Jim Rogers

NRG Member-

Posts

1,381 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jim Rogers

-

Untangling and rerigging or start from scratch?

Jim Rogers replied to Rgpracer's topic in Masting, rigging and sails

What Allan said perfectly. -

Untangling and rerigging or start from scratch?

Jim Rogers replied to Rgpracer's topic in Masting, rigging and sails

I would remove it all. The shrouds are not rigged correctly, they should be in pairs and and stacked port and starboard. The foot ropes appear to be just glued in place are not clove hitched. You can get proper size line from Syren Ship Company. You’ll learn more doing it correctly. My 2cents -

Realistic Water

Jim Rogers replied to taylormade's topic in Painting, finishing and weathering products and techniques

I use Realistic Water from Woodland Scenics. They have a slew of water products. -

Pin pusher. Help please

Jim Rogers replied to Steve G's topic in Modeling tools and Workshop Equipment

I use needle nose pliers. -

Let me check my stash. PM me.

-

That sounds like a great idea.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Chuck are you going to make them a little long so we can adjust to our model. And can you supply two for the inevitable breakage.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Love the painted figure head.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

This is all a great teaching and learning experience for me. If I had to hand form and carve these fittings I would think it was going over board but you are providing us laser cut parts so it is much,much easier. I admit some are pretty dainty like the railings on top the Quarter Galleries which I broke months ago. Please don’t dial it back. You also think some of us are rushing, not true. You have only so many hours to devote to this project because you have a business to run and you are designing parts and test lazing. That takes a lot of time. I have hours to spend everyday just on this.The Winnie is all I got to do. Keep up the good work Chuck.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Don, I’ll try rotating my iPad. Oh and Don your Winnie looks great!

- 105 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Test flipped photo upside down prior to posting. It loaded upside down. I am going to flip it back and try again. And ditto. Same thing.

- 105 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Taking it on a iPAD. I am going to try flip one upside down and see what happens.

- 105 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

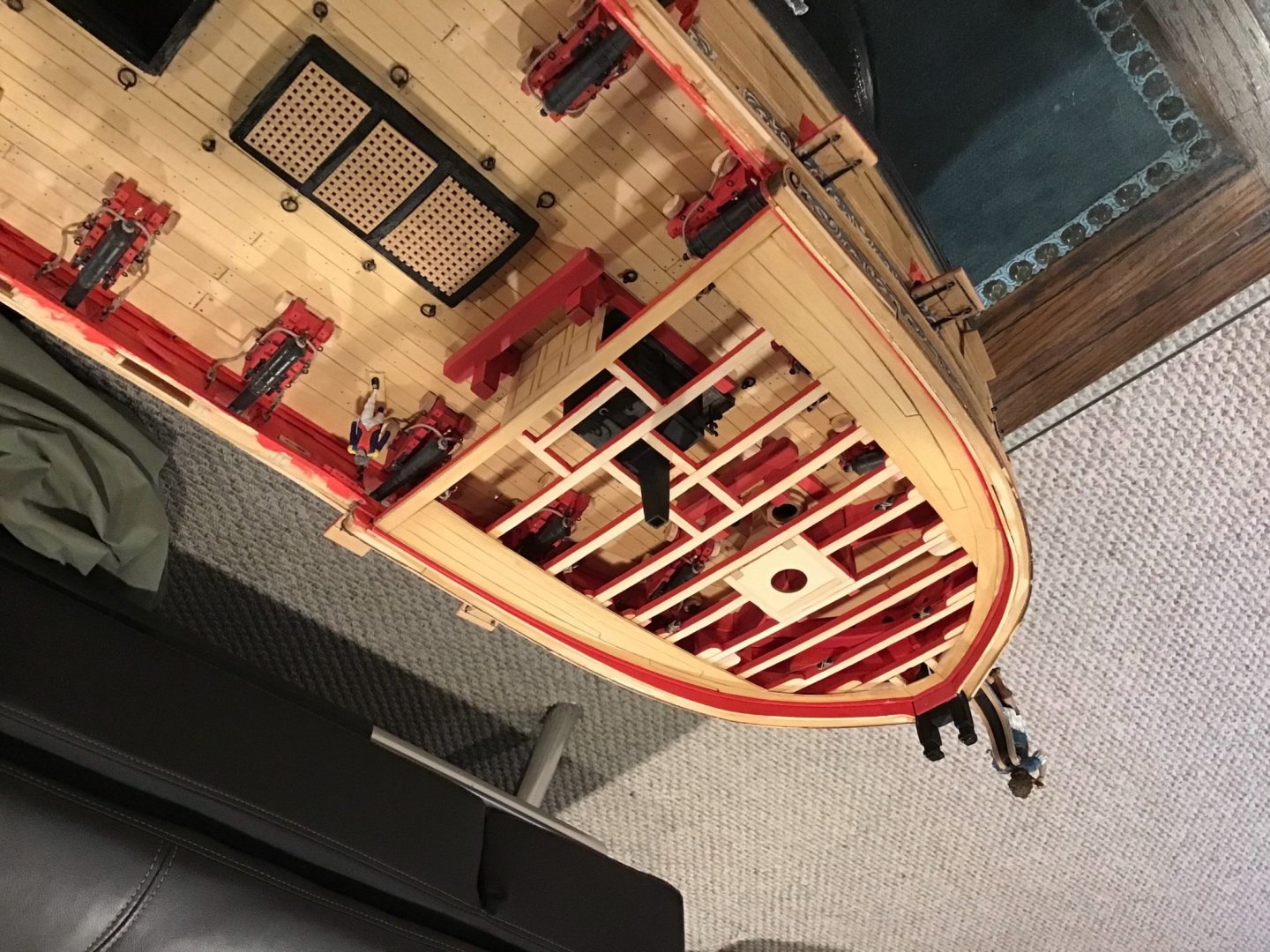

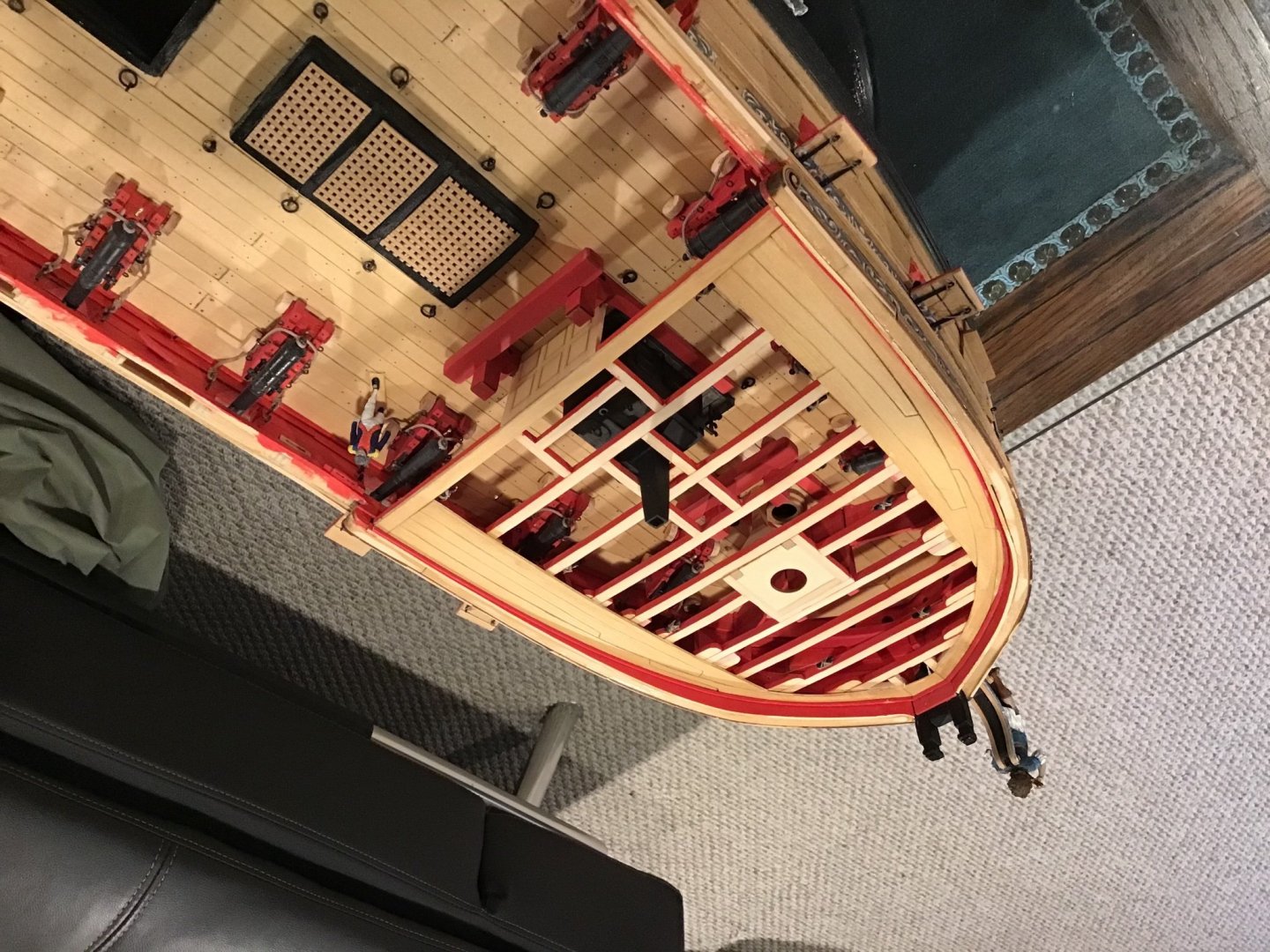

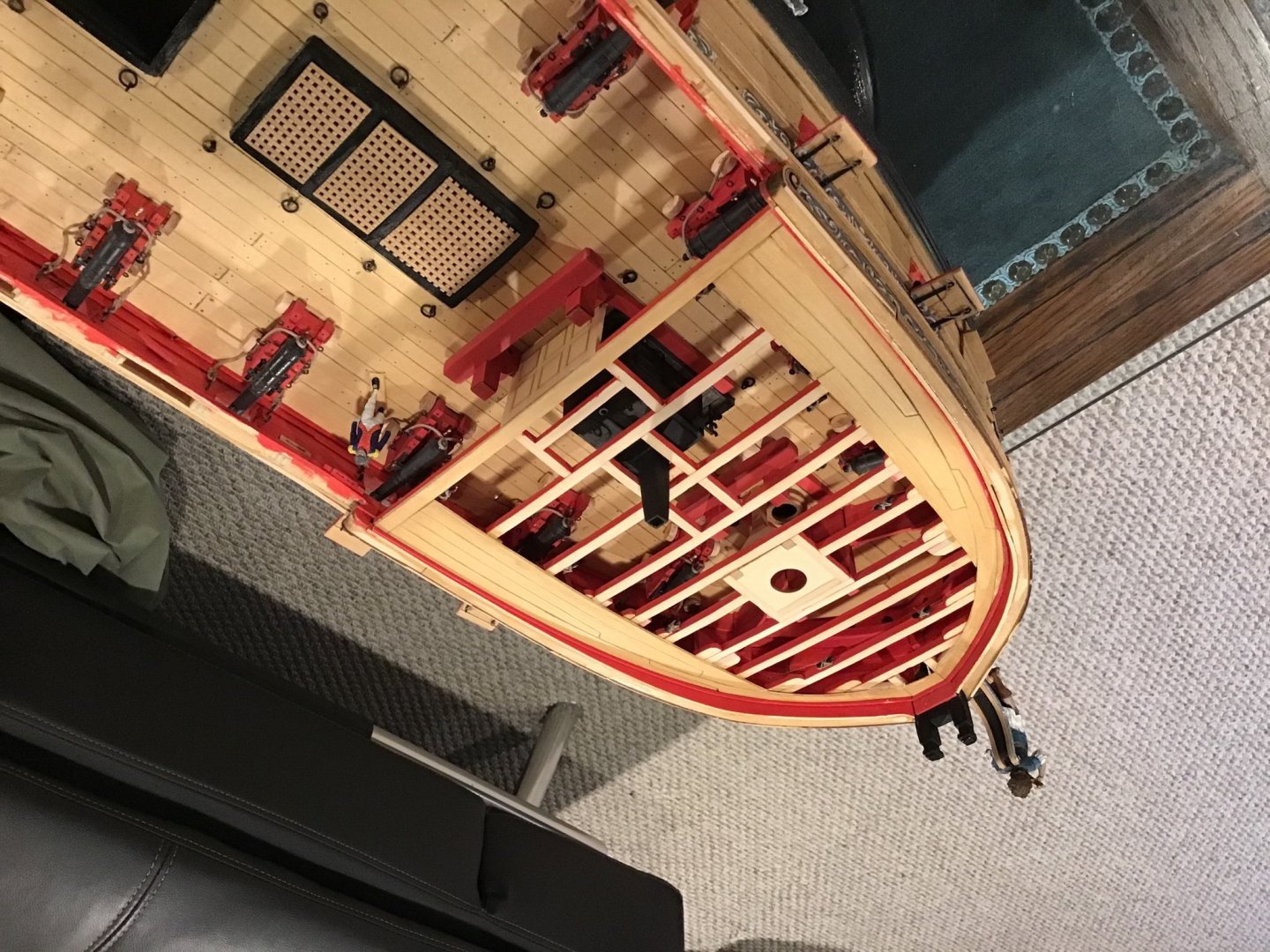

Winnie update. Got the outside planking done on the fore castle and weather deck. What is it going on with these upside down images. This is the only site on which this happens. They are basically the same size. Some post correctly others don’t. It is frustrating!

- 105 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

What I did was take a three inch wide piece of cedar laid it on top and used a compass to draw the curvature of my bow on the wood. I then cut out the template matched it up as close as it would go with the curvature I just drew and cut it all with number11 blade. Did the same for both port and stud sides. Glued it in place, a little sawdust filler and done. Came out great. I would post photos but get annoyed with them always being upside down. I am in hot standby for cap rails.

- 1,784 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Rotary tool recommendations, preferences

Jim Rogers replied to Steve116's topic in Modeling tools and Workshop Equipment

I use a Dremel with Flex shaft and foot control and a rechargeable Dremel and needle files. I find you need all dependent on situation. -

Agreed

-

Great job! One of the things I do not understand is why they would configure their coal bins the way they did. The lids would always be in the way of shoveling coal. Makes zero sense to me

- 51 replies

-

- model shipways

- picket boat

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.