-

Posts

566 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by FlyingFish

-

Hi Marty, Wow! I'm delighted, and very flattered to hear from you - thank you so much for taking the time to comment. It's particularly pleasing to have the original 'Orca' builder complementing the process; I guess you have seen many many models of your work - which is of course the best complement we can pay you! You have inspired so many of us to have a go at recreating the boat, and we all enjoyed (or were terrified by) the movie enough to get involved in the story. You did a great job back then. I'm very pleased to be an honorary member of the crew - I must get a T shirt printed now! Of course you can print the photo - message me with a contact email and I can send the original if you like. Thanks again!

-

Just spent a very enjoyable time catching up on your build. I do admire the way you have gone about the research, and been prepared to go back and change things when needed. The result is spendid!

-

Blimey Nils - you are cracking on with this - great work! The director would have hired you for the movie progress like this! The sheet metal work looks spot-on!

- 330 replies

-

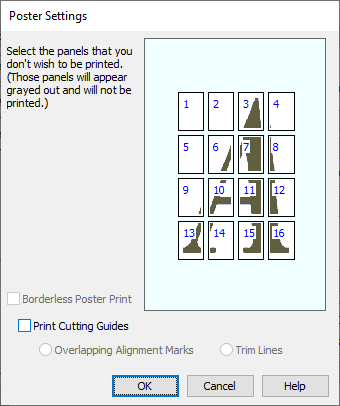

Some national ones do A0 for £1.20 a sheet, folded A4 which seems ok (though I come from Devon which may explain it). I think the issue is more that they will charge more to post in a tube. No doubt you know this, but just in case - my print settings box has the option to print 'cutting guides' for posters which I have found helps greatly with aligning the whole thing.

-

Thanks Keith for sharing a very accomplished and well presented build. The final pictures are a great testimony to your work! Looking forward enormously to the next build, but agree that a little 'pause for thought' is always a good thing.

-

Another approach might be to use thin UV resin to cover the flat area. The surface would need to be horizontal to avoid pooling at one edge. I've used this on instrument panel faces before. Seal with a thin clear nail varnish as it can remain slightly tacky otherwise.

-

Thanks Roger and Wefalk - thats very helpful, I have found myself turning to hotter finer tips on the iron, so I'm heading in the right direction - 950f is a little above my set-up which I think is 450C . I'll get myself a bottle of Bakers Fluid. I see 250ml (a little over 8 oz) costs about as much as a good bottle of wine, but no doubt will last a great deal longer!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.31ae66ac334f7b7d97c002f465f20cbb.jpg)