-

Posts

5,518 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rwiederrich

-

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

This new image of Glory as she rested on the beach at Endoline...definitely shows here near vertical entrance....verifying what our group had speculated. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

One image of the fine model. The model shipwright Michael employed over 40 years ago did a magnificent job. And this model was built entirely from Balsa...it was finely detailed and as light as a feather. Impeccable. She was built in her later configuration with extended helm to the poop cabin and both the cabin boy house and the chicken coop over the main hatchway.

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Much of our conversation revolved around Glory's history and of the many revelations he gained along his long journey of exploration. His daughter Arina is quite the historian in her own right. We are discussing the many side topics concerning Glory crew members family and how Michael acquired so much history. This meeting was a highlight of my own historical endeavors. I was so blessed to have them in my home and to enjoy their subject matter expertise.

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

He was enthralled by my Great Republic. He himself is not a modeler, but he was so impressed...he knew I would create a superior model of Glory based upon the new drawings. I was so honored.

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

I could not let this encounter slip away without a proper book signing. He signed three of my books. We talked about the third book that he has at the publishers about the last voyage of the Gory....exciting!

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

I'm showing Michael my original composite build of Glory, explaining to him how I modified the hull of an old Revell Cutty Sark. He was impressed......as I was enjoyed.

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

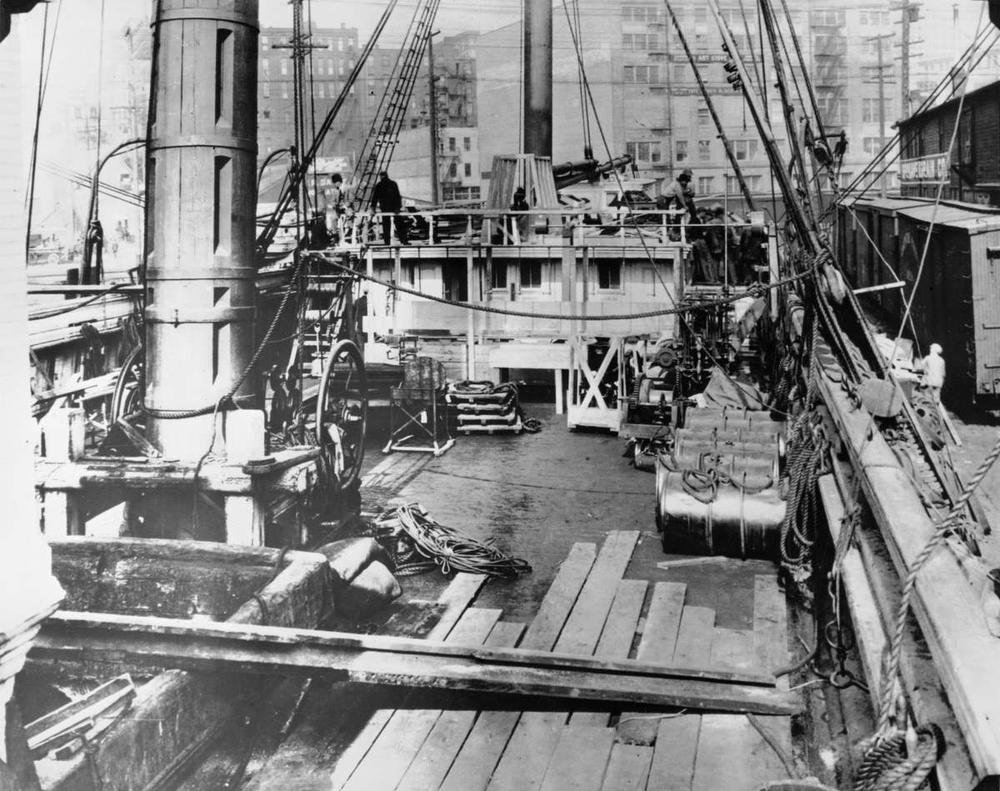

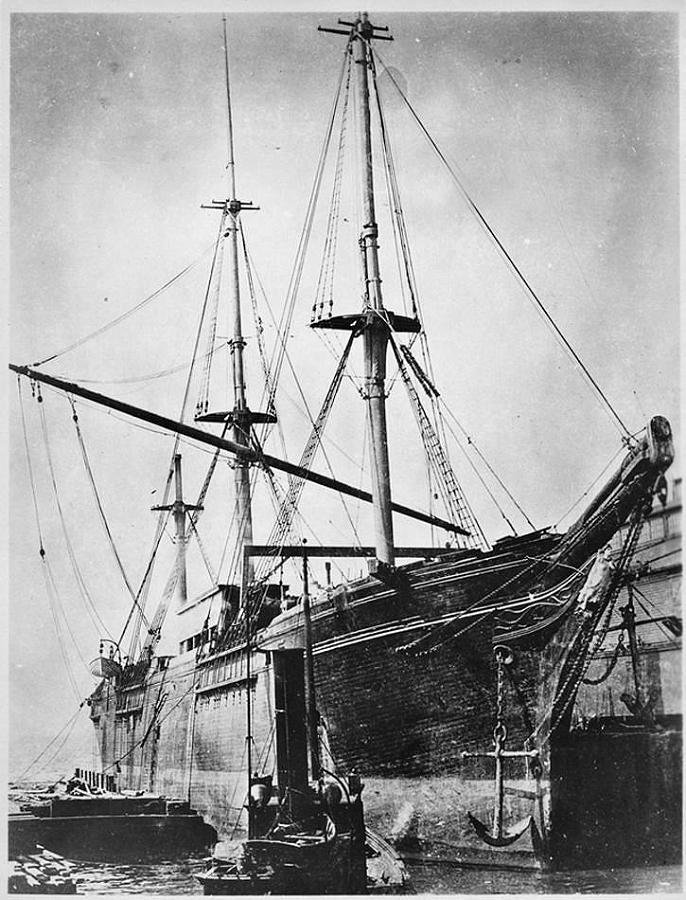

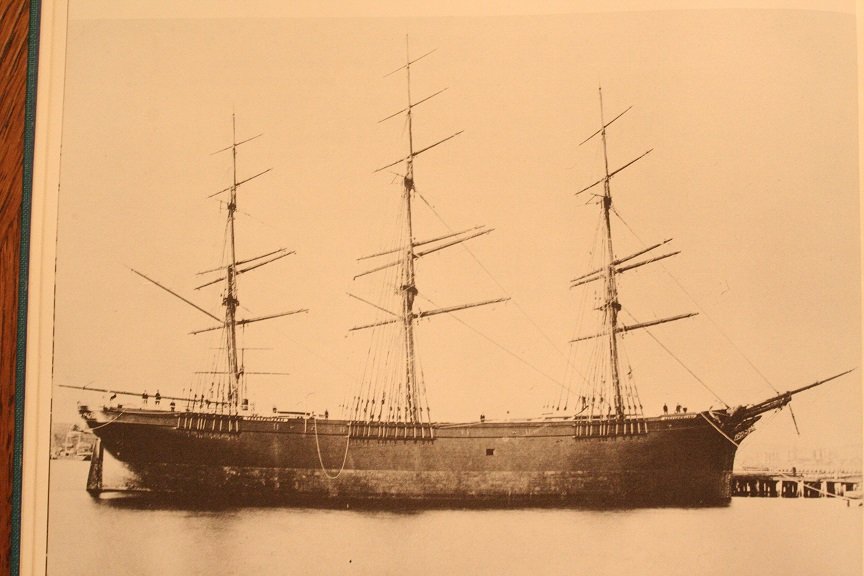

Michael explaining the error in the identification of this famous image of Glory. He told me that it was not of her in San Francisco...but actually of her just after launching in Donald McKay's yard...

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Well here is a brief description of my meeting with Michael Mjelde and his daughter Arina(The authors daughter). We enjoyed several hours of discussion and quite frankly....astounding revelation. Michaels involvement in Glory's history is far more reaching then anyone could ever imagine. I learned that there are over a hundred additional photographs of her that he has acquired from family of former crew members and other sources...that have NEVER been published. Even original hand written letters from Donald himself. Needless to say at this news I was overwhelmed. So much history that I was unaware of was discussed. History that I hope to be introduced to in the near future. Michael brought with him an original model that he had commissioned by a model shipwright over 40 years ago....built from the vary original plans he had devised. they did contain some of his original errors...but since having the line drawings remade and corrected...a new model...a more accurate one can be built. Not failing to recognize the extreme quality of this model...the builder was very experienced. I'm enclosing several images with a mild description of each. First...Michael with Arina discussing the original model.

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Yes the Donald McKay clan figurehead spent years in this field by that tree..before it was collected up and donated to the Seaport Village in Mystic.

-

Coming along nicely. I like the idea of painting her green as originally designed by McKay....getting the *right* green may be more of an issue. It may take some research to find what color compositions existed for green back in the 1850's. Rob

- 602 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

Nic...she's beautiful. wonderful job for sure.....just wonderful. Where ya gonna put her on display at? You making a case for her? Rob

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

Arina....you've been instrumental in the entire process of introduction to your father. I've only read of other artists(Model shipwrights) having an audience with your father...but to imagine myself in that company is a real honor for me. Thank you. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

I told Michael of the wonderful membership of fellow model shipwrights and our cooperation in working out the most accurate hull of the Glory and how we concluded that the drawings he made over 20 years ago were inaccurate. He completely agreed and was excited to hear of our project that nearly mirrored that of his own and his Australian accomplice. I’m so excited to show him our communitive progress. I have so much to discuss with him......and to show him my collection of Glory artifacts.

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

I've been in contact with Michael Mjelde and boy oh boy do I have some news for you all. Mike has been in touch with a professional shipwright in Australia who through much effort by using every available photograph and being a designer of *DownEasters*, has designed and produced accurate drawings of the Glory of the Seas. Mike is meeting with me this weekend and we will discuss my own current project and he will be giving me a copy of the hull plans......... I will be getting him to autograph my two volumes he has written on the subject and If I am very fortunate I might get a peek at his new manuscript of his new book on the Glory of the Seas. I am like a kid in a candy store. Best wishes to all.... Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Well I completely disagree. This vessel is not the Young America. This vessel has only 5 yards on her for and main...the YA had 6. this vessel definitely has the shrouds and deadeyes originating from on or within the bulwark (a typically British method for her composite ships). The stern ornamentation location is incorrectly located...not to mention the blatant poop rounded exterior...which is very much a British clipper design. Lets not forget the chain plates and channels which are NOT exterior or below the planksheer. These items alone would require significant hull and rigging modifications. Note the existence of a fifth shroud on the mizzen. If Ed did his do diligence,(And I know he did), he would have never made this mistake on his model. And I find it hard to believe she would have been modified to mimic a British clipper. No Monkey gaff and the gentleman in the for ground appears to be wearing a Bowler hat......come on....(Had to throw that in there). I can see far too many inconsistencies for me to be comfortable saying this vessel is the YA. Personally I think this old image was incorrectly identified by an uniformed bystander. Rob

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Well since it's getting cold outside...it usually means I have to have the material laid, and trawled out in about 10 minutes. If it was warmer even less. That mean the initial set has occurred and I can begin carving down any over exaggerated material shortly there after. I generally prefer the material to be totally dry so I can carve and sand without clogging my discs. I spent some time sanding and filling also tonight...this I'll let cure over night and will work some more after work tomorrow. Just to keep this build interesting...I plan on using lots of dental materials in its construction. I will be using UVL cured cements to afix the main and monkey rails..not to mention any and all the sheer and chainplate structures and moldings. UVL cements cure instantly and become a hard plastic...10 times stronger then typical type cements. Plus this makes the build go by far more rapidly. No waiting for glues to dry...just zap the cement with a UV light and done. We're getting there folks. Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

Back to my insanity. I laid down the sub veneer on the port side....once dried I will then again begin adding the coats of acrylic stone to form this side of the hull. The starboard side has its second coat already and it is dry...a few more touch-ups and it will be ready for final finishing. I'm waiting to get the starboard side to the same level of finish before I finish both sides together. I pray, I have not lost a faithful audience...thinking I have gone completely mad..straying away from hard and true planking techniques for a back alley quick remedy for success. However I have always contended that I use unorthodox techniques and materials when I build my models. Remember friends it is the finished product that maters...not how we get there. Here are some pics of the doings from my frankensteinian laboratory...... Rob

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

-

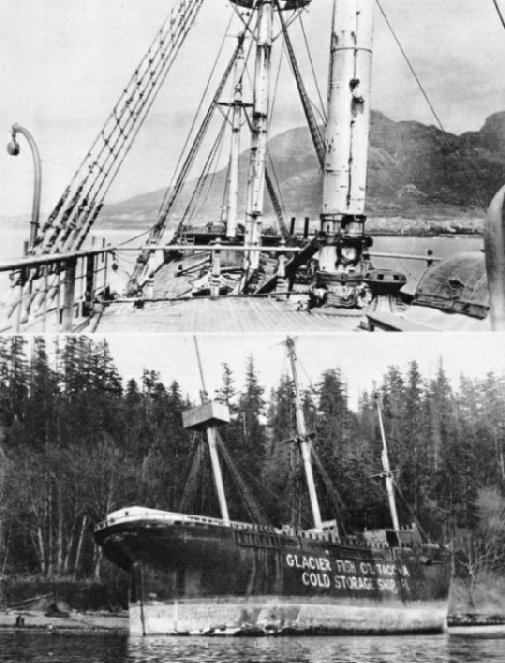

Great sleuthing Clipper fan. I had realized she had very tall sides...39 1/2 ft was my goal...but the new eval of 40' 10" makes sense. Just use deductive comparison analysis....look at these already posted images to see what I mean. Look at the height of her sides above the copper line and the height of her gunals from main deck level.

- 3,560 replies

-

- clipper

- hull model

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpg.b40da3e797fb3f2bf492f6d3cf96d8e9.jpg)

.jpeg.37e29255d37a0f23740223c73ffe069d.jpeg)