-

Posts

495 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by bobandlucy

-

-

- oneslim, Ryland Craze, CaptJoe and 3 others

-

6

6

-

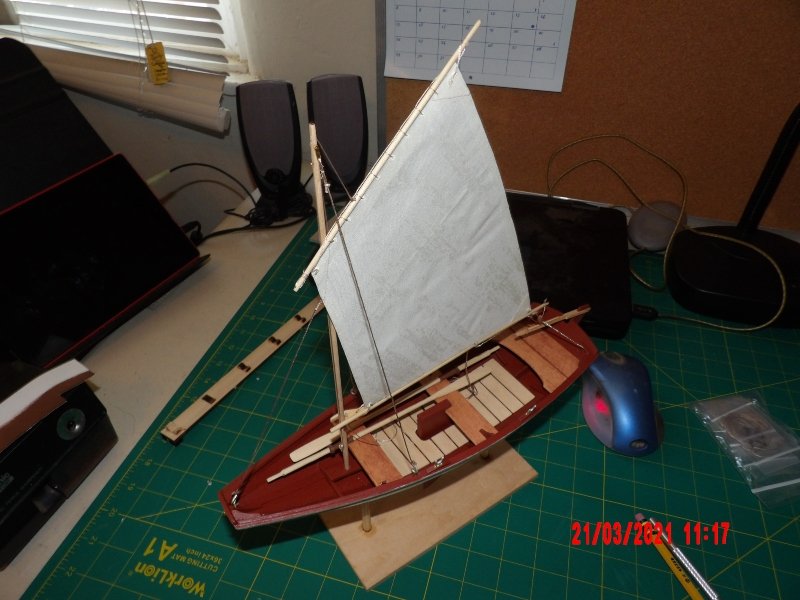

Rigging is done. Brutal, but fun. I was trying to get the sheet line through the middle eye on the boom (where I had broken it) and it broke again. I did an in-place repair, as I could not see starting over. I was able to CA glue it back together reasonably straight, but it is more visible than before. During this operation I spilt a good blob of CA onto the hull interior, and did not notice until it had dried, and anyway my hands were occupied. I don't know if I will attempt to correct. Sometimes it's best to walk away for a while. I think artful placement of the oars may obscure this (to all but myself), or maybe I can make something, a bucket or picnic basket or whatever, to set in front it. I also lost the brass eye to the break, but had some small eyebolts and put one in the remaining hole. A little out of scale, maybe. . .

The manual calls for passing the traveller line through holes in the stern transom knee. This is a typo, should have been stern quarter knee, but there were no holes. No big deal to drill them. There is a hole in the transom knee, but it is unused.

The boom hit the rub on the mast, but a little high- that's the end result of my not adding a stop to the mast step. I tried to improvise, but saw potential for damage, so the mast is resting on the floor.

I wired up the block for the traveller upside down, the hole for the rope should have been at the top.

I can also see that the under sizing of the sail (see earlier post) left more mast exposed above the sail, but it's probably no more than 1/4 inch extra.

I just have to finish the oars, and coil the ropes and glue them to the floor. I'll make one more post at completion and call it good.

I can recommend this kit to other beginners, after they have completed the dory. I bought all the necessary tools and some of the optional ones, and used them all. The jeweler's broaches are a must-have, and they are beautiful little things in themselves. The techniques taught in the manual will serve well into the future. I learned so much, including terminology and some history. Based on my experience with this model, I ordered the Muscongus Bay Lobster Smack yesterday.

- G.L., druxey and Ryland Craze

-

3

3

-

Very nice, both the figurehead and the anchor!

- Shore thing, thibaultron and Canute

-

3

3

-

-

Thanks, Bradley! Great diagram.

-

Butterball, to the best of my understanding the bevel lines should marry to the next plank. Consider the curvature of the frames. Without a bevel on one side, you'd not be able to meet the lines. They kind of overlap, but it's not a full overlap. I know this is confusing. If I had the means I'd draw a picture. There are pictures and explanations somewhere on this site, I've seen them, can't find my way back at the moment. Draw yourself a picture, I wish I had, exaggerate the curve of the hull, draw the planks in cross-section as flat, and you will see how it goes.

I hope a seasoned vet will jump in and help you. I I find something in the meantime, I'll be back.

Bob

b

-

-

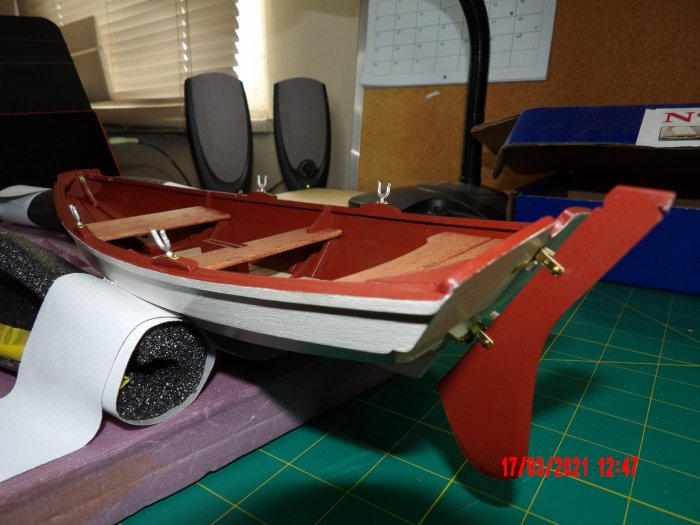

It was a tough day in the hobby room (Sleepless night), but it started well. I put the recommended clear satin coat on the exterior. I am happy with the result:

Then I assembled the tiller. Tough going there. I broke one of the pre-drilled holes in the tiller side pieces while trying to perform the riveting. I could not get the 1/16" hard brass rod to mushroom as described, the rod bent and caused the break. I think that I should have paid more attention to squaring the clipped ends of the rods, and it's also possible that my hammer was too light. I did a repair with CA glue. Then I forgot to drill the hole in the tiller extension piece, and had attempted to rivet it to the tiller arm, where I broke this hole as well. I saw pretty quick that I would not be able to drill the hole, and decided against doing so. During my CA repair, I accidentally glued the extension to the tiller. What a mess.

I'm thinking of filing a groove and attaching the rod to the extension that way. I know the preferred method of display would be to show the extension slightly to one side of the tiller, but of course, can't do that now. . . BTW, the instructions call for the grooved slot in the transom to be filed with a 3/8" round file, which I purchased, but the laser lines show a much narrower slot.

Next I did the eyebolt and bow stay, no problems there, but gosh the piece of tubing to simulate a hex nut is tiny, and I kept losing it once cut. Heads up, the instructions to anneal the tubing come after this installation and seem to apply to subsequent steps, but you will need to soften the tube before cutting.

I do understand that I should have filled the gap towards the rear of the sheer plank, I think I thought that the paint would fill them. Lesson learned, Fortunately, this won't be real visible in the finished, stand-mounted model.

-

Thanks, Gregg

I thinned the paint a bit with water. It took 8 coats before becoming opaque all over. A little tiresome, but I do like it when each coat is progressively smoother and easier to apply.

I used Minwax pre-stain conditioner and Red Oak stain, followed by Wipe-On Poly.

-

-

Painted the outside of the hull. 8 coats! The line where the two colors meet is not as crisp as I would have liked, but is not bad enough to obsess over.

After obsessing over this for an hour (haha), I went back in to see if I could make this neater. BTW, I caused this problem by masking before painting the hull exterior, instead of taking the author's advice and simply dragging a flat brush at 90 degrees to the edge. I did improve it using this method, but think further work would be detrimental.

.jpg.b2101998e96a31b59446eff07a1ed379.jpg)

-

8 minutes ago, GGibson said:

Interior paint work looks very nice, Bob! I learned on my Pram (as I'm sure you did on your Dory), keep that paint handy, as you will now continue to find little spots that you missed or just don't look quite right. I continued to "touch up" practically for the remainder of the build! But it looks very nice! And you will find that the seat installations will help hide some of those underneath concerns. Enjoy!

Thanks, Gregg. Yeah, it's funny how a photo will reveal flaws unseen with the eye. . .

- Ryland Craze, druxey and GGibson

-

3

3

-

I have painted the interior. I put a lot of effort into painting the area that is essentially hidden by the floorboards, but could not help but try and make it perfect. The instructions are to do the exterior next, but I needed a break from painting, and decided that there was no reason I couldn't install the floorboards. I left them unfinished per the instructions. I should have centered each array between the thwart frames, but did not, and am left with exposed cleats at each end of each run of boards. I feel that this will be less noticeable when the thwarts and stern sheet are in place. I am thinking I'd like a third color element in the interior on the thwarts and stern sheet and may just use a light red oak stain as I did on the Dory.

- druxey, Matt D, Ryland Craze and 3 others

-

6

6

-

Looks good, Gregg! You just clued me in on a mistake which I also made. I only have two rowlock pads also. The instructions do not call out 4 pads, just that they be installed at 1'-6" aft of the forward thwart frames and does not mention doing the same at the amidship frames. But the pictures of the completed boat do show them. I have already applied primer, I suppose I could sand it off and glue in another set, or maybe just stick them on with CA glue, or not add them at all. Decisions. . .

Congratulations!

-

Thanks, Gregg, I am painting now. It's difficult to do by hand inside the boat. I look forward to the challenge of the metal work.

Bob

-

- Ryland Craze, G.L., kuya and 1 other

-

4

4

-

On 2/27/2021 at 5:07 PM, kurtvd19 said:

The rigging line in the kit is better than the typical kit line but I got spoiled with Chuck's rigging line. There is no comparison between Chuck's line to any kit's rigging line.

However, if I had known that Chuck was dropping the rope I probably wouldn't have mentioned it. In fact I have now edited out that sentence.

Thanks very much, Kurt

- Canute, thibaultron and mtaylor

-

3

3

-

Kurt, what is the reason one might want to replace the rigging lines?

Thanks, bob

- thibaultron, mtaylor and Canute

-

3

3

-

I glued in a replacement mast step after breaking the supplied 2 piece stacked assembly. The bottom piece was described as having no hole, to serve as a stop for the mast, but both of the kit's pieces had holes. Since the wood grain ran in the short dimension (oddly), the assembled part was very weak in the area of the holes. I made a single-piece step from scrap, with the grain running in the long dimension. I blew it and put the hole through, but I can deal with that later. Update 3-19: Don't deal with this later. Put in your stop before gluing the step down!!

I had to remind myself to breathe as I made the chain plate slots in the inwales. Using the recommended drill size, I could not get the sawblade through the inwale. I drilled a line of holes along the length of the slot and began cutting and chiseling with an Exacto blade. When I had broken through, I then used the sawblade to neaten and square the slots. So glad I did not create a mess.

Shoot, I blame myself as I have the parts on hand- just read on another log for this model that the 2" scale lengths for the chain plate slot per the printed instructions is wrong as the plates are 1" wide. And so they are. Now I have to decide whether to add filler on the top of my pristine inwales, or just live with it.

- Arild Moland, Ryland Craze, ubjs and 1 other

-

4

4

-

She is free of the building board! Glued in the quarter knees, dagger case, and internal frames. I found these parts difficult. Will have some gaps to fill, and I can see that material might have to be subtracted at some support points for the thwarts and stern sheet in order for these to sit nicely. I have done a better job controlling/removing glue squeeze out this time. Getting close to painting of the hull, which will take me a while, going by my experience with the dory.

-

-

-

Finished planking. Naturally, the side planks were more difficult to fit. Ended up beyond the intended line at the rear transom and will have to increase rear transom vertical dimension to compensate. I was very careful, but failed to hit the mark in all respects. This is the best I could do at this time.

-

- Ryland Craze, GGibson and ubjs

-

3

3

Norwegian Sailing Pram by bobandlucy - FINISHED - Model Shipways - Scale 1:12

in - Kit build logs for subjects built from 1901 - Present Day

Posted

Thanks much, Gregg and G.L.!

Bob