-

Posts

7,407 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Mirabell61

-

Bob you shall make me very happy if you go on pleasing your mind (thought), and very welcome to the stoker gang, who really knows in our days of gas turbine and atomic operated ship powerplants, what a stephenson reverse device is Cheers Nils

- 113 replies

-

- heinrich kayser

- steamship

-

(and 1 more)

Tagged with:

-

Hi, trust you are reflecting to the outlet (suction mode) vents... well, the longer vertical tube is cut to fit soldering a small short cross-tube on top, an then for the parts of the intake side and for the discharge side I cut these off the Ends of small steel-brassplated mini Christmas Jingle bells In case you mean the spheric bowl typ, this is shown earlier in part 4 of my build log Hope this serves your question Nils

- 113 replies

-

- heinrich kayser

- steamship

-

(and 1 more)

Tagged with:

-

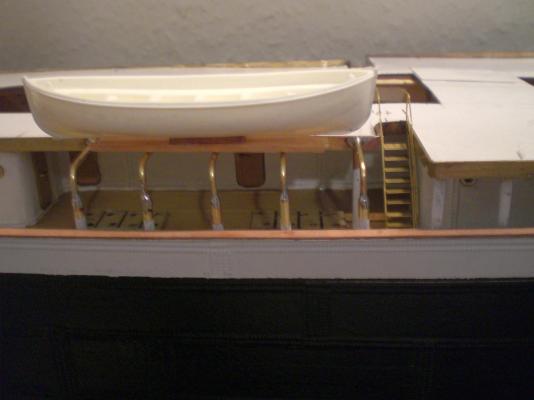

Build log part 11 be invited for a walk on the boatsdeck and on the poop working deck flag tabernakel and grating on the upper bridge lifejacket Containment on the Forward portside boatsdeck Fitting of load beams Fitting beams to mast bearings (sorry for pic Quality) Tackling davit checking Position of Davit-block to boat upper Bridge Cage completed build log part 12 to follow....

- 113 replies

-

- heinrich kayser

- steamship

-

(and 1 more)

Tagged with:

-

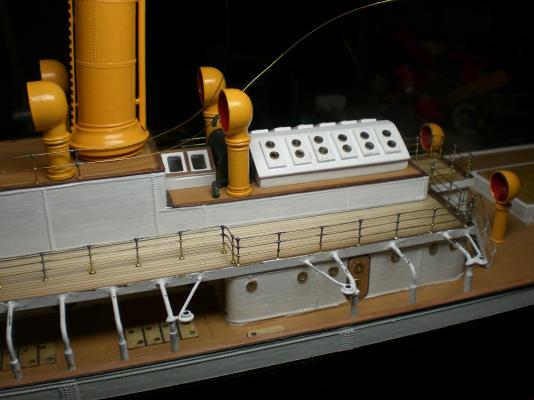

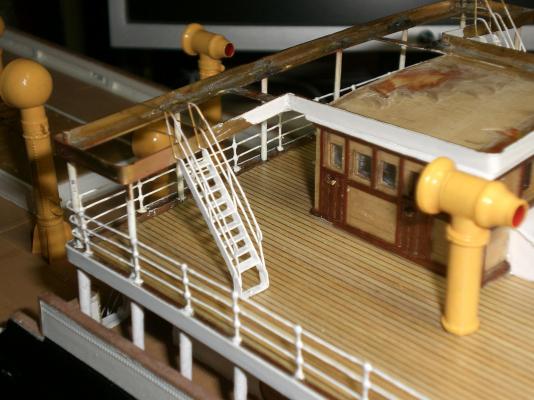

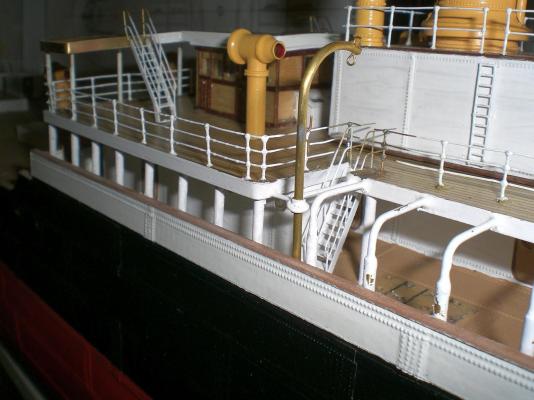

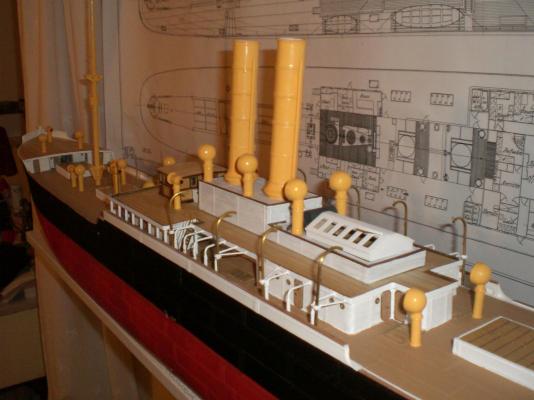

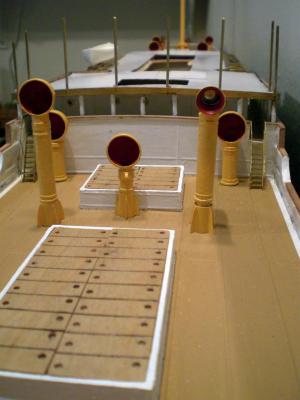

Building log part 10 machine well Skylights done, railings on boatsdeck and started on funneldeck forecastle railing fixed this and next Picture railings fixed railings, pillars for boatsdeck and upper Bridge stachions painted white stairs to upper Bridge fitted and all stairs painted upper Bridge rim completed prefitting for davits outer Bridge rim White (except for soldering area of stair) attaching middle wires of stairs to boatsdeck and railing Build log part 11 to follow.....

- 113 replies

-

- heinrich kayser

- steamship

-

(and 1 more)

Tagged with:

-

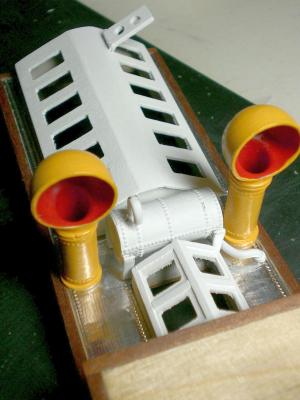

Build log part 9 different size vents machine room skylights ongoing Fitting out cross check with plan starting to look like the Heinrich Kayser copper Fittings from the crafters used for Basic funnel construction, have to do some cutting though angle of funnels match mast angle Building log part 10 to follow

- 113 replies

-

- heinrich kayser

- steamship

-

(and 1 more)

Tagged with:

-

Bob you are right, I feel the same, and have therefore gathered quite some experience in soldering (solderable metals) with either small gastourch or with soldering iron Nils

- 113 replies

-

- heinrich kayser

- steamship

-

(and 1 more)

Tagged with:

-

Crackers, that idea is not completely out of this world, because I`m running out of space in my Hobby Office right now, I am 66 years old and I hope that they might find an honorable anchoring place in my childrens homes one day. Right now I have 2 steamships, two Tallships, and the uncompleted scratchbuilt 18th century Pegasus in Progress. Besides that you might know or have experienced yourself, that the modelers fingers start itching when one gets mind-pregnant with the next "Project", at least the ideas Keep on sparkling... It is since I had retired from my work that I again have time to go after this Hobby. Cheers Nils

- 113 replies

-

- heinrich kayser

- steamship

-

(and 1 more)

Tagged with:

-

Danny I`m absolutely with Adam... As you probably recognized, I`m taking a Little pause on my own P.Sue build, but seeing your fabulous work in process really encourages me....to get further going on it again Nils

-

Hi S. Coleman, Tom and Daniel, thank you for your appreciative words, I`m preparing to post Log parts 9 + 10 tomorrow morning, stay tuned Nils

- 113 replies

-

- heinrich kayser

- steamship

-

(and 1 more)

Tagged with:

-

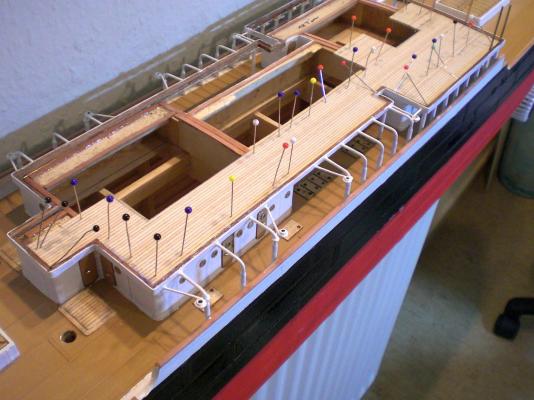

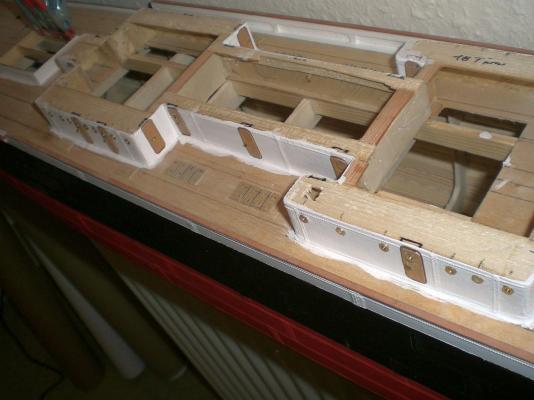

Build log part 8 template topview for boatdeck checking Position of midship stairs down to Forward working deck deckhouse stairs to boatstations aftstair from boatdeck to working poopdeck view backwards at this building stage wooden planking of boatsdeck, here also the bearing Support-sleeves for taking up the Davits already mounted main wheelhouse, Navigation room and officers duty station freshwater storage tank with vent on top Build log part 9 to follow....

- 113 replies

-

- heinrich kayser

- steamship

-

(and 1 more)

Tagged with:

-

well done Bob ! beautiful work, a pleasure to look at Nils

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

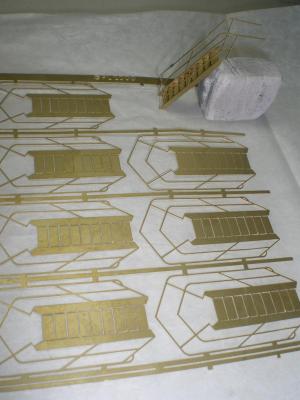

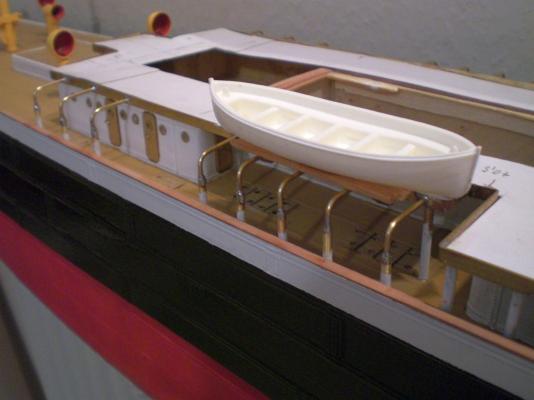

Build log part 7 ship is now tugged out alongside the Fitting out quay of the yard etched brass stairs check, fit to scale approved OK brass rim fitted to lower deckhousing, all around the boatsdeck self explaining in opposite to the workdecks the forecastle deck is Wood planked the soldering Task gets a Little tricky here (too much heat in one place loostens the already tight neighbour ones again) checking with plan, space requirements for boats, Davits and boat Access platforms cardboard template for complete boat deck base stanchions for upper Bridge fixed and soldered note the workdecks are painted tan, "earthbrown" self explaining... Build log part 8 to follow....

- 113 replies

-

- heinrich kayser

- steamship

-

(and 1 more)

Tagged with:

-

Build log part 6 hold rim with removable hatchcovers raw Forward mast crows nest, the Access ladder from deck not fixed yet take up Points for swivel loadbeams after some paint touchups ... plymsol marking at waterline marking of Name and Registration port These 3 pics..., quite pleased with the results so far Build log part 7 to follow

- 113 replies

-

- heinrich kayser

- steamship

-

(and 1 more)

Tagged with:

-

Hi Guy, the toothwheel Comes from an old mantelclock-clockwork, obtained from a fleamarket, and so providing many individual brass toothwheels with different toothsizes. thin wheels for single row riveting broader ones for Multi row riveting, etc... From twinrow on upwards the toothbreadth would Need to be reduced by binging circular groves in like the Picture Shows. Provided you own a Hobby lathe and appropriate cutting chissels, no Problem..., if not, span the wheel on a Center fixed screw span into your Drilling machine and tangentially (sturdy Hand!!) bring cutting side tooth-direction of your metalblade small handsaw into Operation, with running Drilling machine. Some Trials should be done with scrap- wheels before, to get the Feeling. The saw toothdirection must be in the "pushing mode" as if it were a chissel. Remove grit care fully and brush over with brass-brush, to slight break the sharp edges carefully. Hope this is of help... Cheers Nils

- 113 replies

-

- heinrich kayser

- steamship

-

(and 1 more)

Tagged with:

-

Thank Thank you Bindy for you nice words It all was due to the nowdays possibilities via web for doing all this Research, for instance in gathering all available to myself historic US newspaper clippings, state archives, etc... Nils

- 113 replies

-

- heinrich kayser

- steamship

-

(and 1 more)

Tagged with:

-

Hi Creackers, this I have also asked myself many times, but it is also fact that from radiocalls received, the stearing rudderchain had broken in a full gale, making the vessel unmanouverable and probably immediately going square to the huge waves the hull rolling heavily, and fact is that the hatchcovers had been destroyed, this causing the uncontrolled take of water, until the ships superstructures could not withstand the stresses anymore. She may have sunk or suddely have broken through. We shall never really know what hapened in the last minutes Nils

- 113 replies

-

- heinrich kayser

- steamship

-

(and 1 more)

Tagged with:

-

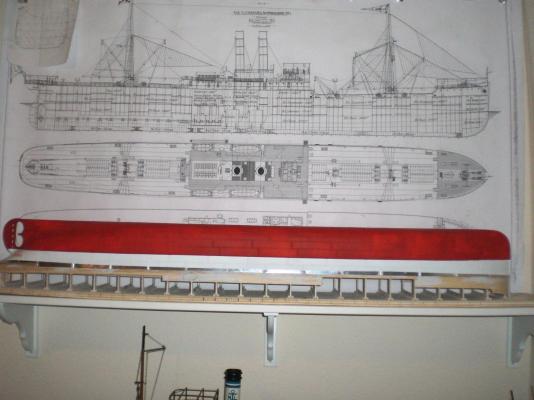

Richard thanks for your word. Regarding to the plan I received it upon Special request from the birth shipyard (which does not actually sell plans of their builds), but I told about my personal relation to the ship because of a Research of the fate of itt foundering and the fate of my grandfather. Nils

- 113 replies

-

- heinrich kayser

- steamship

-

(and 1 more)

Tagged with:

-

Bob, thank you, I`m glad you like it there is more to come soon Nils

- 113 replies

-

- heinrich kayser

- steamship

-

(and 1 more)

Tagged with:

-

Build log part 5 for making the stand Posts I use brass candle holders (found on flee-markets) the anchorchain port reinforcements are fitted begin... rivited structure to deckhouses and hatch rims further Fitting out midship deckhouses, on deck inbetween the coal bunker hatchcovers forecastle compartments so far well under way... workdecks ready for priming, painting the figures are scale 1:100 the portside depth indications are in Roman figures Build log part 6 to follow....

- 113 replies

-

- heinrich kayser

- steamship

-

(and 1 more)

Tagged with:

-

Build log part 4 characteristic for These old steamships are the large vents, necessary more than ever when going through hot,tropical zones of calm sea... Here is to give my Version of the vent Hood making..., and the main masts, and crows nest sizes and types of vents an Arrangement of inlet and outlet vents prefit check with the decks application of primer after soldering and cleaning the brass surfaces was quite a bunch of individual parts inner Hood surfaces have their own color as well as the outside surfaces Forward and aft mast do not throw away your old dome-nuts, they serve for exellent venthoods especially those where the dome Shell is made and brased on of thin pressed sheet Build log part 5 to follow.....

- 113 replies

-

- heinrich kayser

- steamship

-

(and 1 more)

Tagged with:

-

Hello Max, what a cute member Icon you have, gives me a smile on monday morning. Thanks for your words, and enjoy the further parts of the Heinrich Kayser build log Nils

- 113 replies

-

- heinrich kayser

- steamship

-

(and 1 more)

Tagged with:

-

Building log part 3 brought on White primer coating and Sub waterline red the last Picture where the hull is still fixed to the baseplate. The upper hull portions shall be plated and painted when the decks have been permanently mounted hull seperated from baseplate, all went well, no Twist, no destortions extreme lightweight hull, prop- and ruddershaft already mounted, superstructure for deck Support can be seen riged structure in forecastle area decks made from 1,5 mm thick 4-layer Aeroplywood the Forward maindeck, 3 hatches, and the quite Long poopdeck, 2 hatches,(working decks) are going to be metal plated. These decks were of steel plating due to rough cargo handlingand overcoming heavy seas. The cardboard template behind hatch #4 Shows the riviting pattern for deck plating hatch # 1 behind the forecastle bulkhead bow section before finalizing the decks and the final plating raw workdecks mounted, midship deckhouses started, hull painting done and forecastle bulleyes mounted. It`s now slowly looking like a ship should be... Build log part 4 to follow.....

- 113 replies

-

- heinrich kayser

- steamship

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.