-

Posts

1,232 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Kevin-the-lubber

-

Bill, did you solder them? I know this sounds mad but years ago, when I still smoked (silly man) I was given a lighter than is like a mini-blowtorch, which is just right for this kind of thing!

-

3d printing process

Kevin-the-lubber replied to henrythestaffy's topic in 3D-Printing and Laser-Cutting.

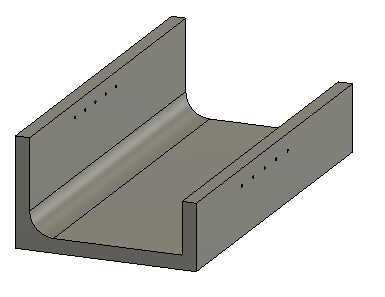

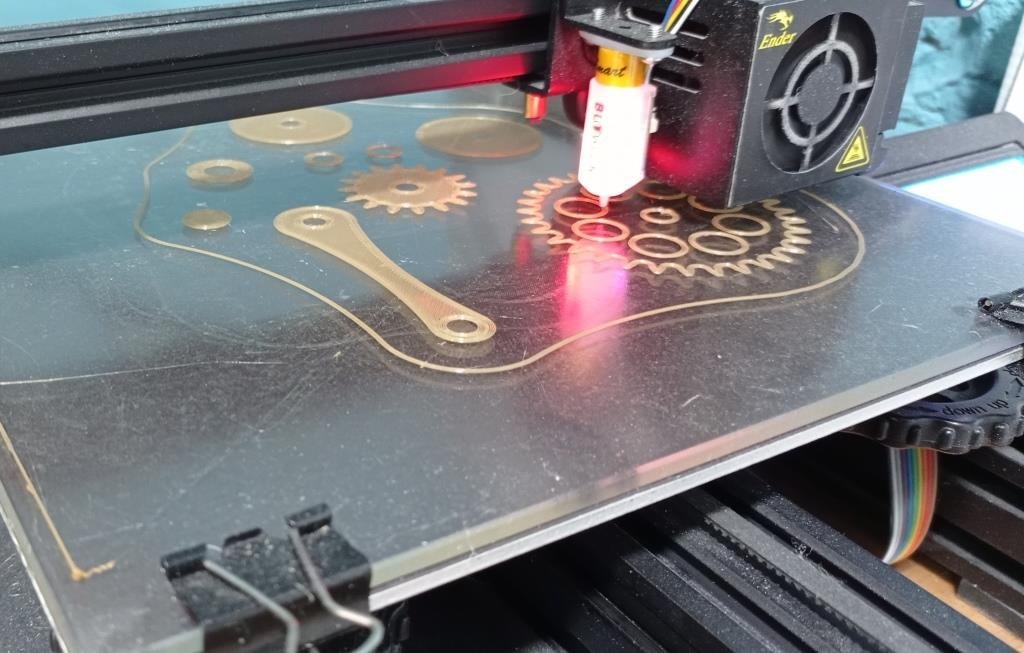

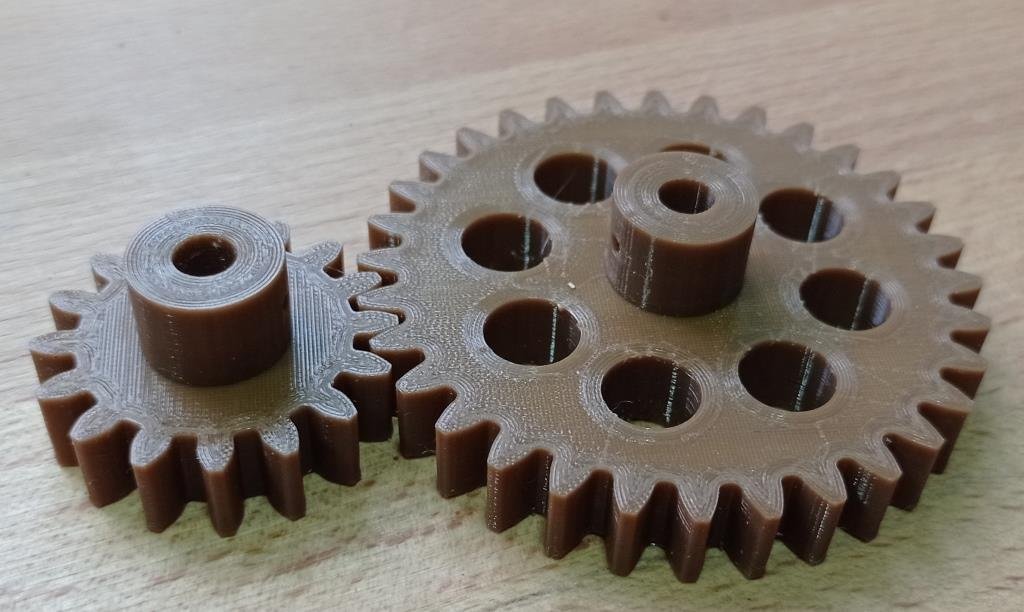

Thanks Ron, Paul. I should have found some other examples but this was all I had to hand; this outcome happens to some degree or other on all kinds of larger pieces regardless whether it’s tilted and even with a dense array of heavy supports. A little while ago I was printing what in effect is a simple box with no lid or bottom, about 8cm x 5cm, with a 2mm wall thickness. Whether angled or flat, it would warp during the print. Yet I can load up the plate with loads of individual smaller objects and have no problems. Equally, I’ve printed some large-ish delicate things using only thin supports and been fine. It’s perplexing. For the object in the photo I did indeed print it edge on in the end, this is fine when that’s an option but sometimes the orientation options are limited. -

3d printing process

Kevin-the-lubber replied to henrythestaffy's topic in 3D-Printing and Laser-Cutting.

Hi Ron, you mentioned you've found some good forums for resin printing - would you mind sharing the links please. I've found it quite difficult to find anything outside of facebook, which I simply won't use, and have a recurrent problem that I'm struggling to fathom. I doubt it's unique and some of the old hands will most likely point me in the right direction. In case you're interested, it's this; This is supposed to look like this; As you can see, the bottom gets ripped off the (heavy duty) supports and warps into a curve. This is not a particularly large piece and, although in this instance I've printed flat, the same kind of thing happens on anything large where I need a straight edge. It can't be a question of just adding more support, if there was any more it'd be ridiculous. Something similar happens if I print it straight onto the plate, you can see striation where the layers are being pulled apart. I think it may be something like the FEP isn't sufficiently tensioned, or that the settings need adjusting, but I'm always a bit fearful of playing with these too much in case I tear the FEP etc. On the larger printers this gets expensive! nb - I do wish that test was available for elegoo printers, but unfortunately it's not. There are plenty of generic test pieces out there but none that, like this, change the printer settings during the print so you can just do one test. -

Bruma, can I take you way back to post #5, where you drilled the deadeye holes in line with Campbell's plan. Did you look at whether these new positions might cause any fouling, especially those for the mizzen? I'm asking because this evening I'm fine tuning my replacement bulwark rails and there is a significant difference between the spacings and positions of the deadeyes between revell and campbell. I'd much rather use campbell as this gives more space for the belay pins but I'm nervous that by moving the deadeyes aft, the mizzen backstays might foul the quarterdeck pinrails or cabin rail. I imagine this is unlikely but thought it worth asking.

- 399 replies

-

- cutty sark

- revell

-

(and 2 more)

Tagged with:

-

Which book are these in, or site? Although I do find the campbell plans a tad sketchy (literally), in his defence he seems to have published a fair bit on clippers, leastways I have his book 'China Tea Clippers' which goes much wider than the Cutty Sark.

- 481 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

And I'll happily be Mr man-in-the-middle. Clearly the boss (he gets to sit down), and you wouldn't want to meet him in a dark alley :-). Though in reality I'm probably more that chap lurking in the background. It's a fantastic photo though, isnt it.

- 481 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

I read, in either Hackney or Campbell, that there were iron plates on the deck for the chain. Likewise, that the fore hatch was much smaller. I also read that when first built, there was only one deck cabin, the second was added a couple of years later, though Hackney didn’t mention which one.

- 481 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

Shipman - now there’s a thought. But one I’d only turn to as a last resort. As a variant on that theme, it’s quite easy to model and print rope I.e. to remake the revell parts but better, but I know I’ll get far more satisfaction from doing it for real. Rob, wise words. I don’t want to get bogged down and, a bit like bcochran, wil be happy enough if the end result looks reasonably “shippy” and not too much like some plastic moulded toy. bcochran, you and me both. But I have a feeling that between the three of us, including Bruma, we’re going to learn a lot more about rigging by the time we finish. I also really struggle with the very fine detail and small parts. These hands were made for building full size ships, not miniatures. I think the revell blocks have ring bolts don’t they, and I’ll probably do the same, just pretty them up by serving the ropes. Ian, I think that’s the nail being hit on the head. At this point my reference is the kit parts. Once I’ve done the reading on them, I start to see what’s missing and whether I want to remake that part. This has been fairly easy so far as the ‘body’ is relatively simple, but nevertheless I’m figuring out some stuff, like the deck height, too late in the day.

- 444 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

Rob, I meant wool. Not that I’m at all pinning her to any particular era, just wanted something in the hold. At one point I thought of tractors, but when I started googling I got in trouble with my other half. (Sorry, highly contemporary Brit joke). I tried tea chests but unless you scatter them they just look like a square block, whereas the wool bales at least have a bit of shape. Thanks for explaining spreaders, the cross trees etc on this model are still a mystery to me, but I guess it’ll all fall into place once I start looking at it properly. Ditto going out of scale on the deadeyes. 2mm really is a bit too small, I think I’ll bump these up to 3mm and the 3mm to 4mm and see how it looks. I think there’s a link here with the discussion over on your Glory build about perspective distortion, that the viewer has a certain expectation. In my case, when I look at properly scaled deadeyes they simply look too small, they lack the presence of those on the real ship.

- 444 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

Hi Ian. You've given me some homework (which is fine) - spreaders... I think I'll probably need to assemble the masts in order to understand the rigging points, so that I can then understand if and where the kit parts are wrong; and accept that if I make a complete pigs ear of the masts I'll have to remake them (but not printed, that's not good for these).

- 444 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

This is the deck being too high. The hull itself seems fairly true to scale but this one strange decision imparts on many things, from the hencoops to the windlass. If I was starting over (and there are still moments where I eye up the spare kit) I'd almost certainly lower the deck, but I guess one could also reduce the height of the cabins. But I think anything other than lowering the deck and you'd be chasing your tail. Well done getting the pinrails in, and the fore and stern rails. I have quite bad warping on these kit parts which is what tipped the decision to remake them.

- 481 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

I read, probably in Campbell, that the first deadeye should be dead in line with the relevant mast. Is this critical? Now's the time for me to tweak it. I took the positions off campbells drawings and currently they look just slightly aft of the masts. Logic also tells me that the deadeyes would be equally spaced across their group, is that correct? Just how critical are the positions of the deadeyes in the grand scheme of things. I sense the answer is 'not very, within reason'. I'm at the stage of printing the replacement rails for real, so at this point I'd want to finesse the positions of the deadeyes and belay pins. As you can see, I'm incorporating the 'lozenges' by having very thin sliver of a 'cover' that glues to the inner bulwarks. The ribs in between the lozenges hopefully give a bit of added strength but in any case, having the deadeye stanchions glued down at the waterway should mean there's no real strain on the pinrails. bcochran, we're on the same journey and I'll be watching your log as much as my own. I started reading the Hackney book last night, not a bad place to start because, until the simple terms start to mean something I final the likes of longridge far too heavy going. Rob, these lower deadeyes are going to be very challenging to reeve, especially the little 2mm one's. Probably a little easier if the thread slips easily through the eyes, on my practice piece I needed to use a sewing needle threader, but I don't think that'll be possible with them in situ. (Note the cotton bales in the main hold. I wish I hadn't glued them in now, seemed like a good idea at the time as I felt my lack of progress was all about just glueing some stuff in place, but I subsequently changed my mind about what I wanted it to look like. Too late now, it'd take more than acetone to get them out, so I'll just live with it.

- 444 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

Thanks Rob, that's helpful. It means doing the masts and tops first, as the shrouds determine the heights of the upper deadeyes, but I can see that this is a good method. Scratches head... so where do I go from here... start making a serving machine of course.

- 444 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

simple is good. I'll give that a try as well.

- 444 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

That's the thing with such a great forum - it's all in here, you just have to find it. The search function is pretty good though, I've used that to good effect a few times.

- 444 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

That is pure quality. I would think twice about painting these, they are stunning as they stand. And you made all these by hand?

- 399 replies

-

- cutty sark

- revell

-

(and 2 more)

Tagged with:

-

That's a good suggestion, thanks. I'm kind of hoping that someone, after they've stopped rolling around at the floor with laughter, is going to show me a simple way that everyone else uses.

- 444 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

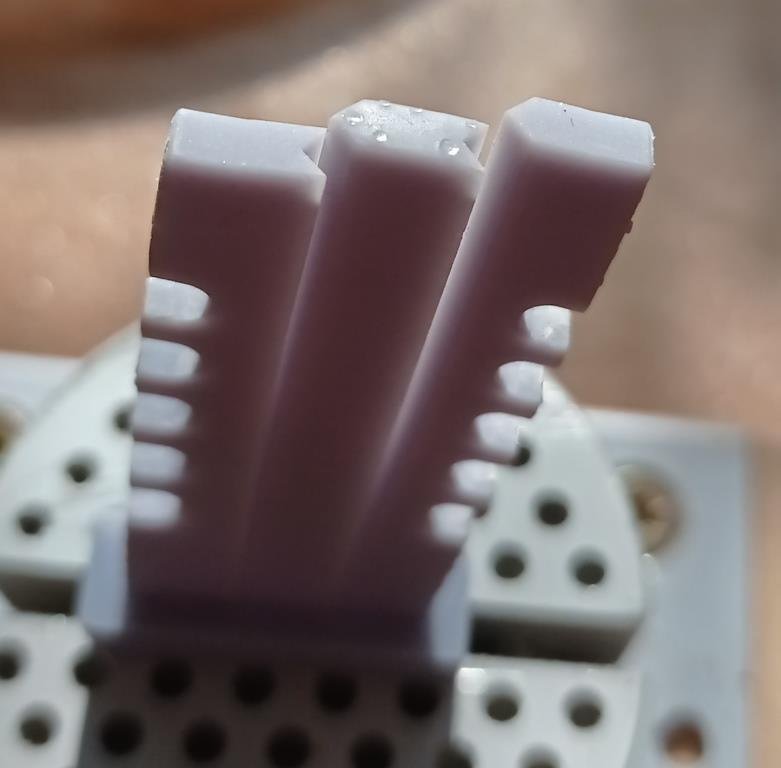

Some quick pics of the jig I made for reefing the deadeyes (if that's the correct term). It is basically three bars of plastic with recesses for the deadeyes at the correct spacings vertically and horizontally on the outer two. It uses Vee shapes to align the bars. When finished reeving you'd slide out the centre bar and extract the deadeye assemblies. The bars are held together by a socket thing at each end, one of which can go in a vice. It works okay but I had to thread the deadeyes first as they otherwise fall out of the jig. V2 will probably have clamping bars to hold them in place, but the third hand may work better and just use this to get them all levelled. You can see how I trashed the paintwork doing this. And also how abs-like resin starts to distort after a day or so.

- 444 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

I did wonder if it was someone on here 🙄. I already have the one for Victory so will probably just sell on the spare and the Mayflower as I doubt I'll ever look at that.

- 444 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

I’ll post my version 1 jig this evening after work (how I envy you retirees), it’s along the same lines as yours. On my first ever attempt this weekend, reeving the lanyards was quite easy, using a needle threader, it was stropping to a shroud that I found hard, as the deadeye has to be correctly orientated to the shrouds centreline. I’m sure people can tell us easier ways but for now I’m thinking of making a little tight fitting toggle to snug up the shroud on the deadeye while I wrap thread around it. I realised too that I’ll need a serving machine straight away whereas I’d thought that would still be months away. And that I’d better get a handle on the terminology as it’s like a foreign language at the moment.

- 481 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

I think you’ll be fine with any resin at this size, but personally, for this I’d use syratech fast, because it doesn’t seem to warp over time. I’m sure there will be plenty of other resins equally suitable that I haven’t yet tried, so don’t take that too literally.

- 444 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

Ps. I got a copy of Hackney on eBay today, all three in the series actually; Cutty Sark, Victory, Mayflower. Published by Haynes, presumably of Haynes Manuals fame. Boy does that bring back memories, of buying motorbikes and cars where having the Haynes manual thrown in would seal the deal. And needing them too.

- 444 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

I can’t remember the scale of your galley but if the oar shafts are anywhere above about 2mm diameter I think even syratech fast would be plenty strong enough. This is what I’ve used for the final catheads, where the whiskers are only 1mm. They make a much stronger ‘industrial grade’ resin called syratech blue, pricey though. I haven’t tried that yet. In some ways resin is a little like glass or carbon fibre; incredibly strong until it pops. I don’t think ABS-like would be the way to go for oars, you want them to be pretty rigid. Re’ the sails, yes, probably a series of fairly shallow arcs, with the canvas quite bunched up. Another way of looking at it is that I want sails but don’t want them spread, in part to avoid running rigging but mostly because it blocks the view.

- 444 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

I’m glad you mentioned that. There are 2mm deadeyes on the pinrails and this is as small as I’ll go. So what I probably need to do now is work out the sizing using 2mm at the top and scale to suit working down. The real ship had loads of different sizes but it’s not realistic for me to try to replicate that.

- 444 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

-

The third hand is a very good idea. I spent ages doing one pair last night using a jig I made, when the third hand would have been better. I’ll have to find mine.

- 481 replies

-

- Cutty Sark

- Revell

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.