Jim Rogers

NRG Member-

Posts

1,381 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jim Rogers

-

Help! Deadeyes and rings issue. Mamoli Constitution Kit

Jim Rogers replied to jfitzjr1's topic in Masting, rigging and sails

I feel your pain. I have sanded one side of the deadeye and then squeezed it into the stroup using needle nose pliers. PITA. So now I just use black wire and make my own. MUCH less frustrating. Good luck. -

Try Chuck’s tissue in the printer method for your flag. Works well and looks great. This is one awesome piece of modeling prowess.

-

Cutting and shaping masts: tips on how to do it.

Jim Rogers replied to Peterhudson's topic in Masting, rigging and sails

Milling Machine -

Byrnes thickness sander vs Micro Mark's

Jim Rogers replied to twintrow's topic in Modeling tools and Workshop Equipment

I have a love/hate relationship with my Byrnes. Does a great job but on occasion when I get complacent it will send a board into the wall at Mach 3. -

mast tapering fixture

Jim Rogers replied to Bob Blarney's topic in Modeling tools and Workshop Equipment

Is there a proper name for this device? -

Diorama Water

Jim Rogers replied to xodar461's topic in Painting, finishing and weathering products and techniques

The best water available for dioramas is available at woodlandscenics.com. They are a model railroad scenery business and they have everything you need plus instructional videos. Here is a couple of photo of one of my dioramas using their product. Most highly recommend. -

As far as I know Uboats did not have noise makers the size of refrigerators nor did they harass freighters over the radio.

-

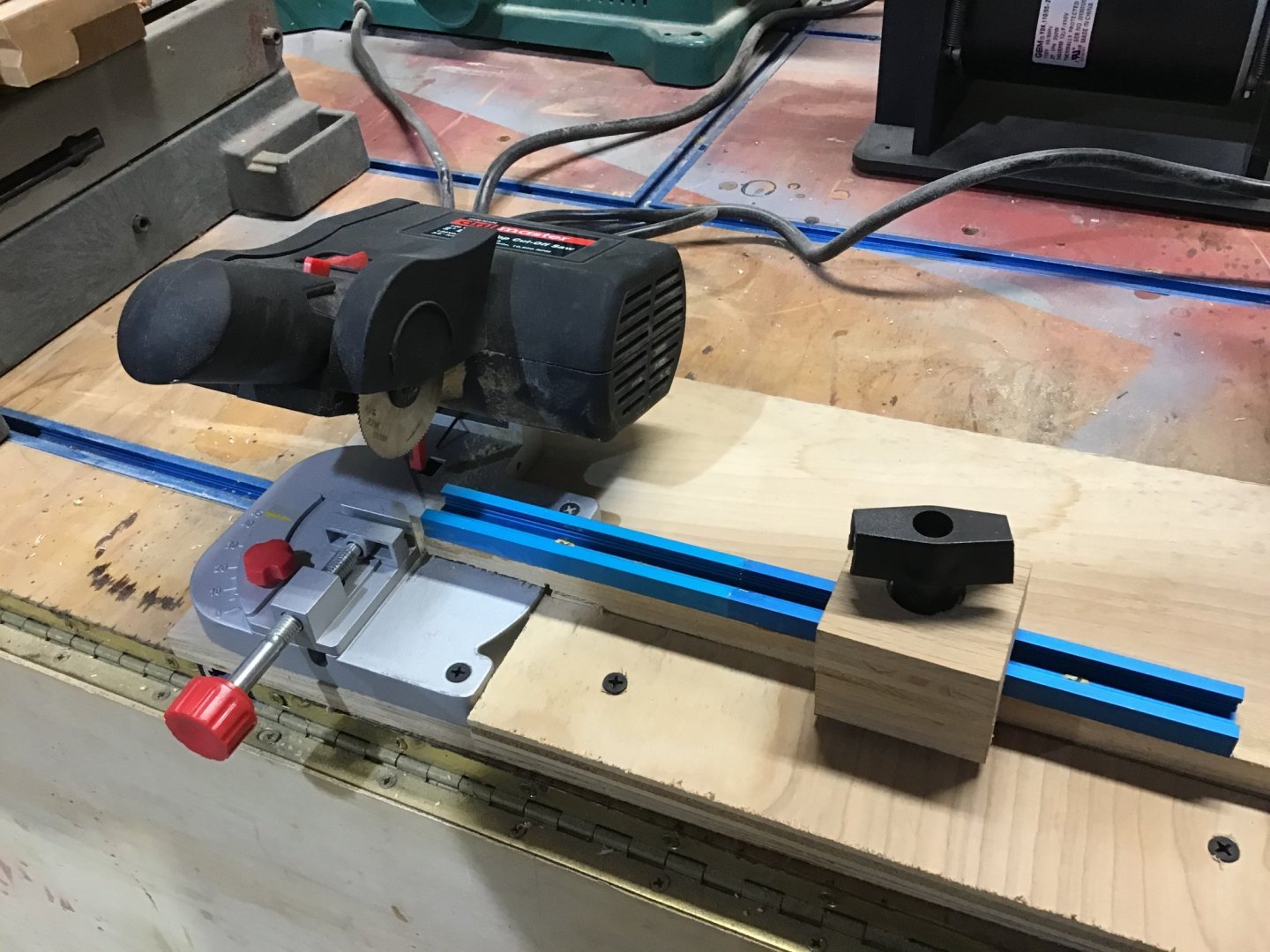

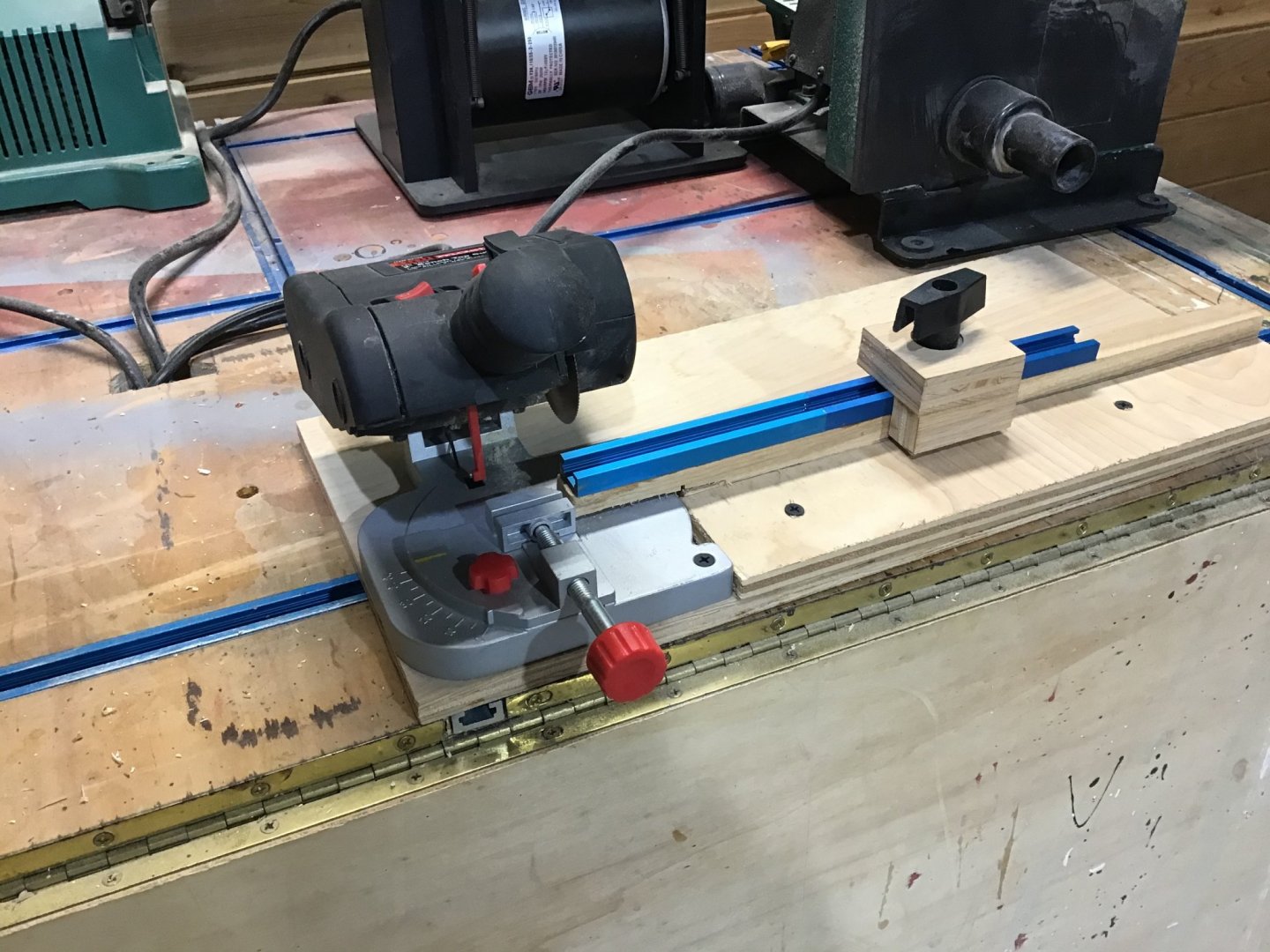

Micromark cutoff saw?

Jim Rogers replied to Brewerpaul's topic in Modeling tools and Workshop Equipment

-

Micromark cutoff saw?

Jim Rogers replied to Brewerpaul's topic in Modeling tools and Workshop Equipment

I picked up almost the exact same saw at Harbor Freight for $25. I mounted it on a jig with a stop to make repetitive cuts faster and more accurate. -

After figuring out how I wanted to mount the ship I got rid of the back braces that came with the mount and cut a rabbet in the base plate. The ship now sits snug in the mount with the hull against Pegasus head and the keel resting in the rabbet. Intentions are to use my Shaper Origin and set the mounts down 1/32 to lock in place. Planning on engraving sextants in the corners with name and date engraved in base.

- 105 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I decided to put my time to good use and start on my stand. I picked up some curly maple, joined it together for a base that is 14x47, ran it threw my drum sander. I purchased the Amanti Pegasus Mounts but really hated the color so I had them painted.

- 105 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.