-

Posts

7,417 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mirabell61

-

good progress Bob, superstructure and wheelhouse looks great... Nils

- 348 replies

-

- pequot

- cable ship

-

(and 1 more)

Tagged with:

-

Hi David, Mark and Greg for your nice comments, and all the "likes" for looking in... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Steve, it will be round about 80 vents in several different lengths and cowl diameters.... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Thanks very much David, Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

Mirabell61 replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

mounting the stand worked out well for you Nenad, it looks very nice, good job ! Nils- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Thank you very much Igor, Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Denis, thanks very much for your nice comment, there is some fiddely work to be done next, but the two forecastle vents are finished.... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

beautiful work Ed, love the way you did the rails and stair-rails, also the skylights and deckhouses look excellent ! Nils

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Danny, the cutaway on the pump tubes showing the p-chains is technical eyecandy , a good idea I like very much Nils

- 268 replies

-

Hi Greg, thank you so much for your appreciative words, I saw that you viewed the complete log to date and am happy that you had pleasure in doing so..... This is quite a challenging build as there are no detail plans available, so many ideas come to me as the sequences have their turn to be done. There will be lots of details to be planed, designed and arranged. relating to the intensive superstructure of this ship. If I have an idea up my sleeve, I have to do a trial straight away on it to a certain degree in order to get my mind working on it, even if its not the turn yet. (like with vents, lifeboats, etc....), and keep eyes open to implement any improvements. Wish you further much fun in viewing, stay tuned... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Steve and Piet, and all the "likes"....., and especialy my freind Greg, (the peg leg sailor), who, as I saw, took a real deep dive into the log with big interest.... thanks so much for all your kind appreciations Steve, here`s a better pic for recognizing the stud link chain.... thanks Piet, this is where a compromise is adequate for the real working stoppers, due to the small scale. The slide rails will get some light supports fitted underneath Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

very nice vintage tug Steve the wheelhouse also looks great Nils

- 208 replies

-

- john cudahy

- finished

-

(and 1 more)

Tagged with:

-

Thank you very much Pete, for your nice comment here is one of the two anchorchain slide channels, (inclusive the chain stopper), between capstan gypsy and anchor hawse tube..... I know that the actual stoppers looked different, but I had to make something more easy and workable on the model Nils stopper closed stopper free, chain can run out channel with blocked chain (closed stopper)

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

very nice progress Druxey, a clean and accurate build, a pleasure to see it grow.... Nils

- 641 replies

-

- greenwich hospital

- barge

-

(and 1 more)

Tagged with:

-

Welcome aboard Dan, and thanks for your comment. Although the Aluminium skin is very thin it also feels like metal when holding it in hands... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

thank you very much Albert, Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Update am now making the breakwaters. These have to be cut from two / four brass halves due to placing the railings on to early. Trust this is a good solution There where the parts penetrate the railings I put on some small metal reinforcements to the railing. The shapes of the breakwater halves are made from card templates. I hope to get the metal work on the forecastle deck done by end of this week. The stud-link chain parts are allready blackened and look good Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hi Kiwiron, artificial sea level, cutaway, and seperate disposal of crew, marine soldiers officers, storage and cargo, lovely details whoever built that model should win a prize for the idea, thanks for sharing that inspiring pic... Nils

-

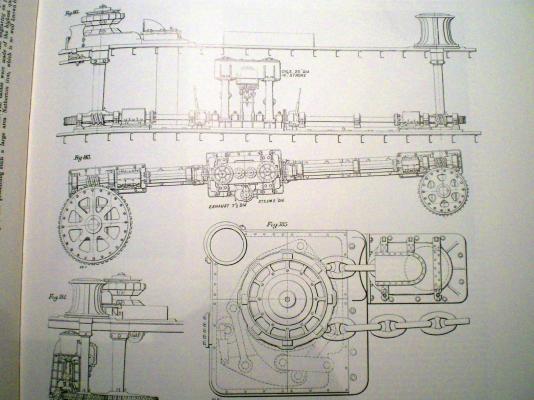

Hi Steve, your input on the winches is much appreciated, thanks very much. On the KWdG the steam driven winch machinery is situated beneath the forecastle deck, whereby the capstan drive rods with mounted gypsies and drums and stick up through the deck Enclosed an example of the anchor winch equipment on Cunard`s "Lusitania" (from Mark D. Warren`s book ) Nils stick

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hi Martin and Michael, and the "likes"... many thanks for your kind comments..... Martin, the solution with the breakwaters is under way Michael, it was of no use to use a dummy chain, today I received the actual stud-link chain and it did`nt fit the trial gypsy, so the gypsies had to be done over again. All OK now. It`s really amazing how the slightest variation in chain dimension fouls the fit. Also made a trial to chemical blacken the new brass chain. That worked out well at first try. NIls

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Kees, a beautiful made negative mould thanks for showing the procedure, very inspirative ! Nils

- 434 replies

-

- pelikaan

- beamtrawler

-

(and 2 more)

Tagged with:

-

Thank you very much Bob, Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.