-

Posts

1,194 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by CPDDET

-

Finished building the compass housing, just have some sanding cleanup and painting to do. Really tried to keep things in scale and decided on 1/16 wide by 1/32 thick boards for the top cover. This is equal to 2 inches thick by 4 inches wide. I started by putting two pieces of 1/16 stock together with double stick tape. Copied the shape of the front panel from the plans, cut it out on a scroll saw and sanded the edges of both pieces smooth. After separating the two pieces I drilled the needed hole in the front panel. Using another scrap of 1/16 stock I made a base to join the front and back panels. Then ripped a piece of 1/32 thick stock to make a 1/16 wide plank several inches long. After cutting the plank into 10-12 pieces, which were slightly longer than needed, I glued them in individually to form the cover of the housing. Cutting the planks / boards a bit longer than needed allowed them to slightly overhang both the front and rear panels. Then it was a simple job of sanding them flush. Came out fairly well. When this is done I’ll move on to the vent / smoke stack which I plan to build from brass tubing. Time to gather the needed tools and material for that.

- 389 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

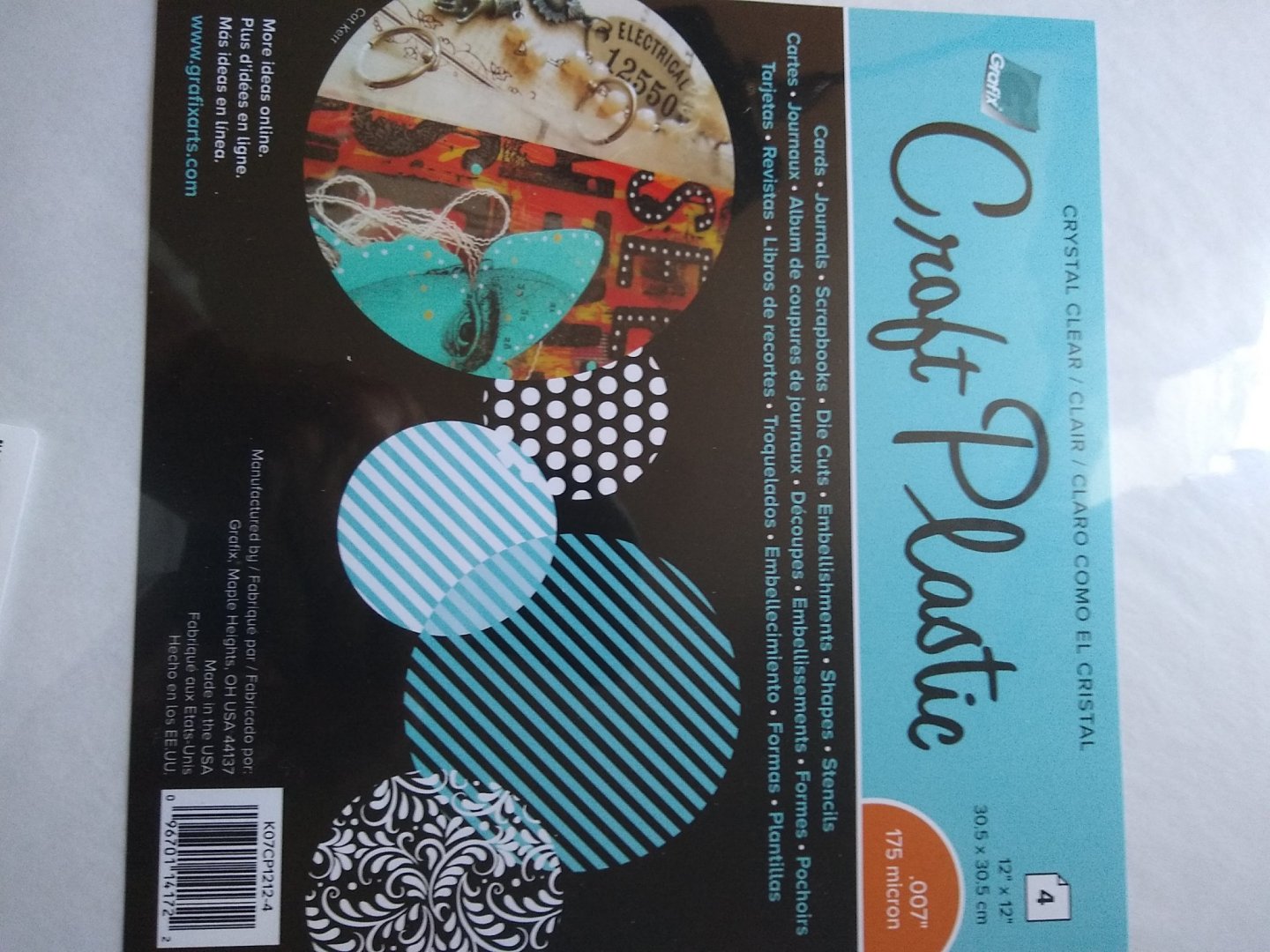

Finally back in the boatyard. Had some emergency medical issues to deal with but back in fine shape now. Also decided to reorganize my work area as things were getting too cluttered. The issues I was having with the skylight are now solved and thought I would go into a bit more detail on how I solved them. The workmanship still isn't what I would like but at this stage of my skill I feel its my best effort. The two problems I was facing was building a strong enough window frame and drilling holes for the bars that would line up from the top frame to the bottom frame so the bars would be straight. I built a jig that would hold 2 pieces of wood stacked on each other. Then, using my Dremel drill press, drilled five 1/64" holes through both pieces. In order to build a stronger window frame I decided to use thicker stock and cut lap joints to give the Titebond something to adhere to. So I made jigs that would limit both my vertical and horizontal cuts. Then carefully cut the 4 sides of each frame. Using pins that would eventually become the bars for alignment, I glued the frames together. After painting the frames I inserted 5 pins in each and trimmed them to fit. For the housing I glued in a piece of craft paper to hide the framing that would show through the skylight. I glued some very thin craft plastic to the back of the frames to serve as windows panes. After gluing the windows to the housing I fashioned the top piece. This took a bit of doing but my new Byrnes disk sander made it much easier, sanding the 40 degree angles to fit. Then stained the piece and glued it in. Now it's on to the compass housing.

- 389 replies

-

- bluenose

- model shipways

-

(and 1 more)

Tagged with:

-

Welcome to the best site on the web for model shipbuilding. I'll chime in on the scale of the model you choose. I'm on my first build, Bluenose, which is a 1:64th scale. That means 1 inch on the real ship equals 1/64 inch on the model, or 1 foot on the real ship equals 3/16th of an inch on the model. At this scale, details become very small and can be difficult to produce. I would advise a larger scale model for your first build. Check around this site for more information on kits, card builds, scratch builds.

-

Could the cracking be caused by to thick of a blade? I had this happen once when trying to use a utility knife. But if your using a single edge razor blade you can't get much thinner than that. Basswood isn't the easiest stuff to work with for sure. Dents easily, difficult to cut straight and clean, tough to paint, way too absorbant and on and on.

-

Byrnes Sander or saw, that is the Question?

CPDDET replied to Nirvana's topic in Modeling tools and Workshop Equipment

I had the luxury of ordering both with my tax refund. But if I had to choose one it would definitely be the saw with attachments. -

The sand paper I used is available at any hardware / home improvement store. It comes in a roll (3 feet long?) And an inch or so wide. It's used by plumbers to clean copper pipe before soldering. I also have the NRG half hull kit waiting for me once I finish my Bluenose. I really need to get a firm grasp on proper hull planking before I attempt any further models. While the painted hull of my Bluenose looks pretty good, I had to use a coating of wood putty over the entire hull to get it than way. I've decided I don't want to paint any future models and only use oils / stains on the wood. But to do that my planking techniques have a long way to go. Carry on, Pat. You're doing good work. D

-

Sorry to hear about your frustrations. But I can easily relate. Sometimes I find it better to just walk away from my build rather than trying to push through the problem. My mind continues to ponder on the problem even away from the shipyard, and sometimes I will come up with an out of the box solution. I know this doesn't answer your question, but I wanted to at least offer some moral support. As for tapering hull planks, and deck planks for that matter, here is what I did. Probably not the best solution but it worked for me. First I took a board of the same thickness and length of the planking boards but 3 to 4 inches wide. Then I took a metal ruler (12-16 inch) and glued a sandpaper strip to the backside. I then drew the taper on the plank, butted it up against the larger board and placed the ruler along the line I drew. The ruler overlapped both the plank and the larger board. I found the sandpaper on the backside of the ruler trapped and held the plank firmly enough to allow me to taper it with a knife. Perhaps there is a way to also get sandpaper below the plank as well and "sandwich" it in to hold it firmly. I think this may work better if the larger board is very slightly thinner (1/64) than the plank. Too much difference may cause the knife to run at an angle. I took the dive and invested my tax return in a Byrne's saw. I would hope this will solve any future problems with tapering. D

-

Byrne's saw accessories question..

CPDDET replied to CPDDET's topic in Modeling tools and Workshop Equipment

While I have owned a radial arm saw many years ago, I've never owned or operated a table saw. Seems to me my Byrne's saw is just a smaller version of the full size machine so the same techniques and safety rules apply. While waiting for delivery of the saw I decided to purchase the following and get some education. https://m.barnesandnoble.com/w/tauntons-complete-illustrated-guide-to-tablesaws-paul-anthony/1103185359

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.