-

Posts

3,170 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gregory

-

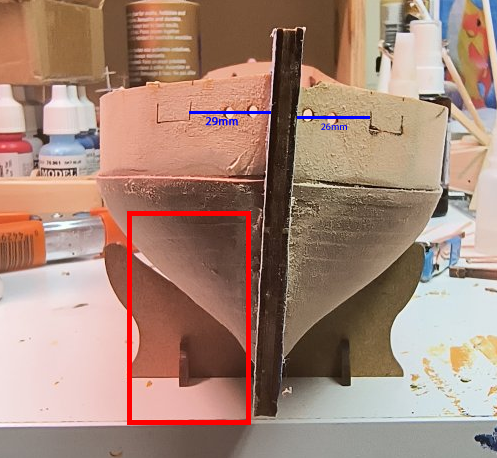

Somehow I twisted my hull

Gregory replied to CJensen's topic in Building, Framing, Planking and plating a ships hull and deck

The stem is not square to the table or the camera. The perspective is skewed. I don't see any reference on the transom to show me where the problem lies -

Somehow I twisted my hull

Gregory replied to CJensen's topic in Building, Framing, Planking and plating a ships hull and deck

If the hull really is twisted, (bent, warped ) by a noticeable amount, the only resolution would be to do it over. The problem is not really that apparent to me from the image above. On what plane is the hull " twisted" ? The stem is not square to the work table, or perpendicular to the line of sight. A straight on view where the deck is visible might be provide more information. What do you see if you sight along the keel itself? Do you have an image like that above, but with the hull inverted? -

The wood for the strips and the laser cut parts could have come from different trees. There may be different trees represented just among the strips, or at the least different parts of one tree. The only reasonable assumptions you can make about the color variation with age, among several pieces of wood, is when you know it was milled from the same stock.

-

A search for "black prince" does return one build log . If you have any specific questions, I'm sure someone will try to help.

-

If that information is not included in the plans they do not appear to be very useful for building a model ship. Have you considered getting a kit? The contents of a kit will give you a good idea of what is required in the way of plans, material and instructions to build a model, even if you decide to go ahead with a scratch project. You might take a look at some of the kit reviews here to see what is required to build a ship model. Here is a log where James builds the prototype for HMS Harpy, a Vanguard kit. It will give you a good idea of what materials are needed even if you make the parts yourself. You can also see how the plans and instructions show how things should look.

-

The plans do not show anything? Usually, with a POB model there are instructions for 'stepping' the masts and bowsprit. Without seeing your drawings it would be difficult to suggest anything. You could look at just about any kit build log to see how it is accomplished. There is usually an opening in the deck and some type of cut-out in the backbone to locate the masts in their proper position.

-

The Fiebing's is alcohol(ethanol?) based but I seemed to have gotten pretty good penetration. I would suspect the formulation might be different across intended applications. One caveat to keep in mind is that DrPR talked about using shellac on some of his block rigging and the dye was bleeding into the rope. Not a problem if you don't use shellac.

- 714 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

OK that brings up my next observation. I never cared for the bright look of Syrens boxwood blocks, but there was not any alternative that came close to the shape/quality. Myself and others found that the boxwood did not take traditional wood stains very well. I experimented with Fiebing Leather Dye .. Just another option you might consider. The difference in color here is the lighting. With hindsight I would have polished them a bit more. I would like to get more of the look I see on contemporary models.

- 714 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

Are those the newer Printed blocks from Syren?

- 714 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

Mini Table Saw recommendations

Gregory replied to captainscott's topic in Modeling tools and Workshop Equipment

I’m at a loss by what you mean by “thick” . What are the dimensions of the stock, and what do you want to end up with? -

I just cut a 1/16 strip from a 1/4 sheet of cherry with no burning. This is with a Proxxon FET and a Malco .03 blade 3" 90t. ( CT303012000) It's a fairly used blade, but mostly for basswood strips. I noticed this piece of cherry was well seasoned and not particularly aromatic as it can sometimes be. I suspect if it has more sap it might have more of a tendency to scorch. I don't know if I do everything properly, but it works for me. I try to keep pressure against the fence right in front of the blade and avoid putting pressure on the blade itself. I keep the blade fully elevated for maximum tooth contact with the wood. I have had burning/scorching problems, but mostly with harder woods like mahogany and walnut, and older blades.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.