-

Posts

566 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by FlyingFish

-

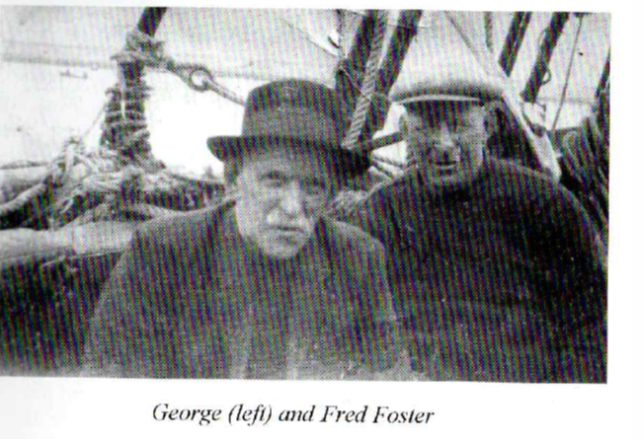

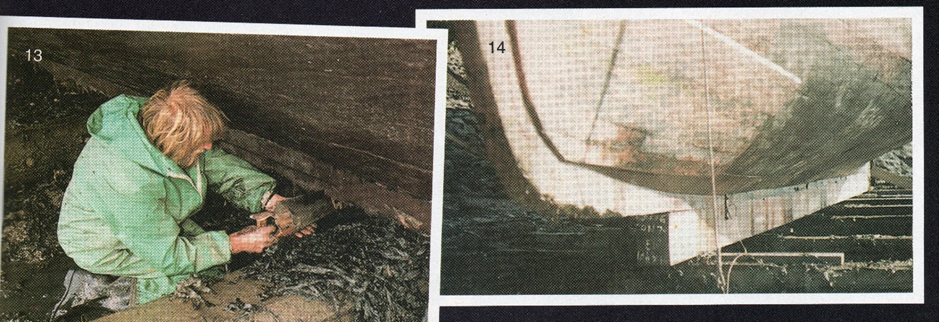

Getting to know Vigilance. The history of the ‘Vigilance’ BM 76 is well documented, so I’ll only include a summary here. Built in 1926 by J W & A Upham’s Yard in Brixham, She was worked out of Brixham and the SW coast of Devon and Cornwall until 1937 by Fred Foster, brother of George who commissioned her. She won the George V Perpetual Regatta Cup in 1933 – she was no slouch. By then falls in fish stocks and competition from steam trawlers forced her into retirement. Upham’s Yard bought her back, and still unused she was damaged in 1938 when a NNWesterly drove her port side into Torbay Lass. After a spell serving in the War as a barrage balloon pontoon she was converted into a yacht and sold in 1949 to William Meldrum and shortly after to Harold Owen and moved to Shoreham on the South Coast. Owen sadly drowned in 1952 from another vessel, and Vigilance was set on fire on the day of his cremation - it’s said by his grieving wife to prevent their son going to sea. Another spell as store alongside, before an Australian bought her in 1955, and somewhat recklessly took her to sea intending to make passage to Australia. She was in a parlous state, considered unseaworthy and towed ashore to Littlehampton by the lifeboat. Enter Ken Harris who crewed for the Australian who later skipped the country. Ken bought her for £80 in lieu of depts he was owed. Ken seems to have been an indomitable figure – single-handedly rebuilding Vigilance over the next 16 years, and on a very tight budget. He lived in the deckhouse onboard. Most frames, the deck most beams, bitts and planking were replaced. When Ken Harris took on the boat in 1955, she had been gutted by fire; the decks were sagging and timbers rotting. Dan Houston writing in ‘Classic Boat’ magazine remarked that it looked like she’d ‘crawled into the Arun River to die’. Ken lived on the boat for the next 43 years making a living on building sites and working on Vigilance in his spare time. It must have been an enormous effort – 19 tons of oak were used, and an uncertain tenancy at the berth with a sceptical harbour authority wanting this eyesore gone. It’s a compelling story, related in detail elsewhere, but suffice to say over that time much of the boat was replaced. Perhaps the most remarkable piece of work was the addition of a slab of greenheart to the keel. Ken used a skillsaw to remove 5” depth of the original; then floated the boat above the greenheart on the tide, with a diver under her directing operations as she lowered down onto the new piece. He moved the boat to Cowes, and somehow found enough work to keep her going, even sailing her to Arctic waters in 1986. Without him, Vigilance would surely be but a memory today. By 1997 Ken was chartering her from Peel in the Isle of Man. Under doctors’ orders to take things easy, he reluctantly let her go to a consortium back in Brixham – she was coming home. The charitable Trust who own her now have done a remarkable job raising funds to maintain and restore her, but time and tide have aged her, and she is now on the slip of Will Stirling’s yard in Devonport undergoing a major renovation. Their websites catalogue a remarkable tale of the passion of her owners and volunteers help who are keeping her alive, and I urge readers to visit (link below) and read more of this story of survival. Some models exist of her – but to my knowledge not a fully detailed revision of her in her original 1926 form, and that is my happy task ahead. https://www.facebook.com/people/Vigilance-of-Brixham/100063526150738/

- 174 replies

-

- Vigilance

- Sailing Trawler

-

(and 1 more)

Tagged with:

-

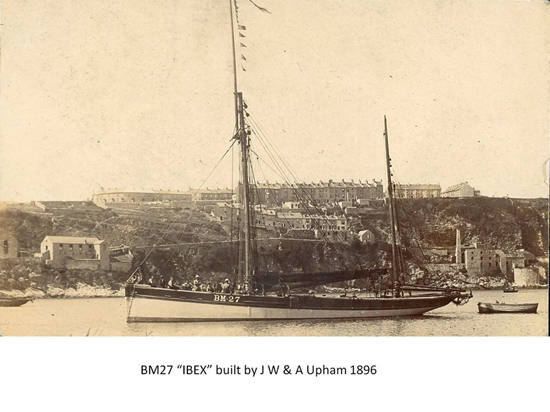

Next Build decision… It’s been a while since the last build, and summer has been busy. Over recent months I have been doing my due diligence, looking for a candidate for the next build. It had to be a fishing boat of course, and this time with sails. Two candidates emerged. Living on the southwest coast of England I turned to local boat heritage. In Falmouth, Cornwall, a handful of boats still work the Port of Truro Oyster fishery, by sail – no power allowed by ancient bylaw. For centuries the fishery has operated in this sustainable way. The boats are being kept alive by a group of dedicated owners and friends. One example of a Falmouth working boats is the 26’ gaffer; pitch pine on elm and oak, built by Alf Smithers and Peter Mayes in 1966. There is something compelling about the tremendous effort the owners are putting in to keep the tradition alive. Added to that it is possible to take a trip on the boat in the summer and watch her at work, as she pulls the small 3’ dredge along the shallow sands. A worthy cause. The ‘Alf Smithers’ made it to my shortlist, and I’d like to build her - or should that be ‘him’? Secondly, I searched through Edgar J March’s book on English sailing trawlers. This well-known and rich source of information includes the second category of boat I have been looking at. I read of the sturdy nature of these gaff ketches or ‘smacks’; built in yards like Upham’s, Dewdney, Jackman, Munday, Furneaux, Chilson and many others. They have evolved to have the power to pull a deep beam trawl, the stability to weather the unpredictable seas beyond Torbay in the Western Approaches and yet the speed to land the catch and get the best price at market. I had read how the design had been taken to the North Sea ports and to Denmark and adapted for the waters there, and how the introduction of steam had eventually consigned them all to history or to be converted into gentleman’s cruisers. However, in their day they evolved a technology for catching fish that was taken all over the world. In the famous fishing port of Brixham, just up the coast from here, a handful of examples remain from the turn of the 19th century thanks to the tireless support of local volunteers: Pilgrim; Leader; Vigilance; Provident - a ‘mule’ class trawler, and Golden Vanity - a gaff cutter known as a Mumble Bee. March’s book has plans of Trawlers which he had measured; the Ibex; the Master Hand, a later boat from Lowestoft, and others. His drawings and thorough lists of scantlings and methods of building have informed some wonderful scratch models of Ibex and Master Hand, some already on this forum. But many of you will know all of this, so I’ll cut to the chase. The Brixham trawler the Ibex caught my attention – there are outline plans; an excellent existing 1:20 scale model by Jan van den Heuvel with a good gallery of photographs; an RC model by Allan Read, and I’m sure many others. Skippered by John Henry Widger for 18 years, she was fast, winning the local regatta in 29 out of 33 races – so many times they gave her the trophy to keep. She came to a sad end, sunk by a U boat in 1918. Brixham expert (and past head waiter on the Queen Elizabeth II) Bob Higginson told me that legend has it that the U boat skipper Kapitänleutnant Ralph Wennenger apparently knew the area from visits to Tor Bay before the war, which presumably is why he had been ordered to the area. Not wanting to waste a torpedo on such a small vessel, he surfaced, and mercifully allowed the crew to abandon ship, before opening fire on the vessel with the machine gun. The crew escaped to safety. The submarine also put down the Addax, General Leman and the Perseverance the same day. Recently a local trawler brought up timbers in her net at the exact coordinates 14 miles S.E. by E. off Berry Head where the Ibex sank. Some had bullets lodged in them. I have a section of her beam timber here by my desk as I write. It’s a compelling tale and building her would be an opportunity to return some of her original timber to a model. Then a local news story caught my eye. A not-for-profit charitable trust in Brixham had been successful in its bid to the National Heritage Memorial Fund for £820,000 to fund repairs to ‘Vigilance’, the last Brixham sailing trawler to be built at Upham’s yard in 1926. She was converted into a cruiser in later life. Her sister ship, ‘Valerian’ (or her original plans) were surveyed by Harold Underhill, and his plans are available to purchase. Models exist, notably one in the Royal Museum at Greenwich in 1:32 scale. I got in touch with the folk that sail the Vigilance today. I wanted to know what differences there were between the two original sister ships, and whether they could help in my research on plans. Tony Bridle the volunteer ‘first mate’ of Vigilance and member of the ‘Friends of Vigilance’ couldn’t have been more helpful. We met in the pub named after the boat in Brixham and poured over the Underhill plans of Valerian I had bought from Brown Son and Ferguson Ltd. Tony understands these boats from a fisherman’s point of view – his family has fishermen going back to the 17th century, and we spoke of how the boat would have been rigged to set the beam trawl, and of the lives of the crew, including the ‘tackers’ - lads who had to help work the sails, coil the hundreds of feet of 6” trawl warp in freezing weather and cook the food all for no wages. Little did I know at the time that the plans would prove of very little help. Vigilance is now hauled out at a shipwright’s slip a few miles from here, under restoration to return her as far as is practical to her original state. With the kind permission of the Vigilance Trust’s Chairman, I got in touch with the boatyard’s owner, Will Stirling. He very generously allowed me to visit the slip to measure Vigilance and catalogue her timbers. Visiting the slip today you are immediately immersed in smell of the sea; of green oak, the trappings of the shipwright at work, and the quiet determination and expertise of Will and his team to restore these wonderful ships. Will immediately offered help in the research should I decide to go ahead. As it happens they are trying to align what they were seeing in front of them with the lines plans they have, no doubt aiming to piece together the many changes and repairs previously done through the years. Next morning, I settled with a coffee and the Times crossword. The first answer I filled in was ‘Trawler’! So, Vigilance it is - you just can’t argue with fate, and the Alf Smithers will have to wait.

- 174 replies

-

- Vigilance

- Sailing Trawler

-

(and 1 more)

Tagged with:

-

Those close up photos show how accurate and tidy your work is - its looking very good!

- 286 replies

-

Printable scale rulers

FlyingFish replied to FlyingFish's topic in Modeling tools and Workshop Equipment

Bob and Phil - too right! I've spent too much time 'calibrating' my printers. I recently changed to and Epson ecotank inkjet, and I have to say it's the easiest yet. Yes, and the culmulative error thing is a problem. I seal mine in a lamination which seems to help. That's true Craig, although knife cuts with a steel rule can be super accurate, and scissors can cut a pencil line in half with a steady eye - the trick is knowing where to cut! Exactly - imagine if they came in thin steel with an adhesive backing for attaching to building jigs? Now that would be exactly what I'm after! Thanks all for your helpful replies. -

Printable scale rulers

FlyingFish replied to FlyingFish's topic in Modeling tools and Workshop Equipment

Prints straight from the pdf to correct scale. Nice job Craig! -

Printable scale rulers

FlyingFish replied to FlyingFish's topic in Modeling tools and Workshop Equipment

Craig, that's very helpful - thank you. I'll fiddle with the print settings. -

Printable scale rulers

FlyingFish replied to FlyingFish's topic in Modeling tools and Workshop Equipment

Thanks Bob, couldn't see a 1/32 scale rule in your links... was I missing something? -

Does anybody know of a good source of printable scale rules - in particular I'm after a 1:32 scale or 3/8th" /ft scale?

-

Great work Nils. The 'taper' works well. Not aware of any tapered brass tubes, and tapering a rod would be expensive on that scale.

- 330 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.