king derelict

Members-

Posts

3,266 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by king derelict

-

B-25J Mitchell by Chadwijm6 - HK Models - 1/32

king derelict replied to chadwijm6's topic in Non-ship/categorised builds

Nice, careful wear details. alan -

Yesterday was another day that tries the patience of men. I was adding some highlights to the tunic of the Yellow Boy and the glue (Gorilla Glue) I used to secure the base to the pill container being used as a handle cracked away and the figure dropped. It landed hard, the base separated and the head fell off again. I decided to try 15 minute epoxy to resecure everything and had just placed the head back and thought it was settled when it fell off AGIN. Only this time it landed smack in the little tray of mixed epoxy and got a liberal coat. I gave it a liberal spray of alcohol which I had handy and wiped it off as best I could. Of course most of the paint came off too. I switched to five minute epoxy and tried again and this time I think I got a good bond. Activity was suspended for the day to reconsider and repair the shower. I initially thought of going back and air brushing the black and white undercoats but I suspect I wasn't able to get all the epoxy off and if so then over spraying it was going to obscure details. I decided to use white primer hand brushed where needed and after it was dry, this morning, I started repainting. I may have lost some of the pre-shading on the turban but I think its good enough to carry on. I can try using different shades to deepen the folds. I see a couple of spots on the face which may need attention too then back to qorking on the details I got ambitious and started adding the basic paint to Nabopolassar. In some ways it might be a simpler figure to work on. Its a great sculpt regardless.. The tan colour is an undercoat for the gold decorations that will follow - at least that's the idea. Thanks for looking in and for the likes and comments Alan

-

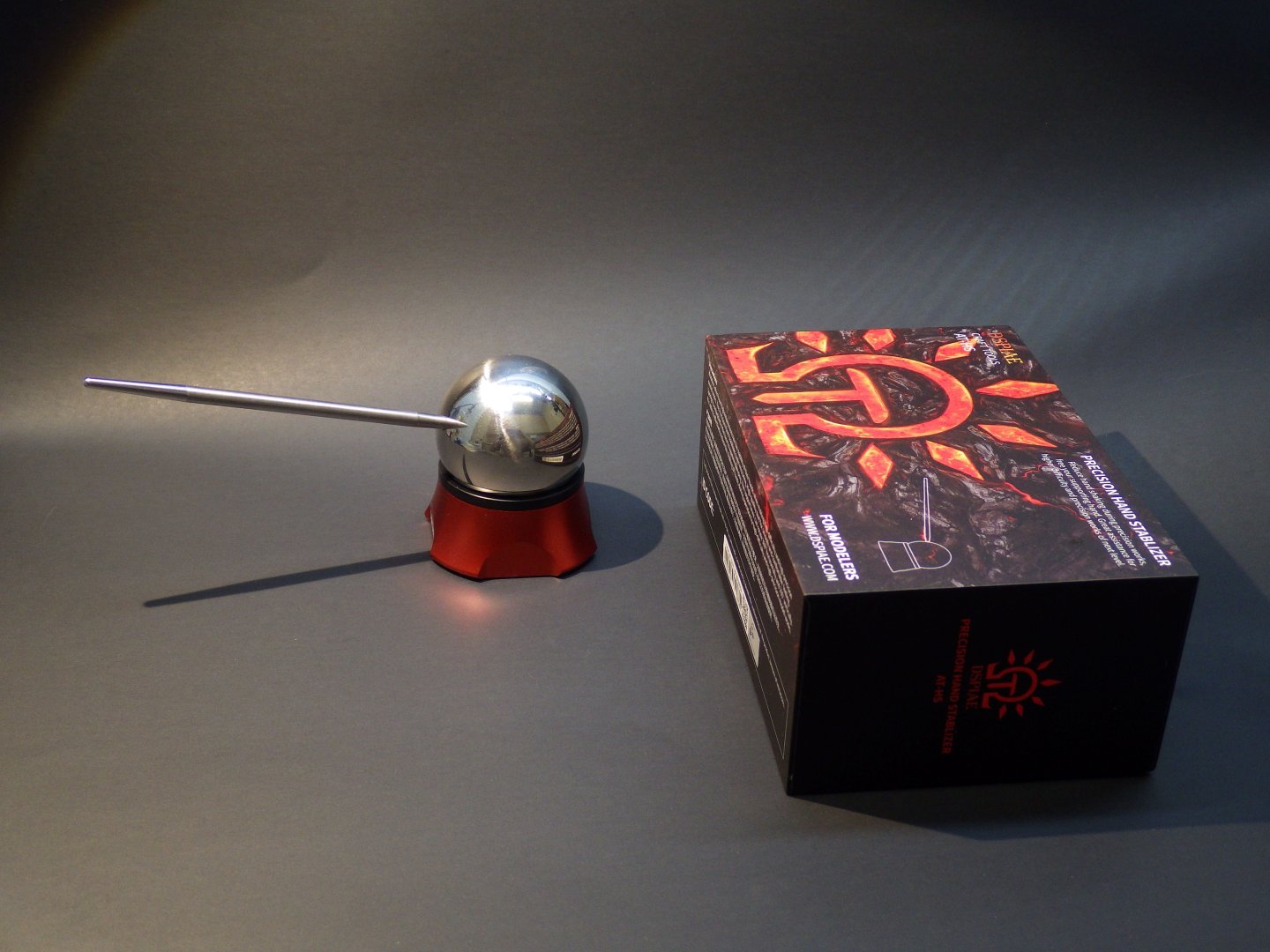

I hope that works out for you OC. It does seem a lottery buying from China via eBay. I'm in the same situation. I've generally been impressed with DSPIAE modelling tools and ordered their magnetic paint stirrer. It sounded like an interesting idea. You drop a small steel rod in the paint bottle and a motor on teh base spins the rod round extremely fast. Mine arrived and I gave it a try. It wouldn't even rotate the rod in the paint. Thinking the paint might be too thick I tried it with water and got a similar result. So far communication has been great and they apparently have a replacement on the way. We shall see. I should have listened to @Egilman about paint stirrers.😄 Alan

-

A quiet Sunday morning and a bit more progress. I completed the turban, started the belts and cummerbund. I got brave and added the whites of the eye which I guess commits me to doing the pupils. Some touching up to do with the belts but I am happy with the face. I added a black wash to the beard and I like it. I need to decide on the next step. The guide picture shows a lot of fine detail patterns on the sash and the turban. Thin stripes of red and brown on the yellow. I'm inclining to just going with some broad stripes seeing as this is my first figure and I want to end up with something I feel okay with rather than a shameful mess. I suspect the guy that painted the figure for the guide might have done a few other figures before attempting that one I'm also looking for a bit of advice. I am wondering whether to try to use a wash to bring out the details and whether to spray a clear coat onto the figure before attempting the wash. Any thoughts or advice? I bought this rather odd-looking device after browsing the DSPIAE range. Its a hand stabiliser to try to control motion when painting detail or using tweezers on small parts. I'm still adapting to working with it and it seems very helpful. I will definitely be using it when I get brave enough to try to paint the pupils. Thanks you all for looking in and for the encouraging comments and suggestions Alan

-

Thank you OC. Let’s see how I do on the details! As I understand it Skinners Horse are the only British Army unit to have worn yellow. Very distinctive. I’ve just found that Art Girona has a lot of 19 th century Indian army subjects in their 70 mm range. That could solve birthday presents for a while (or frighten the credit card) alan

-

Thanks OC. I bought the Life Colour RN Eastern Approaches set which has all three colors I need. Great suggestion. alan

- 97 replies

-

I managed to get a bit of time yesterday and today and got out the colours. About five coats of yellow on the tunic and I am not sure if its too much. I'm feeling my way with the glaze technique. Not too terrible so far. The first coat on the red parts of the turban and some black details. I'm still learning how to use the wet palette so this is all a bit learning experience. The paints are Vallejo Model paints and the BBs really make a difference to mixing them. The face and hands are using Mig Ammo flesh tones which I think are very nice. He may be a bit dark but I will see how he looks with the beard filled in. I'm a bit leery of the clamps after the earlier problem so I think I will glue him to a temporary base of some sort for the remainder of the work Thanks for looking in and all teh helpful comments and suggestions Alan

-

B-25J Mitchell by Chadwijm6 - HK Models - 1/32

king derelict replied to chadwijm6's topic in Non-ship/categorised builds

The B-25 cockpit looks terrific. Great work. That ZM kit looks superb and reading the blog shows it to be a fantastic build. I look forward to seeing you work on it. Your kit choices are excellent. Alan

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.