-

Posts

7,418 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mirabell61

-

Hi Mike, that diagram with the sail sheet guidence Looks great, I wish you so much that it will work as planed... is there any slight "backpull" intended with rubber band or so, in order to Keep the Sheets from sagging and getting hooked up somewhere when going through the wind with the Stern ? Nils

-

thank you very much for your Kind comments B.E. and Mauro, and all the "like this" button appreciations... B.E., yes, I was already evaluating which side would be the best to display. The "open" side would allow a better view to the rigging (weather side), when the sails are sharply braced, (not done yet). The closed side would give more of her approaching view under full sails from the leeward side. Agree with you, that a display view from all sides would be best. Unfortunately have not found a suitable place in my home yet Mauro, thanks for your word, I`m glad you like it... Nils

-

Thats a beautiful ship Hamilton, I could`nt withstand in scratch-building it myself once, but had to give away the hull, because it was concipated for RC control and getting too large... Wish you much fun and success with the build Nils

-

Hi Denis, Thank you, glad you like it,.... I`m not familiar with HO scale metal siding, would be curious to see the result, provided you give it a try.. Nils I`m quite happy with the results so far cabin walls painted white working rooms under forecastle deck the rear side of the walls with hollow rivets and "glassing ends" sticking out will be hidden under the deck afterwards

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Good work Patrick, masting, rigging and sail Fitting Looks great. Is that black bead thread organic fibre, metal fibre, or Polyester or so ? Nils

-

HMS Alert 1777 by Jaekon Lee - 1/64

Mirabell61 replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

Wunderbar Lee ! Nils -

Hi Bob, I just looked up you "Hoga" build log, and yes, the deckhouse (your post #101 there) and wheelhouse would have been wonderful candidates for "riveted" metal Skin structure. Maybe you are planing an appropriate Oldtimer steamship Project for the future..... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

HMS Alert 1777 by Jaekon Lee - 1/64

Mirabell61 replied to Jaekon Lee's topic in - Build logs for subjects built 1751 - 1800

very neat metal work Lee, Nils -

thank you Bob, I highly appreciate your kind comment. With this build many things are developing as their sequences are due. But still now and then there are things to keep in mind for improvement along the journey... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hi Bob, and thank you for your comment. I have to groove myself in a bit to finalize this "Swan Class" without interruptions by things going round in my head for the new ongoing project (KWdG) Nils

-

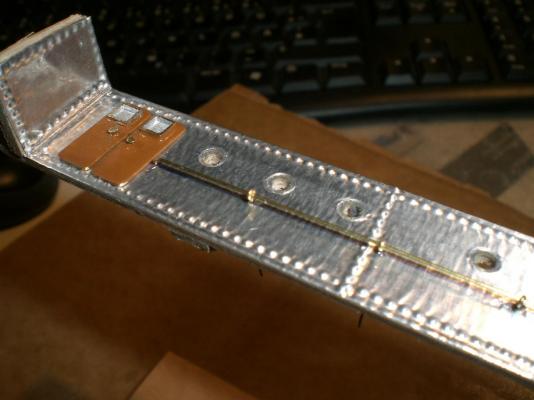

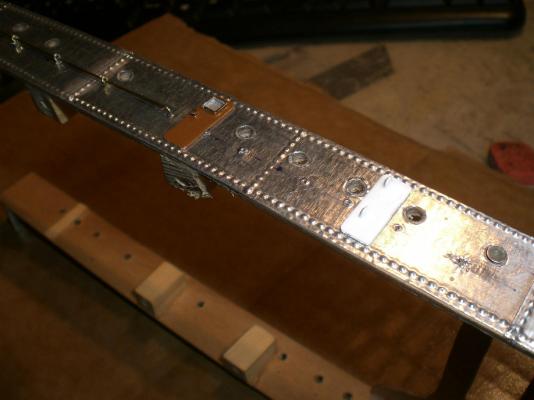

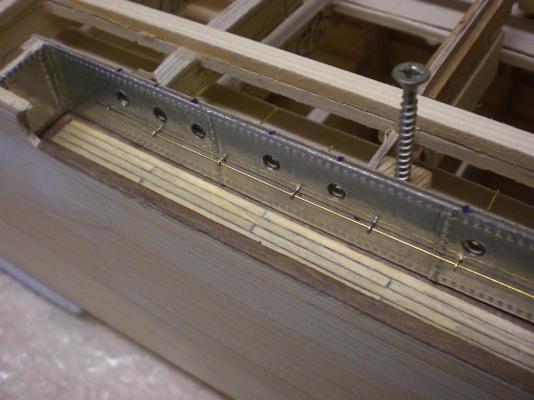

a Little update... Build log part 17 the first Saloon and cabin wall section I start with is in the aft waist area, one deck lower. This has to be done now because the Long Promenade deck (when put on) will not allow Access to this part afterwards. The metal sections of the superstructure will also be plated. The procedure is to produce a smooth wooden surface, and plate with ponced resembled "riveted" metal surface. Then cut free the positions in the foil where the port holes are to be drilled. Dry fit the brass handrails, then take off the handrails, primer the cabin walls, paint the surface, let dry, and then insert the "preglassed" portholes and the handrails again. Secure the handrail stanchions at the inner side of the walls with a drop of CA Nils a clean circular cut through the foil and a good centering in the wood enables the hole drilling in best possible way this part takes 30 portholes and six doors here the first handrail piece is dry-fitted this is a liquid quick drying filler / primer that gives a wonderful surface to the white dull silk finish paint (a Gunze / Sangyo, Japanese product) this is the bulkhead for the step to the poopdeck, primered and painted dry fit on the ship..... four srews will later help hold this section securely in place

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Carl and Patrick, thanks for you appreciative comments which are well appreciated.... Nils

-

Thank you very much Boyd, I`m about to finalize My "Pegasus" soon, There`s not much go any more. The intension is to do it when the follower model "KWdG" hull, which is well on the way, has been plated...... Nils Here the present status of "HMS Pegasus" : made a new, and larger white ensign on cloth of an old fine-structured handkerchief by ink printing / ironing methode, when complete all square sails shall be braced to appr appr. 45° angle. The main courses sheets and tack-lines as well as the bow-lines still need to be rigged. Also the spare spars resting on the gallows still have to be made, whereby the ships boat is already finished for mounting. Half of the anchors are done. Maybe also a securing rudder chain will be fitted

-

Hi Boyd, thanks for your nice words today, glad you liked and enjoyed the log-tour Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hello Paul, Thanks for your tip, seems to be a very interesting book, (resp. six books) I`ll be having eyes open for that publication Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hello Johann, what a peculiar animated appraisal, Thank you, I like it very much... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

-

Hi Paul, would have liked to see one of the "Emperator Class" liners keel-layed by someone here on this forum; The "Vaterland" for instance, being the first American super liner after taking over and re-naming to "Leviathan", a dream of a ship.... Nils

- 2,625 replies

-

- kaiser wilhelm der grosse

- passenger steamer

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.