-

Posts

117 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by wool132

-

replacement X-ACTO blade #30

wool132 replied to Peanut6's topic in Modeling tools and Workshop Equipment

Bit o’ rust on a blade or plane? No problem! Klingspore Sandflex will do the trick. Use ‘em all the time - er, when I need to. Usually fine is, well, fine but medium is there if you need it. Coarse is for people who live on Nantucket Island. 🙂 Jonathan -

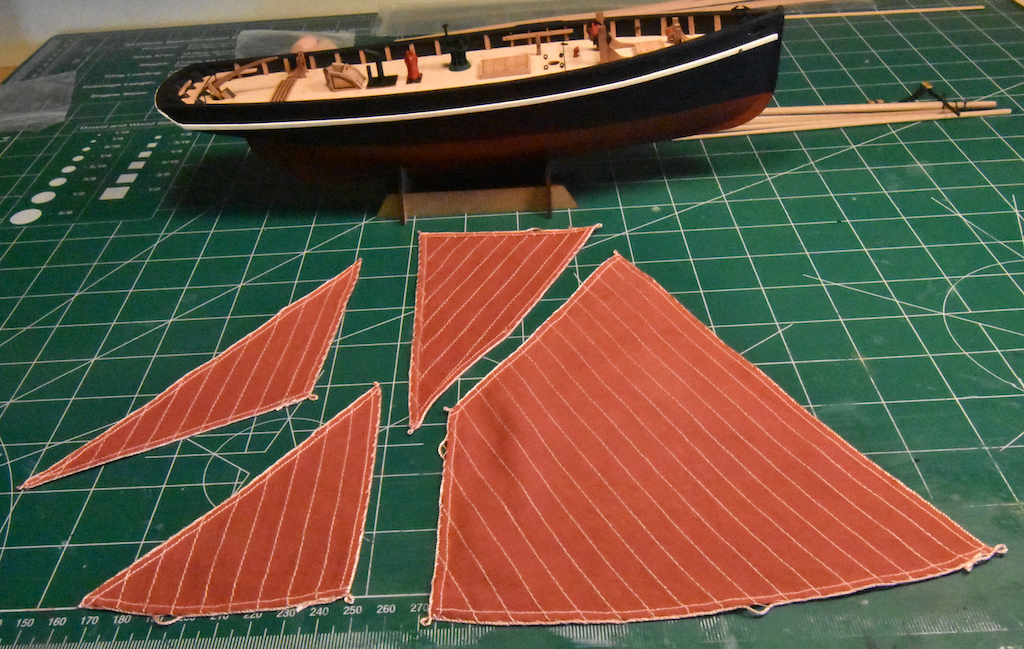

Based on DB789's extensive research (Thank You!), I dyed the sails using 75% Scarlet and 25% Cocoa Brown. They were darker when I first took them out of the pot but lightened up after drying/ironing. Although the label on the bottle said this would happen, I'm still somewhat surprised by how much lighter they are. Next time I'll know to leave them stewing until they look too dark. Then, by the time they're dry, they should be just right. The wooden spoon I used to stir things up also came out a lighter shade. No complaints from the Admiral as I do most of the cooking ("I am an Admiral for goodness sakes, not a scullery maid!"). Jonathan

- 38 replies

-

- Nisha

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I couldn’t help myself: I ordered the Fife. It’ll be here tomorrow. Jonathan

- 38 replies

-

- Nisha

- Vanguard Models

-

(and 1 more)

Tagged with:

-

- 38 replies

-

- Nisha

- Vanguard Models

-

(and 1 more)

Tagged with:

-

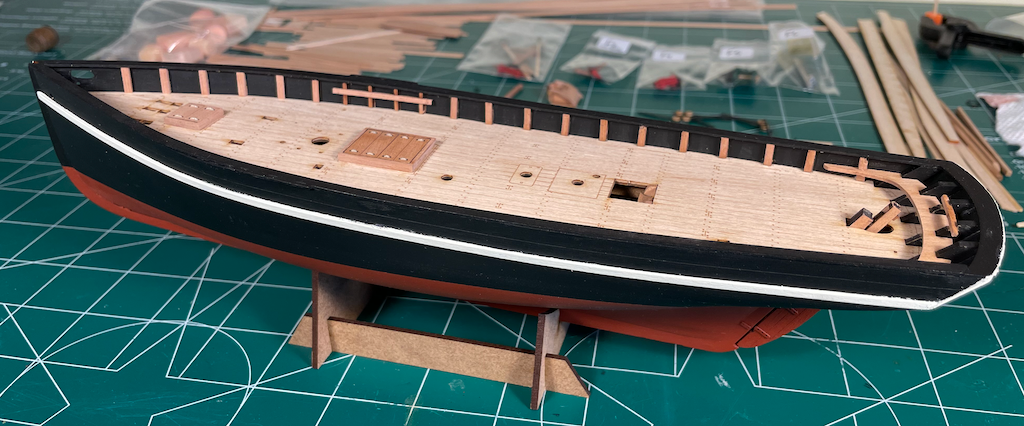

I used Badger Stynylrez black primer for the finish coat above the waterline. I was so happy with the Red Oxide that I forgot to take a picture from the top. 🙂 I've spent the last couple of days poring over the rigging plan sheets and reading @Dr PR's excellent series of posts on the subject over in the Masting, rigging and sails forum. Jonathan

- 38 replies

-

- Nisha

- Vanguard Models

-

(and 1 more)

Tagged with:

-

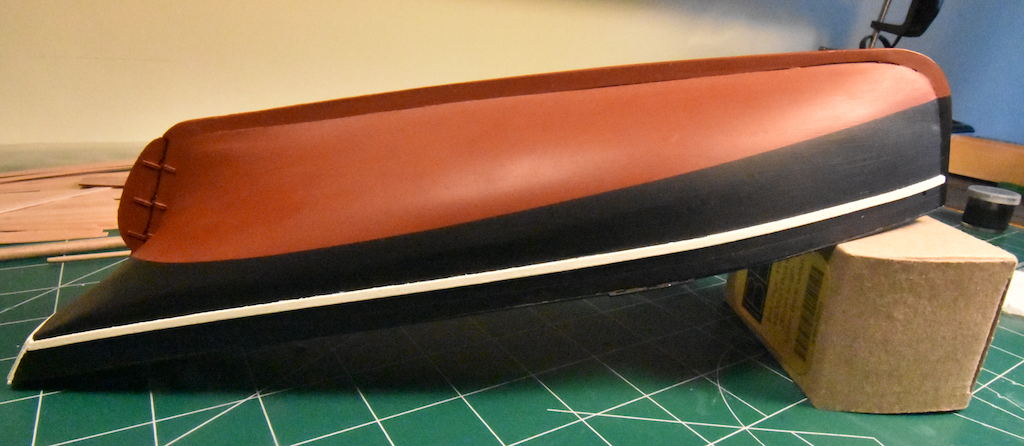

The Badger Anti-Fouling Red Oxide paint arrived on Saturday. I decided to go with DB789's white racing stripe after all. (The starboard side looks the same). While awaiting the paint, I got a head start on the deck paraphernalia (companionway, main winch, ladder, fish hatches, steam winch, mast, etc). In other news, I've started Volume XIV - The Age of Reform in my quest to read the entire Oxford History of England series. A side benefit of all my effort is that "1066 and All That" is now even more hilarious! Jonathan

- 38 replies

-

- Nisha

- Vanguard Models

-

(and 1 more)

Tagged with:

-

If he is it certainly won’t take long! Jonathan

- 14 replies

-

- lady isabella

- zulu

-

(and 2 more)

Tagged with:

-

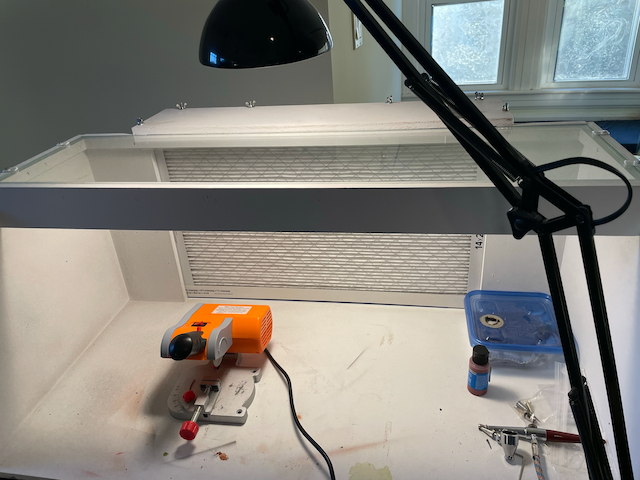

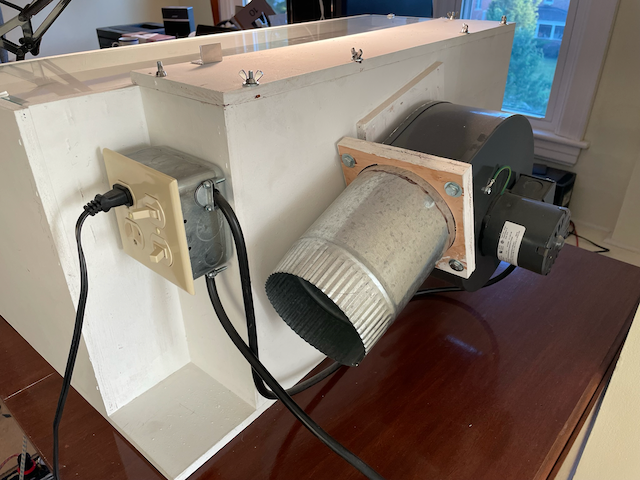

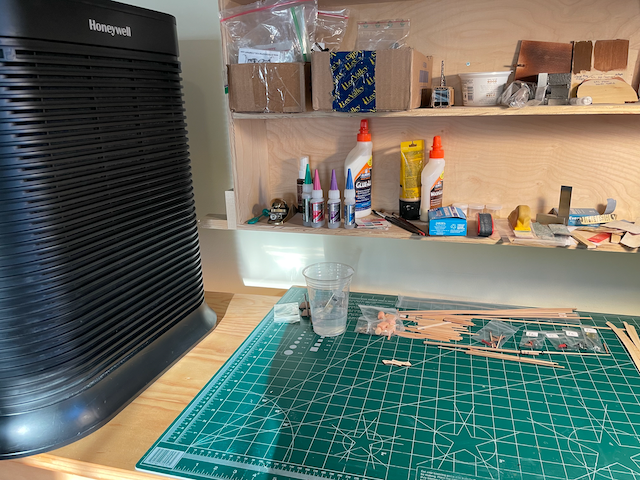

I built a spray booth out of ½" plywood with a tempered glass window along the top a few years ago. When using enamel or other smelly stuff, I vent it to the outside. I don't bother venting it for acrylics to save on HVAC expense. I originally used a plain old furnace filter. Like you, I got to thinking that it could double as a sawdust collector so I replaced the filter with a 3M Filtrete 1900 to catch the very fine sawdust. I didn't bother with an explosion-proof motor. The density of dust particles or smelly aerosols in the booth is nowhere near hazardous levels. Also there's a filter between the motor and the contaminated air. I now use it to collect dust when using my chop saw which has no vacuum attachment. I also use it with my disc sander with a Miele vacuum attached to the built-in dust port (mainly to keep the interior of the sander dust free). I could use it when sanding parts by hand but it's much more convenient to do that at my bench. There, when sanding, I wear a KN95 mask, run an air cleaner to catch the fine particles, and vacuum frequently. I echo Bob Cleek's recommendation to avoid sanding when you can use an X11 blade (or similar), a chisel, or a small plane. The latter is especially useful when tapering planks or masts, spars, etc. The larger plane to the left in the photo below is a Stanley 12-101 small trim plane. The one on the right is a Lee Valley Veritas Miniature Block Plane. For reference, those are 1" squares on the hobby mat. Warning: The Lee Valley website, along with the ones for Festool, Byrnes Model Machines, and the Lie-Nielsen Toolworks, is a Restricted Web Site in the No Surf Zone. Visiting a restricted web site unless under the direct supervision of the Admiral is strictly prohibited. 🙂 Jonathan

-

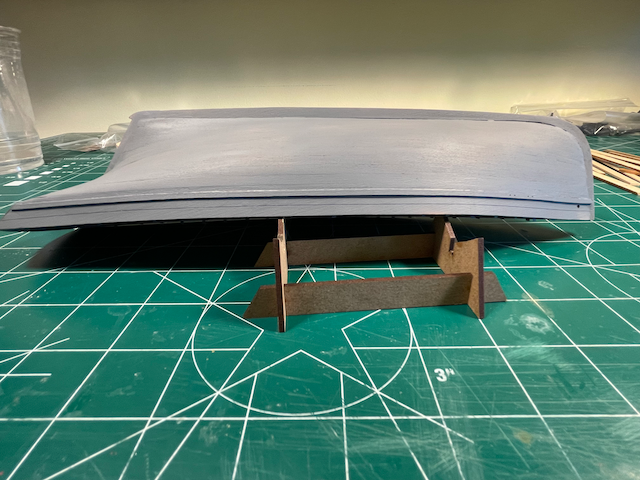

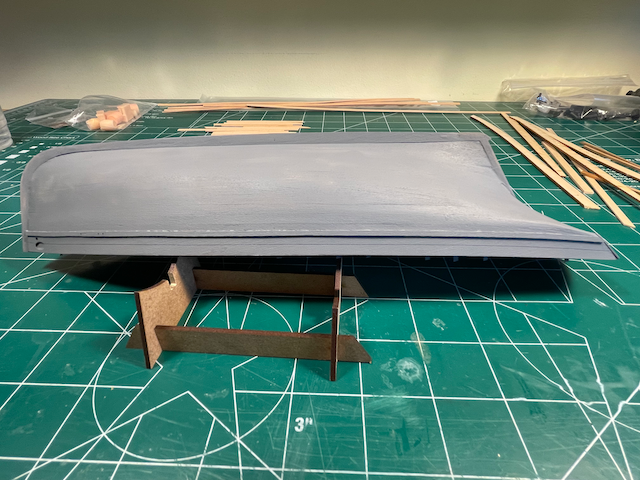

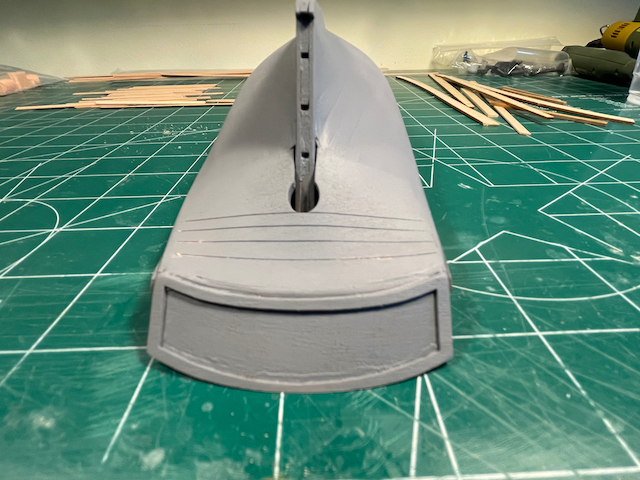

The results are in with the Badger Anti-Fouling Red Oxide paint. I sprayed it on undiluted using my Paasche H Airbrush. I have minimal experience in airbrushing. Here 'tis: The picture was taken with a Nikon D3400 set for f/25 (to increase the depth of field) with a 10-20 mm zoom lens in shaded evening light. It's a pretty good reproduction of the color. Initially I was lazy and used my iPhone 12 but the built-in AutoColorCorrectifierForDummies turned it into a rather garish red - gee, thanks guys. 😕 Jonathan

-

I too am working on the Nisha and trying to air-brush the lower hull with some sort of acrylic. I ordered Badger Modelflex Anti-Fouling Red Oxide from Hobbylinc, based on the recommendation of Kurt Van Dahm in this forum. It's one of Badger's ModelFlex Marine colors. I used their Stynylrez primers, also recommended by Kurt, which has worked out well so I thought I'd give this stuff a try. It's due to arrive tomorrow (Saturday). We'll see how it goes. Jonathan

-

Congratulations on finishing the model - it looks excellent!! 👏 Jonathan

- 62 replies

-

- Nisha

- Vanguard Models

-

(and 1 more)

Tagged with:

-

- 488 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thanks y'all for the likes and comments! Helps me keep going. Like, say, during construction of the infernal Companionway. I can imagine the conversation now: James (working on the prototype): "Hey Chris, these hinges are so large that they're actually easy to put together." Chris: "I can fix that! Bwahaha!" Dan (DB789): Thanks! And if you just take photos of the stern from a high enough angle, nobody would suspect a thing! Craig (Craigie65): It's almost as if you have to start with the fitting of the gunwale and stern gunwale, then work back from there until you reach Step 45. That way you'd know how much to sand off the stern frames before proceeding. I think I read somewhere that Malcolm Darch doesn't like to glue anything until all the relevant parts fit together like the proverbial glove. Finally, a shout out to James H. and Chris Watton for numbering the steps in the documentation. It makes trading information a whole lot easier on the forums. Jonathan

- 38 replies

-

- Nisha

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I'm going to use the Andyrew approved colour scheme. I was shooting for the DB789 look with the natural gunwale (minus the white racing stripe) but it looks like there will be a big gap between them and the stern gunwale that'll need a bunch of filler. Phooey. Maybe next time... (It's like home projects such as putting up drywall or tiling a bathroom: just about the time I actually get good at it, the job is done.) Jonathan

- 38 replies

-

- Nisha

- Vanguard Models

-

(and 1 more)

Tagged with:

-

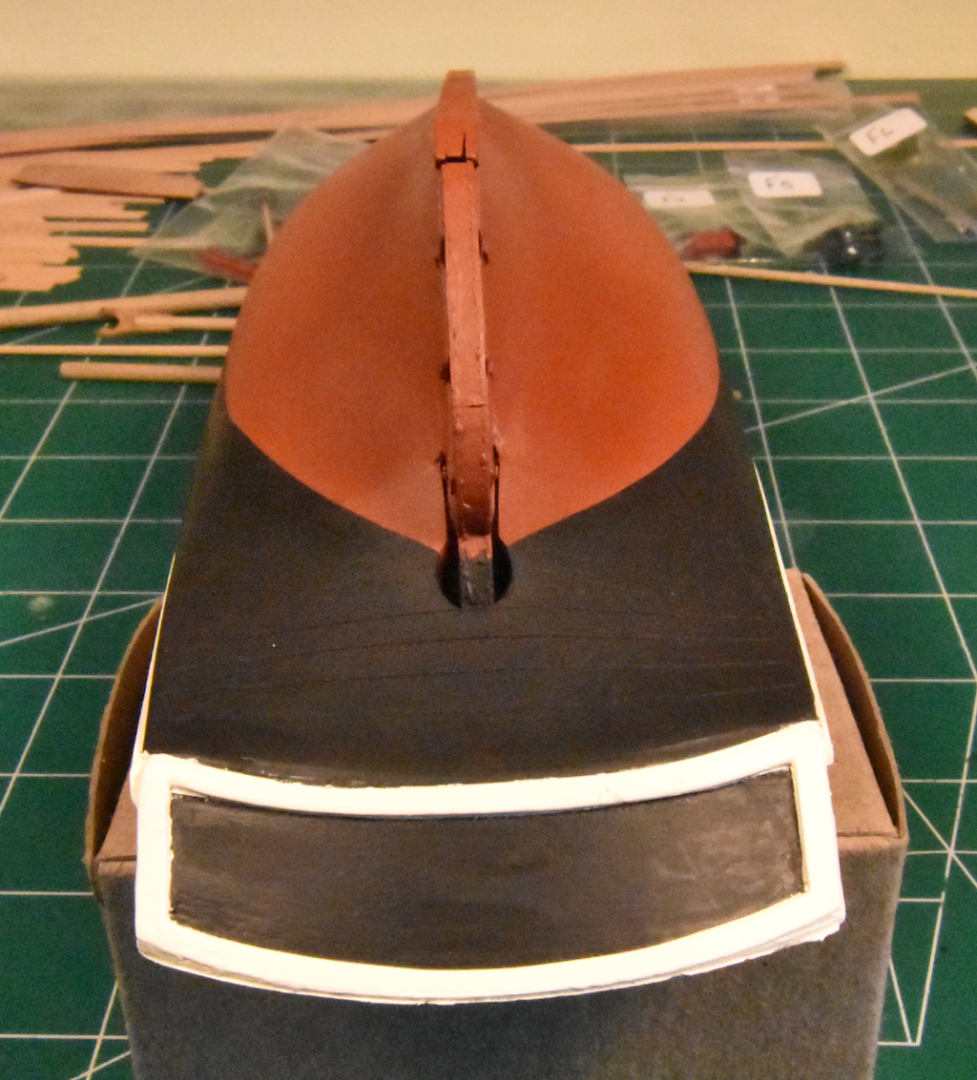

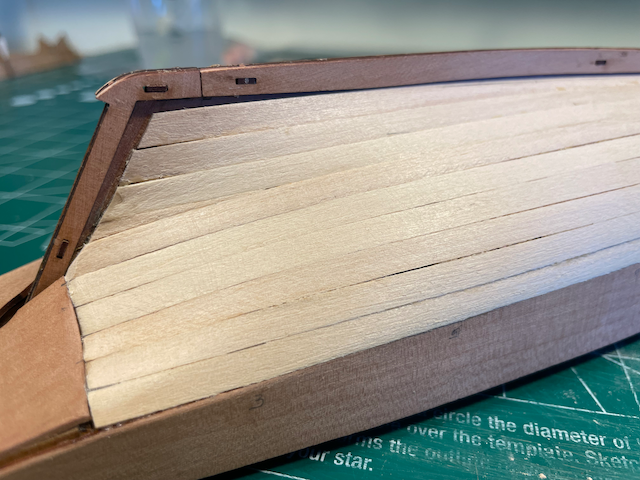

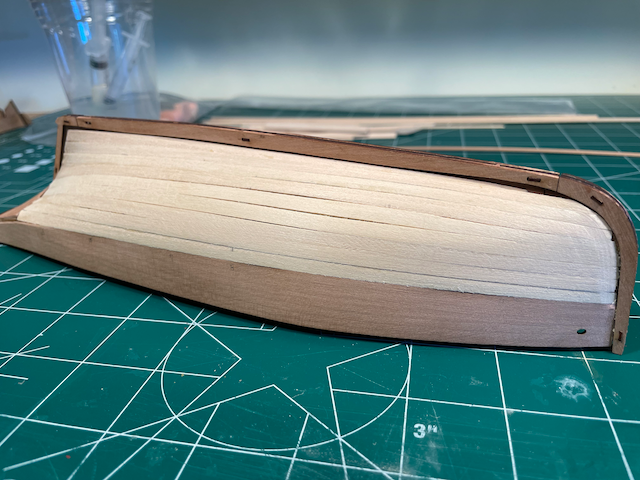

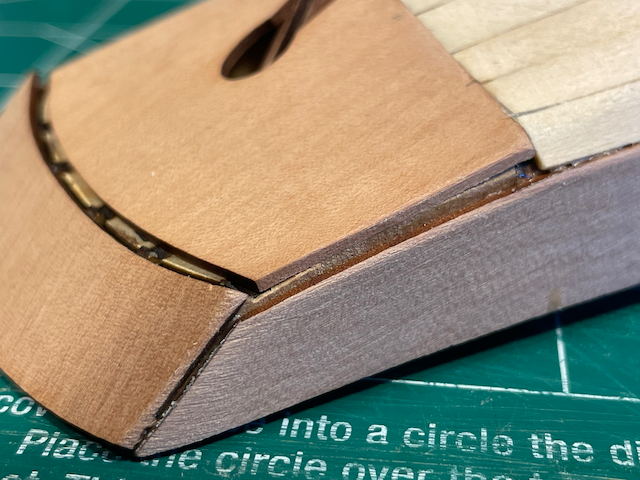

Later that very same build ... Having finished the first layer of planking on the port side, I turned to the starboard side. The results were better, at least at the stern. With three strakes to go there was going to be a 0.05" gap so I tried to distribute that evenly across the four edges, given that everything would be covered up by the second layer of planks. The bow was also a bit ragged. There was quite a gap between the counter and the bulwarks... ... but some filler cleaned that up. There were no gaps amidships after the second planking (I finally got it right - yippee!) but the bow and stern areas on both sides needed some filler in the problem areas. Given all the filler, it was easy to make the decision to paint the entire hull, starting with Badger Stynylrez for the primer. I had to fashion a thin piece of pear to help fill the gap between the counter and the stern board as it was too wide for filler alone. As you can see, I need to improve my sanding and painting techniques. Jonathan

- 38 replies

-

- Nisha

- Vanguard Models

-

(and 1 more)

Tagged with:

-

From a post by tlevine in 2019 … Jonathan

-

Lurked for a few weeks. Here's my intro

wool132 replied to Mark m's topic in New member Introductions

Welcome aboard! And now you have something to do when you get stuck in traffic Jonathan -

Questions Before I Buy My First Ship

wool132 replied to Magarkus's topic in New member Introductions

The GB Dory is a great choice for a first kit. Plus you can easily haul it back out when you're done. I imagine something with masts and rigging would be a bit more problematic. For tools, James H's list is great plus: Woodworker's glue (Elmer's or Titebond, etc) plus alcohol to undo errors CA glue plus CA dissolver to undo errors Xacto knife w/spare blades plus band aids to patch errors Eyewash kit to rinse out errant wood particles A couple of lego blocks to ensure right angles 0.3 mm mechanical pencil and spare leads Wood filler Some acrylic paint and Winsor & Newton (or equivalent) quality brushes An inexpensive brush or a box of toothpicks to spread out the woodworker's glue A handful of #16 and #33 rubber bands You may not need spare wood. The GB Dory kit already comes with some extra pieces plus you can recycle the leftover cutouts. If you worked out in the gym with the offensive or defensive linemen in high school or college, you could also bring a hair dryer and traveling iron for bending planks, a Byrnes table saw, disc sander, and thickness planer plus a suitably large portable electric generator. 🙂 Jonathan -

Hole too large? Insert a toothpick (pared down to fit) along side the mast. Too small? Twirl the mast between some sandpaper to shave it down. Just right? None of the above 🙂. My mast rested on the hull though I don’t think it matters all that much. I mean, how much vertical force can there be to warrant the extra support? As I recall, the instructions said that either straight up and down or having an aft tilt is okay. With that in mind, I just made sure that the mast wasn’t tilted forward. Lookin’ good so far! Jonathan

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.