-

Posts

3,170 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gregory

-

Unknown Royal Yacht kit.

Gregory replied to Lucius Molchany's topic in - Kit build logs for subjects built from 1751 - 1800

Why is it banned? We don't ban kits just because they are of Chinese origin. Do we know it is a knock off of another kit? I didn't see another match. -

Unknown Royal Yacht kit.

Gregory replied to Lucius Molchany's topic in - Kit build logs for subjects built from 1751 - 1800

On 2nd look, has a lot more bulkheads than the Mamoli kit. Still looks like a similar design. I found this which looks like a good match. Free Shipping Scale 1/80 The Dutch Royal Yacht Wooden Model + Brass Upgrade Parts+ Alloy Anchor - Model Building Kits - AliExpress -

Unknown Royal Yacht kit.

Gregory replied to Lucius Molchany's topic in - Kit build logs for subjects built from 1751 - 1800

Looks like Mamoli kit Mary. Check the link in my signature.. -

Occre VS Artesania dyes

Gregory replied to Johngr's topic in Painting, finishing and weathering products and techniques

I like the Artesania oak. It reminds me of a shade called “golden oak “. I’m not seeing much difference across the sapele’s and walnuts. I think it’s a matter of what you prefer. Because of the differences in display devices, we will all be seeing different shades. You will see as much variation across actual pieces of wood. -

I’m looking forward to your next project, whatever you decide.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

FWIW, just got spammed with an add from Temu with what looks like Innocraftsman's $78 belt sander. Temu's price: $39.68. Their $269 mini lathe is $145 on amazon. Here is the topic where the mini drill press was discussed. It's currently selling for $83 on Amazon. That discussion led me to buy this: Mini Drill press I reviewed it here:

-

Byrnes Alternatives - Saw and Thickness Sander?

Gregory replied to Jcredding's topic in Modeling tools and Workshop Equipment

Love my FET. The Proxxon branded saw blades will bankrupt you though. There are some decent alternatives, so check back if you need some help finding them. -

Please note who posted post #9. I guess you are not familiar with how the forum works. Post #9 was made by me, in which I provided a link to another discussion on this Forum that was started by DrPr over 5 years ago. It also contained a lot of other information about gun rigging, recycled as it may be. We share a lot of information by 'recycling' relevant discussions, instead of trying to answer the same questions over again. In addition to Henry's excellent answer, consider how much tension was on that hook when the gun as run out; it couldn't have been unhooked without loosening the tackle, which wouldn't have been a good idea on a rolling sea. That might be a good point to bring up at " the other Forum ".

-

What linked blog are you referring to? Dr PR hasn't posted in this discussion. My links are to discussions in this forum, one of which had 126 replies. Those discussions contain contemporary documents and informed research regarding your question/s. This is not the first time these questions have come up . A search for "gun tackle" returns 439 posts. Showing results for '" gun Tackle"'. - Model Ship World™

-

I don't feel like giving a review of this at this time because it had obvious problems out of the box, and I don't want to take the time to give it a thorough work-out. The variable speed control was loose, and though I was able to tighten it up, the speed control didn't really work. There were dead spots as it was rotated. Overall it seemed well made for the cost, but the quality control was obviously lacking. It was Amazon Prime, so I am going to request a replacement and see what happens.

-

Quite a lengthy discussion here: This is how dafi has rigged his Victory, and I know he has done a lot of research. We have had other discussions about rings which are difficult to find documented explanations, however they appear on many examples. There is speculation that they may be for lifting/moving the gun about. Here is another lengthy discussion.

-

Don't be afraid to use a bit more coarse for fairing. 180 or so. If you think you will be doing more of this going forward , here is a great item to have.: Soft Sanding Blocks. I also really like Dura Gold adhesive backed sand paper. It has virtually no clogging in a wide range of grits.

- 84 replies

-

- half hull planking project

- NRG

-

(and 2 more)

Tagged with:

-

It looks more like a mass produced decorator model rather than a kit.

-

Posting photos in build log problems

Gregory replied to Desertanimal's topic in Photographing your work. How to do this.

Google for a .HEIC converter. There are free ones out there. Is your PC Windows? You can open in Windows photo viewer and save as .jpg. -

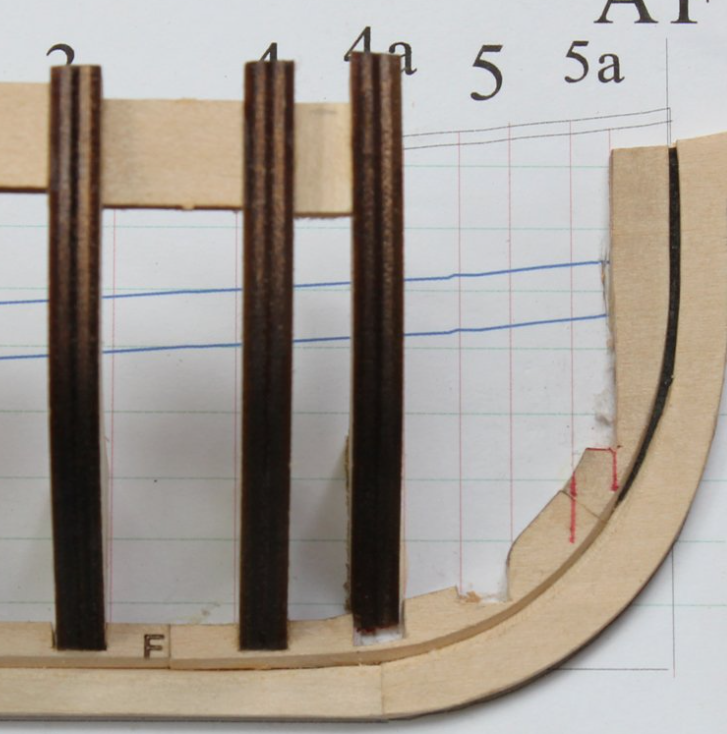

I see the same issue on Toni's log. She doesn't mention it. I think you should be able to just forge ahead without doing any trimming, without affecting the final outcome. But of course that is up to you. Looking ahead in her log, I still see a small deviation there at 4. So I think you will be good.

- 84 replies

-

- half hull planking project

- NRG

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.