yamsterman

Members-

Posts

550 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by yamsterman

-

Hi mark Thanks for the high praise! Still regard myself as a learner......I look at some of the work on this site and words fail me.....if I can emmulate some of that standard of work I shall be a happy bunny. It's a good job Bob at timberline was generous with the timber order!!!! Cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Carl Yep you're right about thefat fingers! Not so sure about master carpenter.....maybe a journey man? But thanks for the accolade! Plenty of time yet to drop a complete clanger! Cheers ....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

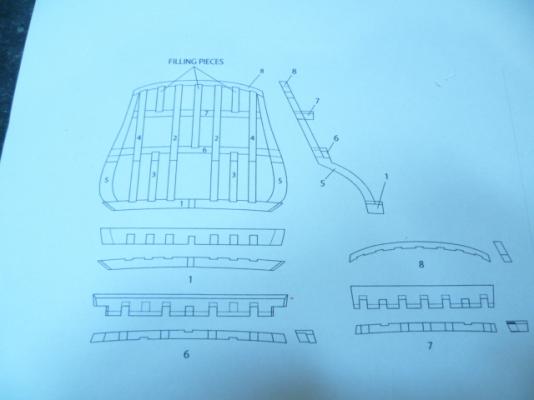

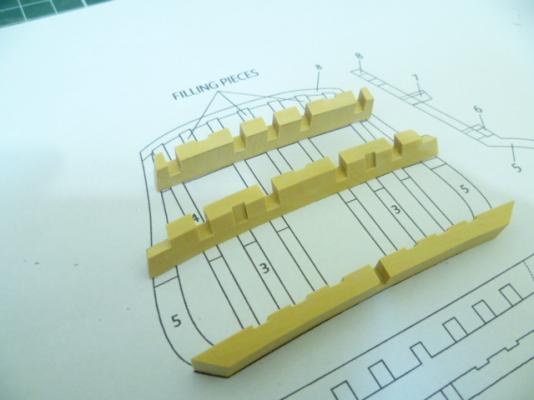

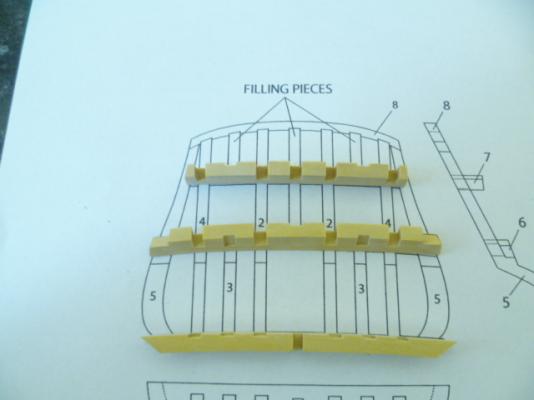

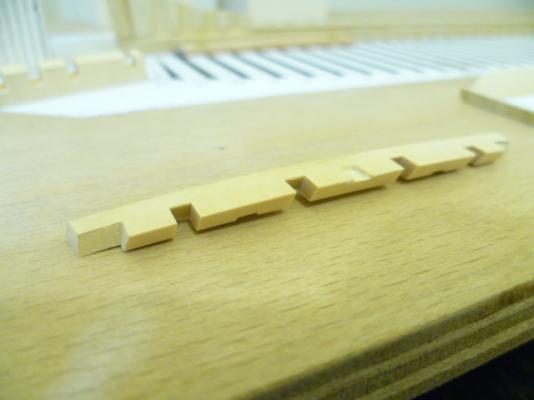

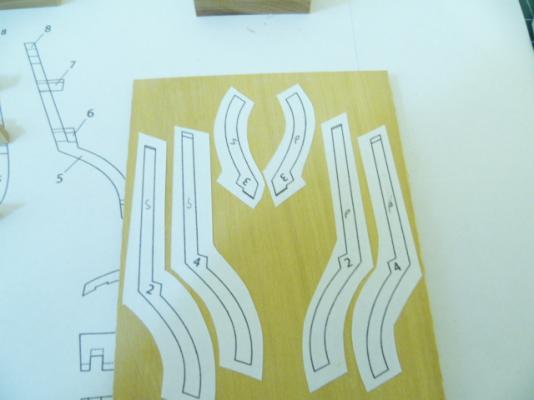

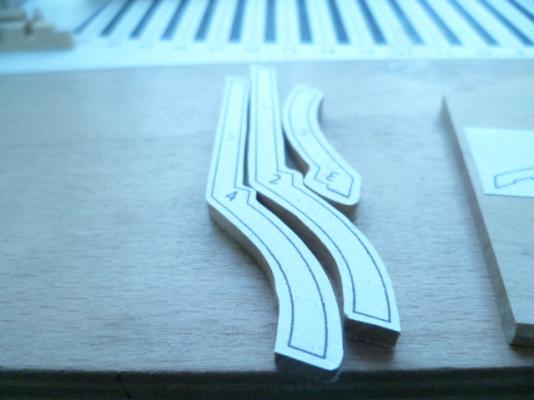

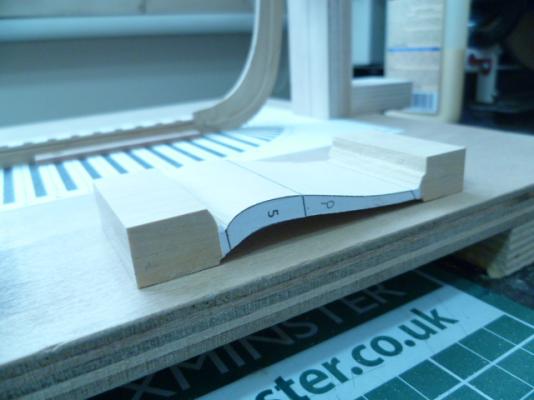

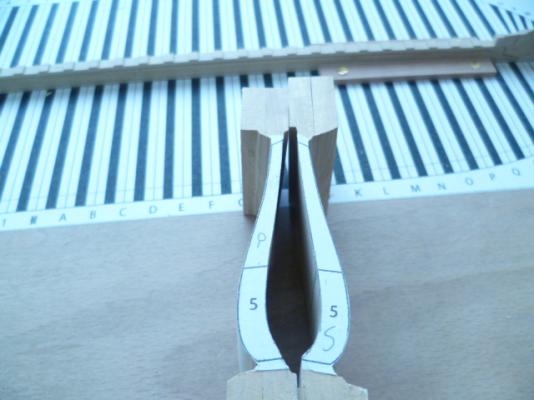

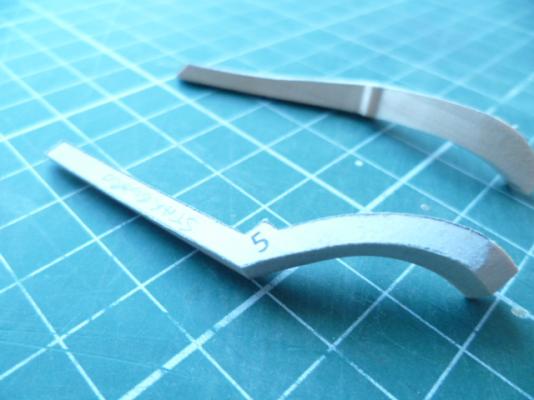

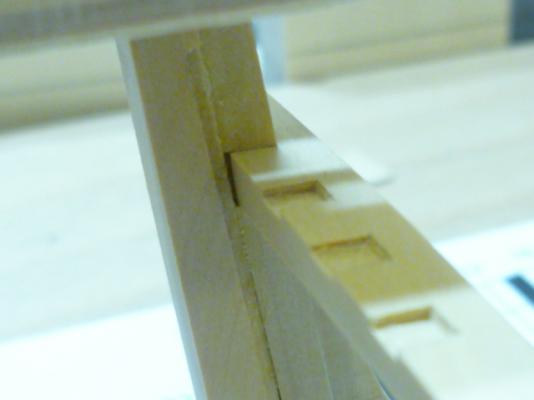

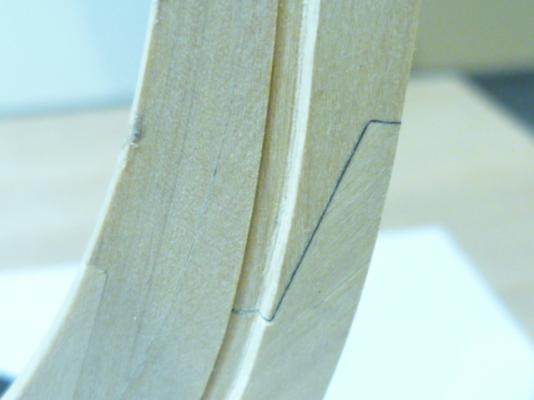

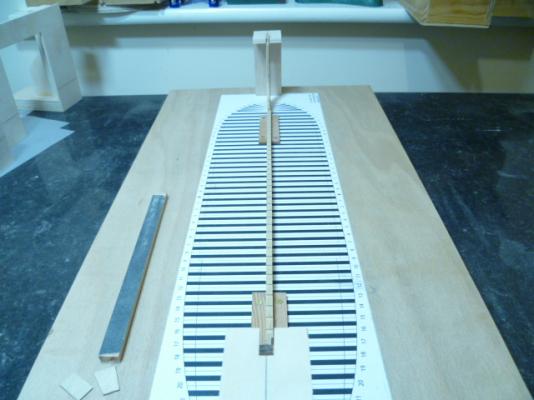

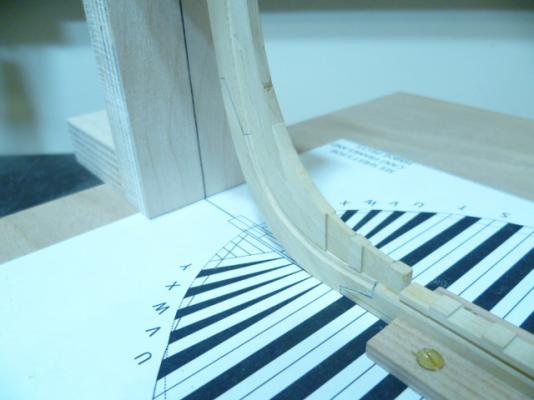

WASHINGTON GALLEY PART 5 . MORE TRANSOMS STERN TIMBERS AND FUNNY BENDY THINGS. HI ALL BEEN BUSY BEAVERING AWAY MAKING LOTS OF SAWDUST. STARTED MAKING THE STERN FRAMING COMPONENTS AND THE REST OF THE TRANSOMS. ALSO DID A PRACTICE RUN WITH THE STERN COUNTER FASHION PIECES,THESE ITEMS ARE SOMEWHAT AWKWARD THINGS TO MAKE,I ENDED UP GLUING TWO PIECES OF 1/4" STOCK TOGETHER IN ORDER TO GET THE RIGHT THICKNESS. I THINK IT WOULD BE BETTER TO CUT THESE FROM THE APPROPRIATE SINGLE THICKNESS......MAY BE ANOTHER ORDER TO TIMBERLINE! THE PRACTICE PIECES DONT LOOK TO BAD AND I MAY BE ABLE TO USE THEM......BUT THAT WILL HAVE TO WAIT UNTIL THE STERN FRAMING GOES TOGETHER AND I CAN PROPERLY TEST FIT THEM. ANYTHING NOT UP TO SPEC GETS REMADE!!!!! I WILL LEAVE YOU WITH SOME PHOTOS TOO SEE WHAT YOU THINK. CHEERS.....MICK P.S. ANY PHOTOS OF PLANS ARE OBVIOUSLY COPYRIGHT OF THE N.R.G. AND JEFF STAUDT.

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

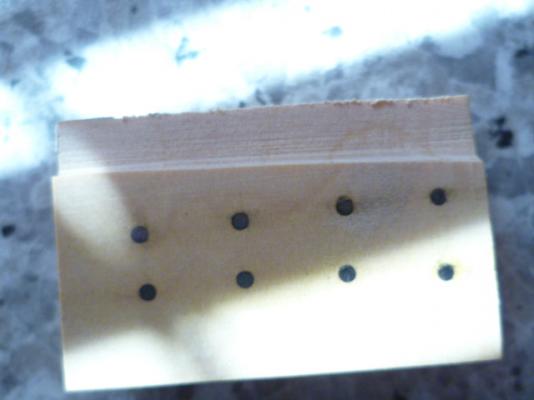

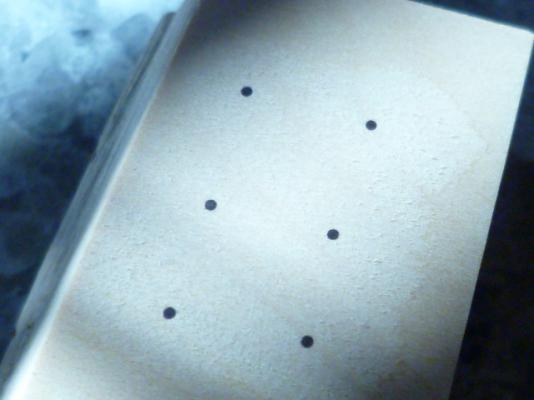

EXPERIMENT WITH LIVER OF SULPHUR. THIS IS IN RESPONSE TO CHUCK SEILERS QUESTION AND ALSO TO SATISFY MY OWN CURIOSITY. FIRSTLY I PURCHASED A 1 OUNCE JAR OF LIVER OF SULPHUR GEL (SEE PHOTO) APPARENTLY IT LASTS FOR QUITE A LONG TIME WITH NO DEGRADE BASED ON HOW MUCH YOU ACTUALY NEED THIS SHOULD LAST SEVERAL LIFETIMES!!!! FIRST PHOTO IS OF THE PRODUCT ITSELF THE NEXT SHOWS SOME 1MM COPPER IN A SCRAP OF BOXWOOD. I USED THE GEL NEAT FOR EXPERIMENTS SAKE ,LET IT DRY FOR A FEW SECONDS AND THEN WIPED IT OFF WITH A CLEAN TISSUE. COPPER WAS NICELY BLACKENED AND THE BOXWOOD WAS STAINED A GREENISH BROWN......NOT GOOD. SECOND LOT OF PHOTOS SHOW SOME 0,6MM COPPER INSERTED INTO THE OTHER SIDE OF THE BOXWOOD BLOCK. THIS TIME I USED A SMALL DROP ABOUT THE SIZE OF A MATCH HEAD AND DISSOLVED IT IN AN OLD MUG OF WARM WATER. THE RESULT WAS A PALE YELLOW LIQUID.A SMALL MICRO BRUSH (SAME THING WOMEN USE TO PUT THEIR MASCARER ON WITH) WAS DIPPED IN AND WIPED OVER THE COPPER . NICELY BLACKENED COPPER AND NO GREEN STAINS!!!! LESS IS MORE WITH THIS STUFF.......IT ALSO STINKS TO HIGH HEAVEN....SULPHUR YOU KNOW!!! CHEERS....MICK

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi crackers Probably right...but I'd give it a darn good go!!!!! Cheers....mick

- 14 replies

-

- yacht

- restoration

-

(and 1 more)

Tagged with:

-

Hi crackers Glen moray....distilled on the banks of the river lossie, Elgin,Speyside......Bonnie Scotland. Unfortunately the last bottle of JD single barrel Ibrought didn't arrive with such a lovely lassie!!!! Cheers.....mick

- 14 replies

-

- yacht

- restoration

-

(and 1 more)

Tagged with:

-

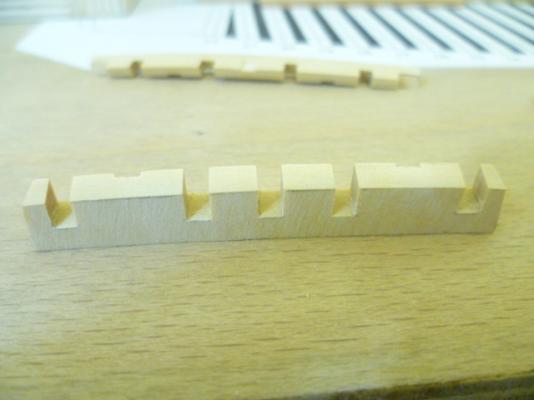

Hi Christian Nice to hear my heath Robinson contraption is of some help! The jig in the picture is mk3. Absolute accuracy is a must otherwise a tinyfraction of an inch or millimetre out leads to a cumulative error. The piece of brass I used as a key was 1/32 x 1\4 a stock price from k& s metals range. The milling cutter was an imperial size of 1\4 inch. All this was specific to this model.....so I would have to make another jig for a different model. The crucial thing was getting the distance from the brass key to the edge of the milling cutter at exactly 9/64 inch. Once this is done its a quick process to run of a length of moulding. I hope this makes sense. Obviously you would have to adapt your measurements to suit. Cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Ken Thanks for stopping by. Driving me nuts trying to get things to conform to the plans! Nice learning curve tho! I have a feeling the cant frames will give me a headache as will those awkward fashion piece's at the stern. All part of the fun of model ship building! Cheers....,..mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi David b Thanks for looking in. Steady as she goes! Progress will be slow but sure I hope......lots of newthings to learn.....especially with these can't frames and hawse prices........seems to be a lot of info crammed into the frame drawings, may take a while to work out which line to cut too! Cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Chuck I've never used liver of sulphur before but reading through various logs on MSW leads me to believe that it won't stain the wood. I will do a test piece first too see how I get on. Cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Nigel Thanks for dropping by. Lots of fun,sawdust and the occasional boo boo! Hope you're getting eqaulammounts of fun from your triton build......imknow I did! Cheers...mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

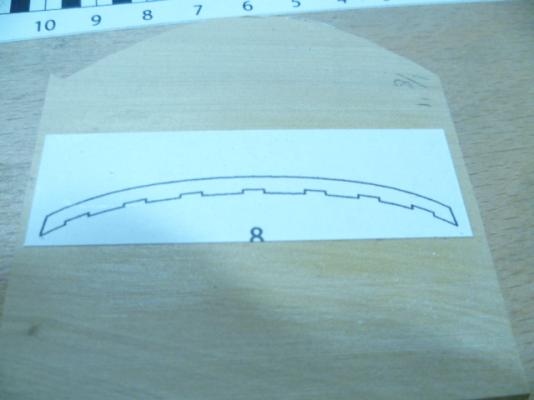

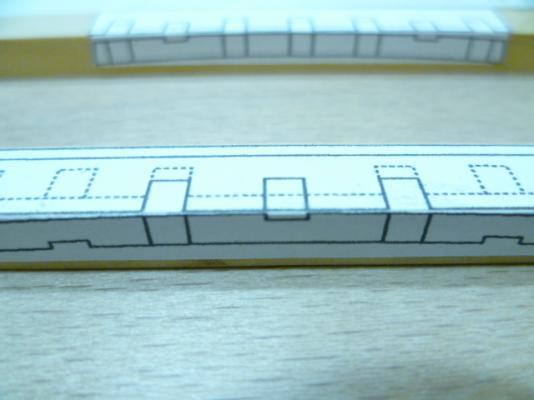

WASHINGTON GALLEY....PART 4.....TRANSOMS TWO UPDATES IN AS MANY DAYS.......BUSY,BUSY.....CANT YOU TELL IM ON PAROLE FROM WORK!!! PATTERNS HAVE BEEN PASTED TO SOME APPROPRIATE STOCK IN THIS CASE 1/4 " THICK,JUST TO ALLOW PLENTY OF ROOM FOR MANOUVER. THE TAFFRAIL HAS BEEN PASTED TO 1/8" INCH STOCK. THE WING TRANSOM HAS BEEN CUT AND SHAPED BUT IVE LEFT THE ENDS UNFINISHED AS YET AS I NEED TO MAKE THE AFT CANT FRAME AND ITS ASSOCIATED HALF FRAME IN ORDER TO SEE HOW EVERYTHING FITS.........OR DOSNT AS THE CASE MAYBE! APART FRON A WEE BIT OF FETTLING IM HAPPY WITH THE FIT OF THE WING TRANSOM TO THE INNER STERN POST. PHOTOS INCLUDED. CHEERS.....MICK

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi carl moon face? mmmm been called worse! best not upload a proper photo that would jus scare everyone! lol......mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Patrick I echo that sentiment!!!!!far more aesthetically pleasing sights!!! Looking at the photos you can see a "score " line where the rabbet is....over exuberant use of a cutting gauge!!! This will be hidden I hope when I fit the garboard strake. Other than the garboard and one plank forward and aft I shall stick to the practicum pretty much. Thanks for the appreciation Patrick....as ever I'm still in awe of your miniature marvels. Cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Carl Transmission should read the transoms.... Blasted tablet is also going to be cosigned to Davy Jones locker as well!! Cheers...mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Carl Transmission are awkward little blighters.....maybe more than one remake! I did try and find the lower part of the stem that I'd previously rejected due too poor fit....but its been confined to the scrapbox in fact Jones locker in a fit of angst! Thinking of changing my moniker to Mick " lovely bum" yamsterman........not so sure the thumbnail would be appropriate for this site !!!! Cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Chuck Yes that is copper you see! 0.6mm copper wire to represent the bolt heads.......I've got some liver of sulpur ready to blacken the heads once the final sanding been done. Cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

hi all the "back bone" is now complete and mounted on the building board. time to make some ribs! first off i will have a go at making the transoms for the stern post......funky little beasts......should prove quite a challenge to get right........plenty off isopropanol in reserve!! photos off current progress enclosed. cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Carl Confession time!!!!! I wasn't happy with the fit of the lower part of the stem too the keel......so out came the isopropanol!!!!! New part made and fitted....now it fits properly to the keel! First redo and probably not the last! Cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Chuck Rebates on the fore and aft deadwood were cut with the Byrne's saw set to1/32 nd inch.once the two outside edges were established the waste was carefully "nibbled" away with successive saw cuts......it leaves a nice flat bottomed rebate of consistent depth any saw marks were removedwith a small fine file. The rebates for the keel were covered in part one...I decided to make the rebates component(hog,rising wood?) As a seperate piece with the aid of a small jig for my mini milling machine. Cheers.....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi all Thanks for stopping by mark and Ken. I'm not sure about learning anything from me!.......I may well be plundering your collective knowledge at some point especially when we get to the fiddly stuff! Cheers.....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Dave Thanks for looking in.might be a sort of self help clinic.....I make enough boo boos during the course of a build! May well be asking for everybody else's help! Cheers....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Patrick Plenty of seats left....I think there a front row seat with your name on if you like! Cheers.....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

-

Hi Carl The jig thingy is called a sled or sledge. It runs on the two parallel mitre slots and is made to be square to the saw cut. Just a piece of mdf and some beech hardwood. You can attach stops to the uprights to enable multiple same length cutoffs,I used the edge of the slot for the saw blade to line up the previously marked patterns on the aft deadwood to cut the rebates....all nice and sqaure and to a consistent depth. Similar sleds are used on full sized table saws in carpentry and furniture making. There's one or two nice examples floating about on MSW. Also keeps those digits away from the blade!!!! Cheers ....mick

- 504 replies

-

- washington

- galley

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.