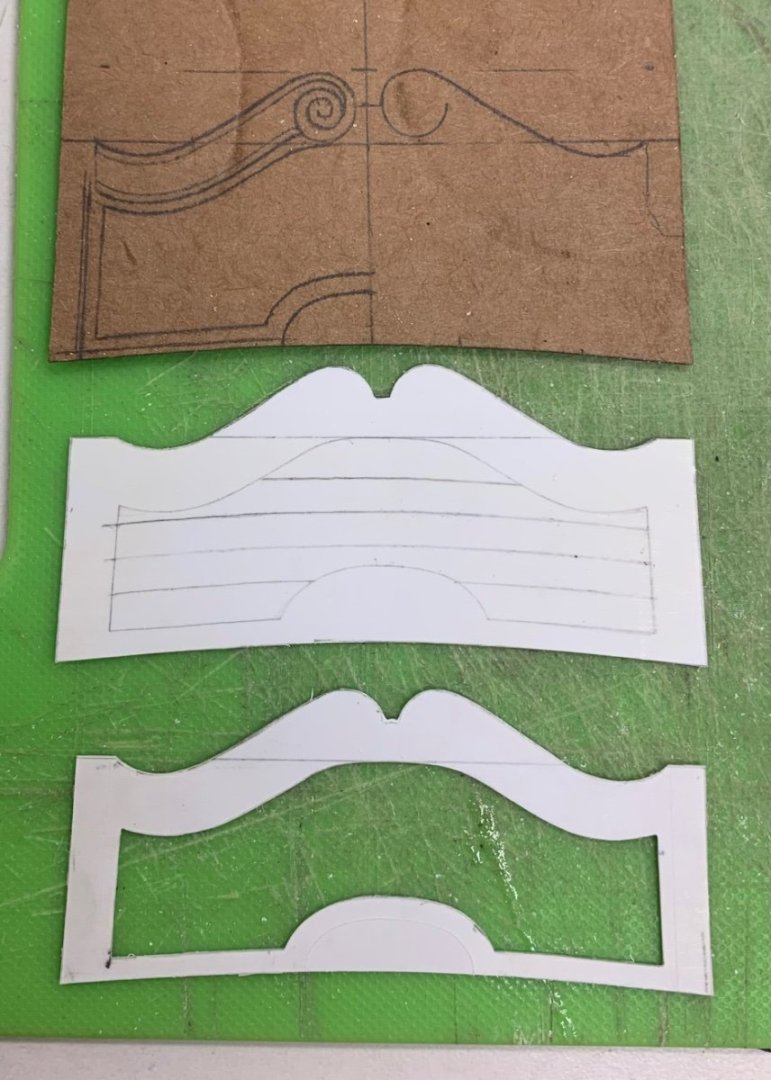

[The following is in response to an observation by John Ott, on the other forum. John pointed out that my problem with centering the French coat of arms has more to do with the fact that the leaves are asymmetrical from the port side to starboard. This was a key insight for me, and one that I hadn’t picked up on.] _____ You are right on-time with that observation, John! Nice to see you here, BTW. Last night, I was measuring once again, and the center pilaster is only a 1/64” to port, which is visually insignificant, so your observation is right-on. I will do as you suggest, and pare down the laurel leaves on the port side. I’ve been making the moulding that defines the lower boundary of the big carving. On Berain’s drawing the shadows indicate an architectural moulding of some significant weight: I experimented with making a coved profile scraper from a hacksaw blade, however, the arched center section of the moulding would be difficult to scrape if the scraper tracked along both outside edges of the moulding stock; there’d be a lot of chatter in the profile. Instead, I tried to make a scraper that would only track along the bottom edge of the moulding, cutting the low shoulder and coved profile only. This wasn’t working well, either, on my straight stock. I decided the best course was to carve the moulding by hand with a gouge: I first blacked the main face and small shoulder side with a Sharpie. I then scribed two razor reference lines, so that I’d know what the boundaries of the coved profile should be. I started with the straight stock: After carving the cove, I used a round file to smooth out any irregularities in the surface. Lastly, I used a sanding stick to round over the top profile. Feeling confident now, I applied the same procedure to the coved section of moulding: I cut a test miter just to see how the two profiles mated. It’ll require a little finessing of the profiles, at the final fitting, but this is not a big deal. I spent a little time this morning perfecting the fit of the tafferal plate. This enabled me to position the arched moulding which, as it turns out, had to shift a solid 1/32” to port so that it centered perfectly over the 3rd and 5th pilaster. This helped my coat of arms situation a little bit: Now, with John’s insight in-mind, I can file down the port side a little bit and then add a little material to the starboard leaves. These adjustments should bring me pretty darn near to center. Once that is corrected, I can inlet the coat of arms into the arched moulding. Thank you, John Ott!

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

This is a truly extraordinary and beautiful execution of this model, Daniel. A real sense of the maker in the work. Congratulations!

-

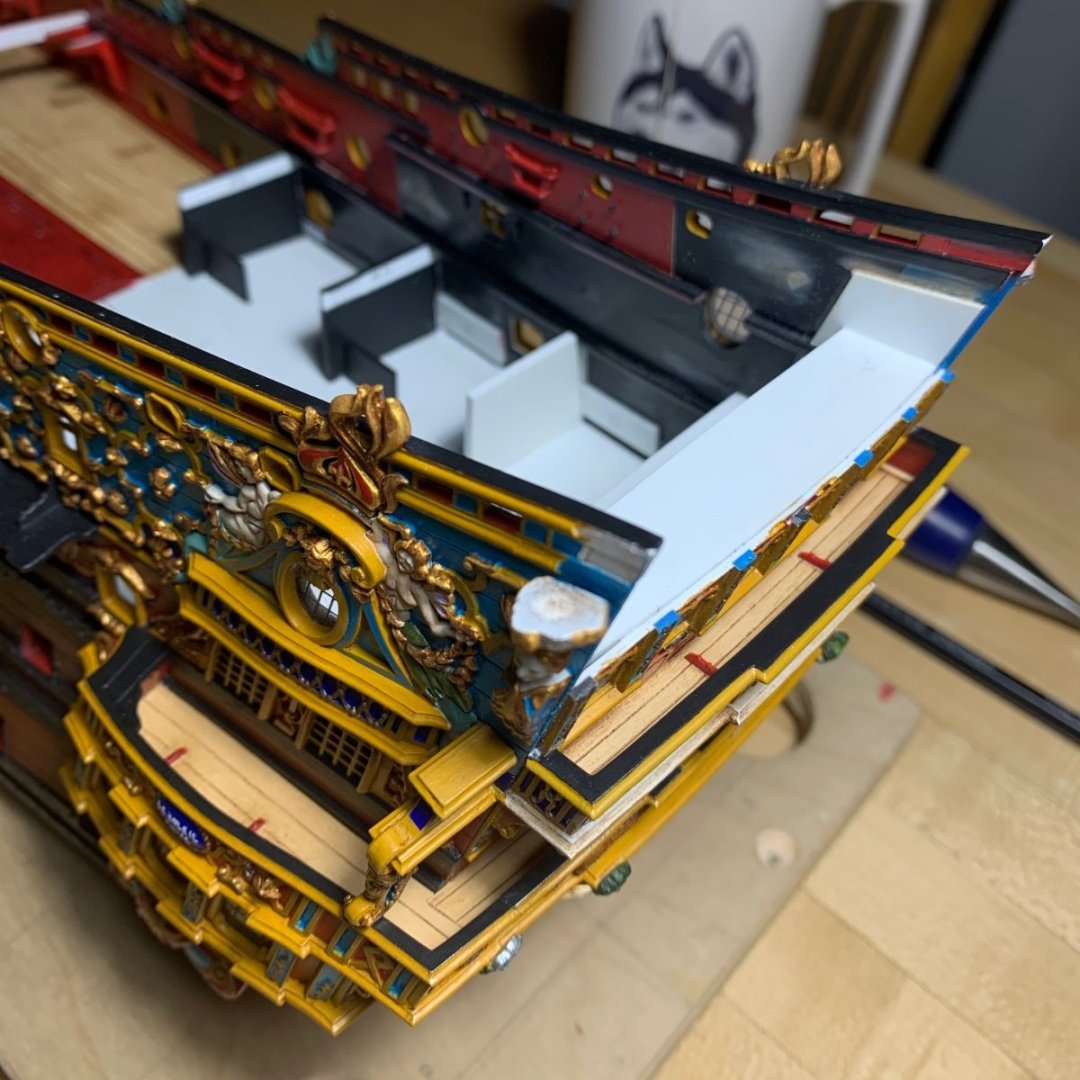

After what has been a very busy time with many competing interests, I’ve been trying to restore some momentum for the project. I’ve been working steadily, albeit at a snail’s pace, on the bow and stern. This pile of crooked pick-up sticks will eventually become my cambered head grating: Each slat section is hand-fit and placed by eye. It will not be possible to neatly align these next three tiers of fore and aft slats with the splayed set immediately aft. This is an imperfect compromise that I can live with. In the end, after the grating surface has been sanded smooth and re-painted flat black, these small discrepancies will hardly matter. It looks like it is going to work out just fine: There’s a significant amount of paint re-touching that has to happen - which I have not been in the mood for - but the upper balcony rail is in-place now; again, imperfect in multiple ways, but I am happy with it: When I really have the focus and determination to, I will re-visit the paint. What has excited me, lately, is that I have finally reached the stage that the entire ornamental program has been inching towards for years - the coronation of the stern! These past couple of days, I’ve been making up and fitting the two primary layers that make up the tafferal: It will take a combination of subtraction and addition, but I am feeling pretty confident that the stock sculptures for Europe and Asia can be re-worked to fit my new cornice shape: Unlike the stock kit, which has an interior backing plate that extends above the reverse-cyma curves of the tafferal, I will make it so that the tafferal shape is continuous to the poop deck. I took some care to scribe-in plank lines for the tafferal backing boards: I am happy that I increased the camber of the middle and upper window tiers because it lends an appropriate sense of lift for the big carving. The extremities of the clouds will be slightly modified so that they sit lower against the frame. The national coat of arms now fits within the dome: While these arms are centered on the central window pilaster, they won’t be perfectly centered within that dome shape. I checked the dimensions of the tafferal framing, and that dome shape is perfectly centered. This discrepancy has likely to do with cumulative error stemming from some aspect of the layout for my lowest or maybe the middle window tier. At this stage, there’s no fixing it, and like all of these discrepancies they will kind of fade to the peripheries of consciousness when the completed stern is considered in its entirety. For the most part, the important details look more right than they do wrong. Most especially, I think I have nailed the correct shape for the big carving panel and the shape of the cornice: There is very much work and layering of detail to come, but I am pleased with where it is all going. Thank you all for your interest!

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

I very much agree with Don. These little scratch projects are so much fun, and you have captured so much extra detail to perfect scale. Very well done!

-

Although not technically correct, I plan to display my port lids fully up and against the hull: not correct because the geometry of the lid lanyards would not allow for the lids to be raised this high. My rationale is that I spent a lot of time on those lid ornaments, and I want them to be visible. They are, after all, complimentary to the frieze. I will have two glue points: at the hinge barrel and where the outside face of the lid meets the edge of a wale. Because these parts are vulnerable and probe to breaking off, I won’t bother installing them until the end of the build.

- 1,508 replies

-

- Le Soleil Royal

- Heller

-

(and 1 more)

Tagged with:

-

You know, you might be right about that Baker. It’s a long time since I built my first one out of the box, and for this version, I had to make a bunch if them from scratch so that they’d fit my new balconies, which are more shallow than stock. In any case, it is easy to just check the corbels to the underside of the balconies to see what the fit looks like.

- 1,508 replies

-

- Le Soleil Royal

- Heller

-

(and 1 more)

Tagged with:

-

Check all you sprue trees. Heller likes to divide the total number of like-parts over many sprues. If you are short, let me know, and I will mail you my spares. I‘m pretty sure I have extras.

- 1,508 replies

-

- Le Soleil Royal

- Heller

-

(and 1 more)

Tagged with:

-

It looks as though there are some mis-print issues with those instructions, Bill. Yes, you have two different sizes of balcony corbels. The shorter ones are for the upper stern balcony. The longer ones are for the middle stern balcony. Actual part #63 is shown as part # 156, in the instructions, but they are one and the same. I like the fleurs you sourced for the gun port lids!

- 1,508 replies

-

- Le Soleil Royal

- Heller

-

(and 1 more)

Tagged with:

-

No problem, Jorgen. It was a small thing, but it will make a big difference in the presentation of the model. Planking looks good!

- 50 replies

-

- vasa

- deagostini

-

(and 1 more)

Tagged with:

-

Your progress, Eberhardt, is incredible, and I am just catching up now. On this point, though, I am inclined to agree with Banyan.

-

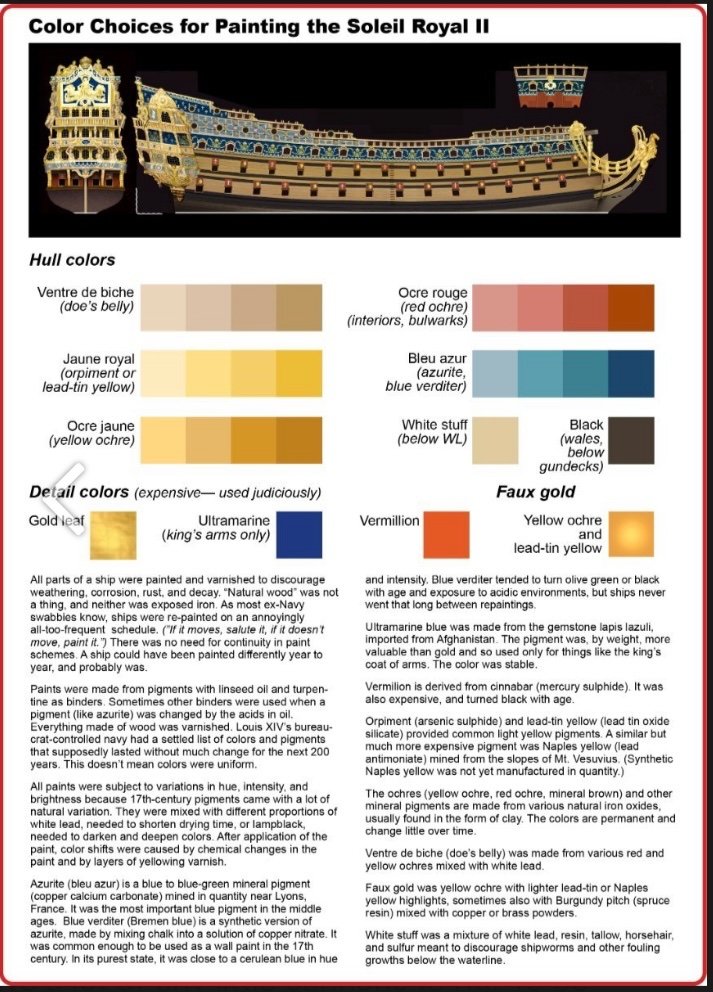

The subject of period colors often comes up on this forum and, fortunately, John has an info-graphic for that as well. And some additional insight: WHITE—I think they mostly used lead white for mixing hull paint. Guy says "calcium oxide," quicklime, which, along with calcium carbonate (chalk), made whitewash. I know they used whitewash sometimes in ship's interiors, but I don't think it's sturdy enough for exposure to wind and waves. Also doesn't cover as well. Lead was a superior mixing pigment, dried fast, was cheap, opaque, and was permanent as hell. BLACK—lampblack. Lampblack was also known as "vine black" because the French had to do something with all those old grapevines. Burnt them to ash and made dry pigment out of them. RED—red ochre, basically red clay. Vermilion (mercury sulfide) was made from cinnabar. It could only be synthesized in small quantities and was very expensive. Almost in league with ultramarine. YELLOW—yellow ochre. More clay. Lead-tin yellow (lead-tin oxide) was the lightest and brightest yellow. Orpiment (arsenic sulfide) was up there with it. Naples yellow (lead antimonate) wasn't common in the middle 1600s because it hadn't been synthesized yet. A natural form of Naples yellow was dug from the side of Mt. Vesuvius, but as you can imagine, it wasn't common. FAUX GOLD—was yellow ochre with painted-on lead-tin highlights and red ochre in the shadows and undersides. Sometimes they painted over it with Burgundy pitch (spruce resin) and brass or copper powders to give it a metallic lustre. BLUE—this is the big one. Guy says it was "copper carbonate mixed with sulfur." Partially right. In all your posts and in all the other discussions about the blue used on 17th-century ships, I haven't seen anyone mention blue verditer. Blue verditer was the synthesized version of azurite (copper calcium carbonate—which had been the most important blue paint pigment in the middle ages). Blue verditer was made by some alchemical mixing of chalk with copper nitrate. You can watch YouTube videos about hobbyists making it with their home chemistry sets. The synthetic pigment was manufactured in France and the Low Countries, and cheap and common enough in the 1600s that it was used as wall paint. Verditer comes from verd de terre, because natural azurite was to some degree mixed with malachite (copper carbonate hydroxide) which was green. The natural pigment was more or less greenish blue, but the less malachite in the mix, the more blue it got. It's not used much any more because the pigment reacts chemically with the low pH in linseed oil and turns dull green or black. Works best with non-oil binders. (I used to have a Winsor-Newton tube of blue verditer watercolor.) It also greened or blackened with age, but ship paint obviously never lasted that long. Interestingly, it also turned black with exposure to sulfur or hydrogen sulfide. Somehow—I don't know how, chemically—but it was often mixed with lead white and somehow that made it compatible with oil paint. (Lead is pH neutral, maybe that buffered the acidity of the oil.) That's why there's all the light blues in Versailles. It was also mixed with lampblack to darken it. When I decided on the light and dark blue hues for my ship, I started with verditer.

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

I think a set of spare fore and main topmasts make sense, but beyond that it’s just clutter and carnage. The carpenter’s stores would have been down below on the orlop deck. Big timber may have been stowed in the hold.

- 1,508 replies

-

- Le Soleil Royal

- Heller

-

(and 1 more)

Tagged with:

-

Well, the English must have been blind that day, cuz they sent the fireships in anyway.

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

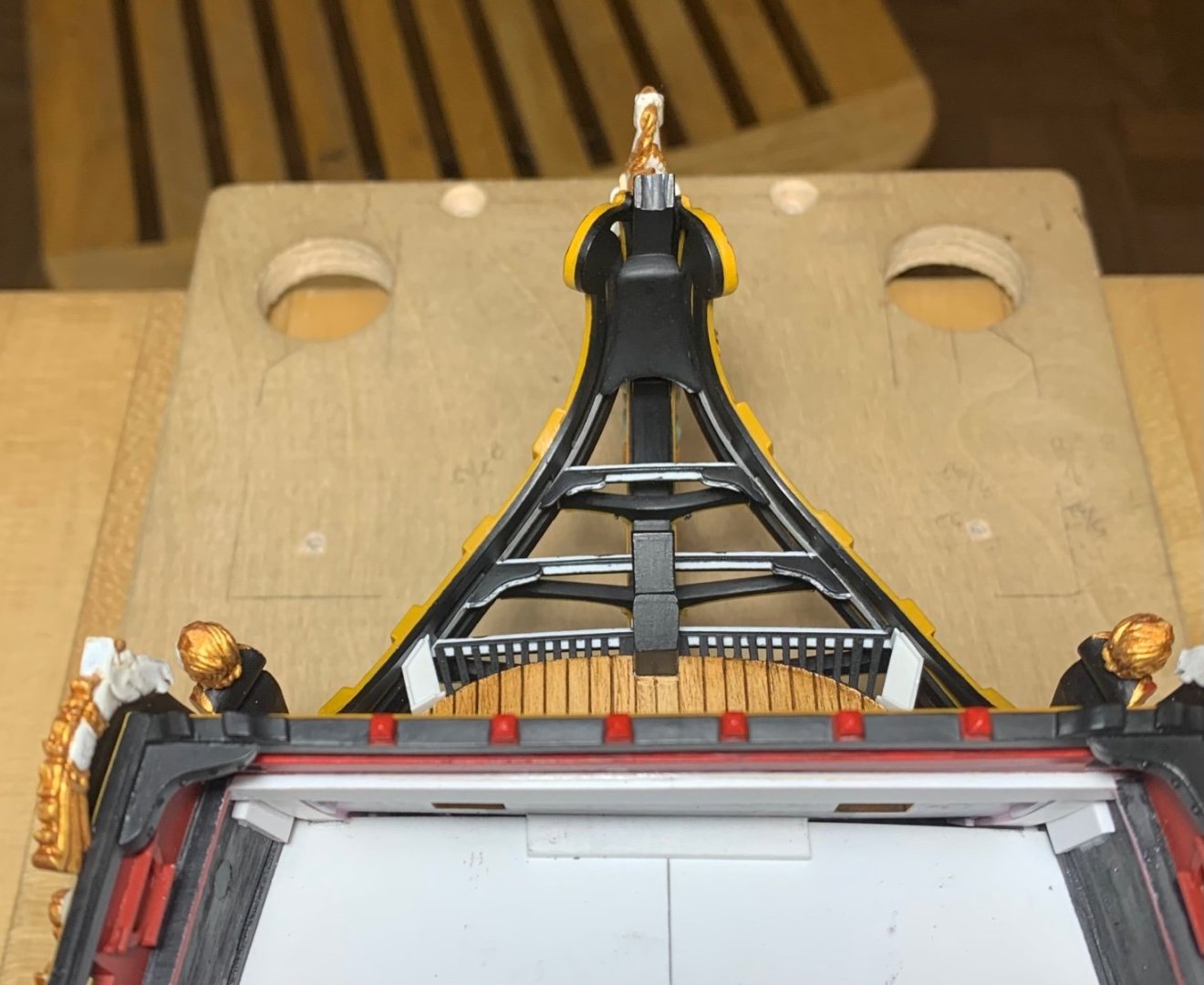

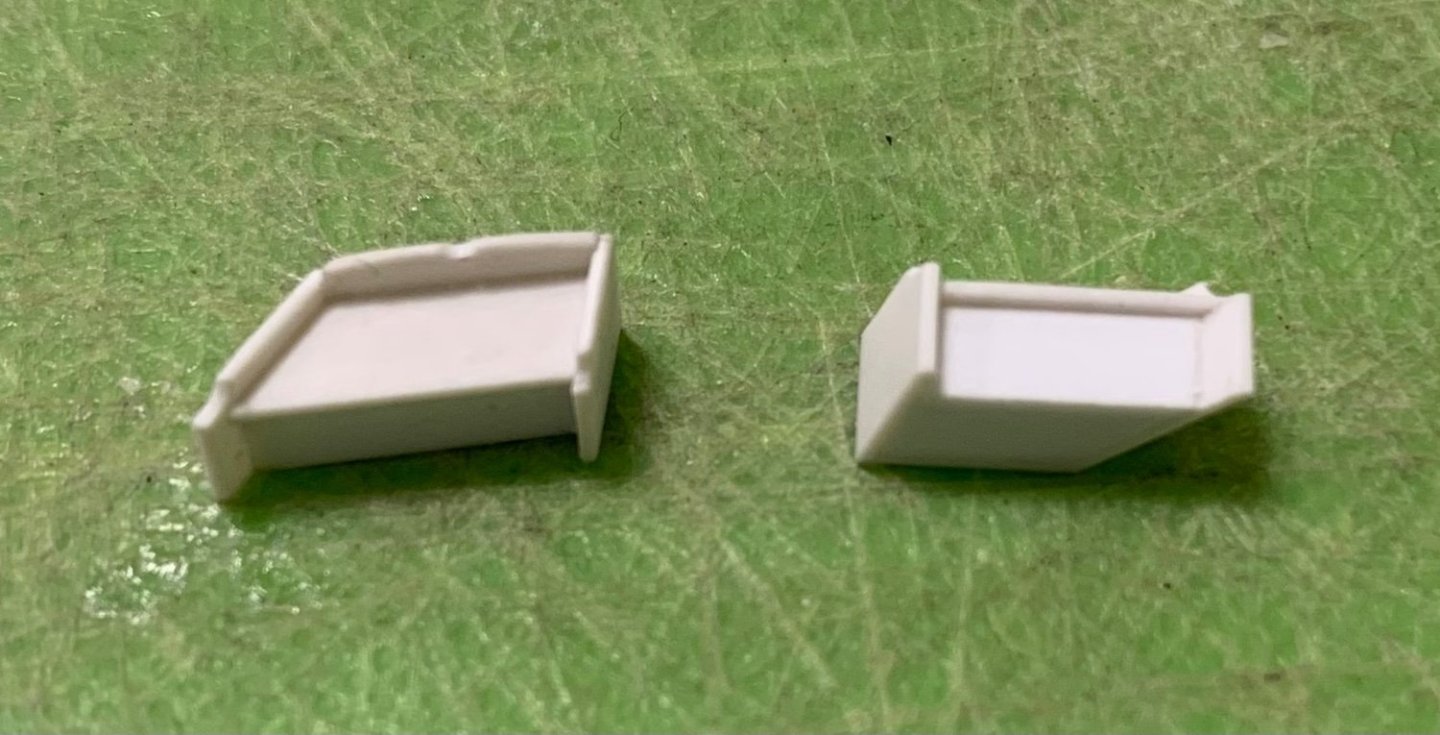

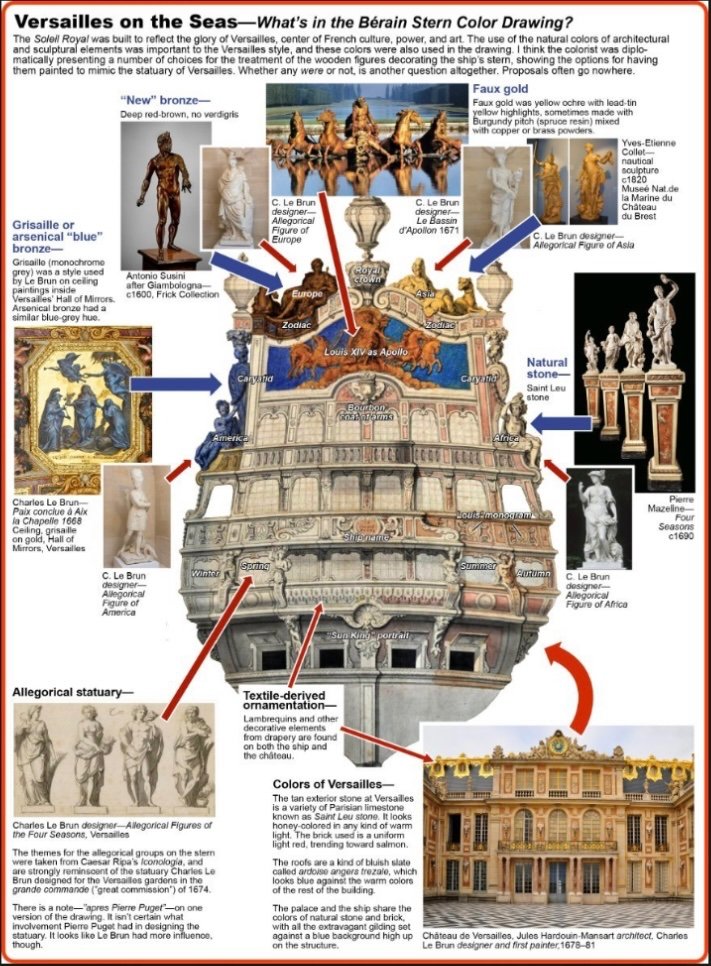

There are still distress washes to apply and some touch-up to do, but things are progressing. The upper stern balcony is finally rounding into form: The balcony rail completes my circumference around the ship with a band of ultra-marine. Maybe I will get to fixing this part in-place tonight. There is still quite a lot of work to do with the head and the head grating, itself, but it is all finally coming together. Yesterday, I made a new pair of seats-of-ease, which are sized according to the space available to them, and reflect the imperfect geometry of my custom head structures: I have subsequently drilled the waste holes in these, but I wanted to tweak their fit to the model before I did so. Here they are in their places: Here is the forward grating terminus in-place and re-touched: Can anyone spot my homage to modern seamanship and navigation, from starboard: to port: It’s a little subtle on this side, but don’t overthink it 😉 My greatest satisfaction rests in the fact that I created enough space below the headrails to craft reasonable headrail supports: As I often say, this is all something of an imperfect approximation, but it is a significant upgrade over the stock kit. As a bonus, John Ott has put together a highly informative info-graphic on the statuary and colors of the stern: As always, thank you for your interest, your comments and likes, and for stopping by. More to follow!

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

This past week, John and I have been corresponding and hashing through a number of the issues he raises in this post. First of all, I’d like to say that the revised almost-VdV portrait of SR is so good that it is completely passable, until you take a closer look at those lower window tiers, or a few other tiny details, like the side-lantern quarter pieces, for example. By his own admission, there are simply limits to how far he was interested in taking that exercise, and it was never his intention to correct everything. The skill it takes to do something like that is just beyond me! John also has a wonderful turn-of-pun - good stuff! Now, the stern drawing John posted above was one that I had always assumed was a re-draft for the replacement SR of 1693. My main line of reasoning, there, was that the stern lights extended to the quarters, seeming to indicate fully closed quarters. This is pretty definitely a feature of the Second Marine. The eye sometimes sees what it wants to, though, and I had always just taken for Granted that Africa was wearing the elephantine headdress, as on the original Berain drawing. Well, those are in fact the same ostrich plumes that Henry describes for the very first ornamental scheme. I can’t find any other D.M. Henry divergences in the drawing, but it is nonetheless a curious detail. John and I have also traded a fair amount of discussion about the curious placement of carvings within the quarter galleries of Tanneron’s famous model. As John notes, they are so random. He offered a fascinating possibility, though; these carvings don’t exactly mirror those that existed on the Grand Chamber ceiling, but they are very closely related. Maybe their placement, here on the model, was intended as a visual allusion to what can not be seen inside. Whatever the answer may be, this is an interesting theory. Since John first posted photos of his project proposals and the model, itself, my head has been spinning at the wonder of it. The coloration and ornamental work is so brilliant, but he has done a masterful job of adding so many small and essential details like skids, scuppers, hancing pieces along the sheer line - which do so much to “finish” this aspect of the model - and an excellent fretted trailboard. This is just a thoroughly remarkable and well thought-out modification of the Heller kit! Thank you so much, John, for posting and I hope you will continue to do so.

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

One other thought, John, which might offer additional clarity and insight into the specific questions you raise: have you read Guy Maher’s research on the development and appearance of SR? If not, and if it interests you, simply PM me your email address and I will send it along. There are so many things I like about your rendering for 1693, and I am just completely blown away by your treatment of the upper bulwark frieze and your color choices. I implore you to open a build-log, if only with sporadic updates, because your followers would be legion for this particular rendition, the coloration, of which, would likely be more palatable to SR traditionalists. More questions and commentary to follow.

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Holy Christ, John - you’re gonna force me into prayer and swear! Does that last pic represent the actual status of paint and ornamental work you have achieved so far, or is that merely a photoshop proposal for now? Either way, it is stunning and completely fascinating. I will respond more fully in a bit. I spent about three hours composing the previous post, but I don’t have that kind of time, this morning.

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

-

Vic, you are both too kind to me and too modest of yourself.

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.