GrandpaPhil

NRG Member-

Posts

6,147 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by GrandpaPhil

-

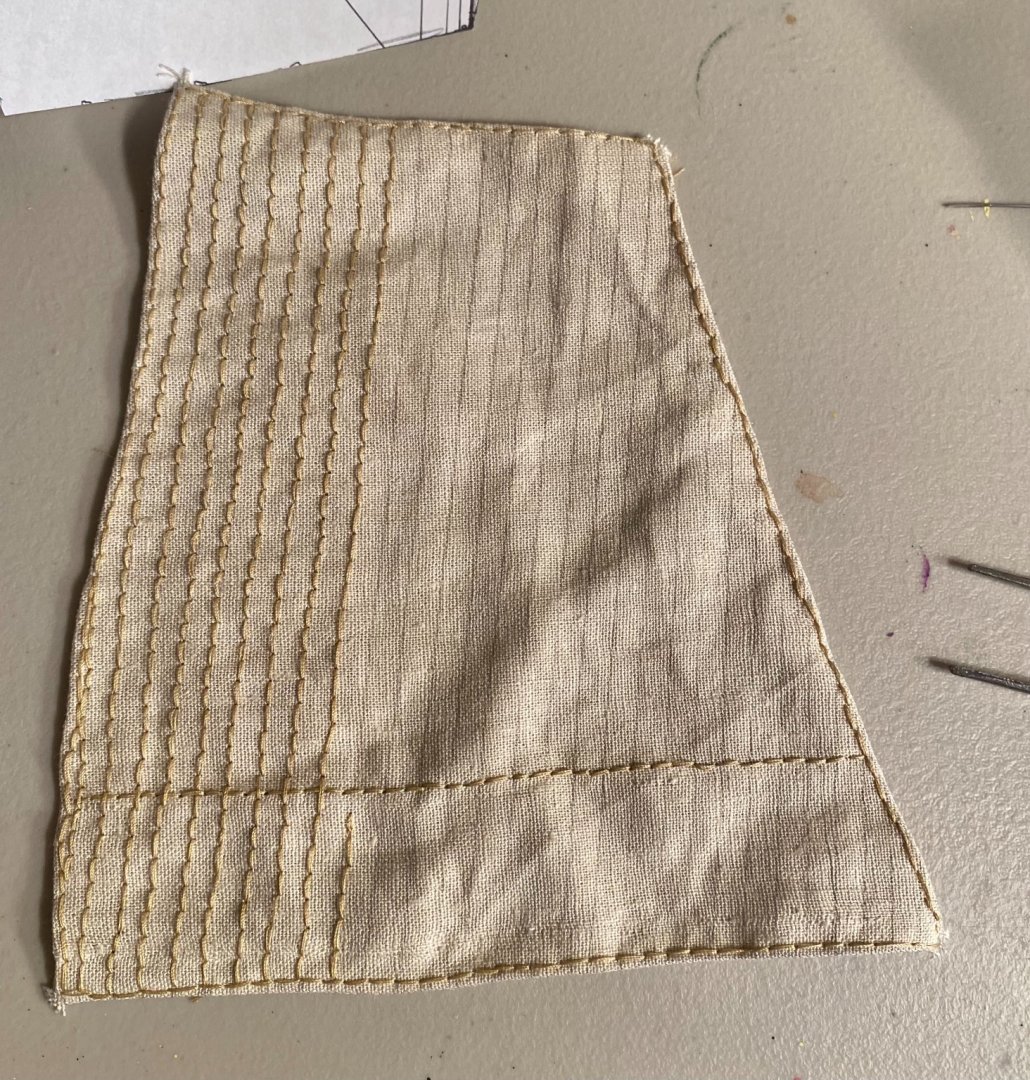

Thank you all for the comments, the likes and just for stopping by! One set of sails, reefing points and bolt ropes included: Now, on to the running rigging!

-

Looking good! The gunport templates are very nice. My Victory had cardboard templates to be used after the second planking, for gunport positioning. Your first layer of planking came out very well!

- 218 replies

-

- Victory

- Caldercraft

-

(and 1 more)

Tagged with:

-

OC, Thank you very much! Allan, I might try silkspan for the Victory’s sails. I’ve been getting more detailed and trying new techniques/materials with each model. I’m still getting better.

-

Installed reefing points: I wanted some thicker thread for bolt ropes, but according to Zu Monfeld, the bolt ropes had thickness between 1/3 and 2/3 the diameter of their respective stays, so… I guess I’ll use what I have on hand.

-

Thank you all for the likes and for stopping by! One rough stitched set of sails: Next up, reefing points and bolt ropes!

-

Papegojan 1627 by mati - FINISHED - 1/48

GrandpaPhil replied to mati's topic in - Build logs for subjects built 1501 - 1750

Very nicely done! -

Making progress: The main sail still needs reefing lines and a bolt rope, but I’ll assembly line those and do all of them at once.

-

Thank you all for the “likes” and for stopping by! I am still working on the main sail slowly. I decided today that I am also going to make bolt ropes. I keep improving and getting more in depth with every model.

-

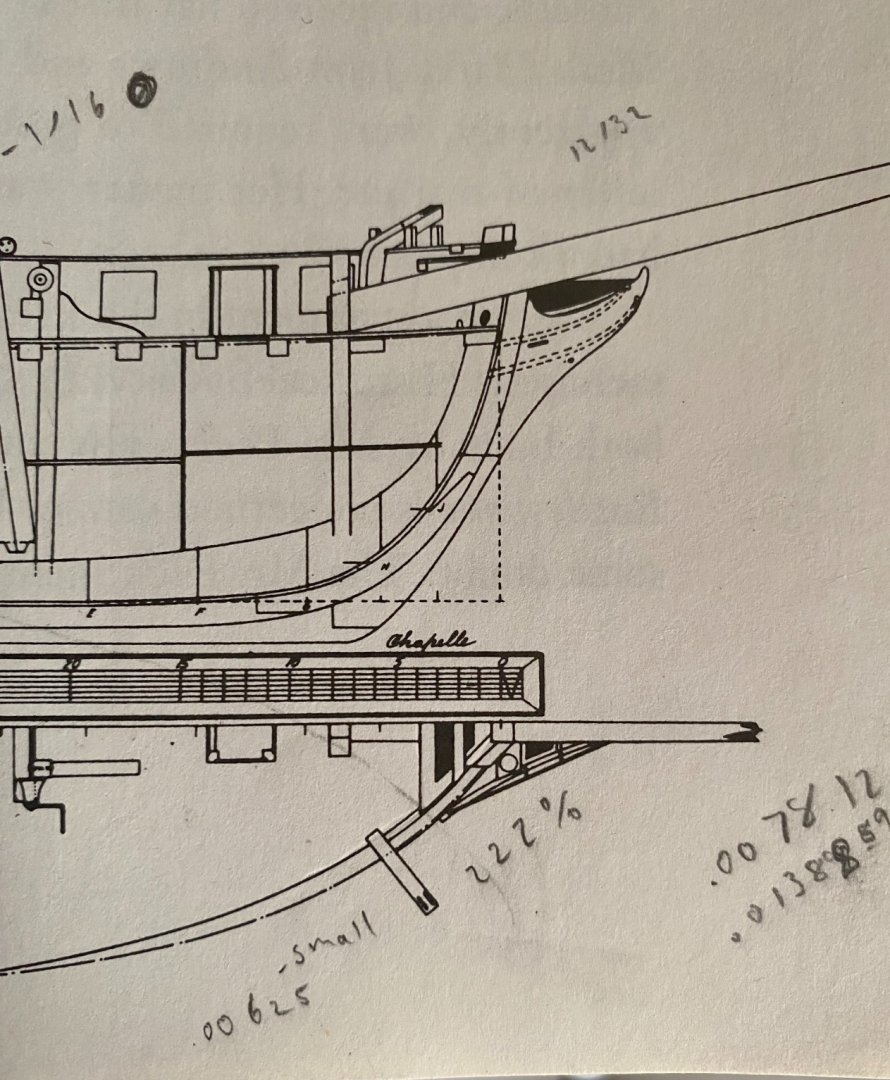

Ingrid And Other Studies is $21 plus $14 shipping on Abebooks Plate V of the History Of American Sailing Ships by Howard I Chapelle shows a single seat of ease to either side of the bowsprit, on the head, on the Prince De Neufchatel. Please ignore my notes. This was my copy that I used to build the hull of my model.

-

Amazing work! Your Soleil Royal is coming along beautifully!

- 2,699 replies

-

- heller

- soleil royal

-

(and 9 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.