-

Posts

3,170 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gregory

-

I think your best go-to would be the build by JLong. A lot of stern detail shown here: Your model looks like the original builder decided a different approach than what the plans called for. To get it right you may have to tear some of that out to do it right. Do your plans include the detail like this, from the log I pointed to above?

-

deck planking options

Gregory replied to manning16's topic in Building, Framing, Planking and plating a ships hull and deck

I think boxwood would give a nice contrast . The holly is too bright for my taste. Do a little testing and see what you like best. -

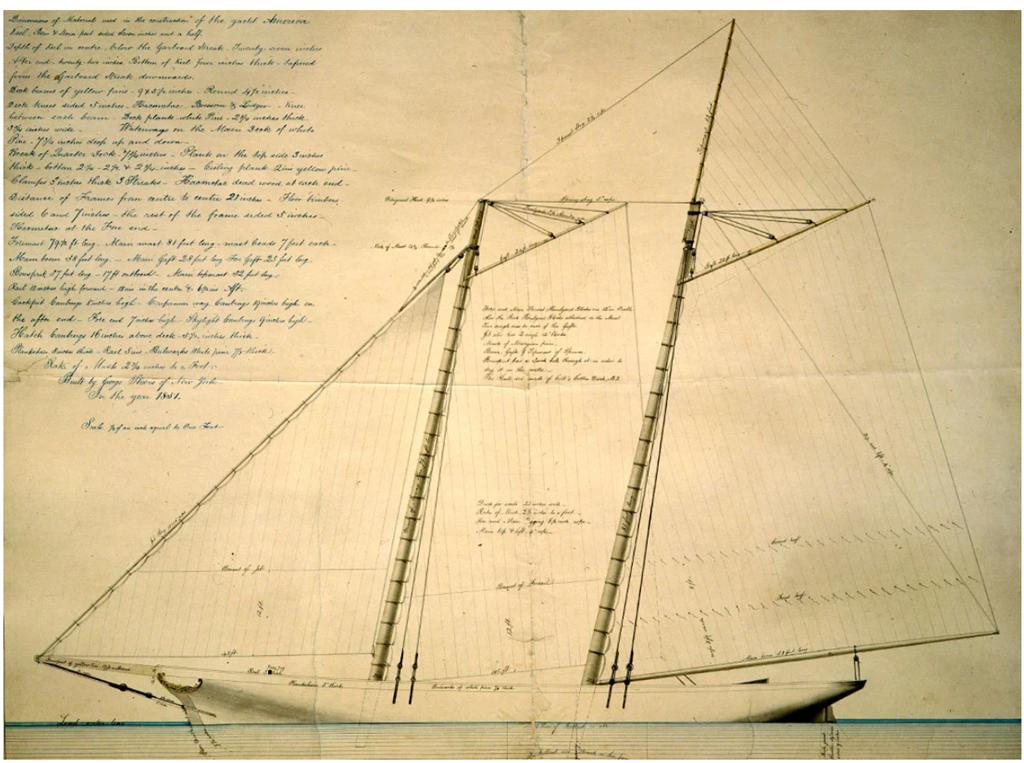

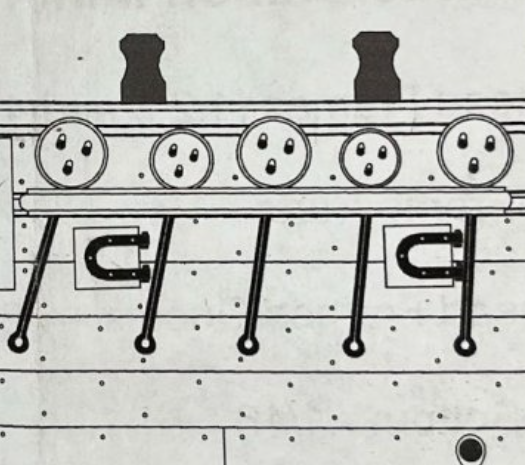

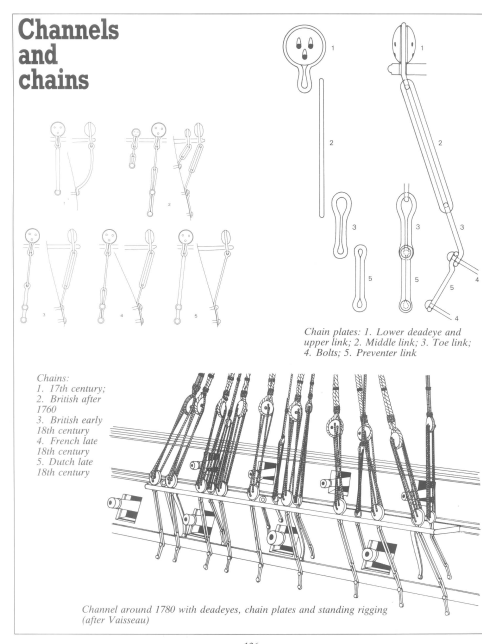

FWIW, here are the chain plates in the Campbell drawings. I feel Campbell can be taken on good authority. I think the kit provided parts really compromise the quality of your build. The look above could be achieved with some annealed steel wire. My best guess would be 22 gauge. This little snip from the Speedwell plans by Chuck show how simple they could be. PS Here is a drawing I found from a Museum in San Francisco

-

The plywood I last used was this stuff from Amazon. I don't know if it is available to you in the UK, but it is very good quality. I used it for the bulkheads on my Rattlesnake. I checked my notes and I'm actually using 75% power at 5mm/s. I do know it took a lot more to cut typical plywood from stores like Home Depot here in the US. Your eBay store really looks nice.

-

I can certainly appreciate the price limitations. Do you have air asist? It makes a big difference in cutting power. Multiple passes should not make the kerf larger. I can cut 5mm plywood in one pass with speed at 5mm/second and about 90% power.

-

I'm using an Xtool D1 Pro 20W with Lightburn software. Ventilation is a must with a laser. If I were buying today I would get one of the Xtool S1 machines. Probably a 20W. If you skim through my Resolution and Rattlesnake builds you can see how I have put it to use.

-

Revell ?

-

Very interesting machine that appears to work very well. People should click on the video. Video here..

-

Do I get a solve for that? 😁

-

Maybe a place like this. Weavers's Leather Supply I don't see anything particularly expensive though. Keeping it sharp may just be an issue of maintenance. If you want to spend more, you could check out a surgical supply place. What do you mean by ' Micro ' ? A good micro awl could be a sewing machine needle fixed in a wood handle. It would probably stay sharp for a long time, while being cheap and easy to replace.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.