-

Posts

163 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by xodar461

-

-

Salut!

The forward side patterns are now on and I am working on finishing the planking between the wales. Both forward bulkheads had to be finished and placed on the model before the side patterns as they would have been difficult to fit after given the curves of this area (pics 2,3). Note that the aft 2 bulkheads have not been placed. test fitting showed that there will be no problem to fit them after the aft pattern has been placed. My goal is to have the exterior planking done so I can fit the last 3 guns with tackle that are below deck (pic 1, blue arrows).

Below, finishing the aft planking between the wales (orange arrow). The door frame (not seen in this photo) was used to allow the proper placement of the planks. Another way to do it would have been to plank up to the opening and glue the frame to the planks.

When laying the plank around the bow, I found that there was not a smooth transition from the forward deck planks to the hull plank. The arrow shows that the lower forward pattern edge is visible - not a good look IMO. So I decided to place a strip of swiss pear 1x2 mm around the curve of the bow for a cleaner look. This required some sanding of the finish from the deck which account for the "unfinished" appearance. A final photo of the area will soon follow.

Jeff

-

I would not worry too much if the model does not exactly match the pictures. And I would not move the opening for the ladder. It will just be extra work that is not needed. This area on my model has a 4 mm strip running across the deck aft of the hatch combing.

jeff

- CaptainSteve and Baker

-

2

2

-

Time for a new update:

The 2 raised upper decks have been planked and installed. This was all pretty straightforward (green stars). I decided to plank the inner bulwark on this deck as I did with the main deck. To support the planks I used MDF from the same pallet as the gunport frames to keep the depth the same green arrows). The planks are 5mm. The cannons will be glued to the deck and rigged with the breeching tackle prior to the installing the quarterdeck. Another modification was to divide the quaterdeck into 2 sections at frame 12 (the one just forward of the whipstaff assembly (red arrow). The work aft of this frame is complete allowing this part of the quarterdeck to be installed at this time.

Before placing the cannons, the side patterns will need to be installed so the external planking can be completed. Next photo shows the starboard aft pattern in place. I have also completed the placement aft of the upper wale, leaving a space for the balcony door frame (red arrow).

The stern window bulkhead and stern windows are installed before the side patterns.

The poop deck side patterns must also placed at this time (blue star). I also had to glue the top the frame 14 (blue arrow) back in place as both sides snapped off during the hull planking. That happened to several frames at the forward deck too.

below is work on the aft section of the quarterdeck. this will be eventually covered by the poop deck with a bulkhead at the forward end of the poop side pattern.

Both side patterns now in place. I have also placed one 2x1 walnut strip across the upper part of the pattern this acted as a guide to help finalize the position of the black wale below so that there will be the correct amount of space for the colored patterns that will be added later.

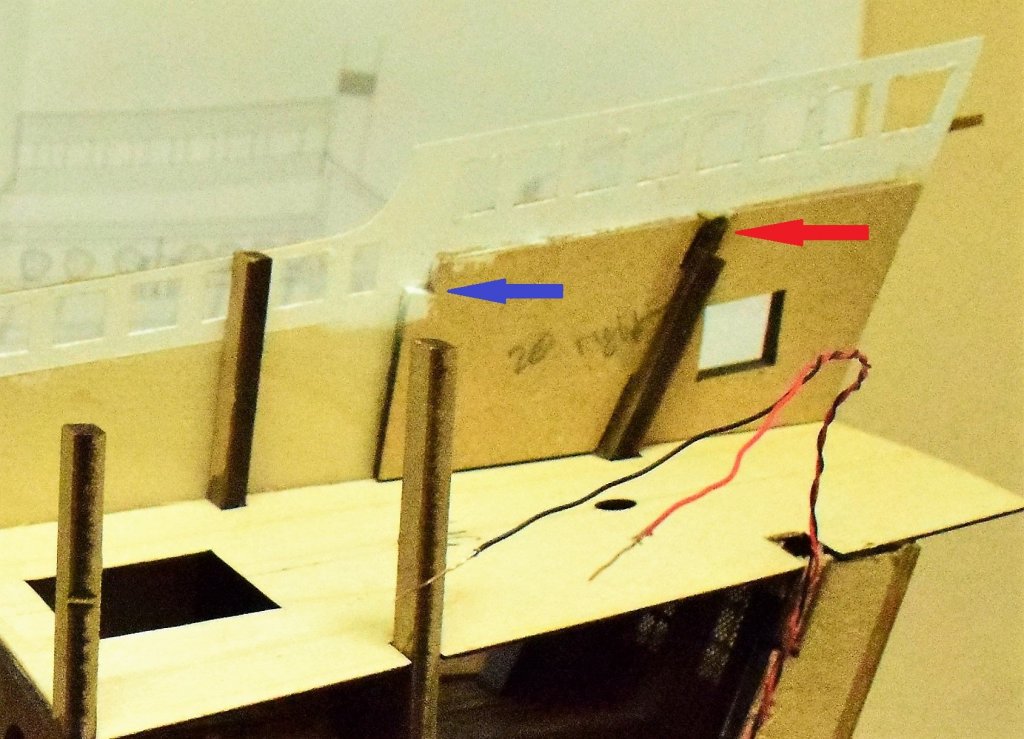

While doing some rough fitting of the poop deck, I decided to discard beam 14B which goes where the red arrow is on the photo below. This beam has a slight camber and for some reason, the poop deck is twice as thick as the other decks making it fairly difficult to bend in this way. Also, there is part 20A which is not listed in the manual but goes across the forward part of the side panel (blue arrow shoes the notch for this beam). Photos from the instruction manual do not show a notch here. This small camber is not really noticeable so I just replaced the kit beams with 2 from some spare wood (4x5mm).

Forward side panels will be installed next

Jeff

- Bill Morrison, Dave B, md1400cs and 3 others

-

6

6

-

I don't think that is a "gap" but rather a transverse plank. only the tabs are left unplanked as they slot into the last bulkhead. Many of the decks have this transverse plank up against a bulkhead. Easy to fix you can just lay one of the 5mm planks used for the hull planking across this deck.

jeff

-

Greetings

Upper deck work in progress. First pic shows some 1x4 mm wood added to each beam to raise up the cannons relative to the lower edge of the gunports (pic 2). The main deck gratings have also been placed with epoxy rather than CA - lots left to do with this model and I don't want them to get dislodged - thus completing the work on the main deck. When performing these modifications it is important to check that it causes no change to anything else further down the line. for instance two bulkheads sit on this deck and they must align with the top edge of the forward and aft side patterns (which they still do).

The instructions call for planking the upper deck almost in full then installing it. Problem here is that there has to be some bending to get the deck in place. This would be difficult fully planked. So a few planks were placed off the ship to get thing started - the aft plank that runs across the deck ship (large black arrow) and the planks that run centrally up to the openings for the bits (small arrows). it is much easier to sand these openings and those for the masts while still off the ship. Once on, the deck is planked almost to the bulkhead frames (which eventually will be removed).

Also seen on this deck is the hatch combing which had to remade as the kit's combing was pretty much destroyed when I tried to sand it. This part is made of a wood called dibetou. I am not a fan of this wood as it is VERY brittle along its grain. even cutting out pieces from the pallet may cause the part to split along the grain. Here's a pick of the original part (upper) and the beginnings of the new one. I have a feeling I will be making more scratch parts along the way! The red arrow shows the tiny tab that hold the part to the pallet. grain runs the same way as the arrow is pointing.

Below pic shows the final hatch combing

Again I digressed a bit from the plans which call for planking the deck and gluing the combing onto the planking. In reality the combing would sit on the beams and planks placed around the combing. This gives a better look I think as well as being more accurate

-

-

Gunports are now complete except for the application of stain and hardware.

The lower deck gun are now in place with the breeching tackle. In order to get a secure bond, some spare wood was glued to the bottom of each carriage so as to create a larger surface area than just the 4 wheels for the glue. Kit instructions call for just the carriage to be placed with the guns going on later. With the guns in place now, I don't want to accidently dislodge them. They are all pretty solidly in place.

I decided to leave the cannons as supplied (bronze) rather than paint them black. Cannons of this age were made of bronze or iron. Also, they are getting a little patina as can be seen below. Makes things a bit more interesting I think.

Last item to add to the lower deck are the gratings. In doing some preliminary work with placement of the upper deck, I found that the cannons seemed to be a bit low, even when accounting for the deck planking. this can be seen with some of the pictures of the model on the box. some spare wood 1 x 4 mm was added to the top of the beams and problem solved, However, I also encountered this with the forward side pattern.

once again another port slightly off. This gun also sits quite low on the box top photos. I plan to cut out the penciled area and fill in the same amount at the top. This will not have any overall effect on this part of the hull. For now, next up is lower deck gratings and upper deck placement and planking

Jeff

- Bill Morrison, GrandpaPhil, Baker and 2 others

-

5

5

-

Hi.

I am one year into this model so please feel free to send a message should you have any questions

Jeff

-

Hi Paolo

Thanks for following my log. I am not a very speedy builder as you can see from where I am in this build. Re: the deck plank lengths, I started with a full sized length of 24 FT which is ~ 4.5 inches at a scale of 1:64. I think I decided on 4 inch planks for the model. To make it easy, I would recommend a plank length of 10 cm. This would also make it easy to shift the planks 2.5 cm with each successive plank so joints on the same "beam" would be separated by 3 planks. Feel free to ask any questions along the way.

hope this helps

Jeff

-

Planking between the wales now complete (glad to be done with all the complex curves at the bow!). Instructions call for completion of the remaining decks before placing the fore and aft side patterns. This would require placing the lower deck gun carriages without the guns. As I want to rig these guns with at least the breech tackle, some changes in the order of construction will needed. First, I decided to plank the spaces between the gunports so these areas could be sanded and finished prior to gun placement. This would require the wale that runs above the gunports to be laid down first. As this wale runs the length of the ship, the part of the wale that would be fixed to the side patterns was left unglued (second pic, arrow). Also, the instructions call for the wales (lower 2 are 1x5 and the upper one is 1x4)to be glued onto the second layer of planking. I felt that doing it this way this would make it difficult to exactly match the run of the planks already placed. Thus, two 1 mm planks were glued together to form the wale and this was then placed onto the model with spacers to maintain the correct distance from between the wales (first pic, arrow). the lower wales were made in the same way.

After the planks were place between the ports, the port lids would have to be redone as those supplied with the kit were dibetou wood and this looked quite wrong against the swiss pear. As the photo below shows, the new port lid was made from 3 planks of swiss pear made to follow the run of the hull planks.

As the supplied port lids were all cut to match their respective ports, rather than waste them, they were trimmed a bit and used to make the inner layer of the port lid (illustrated in to photo below.

The hinges will be added at a later time. Next step will be to place the lower deck guns with the breeching tackle then construct the deck above.

jeff

- GrandpaPhil, Bill Morrison, Baker and 1 other

-

4

4

-

time for a new update. after the planking below the wale was completed, the waterline was drawn and then painted. this is also the time to construct and hang the rudder. The tiller arm (orange arrow, second pic) is also connected to the whipstaff assemble at this time. The quality of the rudder hinges is quite good.

The gunports have also been framed. Next are a few views of the waterline...

Below, the hull sitting in my waterline template...

planking between the wales is next. while waiting for some additional swiss pear, work was started on the forward 2 bulkheads.

- Bill Morrison, CaptainSteve, Baker and 1 other

-

4

4

-

Jond,

I have similar plans for my current build of Amati's Revenge - a 3 or 4 mm thick sheet of plexiglass with the waterline cut out that the ship will sit in. While I have not yet purchased the plexiglass sheet, I found this website that has a variety of thicknesses and will cut to size:

https://www.eplastics.com/plexiglass/acrylic-sheets/clear

Also, I used some large cardboard boxes to get the pattern of the waterline (using a contour gauge) that will eventually be transferred to the plexiglas for cutting. A photo of the template can be seen in my build log and I will soon have some pics of the ship sitting in the template.

Took about 4 or 5 tries to get the waterline cutout correct. not sure about what I will use to simulate the water but that is way in the future

Jeff

-

Second planking now complete. the blue tape protects the wale from sanding. no stealers were used. the largest width amidships is 5 mm however at the stern, I used 1x7 mm swiss pear and trimmed it to the correct width.

After marking the waterline, painters tape applied to protect upper hull. Below the waterline will be painted white.

My ultimate plan is to display the model dropped into a sheet of 4 mm plexiglass which will be used as the base for water (never did this before so should be an interesting project). below is the cardboard template I made that will provide the outline used to cut the opening in the plexiglass. Took a few tries to get it right using a contour gauge

- ccoyle, GrandpaPhil, Baker and 3 others

-

6

6

-

-

now for a slight digression. My final plans for display when the ship is complete require a waterline. Rather that buy a marker (amati makes one and another is available from Hobbyzone for $8), I figured I could build one from the scrap from this kit).

The base is from a 5 mm MDF pallet that held one of the min deck beams. The upright is another 5 mm MDF piece that held a beam. I had to make it wider to support the bolts and wignuts.

the holder for the pencil - 2 more scraps pieces (red arrow) with a grove carved out to hold the pencil (black), 2 holes drilled for the bolts and 2 support pieces between the 2 pieces that hold the pencil (blue)

when the planking is complete, I'll show a few pics of the waterline it produces

- Ryland Craze, Katsumoto, Ondras71 and 3 others

-

6

6

-

With the lower 2 wales complete, it is now time for the second layer of planks. As noted previously, 1x5 mm swiss pear was used.

First pic is shot from the bow with the first few planks placed.

A few more strakes placed. I am working from the wales down and keel up. The numbers on the lower layer denote frames (a few extra added to account for the butt joints) and the tick marks along each frame denote the plank width. I did not lay each plank the full length but rather used planks that are between 20-24 ft in scale (~4 inches)

This next photo shows what can be done with swiss pear a little water. The curves at the bow are pretty extreme.

Next is a shot of the stern as the planking progresses. Calculations showed that the plank width at the stern is wider than the 5 mm I was using. Rather than using stealers, I decided to use 1x7 mm swiss pear and trim to the appropriate size (white arrow)

- ccoyle, Ondras71, Jim Rogers and 3 others

-

6

6

-

The plans call for the first plank to be laid down is the main wale. This required measuring down from the gunports, making marks where appropriate. While this was simple enough amidships, it was a bit difficult to estimate where the wale should fall at the bow. so I decided to place the upper wale first. this one follows the lower edge of the gunports and it's position at the bow easy to figure out as the forward part is staggered and follows the upper edge of the foremost port. Also, instructions say to lay the planks then add another 1x5 strip on top , then paint, to make the wales. I decided to make both wales first and paint.

The lower wale was then placed. The distance between the wales in constant from bow to stern. Spacers were used to maintain this distance. You can also see the difference between the wood supplied with the kit and the Swiss pear that I will use.

This last photo shows the first 1x5 plank placed and part of the second plank on top of the first to make a wale on 2x5 mm.

Next up, the wales will be painted and the on to the second layer of planks

Jeff

-

Greetings!

Prior to beginning the second planking the stem and keels must be fixed to the hull. I used some long brass nails for some extra security for the keel. Could not really do this with the stem as they nails will be visible, however, once the planking is set into the stem's rabbet, it should be secure enough. The frames are also marked to help with the plank butt joints

This pic shows the keel

this one shows the rabbet at the stem

and this shows the stem. Not sure how other builders of this kit managed to complete all of the second planking without breaking the stem as it is rather long and seems a bit brittle. Mine broke off before I even had the wales on (red arrow). Not a big deal as it should be easy enough to glue back on when the time is appropriate

- Ondras71, Bill Morrison, Katsumoto and 2 others

-

5

5

-

while doing all this internal work it became evident that the aft most gunport on the lower deck would be a problem for clearance of the cannon on the lower sill. As can be seen in the pic below, there is minimal clearance already and a 0.5 mm gunport sill has yet to be added.

Seems to me that there should be a slight step up in the deck from gunport #6 to #7. This issue was briefly mentioned by Emelbe in his build log. His solution was to build a small platform for the gun to raise it up.

Not entirely satisfied with that fix, I decided to raise the entire deck 2 MM.

Last photo shows a cannon after new deck installed. Much better and now should have no problem placing a 0.5 mm sill

Next up will be the second layer of planking. Not going to use the kit supplied wood as it is the same type as the decking and seems too brittle for the hull planking. I've decided to use swiss pear from crown timberyard which hopefully will give a better result.

Jeff

- Katsumoto, puckotred, GrandpaPhil and 3 others

-

6

6

-

The lower gunport patterns have gunport frames glued to the inner aspect of the pattern as can be seen below

Although this area will be covered by the upper deck, I did not want to leave them like this as I planned to secure the cannons with not only glue but rigging. This would require some internal planking. First step was to add some deadwood to the internal gunport pattern. I used some MDF from the same pallet that the gunport frames came from. The ships frames were still a bit wider so some planks from those used for the first planking layer were used to make up the difference.

Finished...

- Baker, puckotred, GrandpaPhil and 2 others

-

5

5

-

After the lower gunport patterns are in place, it is time to lay the first planking. Here are a few photos of the progress. no real problems encountered at this stage. Photos also show a bit of wood filler used to smooth out some areas where the planks join the port patterns.

Almost done

First layer finished. It was very helpful to have the bow (up to frame 4) and stern (frame 13-14) filled with wood to allow extra purchase for the planking. Photo seems to show some unevenness to the planking but is is actually quite smooth as can be see from the bow and stern shots

Stern planking using a pattern supplied in kit

- Baker, puckotred, GrandpaPhil and 2 others

-

5

5

-

I am currently building the Revenge by Amati and I wonder if someone could help with a question regarding pliability of holly or swiss pear. The kit is double planked and requires some complex curves at the bow, especially for the wales and upper strakes. The wood supplied is some sort of walnut, 1x5 mm, and not really suitable for bending along its edge, even with soaking in water or ammonia. And I really don't want to make these planks with spiling (and after watching Chucks's videos, seems like you don't really need to do this anyway if you have the right type of wood) I have some 1x4 mm Holly and this wood is so pliable I can bend it along its edge quite a bit without breaking (almost 90 degrees). The same is true with some 1x3 pear wood that I have. So my question is this: can a slightly larger plank of pear or holly, say 1x5 or 2x5, be bent just as easily without fracturing? I am thinking of replacing the hull walnut with pear and would like some advice before I put an order in with Crown Timberyard. Unfortunately I have neither of these sizes to test at home and the 1x4 holly is a bit out out scale for hull planking.

Thanks,

Jeff

-

After a long interlude...Several cannons need to be fixed in place prior to placement of the side gun port patterns. 2 small cannon carriages are placed at the stern. No issue here with the barrels temporarily placed

the plans call for one small carriage at the bow. Problem here is that in the picture of the finished model on the box, this cannon seems to be a large one and there is no way it will fit in this space and be centered in the port. This one is on the same deck as the other large cannons. I ended up using a small one here as the instructions say to do. So I will be short one small and have one extra large. Not an issue now, but easy enough to deal with...just could have one port closed.

next issue was the 2 large carriages towards the stern. When placement was tested, the bulkheads interfered with centering of the cannon in the port. next 2 photos illustrate the problem.

The fix was easy enough...trim back both bulkheads in order to make them more like frames. Luckily, the MDF is muhk easier to trim than plywood!

Since i had to make a few small and large cannons, I figured I may as well make them all. This way I can test cannon placement with the gunport patterns. one of the aft ports was a bit off so about 1.5 mm was taken off the lower edge. Before trimming, I checked that this would not affect the wales as one comes close to this port. Should have room to spare above the wale.

The cannons...

Next step is to affix the side gun port patterns.

Jeff

-

Work on the lighting now complete. All the wires have been joined together with the one lead wire exiting from the keel. This will be eventually connected to a 9 volt battery in the final display. It will be interesting to see how much is visible when the ship is planked. Red arrow in second pic shows an LED meant to represent a torch. The LED wont be visible, only the flickering light will be through the hatches

Here are a few pic of the helmsman's platform and whipstaff assembly.

And finally, I decided to add some filler wood to bow and stern - basswood of a variety of thicknesses - showing one side sanded and the other still rough. Stern has been mostly sanded to shape

Next up - a few cannon carriages have to be fitted before any side panels are placed. I may rig the ones at the stern. Others nay be a bit difficult to rig based on their location.

Jeff

Revenge 1577 by xodar461 - FINISHED - Amati - Scale 1:64

in - Kit build logs for subjects built from 1501 - 1750

Posted

Thanks for your praise. As slow as I work you may catch up to me!

Jeff