GrandpaPhil

NRG Member-

Posts

6,079 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by GrandpaPhil

-

- 355 replies

-

- prince de neufchatel

- schooner

-

(and 3 more)

Tagged with:

-

- 355 replies

-

- prince de neufchatel

- schooner

-

(and 3 more)

Tagged with:

-

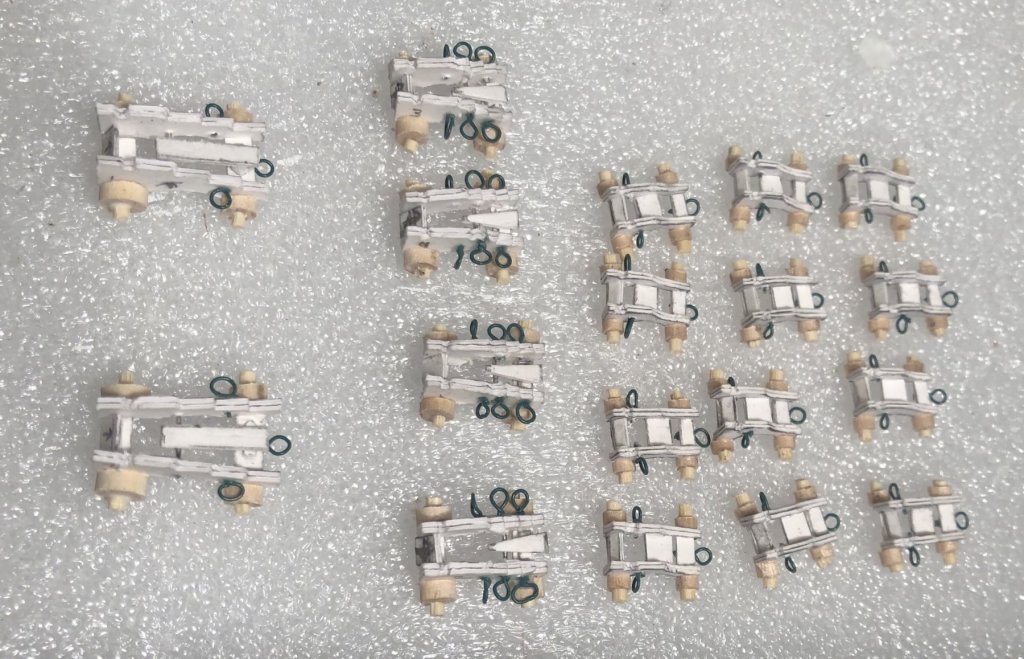

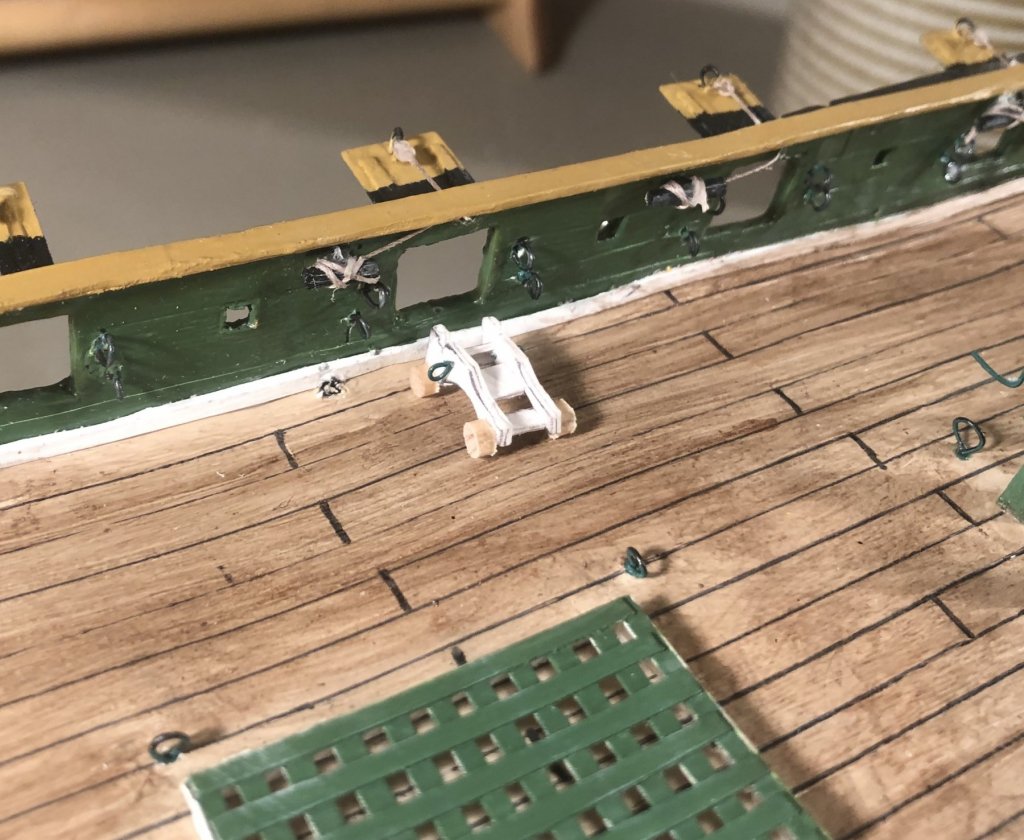

All eighteen carriages are ready to take their guns. Now, I just have to make them. I think that I will try carving them first, from a dowel rod. If I don’t like how that goes, I will try chucking said dowel rod in a drill and making a makeshift lathe. But, carving sounds safer, so I will try that first.

- 355 replies

-

- prince de neufchatel

- schooner

-

(and 3 more)

Tagged with:

-

- 355 replies

-

- prince de neufchatel

- schooner

-

(and 3 more)

Tagged with:

-

- 355 replies

-

- prince de neufchatel

- schooner

-

(and 3 more)

Tagged with:

-

- 355 replies

-

- prince de neufchatel

- schooner

-

(and 3 more)

Tagged with:

-

- 355 replies

-

- prince de neufchatel

- schooner

-

(and 3 more)

Tagged with:

-

San Martin by augustus

GrandpaPhil replied to augustus's topic in - Build logs for subjects built 1501 - 1750

Excellent work! -

- 355 replies

-

- prince de neufchatel

- schooner

-

(and 3 more)

Tagged with:

-

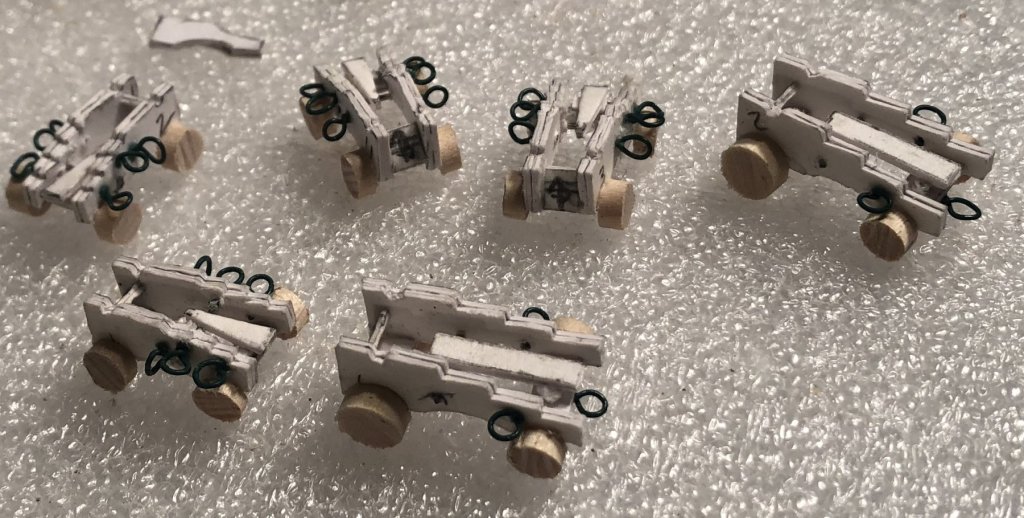

Busy weekend. I rearranged my shipyard so I can put in an actual workbench. I installed eyebolts in the sides of my gun carriages. I tested my new scalpel out on wood. It worked perfectly. I still have all fingers, lol. I need to make the rest of the parts for my gun carriages and assemble them.

- 355 replies

-

- prince de neufchatel

- schooner

-

(and 3 more)

Tagged with:

-

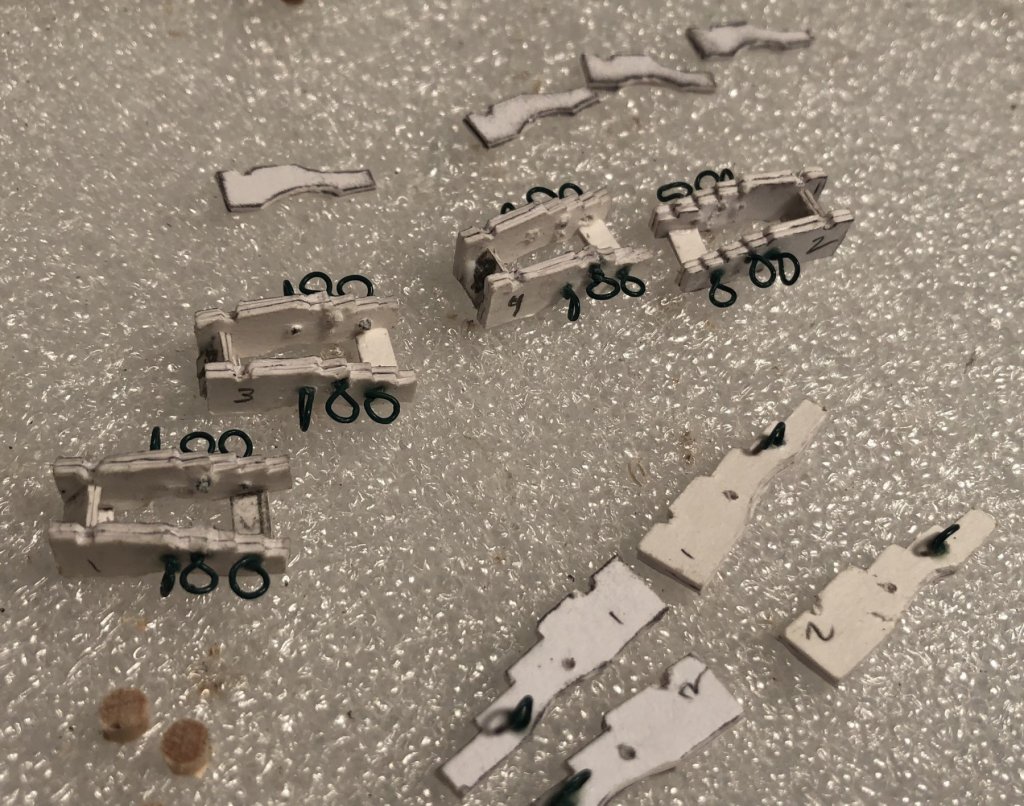

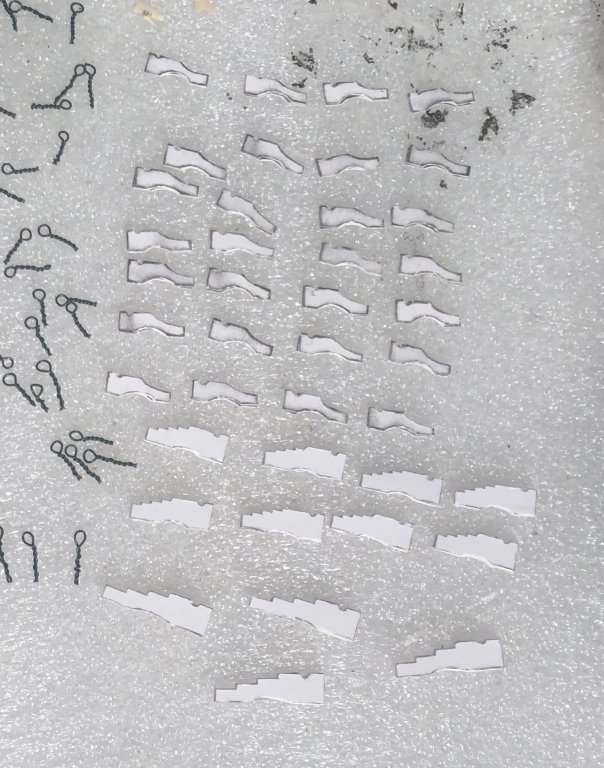

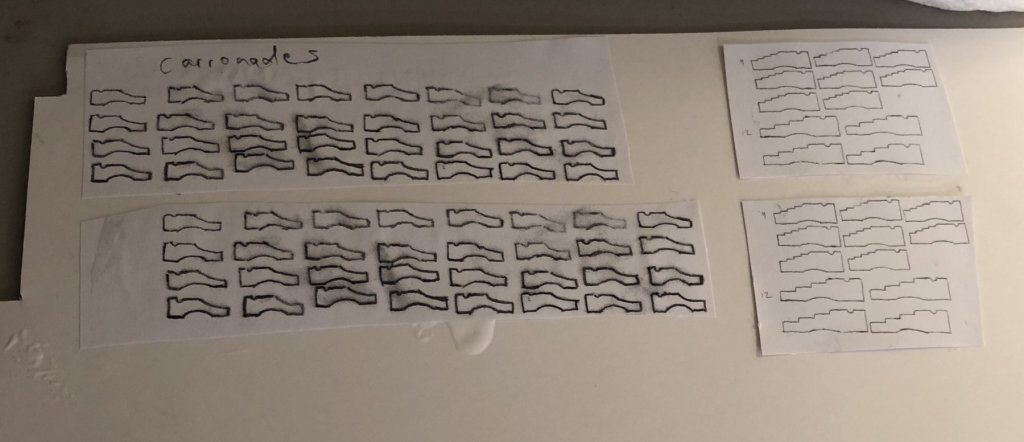

All gun carriage sides are cut out. I am making: 12 12 lb. carronades 4 9 lb. long guns 2 12 lb. long guns

- 355 replies

-

- prince de neufchatel

- schooner

-

(and 3 more)

Tagged with:

-

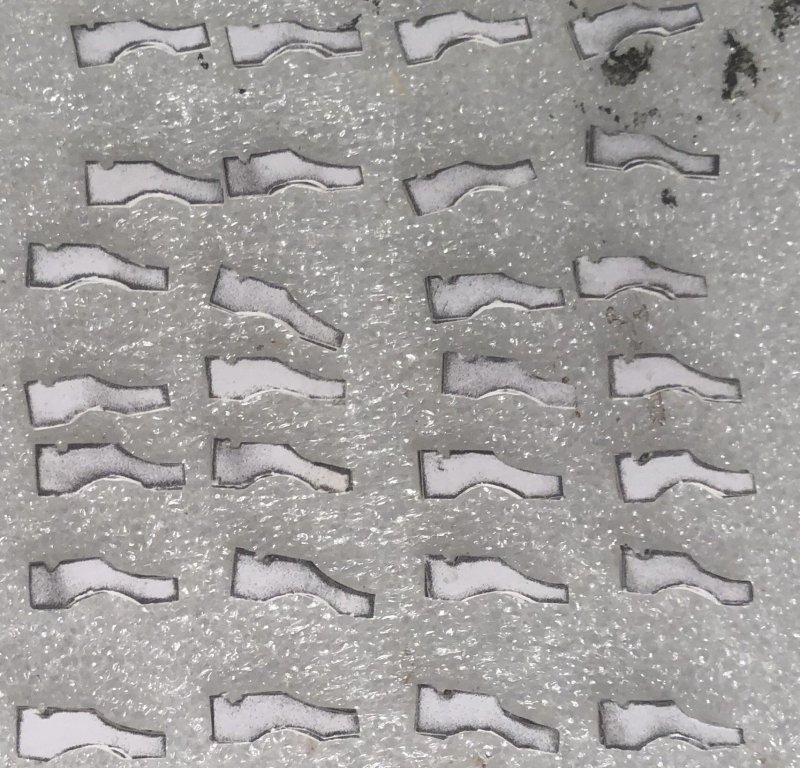

I’ve got enough sides cut out for 14 of the carriages for the 12 pound carronades. I only need 12, but I made a couple of extras. I’m working on the sides of the carriages for the 9 pound long guns. On a separate note, the scalpel is working well. The handle isn’t the most comfortable to use, but it will be okay for now. I want to get a couple of the plastic molded grip handles.

- 355 replies

-

- prince de neufchatel

- schooner

-

(and 3 more)

Tagged with:

-

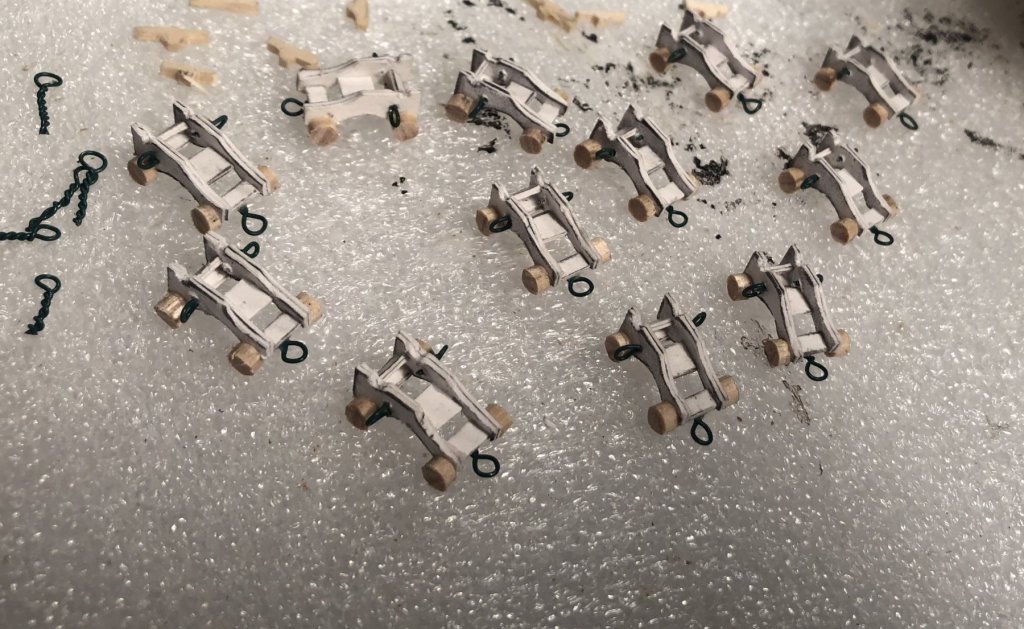

I got my scalpel and blades in the mail today. I ordered them after reading the thread on scalpels on this forum. According to the thread, they work better and last longer than X-Acto blades, which is very important to me, because I burn through an X-Acto blade a week. So, I figured I would try a scalpel out. I tested it out on a carronade carriage when I got home tonight. It worked beautifully. It made a very clean cut, even when I tried just shaving the poster board (which usually doesn’t work very well). I’ll see how the scalpel does on wood, this weekend. I’ll let you guys know how long the blade lasts.

- 355 replies

-

- prince de neufchatel

- schooner

-

(and 3 more)

Tagged with:

-

Patrick and Mark, Thank you very much for the comments! I started cutting out the carriages for the carronades last night. I also bought a 1/8” dowel rod to make the wheels from. I am learning as I go.

- 355 replies

-

- prince de neufchatel

- schooner

-

(and 3 more)

Tagged with:

-

It is slow going, but not onerous. I enjoy it.

- 355 replies

-

- prince de neufchatel

- schooner

-

(and 3 more)

Tagged with:

-

18 gun carriages: 12 12-lb carronades - from Search for Speed Under Sail 4 long 9-lb cannon - from AOTS Bellona 2 long 12 lb cannon - IBID Now to let them dry and then start cutting

- 355 replies

-

- prince de neufchatel

- schooner

-

(and 3 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.