-

Posts

1,568 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by John Ruy

-

Glad to see you back at it, Bob… She’s looking good, onwards one line at a time. 🍻 So much to do and so little time left. LOL 😂 I hear you… Don’t let those Rats get in your rat lines. John

-

Soldering Success.... Finally!

John Ruy replied to GGibson's topic in Metal Work, Soldering and Metal Fittings

Congratulations 👏 Soldering requires lots of practice as well as technique and the right equipment. Can’t wait to see your success displayed on your bluenose. I’m sure we all struggle to get it right and continue relearning as we go. I know I do… 😆 John -

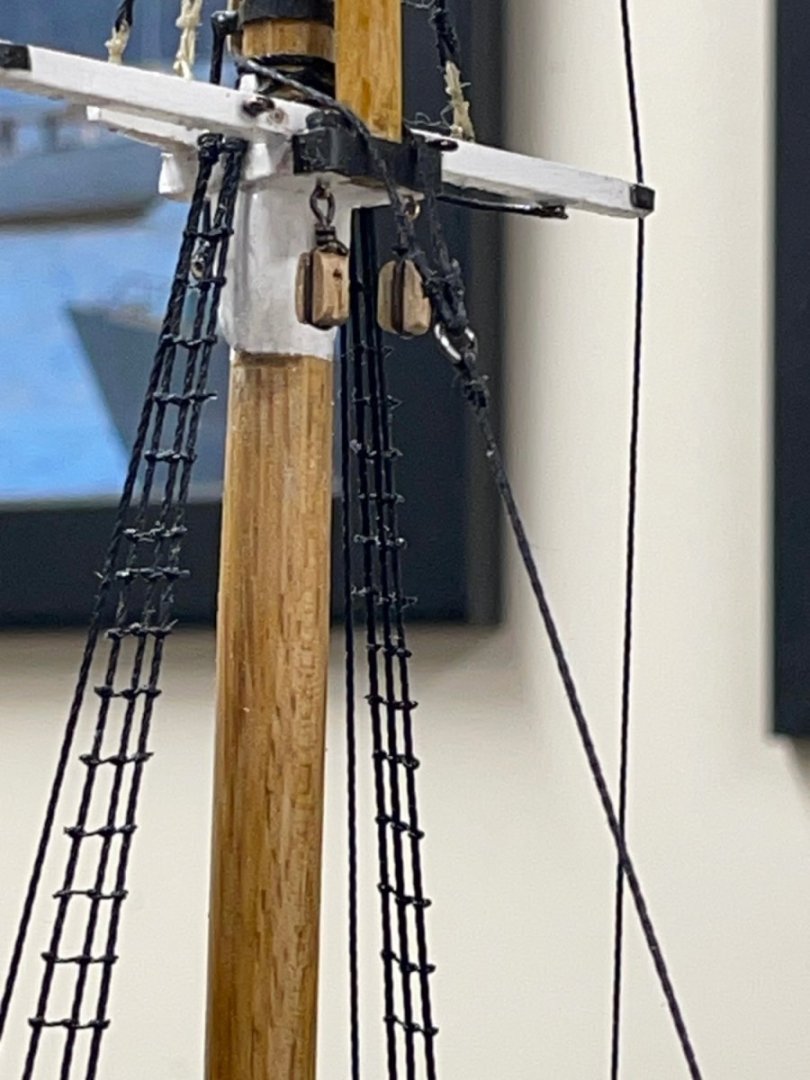

Bow Sprit… Guys and Back Ropes… Foot Ropes… Stirrups… Job Stops… Bow Sprit Rigged, now on to Jib Stays. Onwards 🍻

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

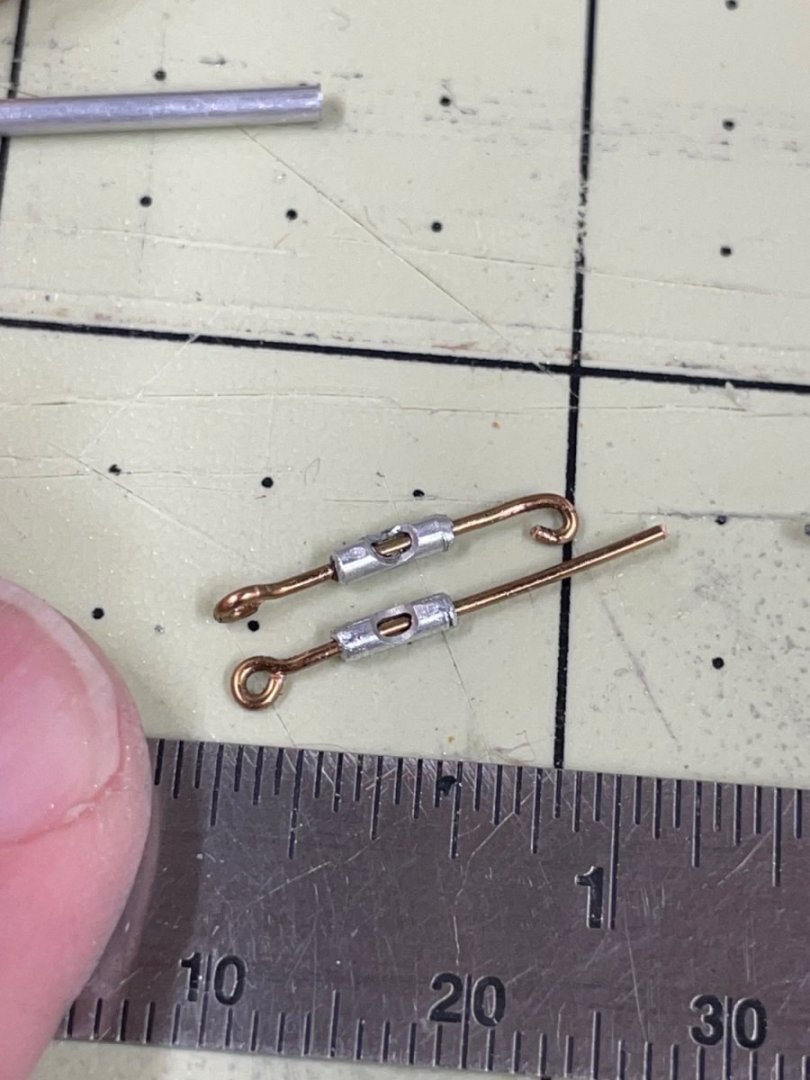

Thanks again Greg, I did the same, looks like 6 total all on the Bow Sprit rigging. I also looked up Galvanizing, invented in the late 1800s, so I’m pretty sure the turnbuckles would be galvanized to deter rusting. I’ll dab a bit of aluminum paint on the copper eyelets and I’ll be all set. I probably need to paint all of the belaying pins as well. 😆

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

Yep… I believe the 1921 Bluenose would have had galvanized steel. At 1/16” OD it might be a bit over scale, but I think it looks good. I’ll have to search out the detail to find out how many more I will need to make up. John

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

Thanks…. Should they be painted black or aluminum to represent Galvanized Steel?

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

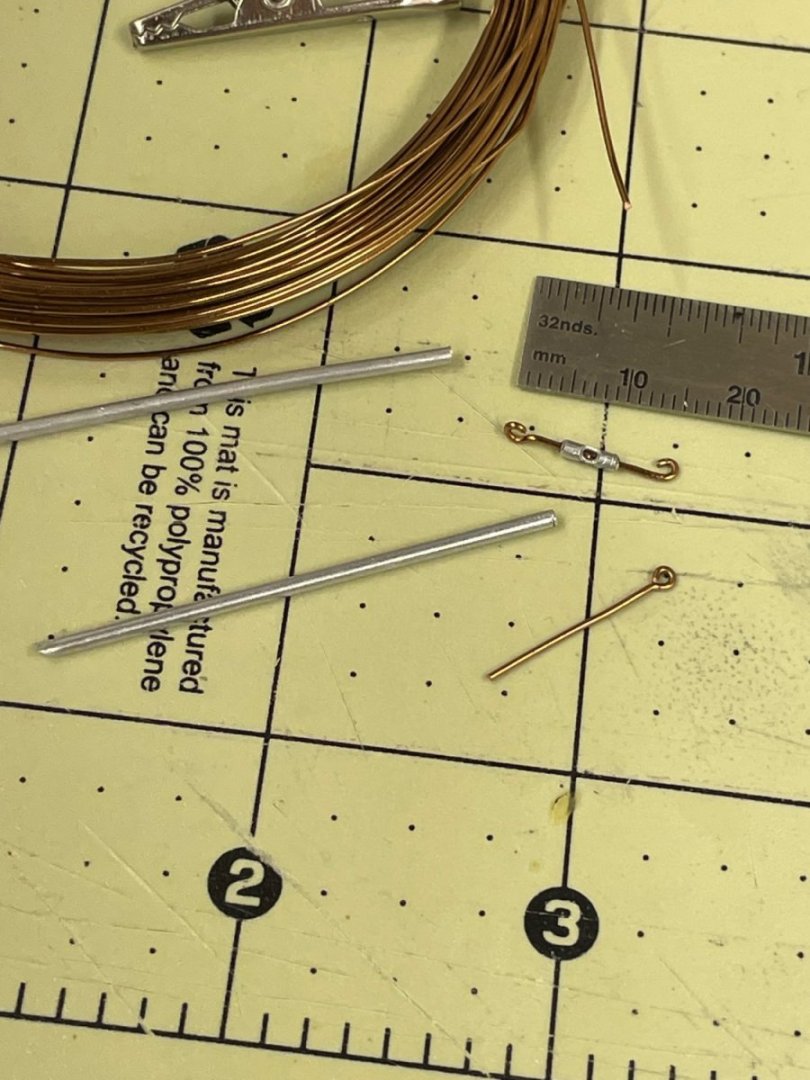

Turnbuckles… I used 1/16” OD Aluminum tubing and copper wire to build dummy turnbuckles. There is no mention of turnbuckles in the instructions. I wanted to try to add this detail and tried to get them small enough to be of proper scale. 😆 Used needle file to cut both sides of tubing. Used Copper wire to fit through the tubing. Turnbuckle body is held in place with a touch of CA glue. Bobstays placed Cheers 🍻

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

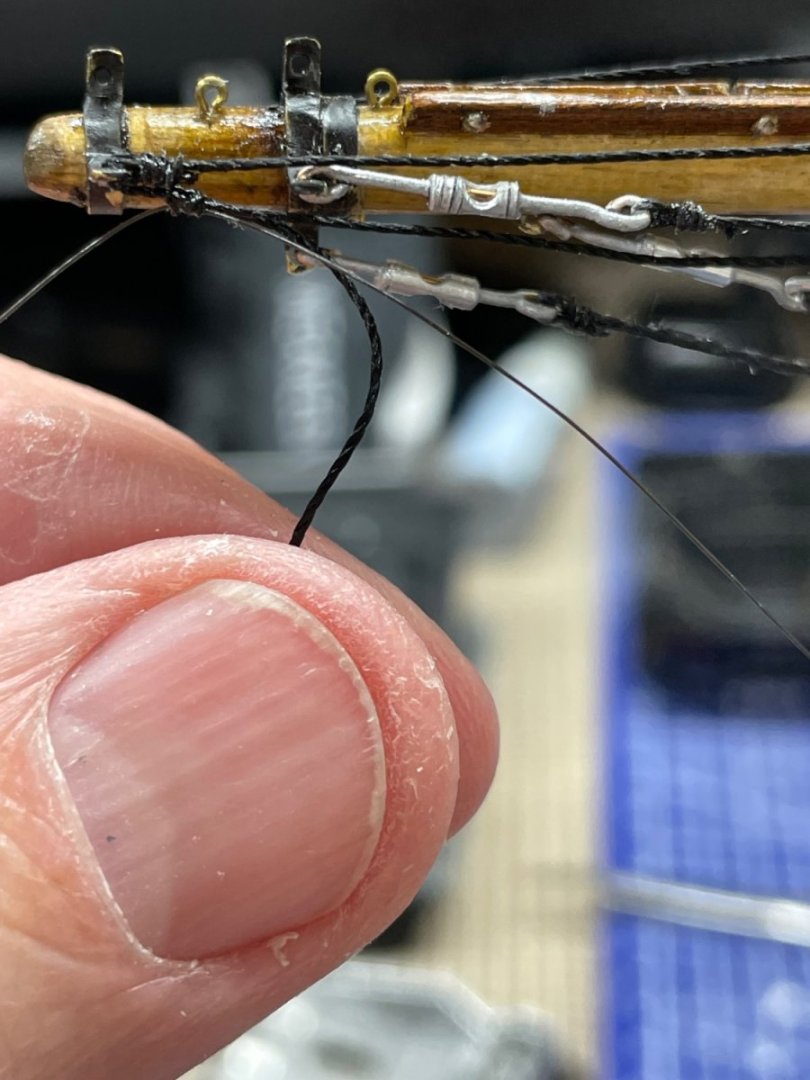

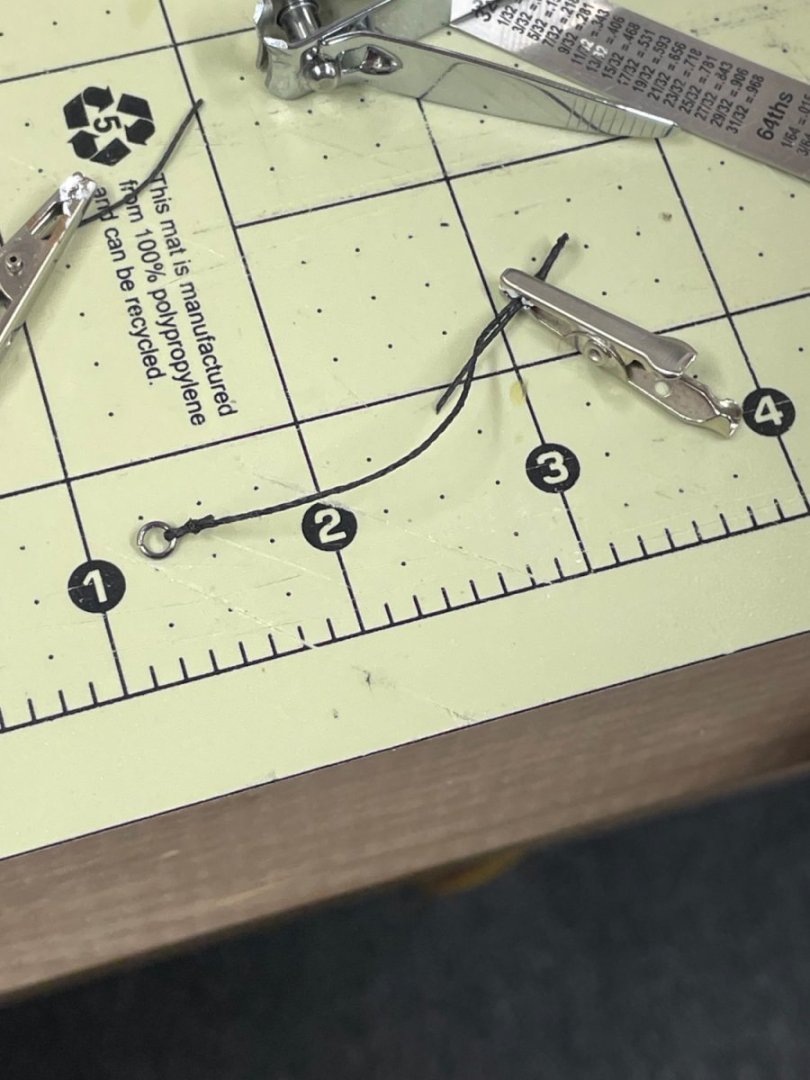

Jumbo Jib Stay… For all stays I am using the kit supplied .021” cotton/ploy line (WP1210) For the lashing I am using .18 monofilament line purchased from HiSModel.com. Lashed up the Stay (including downhaul block to the Jumbo Jib Stay Bail previously placed. Completed rigging the Jumbo Job Stay Bridle to attach the Stay to the Fore Mast. Jumbo Jib Stay completed. Next up is the Bow Sprit rigging, so I can continue placement of the Forward Stays. Cheers 🍻

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

That looks good, I’d say you have got a good start there. 🍻

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

Bob, I airbrushed Model Expo MS 4814 Hull Copper Red and sealed it with Rust-oleum Semi-Gloss Clear. I liked the way it came out. John

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

- 165 replies

-

- Red Jacket

- Marine Model Company

-

(and 2 more)

Tagged with:

-

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

Decent small clamps

John Ruy replied to bigcreekdad's topic in Modeling tools and Workshop Equipment

You might try these… https://www.ebay.com/itm/155905560329?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=us0rbE0ISEa&sssrc=4429486&ssuid=saHjlWAtSV-&var=&widget_ver=artemis&media=COPY -

WOW! I didn’t know you had this waiting in the wings when I walked in on your Pegasus build a few months ago. Glad to see you have sued her off and are going to finish her. Looks NICE… 👍 I’ll pull up a chair and ride along. Good Luck finding all your parts. John

-

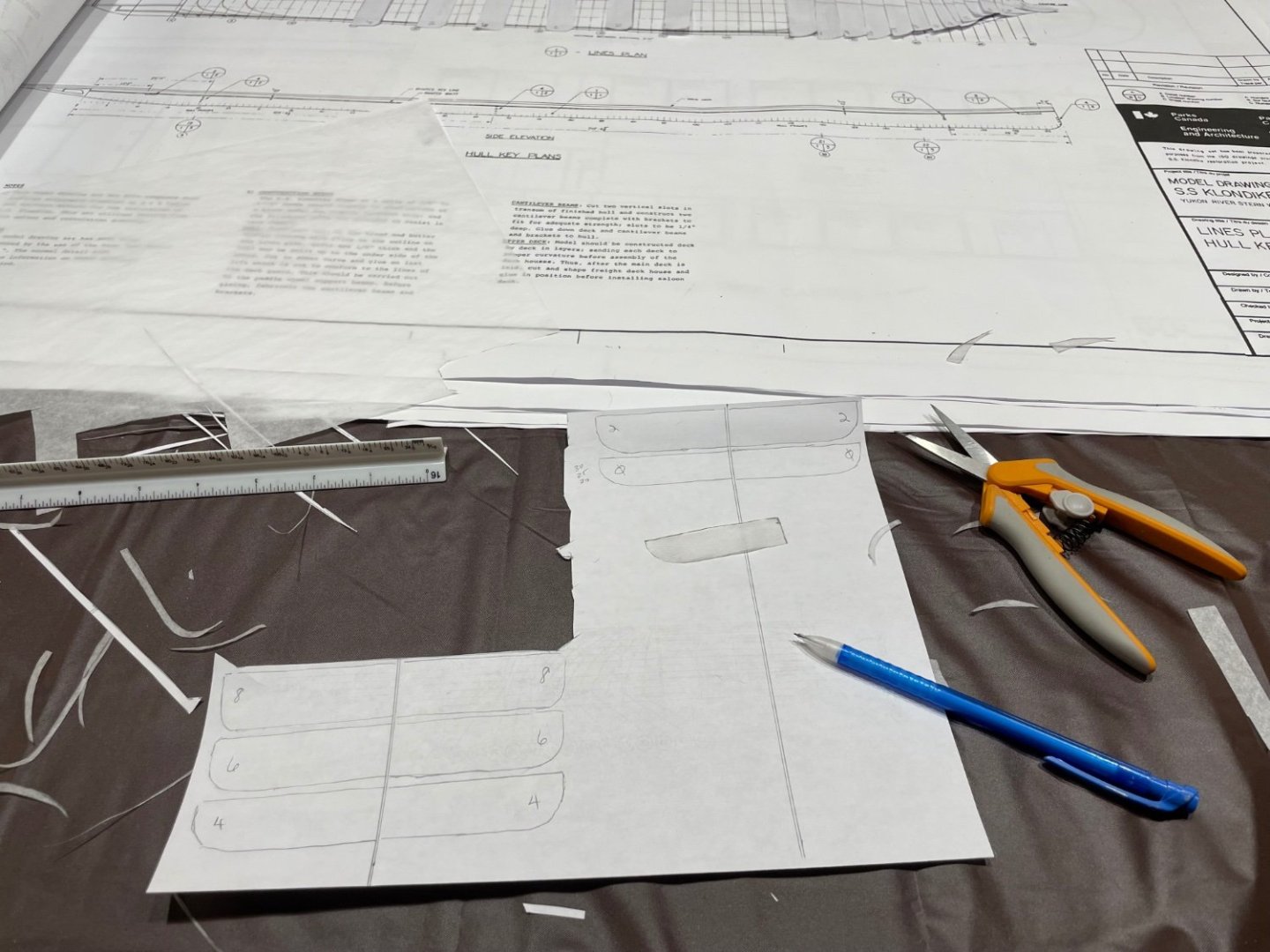

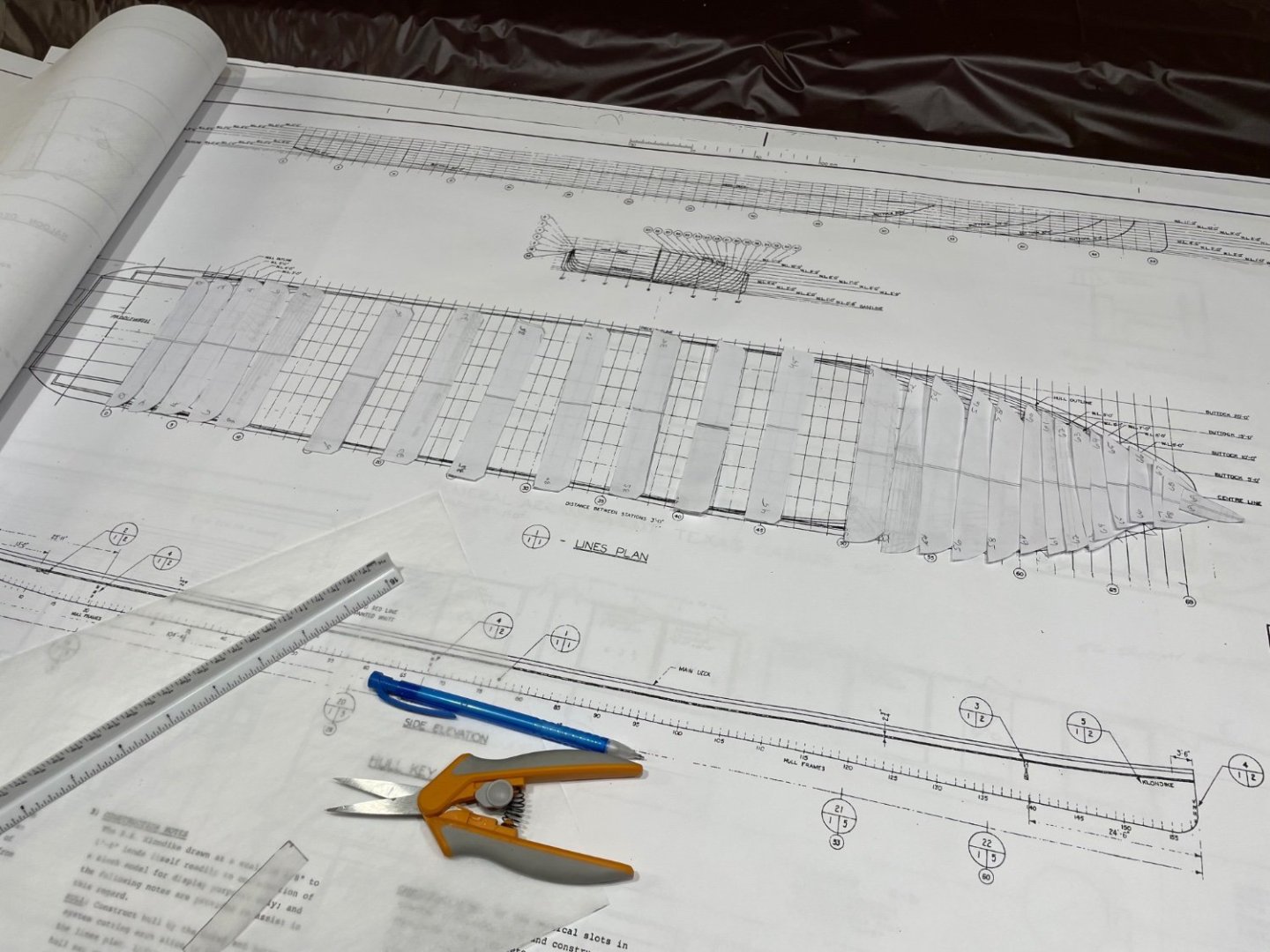

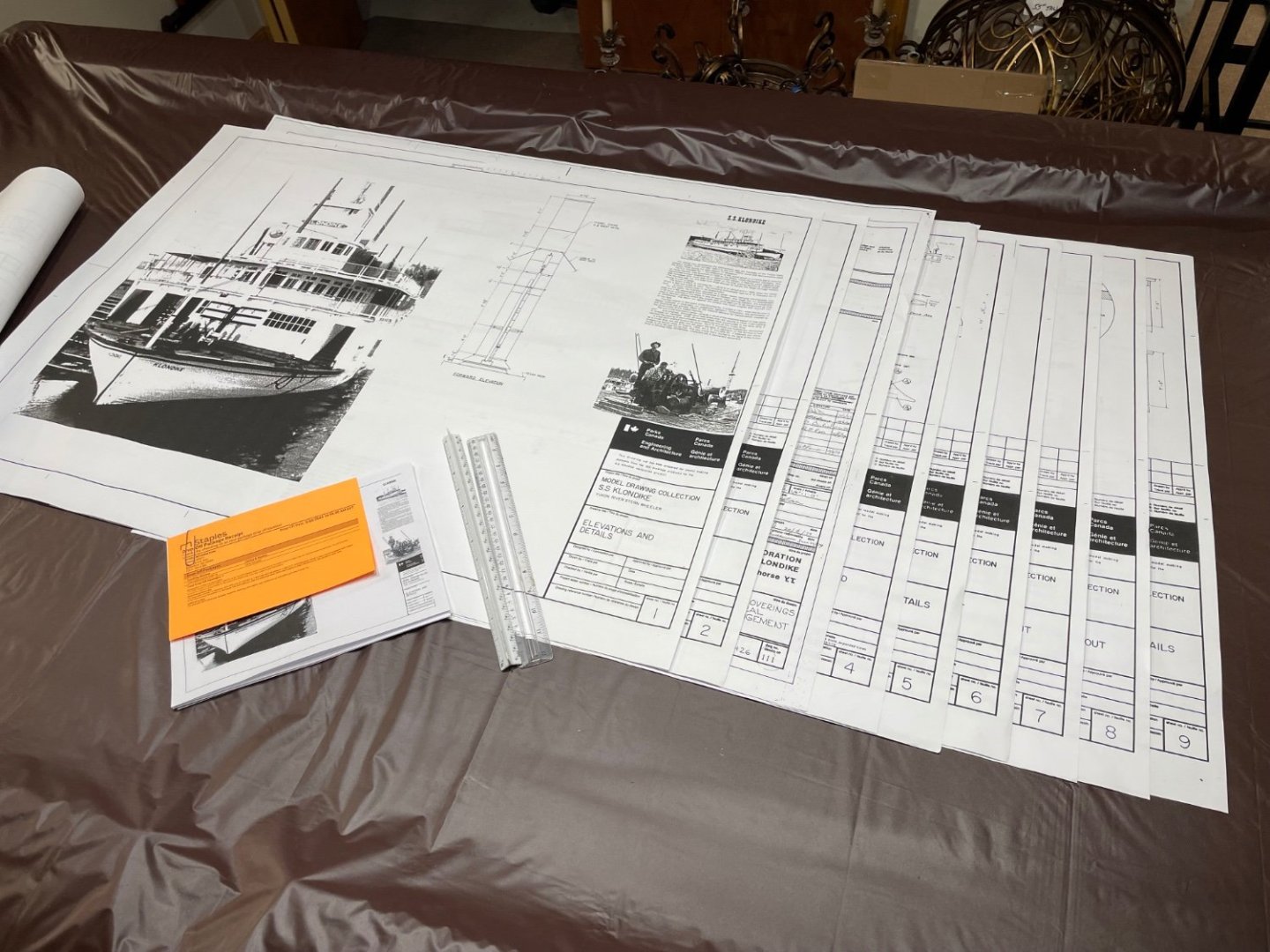

Yes, nice set of plans and some great history. Welcome aboard, thanks for the well wishes. John wanted to share my research… https://ingeniumcanada.org/channel/articles/as-the-world-err-as-the-wheel-turns-or-how-why-ss-klondike-a-cargo-carrying https://ingeniumcanada.org/channel/articles/as-the-world-err-as-the-wheel-turns-or-how-why-ss-klondike-a-cargo-carrying-0 https://ingeniumcanada.org/channel/articles/as-the-world-err-as-the-wheel-turns-or-how-why-ss-klondike-a-cargo-carrying-1 Cheers 🍻

-

Parts 1 and 2… https://ingeniumcanada.org/channel/articles/as-the-world-err-as-the-wheel-turns-or-how-why-ss-klondike-a-cargo-carrying https://ingeniumcanada.org/channel/articles/as-the-world-err-as-the-wheel-turns-or-how-why-ss-klondike-a-cargo-carrying-0

-

New build log….

-

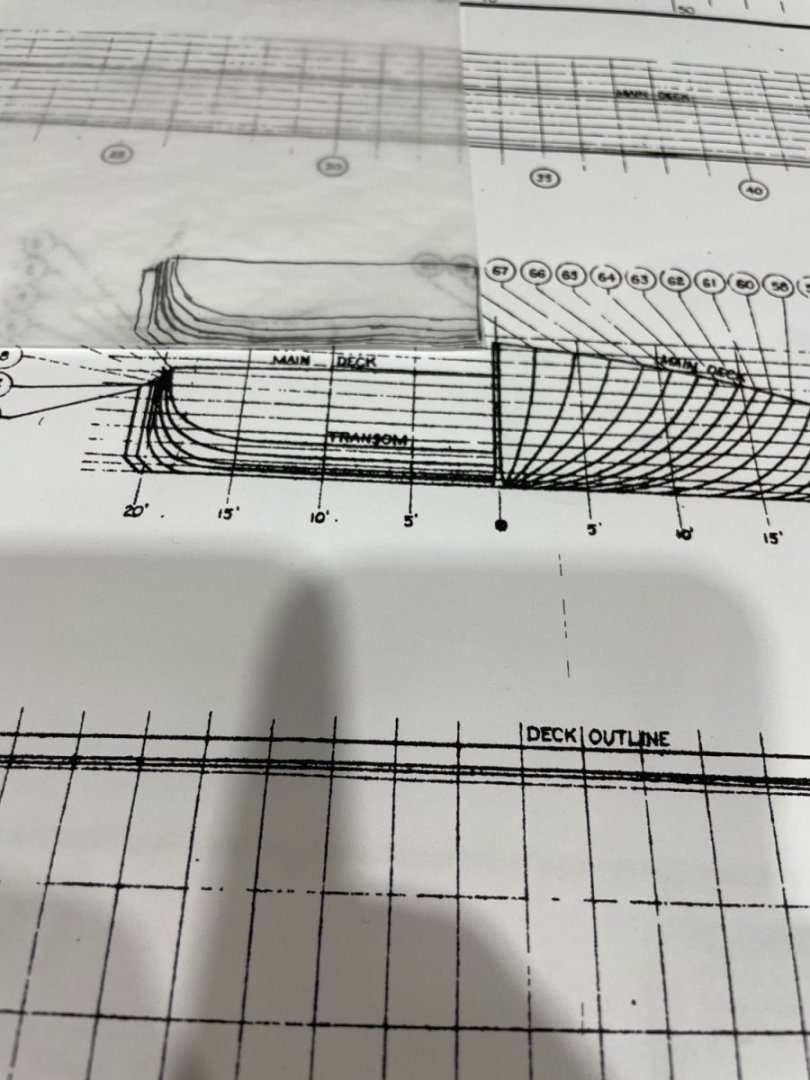

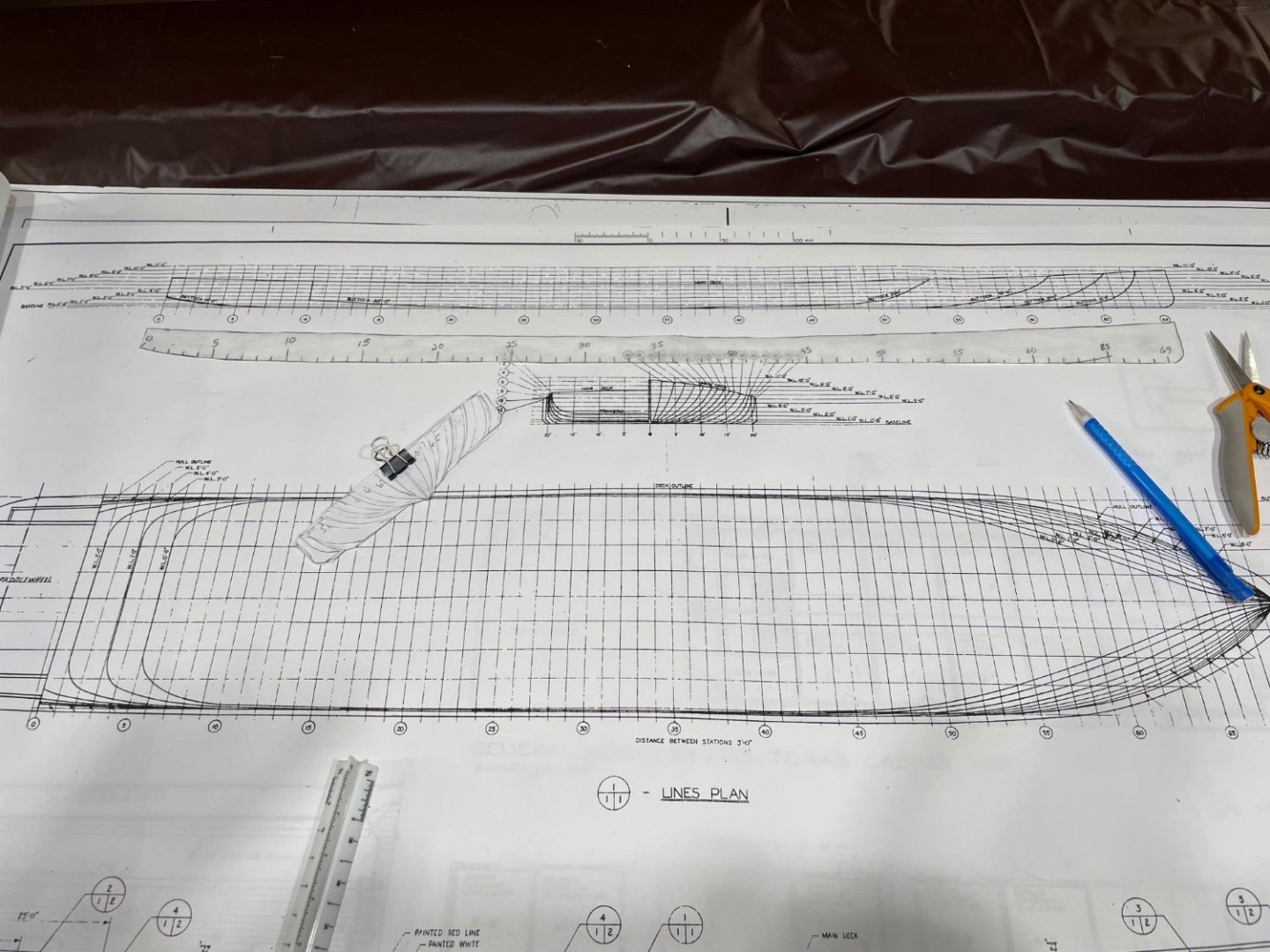

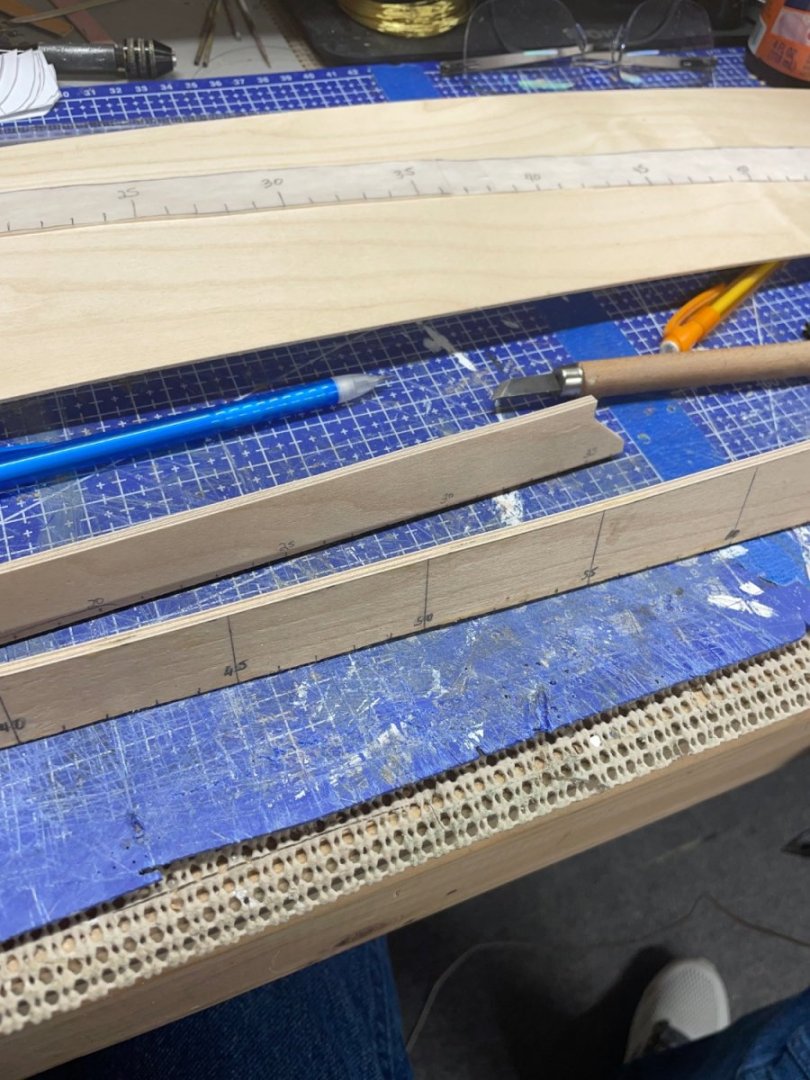

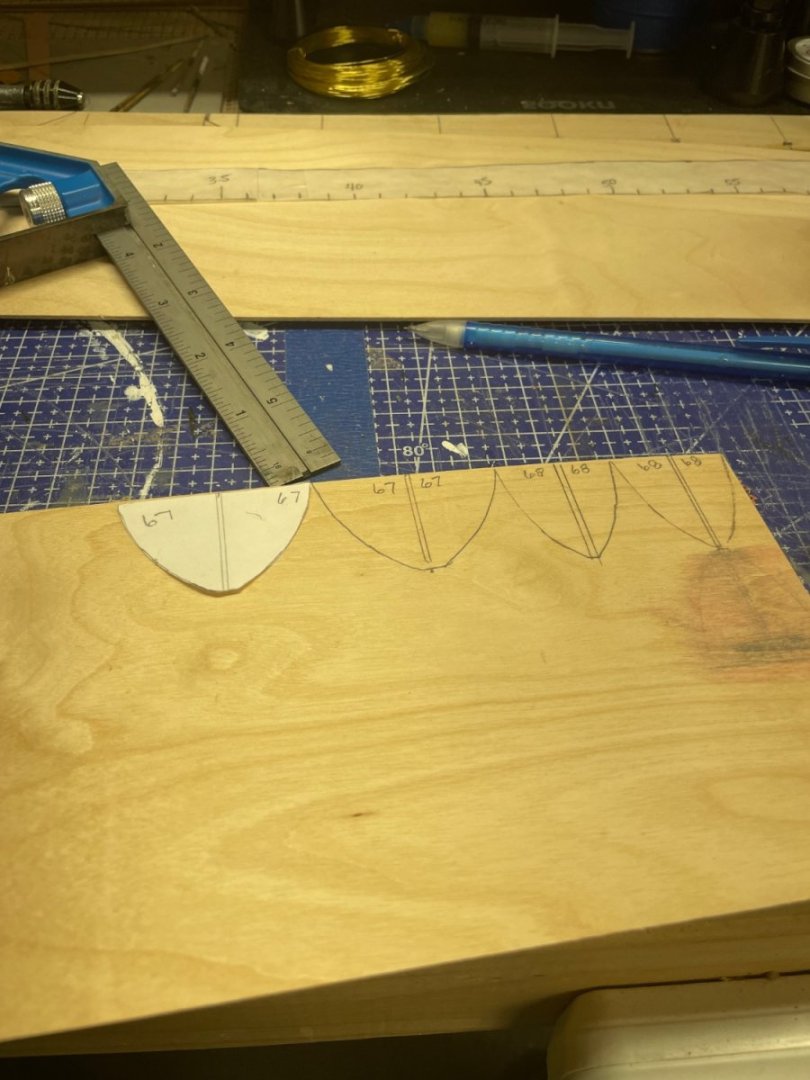

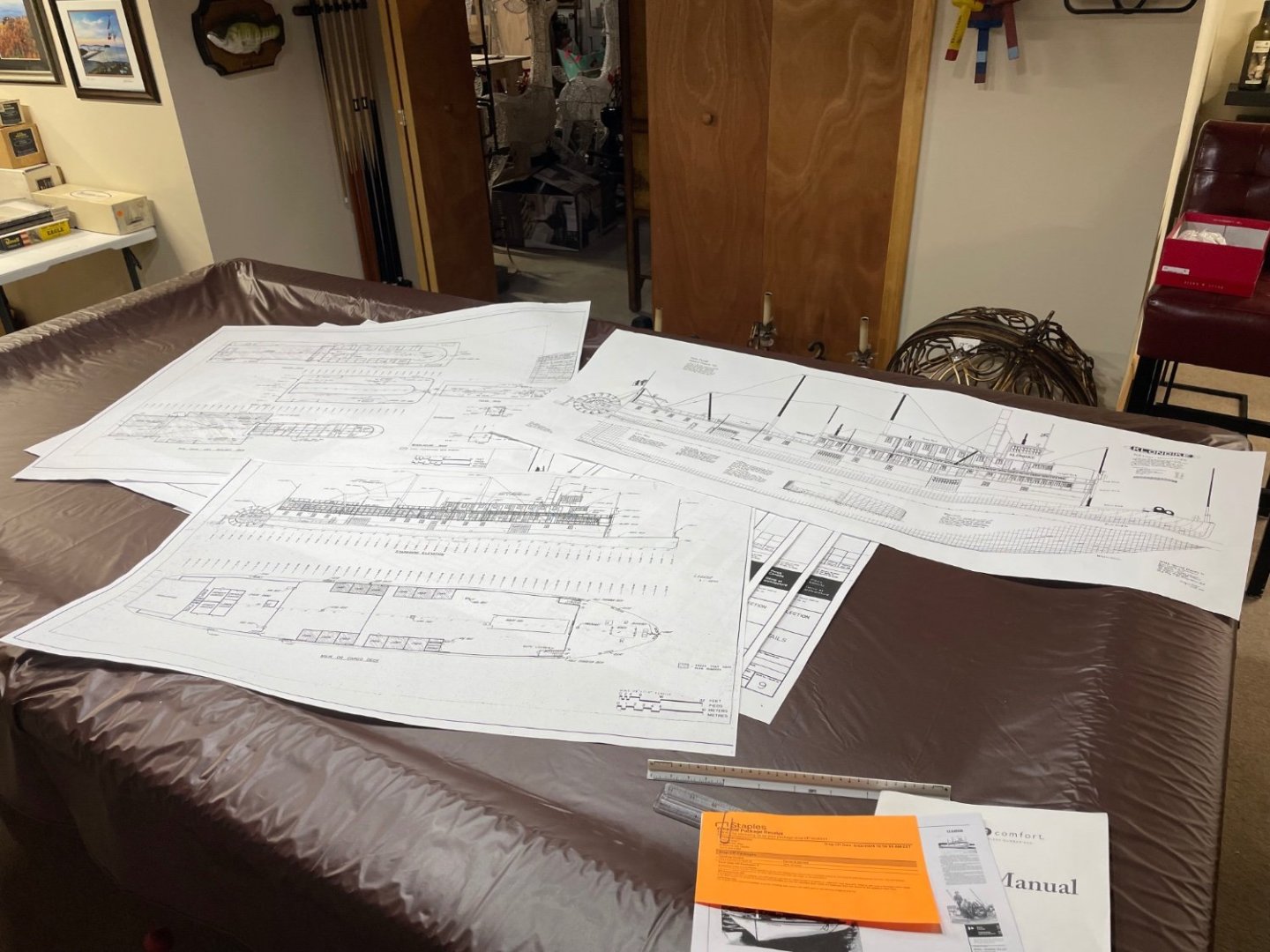

My first scratch build. 😎 The SS Klondike I was launch in 1929 by British Yukon Navigation Co. The Klondike II was built 1937 and now a museum ship and National Historical Site located in Whitehorse, Yukon. https://en.m.wikipedia.org/wiki/SS_Klondike Plans provided by Parks Canada. 🇨🇦 Many thanks to @Kusawa2000 and @Ian_Grant for bringing these plans to light.

-

How / why SS Klondike, a cargo-carrying sternwheeler river boat briefly used for river cruises, became one of Parks Canada’s 1,004 national historic sites https://ingeniumcanada.org/channel/articles/as-the-world-err-as-the-wheel-turns-or-how-why-ss-klondike-a-cargo-carrying-1

-

Interesting article on the restoration of the Klondike. https://www.nationalparkstraveler.org/2022/10/yukon-chat-parks-canadas-only-shipwright Cheers 🍻

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.