-

Posts

321 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by NovaStorm

-

Once you paint it that will blend right in Keith. It looks great! Your just seeing all the aluminum bling at the moment. Just wondering if I ever get around to starting mine, would it be easier to ruff shape out the plating after putting on the first hull planking. Then installing after the second planking and before painting?

- 206 replies

-

Thomas thank you! Your build is my inspiration, thank you for watching mine Been working on the companionway, also added the other pin rail at the bow. Couldn't take the stark white grating any longer and stained it with several soaks in a gun stock stain. It's not the best but ... Take a look, a few picks, haven't added the doors onto the companionway yet just the hatch.

-

Nicely done that decal is tack sharp.

- 140 replies

-

- benjamin w latham

- model shipways

-

(and 1 more)

Tagged with:

-

You are going to have to apply heat to do the bend required. What have you got, try an iron, or fat section of a soldering iron if you don't have the plank bender they sell. Try not to fry the wood when doing it. Also a nice trick for painting sharp edges is to first take the tape and run it down a mirror or piece of glass. Run a straight edge down one side and with a new blade take the edge off. Then apply and paint Cheers it is looking good what you have done! Keep up the good work... ~

- 950 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

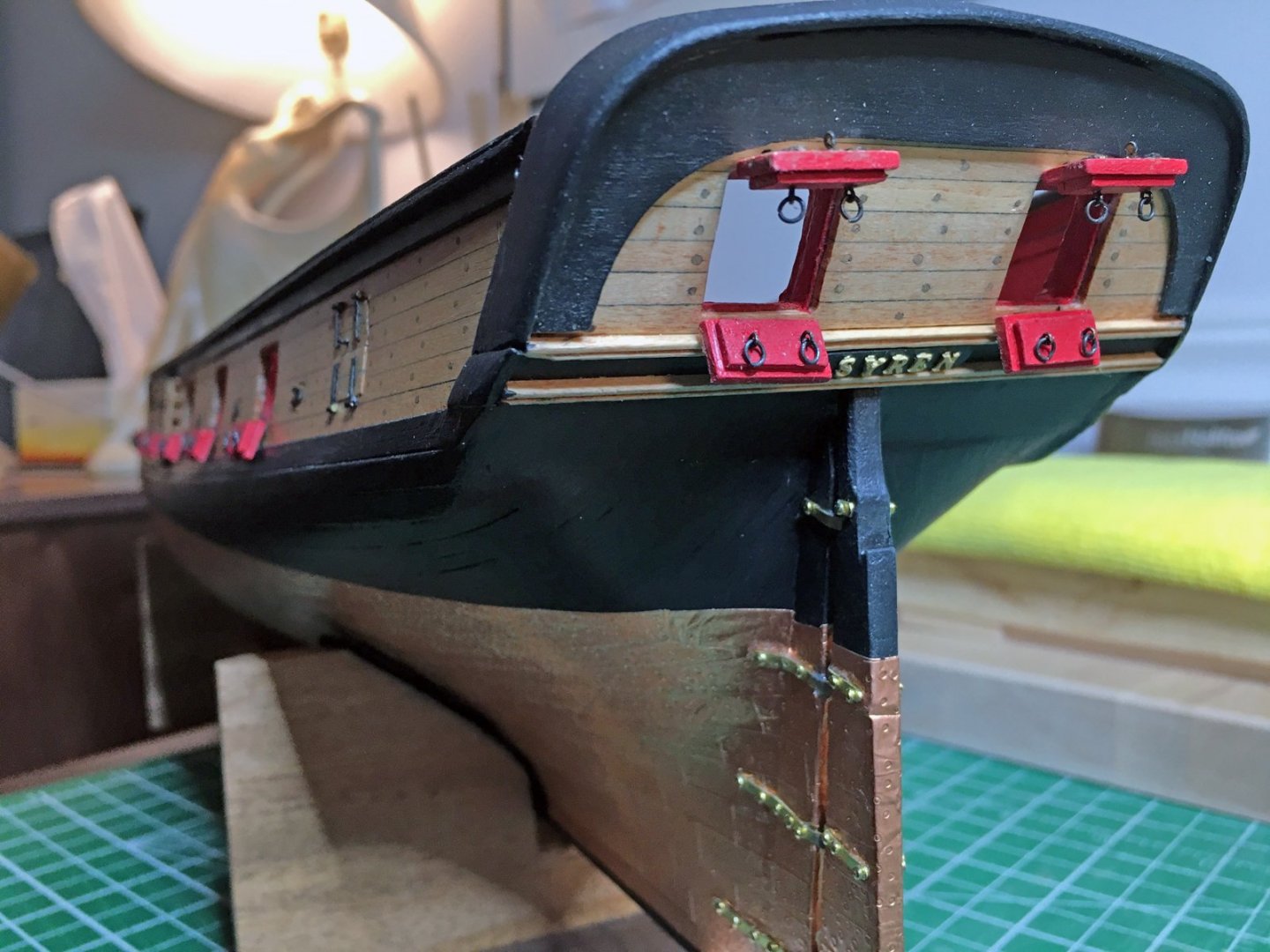

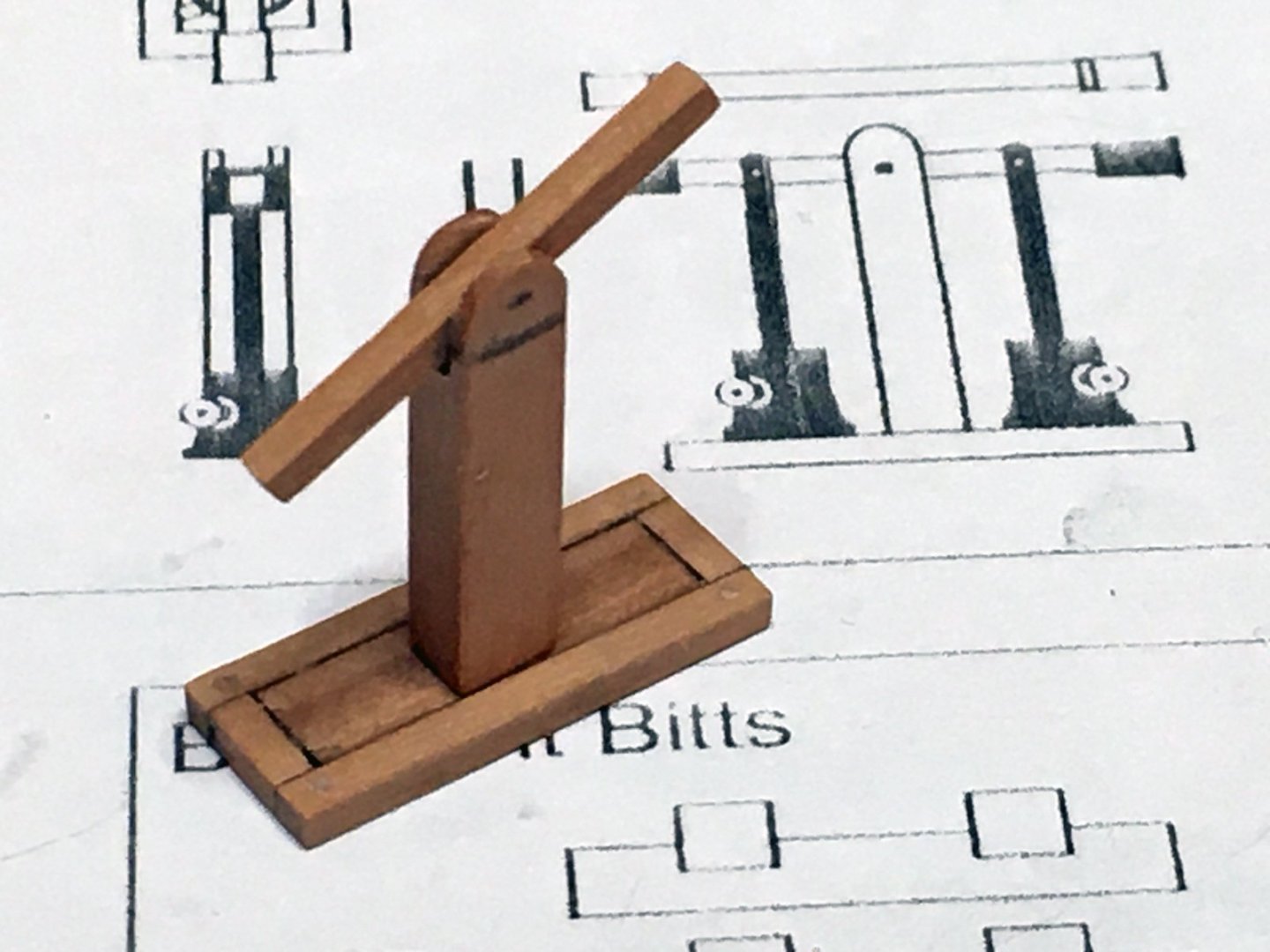

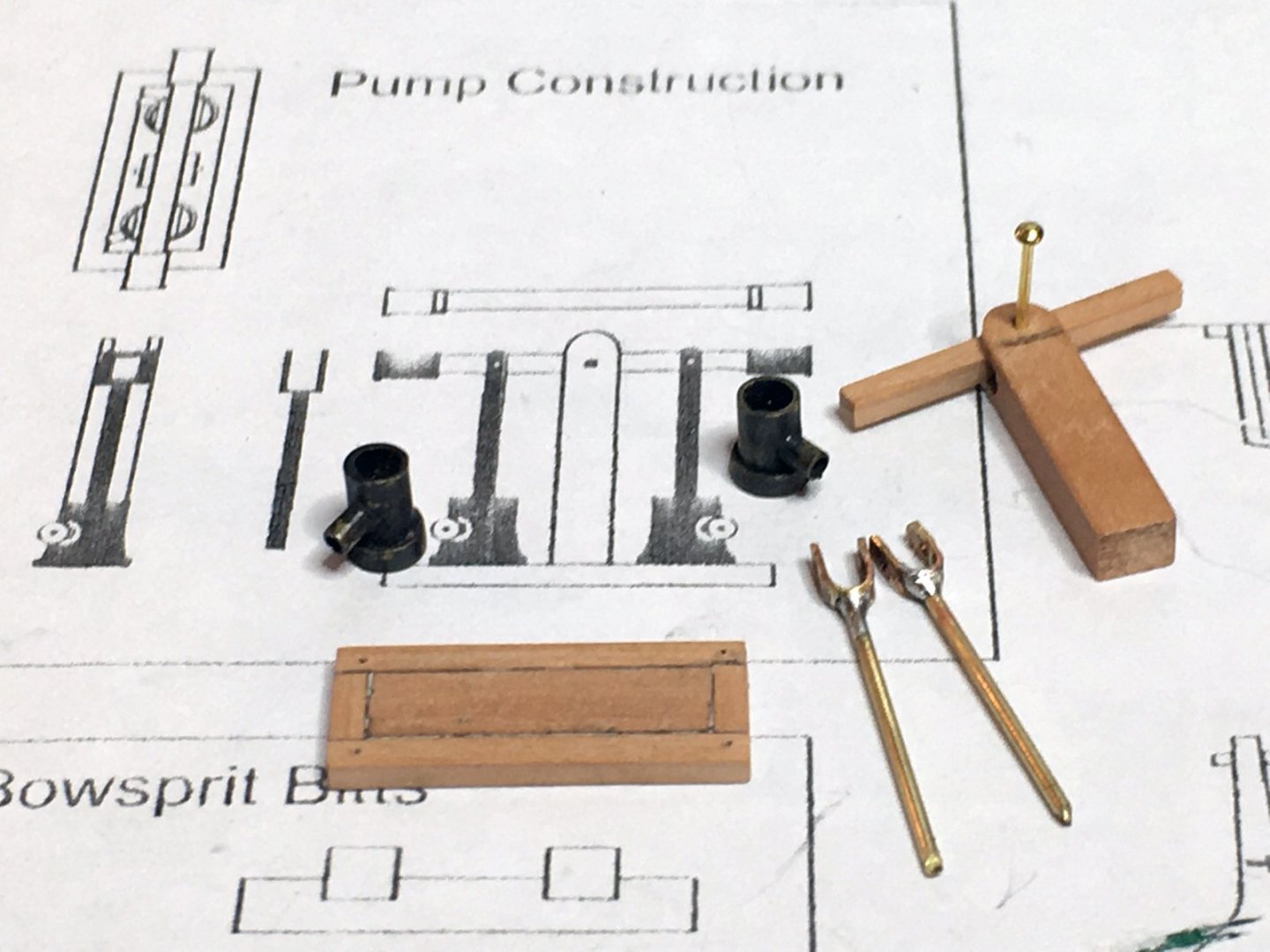

Busy couple of weeks with work but here are some picks of what I've been working at. The stern davits I made out of pear are installed. Tested out the transom post covers. Had a blast making the pumps up which I am pretty pleased with. Added lug nuts to the cannon wheels. Hope you are all well and staying out of trouble!

-

It is looking good Wally, you are moving right along

- 950 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

Your off to a great start. Those port openings did they come like that, they look laser burned on the corners.

- 106 replies

-

Today I gave er a good cleaning followed by a minor paint touch up! Made up the stern transom port covers, painted waiting to dry. Then I did up a signage proto by mounting ``Syren` onto a thin black board. I kinda like it because now it is more visible with more 3d. This is just a test using 2 sided tape

-

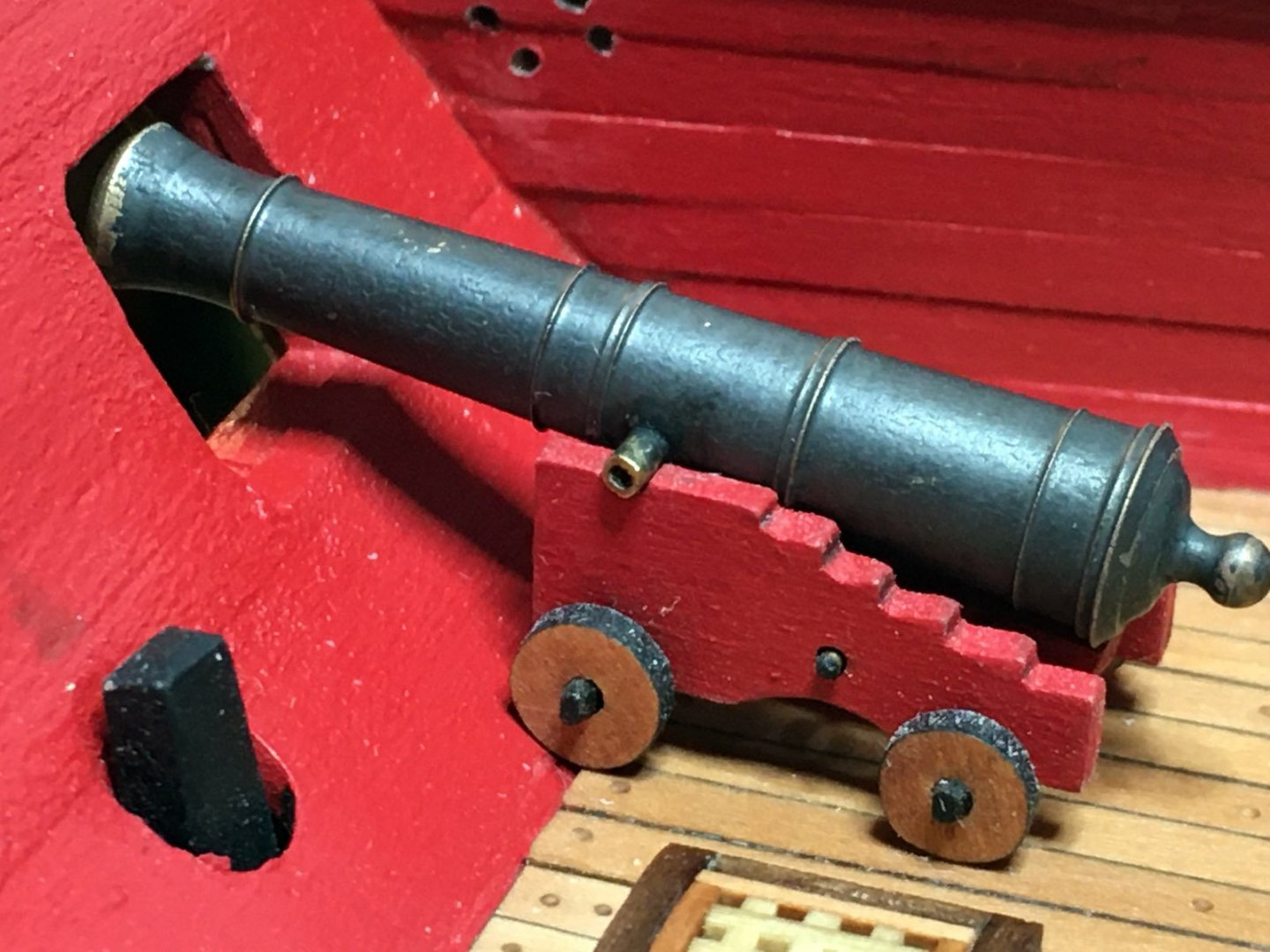

Ok I couldn't take the bling factor on the carronades any longer. Last evening I got into blackening the carronades and one cannon I have done up for the port side. I was pretty nervous given the time spent on them and the sleds, so it was going to be a bit of a do or die moment. Well the results came out fantastic I think. Took a little trial an error to get the results I wanted and I hope you like them as well. I started out soaking the pieces in a solution of Sparex #2 in a warming pot for about an hour and a half to clean them. Then they were dried and placed into a container of (straight) Casey's brass black for ruffly 3/4 of an hour. I then removed them from the caseys and rubbed them down with a paper towel which cleaned off the excess and produced results that were not where I wanted them. This was fine as I then placed them back in the casey's again for about 1/2 to 3/4 an hour and then removed them a second time and again rub off and polished them with a paper towel to get the final result. Here are some pics of the outcome.

-

Now your talking that is really looking like a great way to clamp it. I will remember how you've accomplished it for the next time I am in need of a workable solution. Thanks for sharing, it looks as good as it gets to me

- 950 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

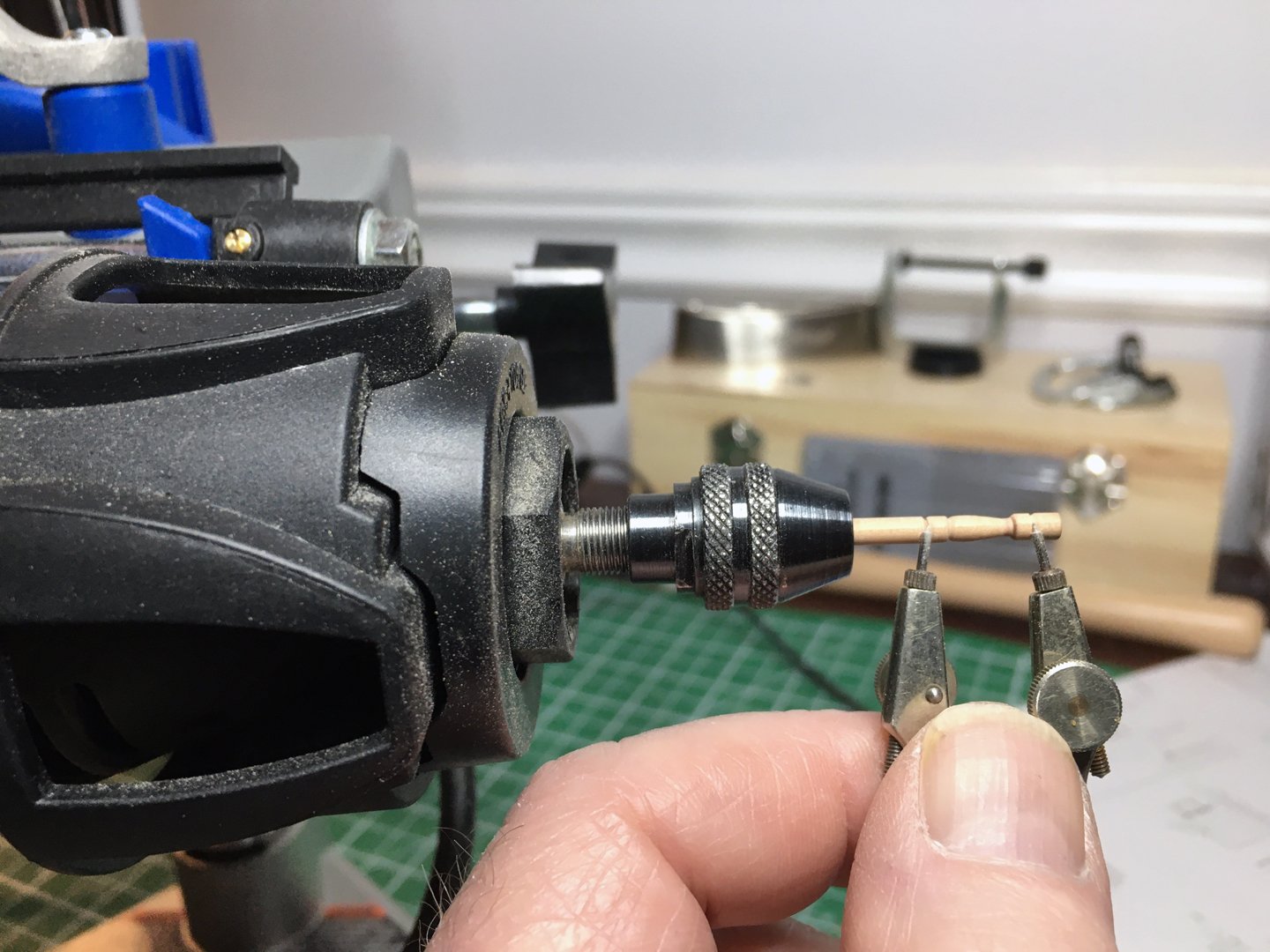

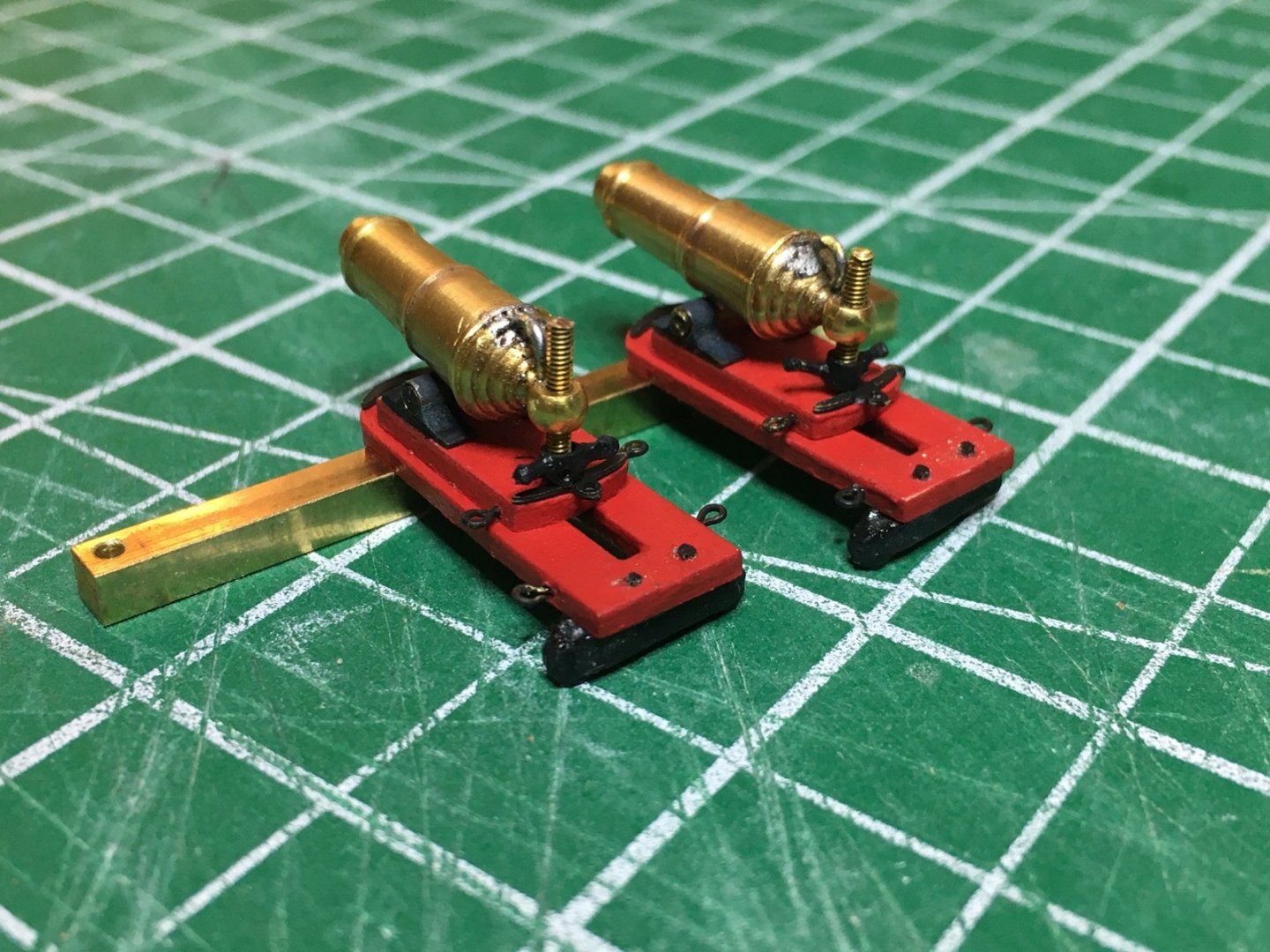

lol thank you my friend. Kinda flying by the seat of my pants here. Tinning the wire for the breach ring really helped with soldering and I managed to get them quite a bit smaller. The one from the first post is the 5th one in from the bow. I am starting a new wish list for a proper pliers set for metal work. The cheap ones I have don't cut it. Only 8 more to go!

-

Yea you gotta get creative with your clamping on the stern area. You need a C type clamp or something like this HERE which is what I used with a rubber eraser between the clamp and plank. The eraser conforms to the bend, protects and holds the wood firmly. When the time comes to start the first garboard plank off the keel rabbet, be sure and follow the instructions carefully and do not start it to far forward, or you will be in for a very hard planking job going forward. Take your time it will pay off

- 950 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

You are coming right along, I think the 5/32 plank was to be curved on the top edge to fit the curve on the port cover piece. Not sure tho as I did mine differently because I planked the transom.

- 950 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

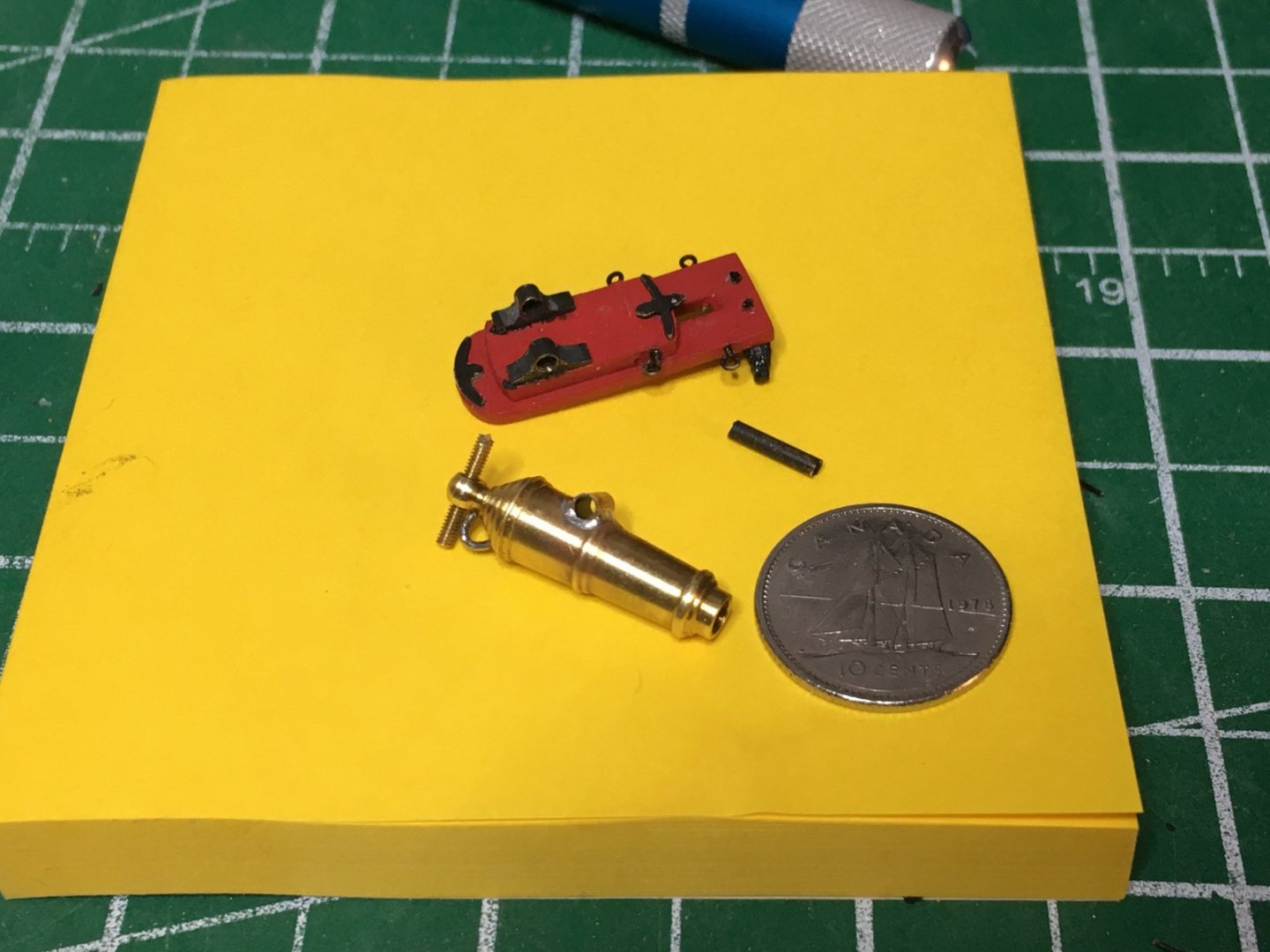

Thanks guys, trying to get the hang of it Here are a couple of pics with the breech ring added and the sleds detailed. Soldering the ring could be a little better. Hopefully practice will help lol. I went with a very thin slice of brass tubing, drilled and inserted wire to make the elevation screw handles. Does they look a little heavy maybe?

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.