-

Posts

3,168 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gregory

-

Have you considered using drill bits to make uniform eyes and rings? That said your work looks really good so far..

- 714 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

@vossiewulf I think this recent post by DrPr gives a good idea about how rigging and mast/yard dimensions was established by the riggers. It doesn't help with the configuration of spreaders and other details, but I think following what you see on a contemporary model is a safe bet. If they are different, it doesn't necessarily mean one is wrong.

-

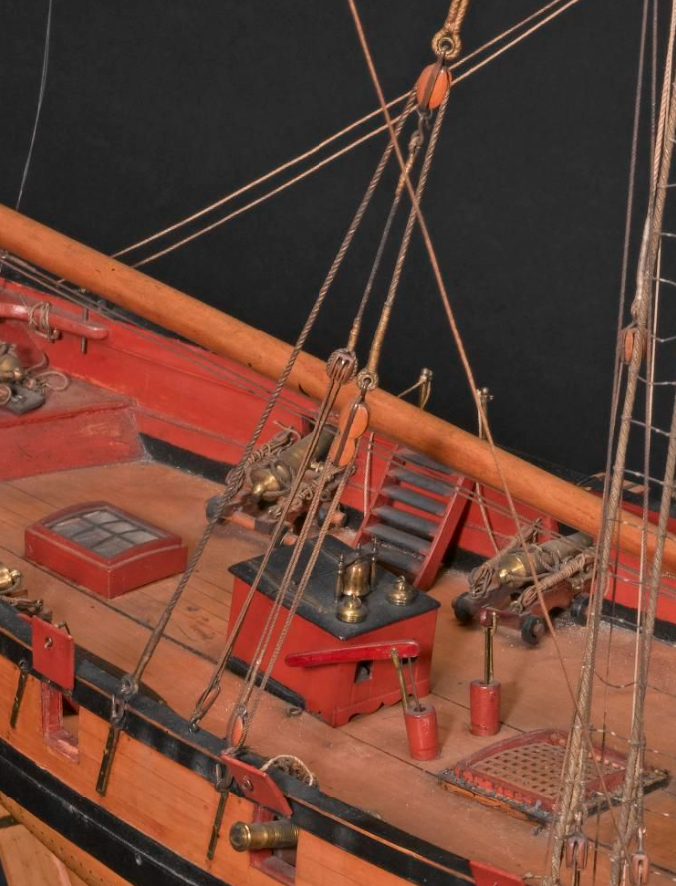

Here is another curious observation about the images in the Science museum. The image on the far left has water line markers and you can see shot in the shot garlands. The other two images show no waterline markers, and instead of shot you see a powdery residue and there is also a chip out of the keel that has been repaired in the first image. FWIW , I suppose we are looking at some restoration work in the first image. I think the first image has an over-all cleaner appearance.

-

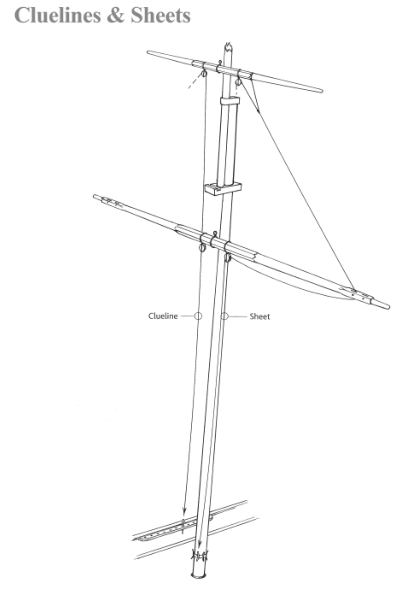

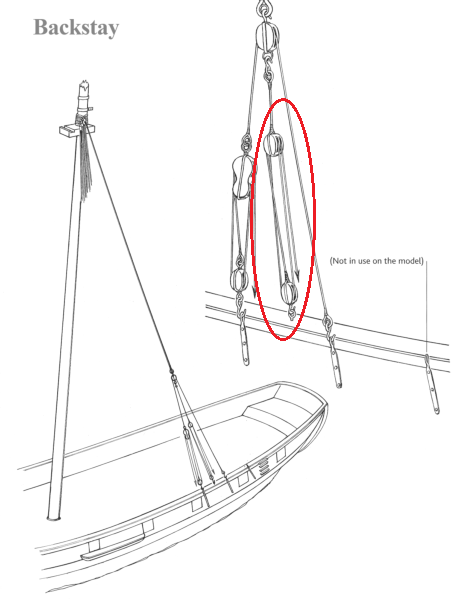

I think the inconsistency is a matter of method for the riggers of the time and how a model builder chose to model it. The mechanics of sail handling are well established across the type of sail whether cutter or frigate. It remained the same for a couple hundred years. The details that changed was mostly about where a block was tied off or how long a pendant was, etc.. The rake/height of a mast the length of a yard and the number of yards could be changed by the master of the boat. Paintings are probably a good source for what worked in that regard. There is a lot of variation across the several cutter models in the gallery, but the necessary ropes/lines are all there. I don't think you can go wrong by mixing the features you like. I like the simplicity of four shrouds (Cheerful), but I also like the look of the extra tackle on the backstay. I think the two sheaves in the lower yard add extra work that I can do without, and the instances of one sheave are well documented. My council would be to not get bogged down in minutia that has several different, right ways of doing it, as it can really take the joy out of the journey. The answer to those who say Petersson got it wrong, is that whoever rigged the model got it wrong, if indeed they did.

-

Here is the information I posted in Oakheart's Speedy log. I found the model that Petersson derived his drawings from: Rigged model of a late 18th century naval Revenue Cutter . The pictures are very high resolution and provide some interesting detail. As we discussed above, It looks like the main stay does go over that collar as shown in his drawing but it looks more robust than the apparent band in the drawing with the actual band being below the collar. The stay itself has a lot of parceling and serving, so it looks workable as shown on the model. The double sheave on the lower yard is apparent, but the Petersson drawings doesn't show the purpose of the outboard sheave. I traced the line to a block at the top of the mast, and can't really tell where it leads down at the mast. I can't make out where it goes from there. I will take a closer look. The other end of the line is hooked through an eyebolt at the channel. I'm at a loss as to the function of this line. I questioned Chuck about this tackle shown by Petersson on the backstay when I was using the Cheerful rigging for my Resolution. Chuck said it was just wrong and didn't belong, and indeed it's not present on the Cheerful model. However, it is clearly present on this model, and I'm thinking it may a working/loading tackle. There is a lot of detail to be gleaned from those images at the Science Museum, and gives the opportunity to be a little different from all the other cutter models, while still being accurate as far as the contemporary model builder was accurate.

-

I found that Model: Rigged model of a late 18th century naval Revenue Cutter . The pictures are very high resolution and provide some interesting detail. As we discussed in another topic, It looks like the main stay does go over that collar as shown in his drawing but it looks more robust than the apparent band in the drawing with the actual band being below the collar. The stay itself has a lot of parceling and serving, so it looks workable as shown on the model. The double sheave on the lower yard is apparent, but the Petersson drawings doesn't show one of the sheaves being used. I traced the line to a block at the top of the mast, and can't really tell where it leads down to at the mast. The other end of the line is hooked through an eyebolt at the channel. I questioned Chuck about this tackle shown by Petersson on the backstay when I was using the Cheerful rigging for my resolution. Chuck said it was just wrong and didn't belong, and indeed it's not present on the Cheerful model. However, it is clearly present on this model, and I'm thinking it may a working/loading tackle. There is a lot of detail to be gleaned from those images at the Science Museum, and gives the opportunity to be a little different from all the other cutter models, while still being accurate as far as the contemporary model builder was accurate. Tim, if I've cluttered up your log too much, let me know, and I can move this stuff over to the topic where we discussed Petersson's drawings.

-

My bad on Halifax. I seemed to have got lost in what seemed to have been the thrust of the original 1st paragraph and the title of the topic. If we go beyond the revolutionary period there are quite a few models available.

-

The Lumberyard has Alfred and Halifax. There is a Mamoli Halifax. Don’t forget Rattlesnake and Confederacy. The other named ships were not contemporary with the revolution. Regarding the OP, I believe there are more kits of Continental ships than British that notably participated in the Revolution, unless some of the Vanguard kits fit that niche. The American Revolution ended in 1783.

-

There have been several errors pointed out in this book, and I am in no position to critique it with any expertise, however, as I have pointed out before , Petersson is an artist and not a rigging authority. He drew what he found on a model with no apparent reference checking. I could be wrong but I have to believe what looks like a stay on top of that metal strap has to be wrong compared to actual practice. Who knows why the model builder did it that way.

-

FWIW, I have found that wrapping wire around a drill bit is the best way to get consistent size eyebolts, rings and hooks.

-

I’ve found that it’s easy to snap off the back end of the scalpel blade so it fits the #11 handle.

-

Great to have you back. I like Petersson’s book, but it has it’s critics, keeping in mind he copied what he saw on a model. I don’t think you can go wrong with Chuck’s Cheerful as a guide. You can download the instructions on Chuck’s Syren Ship Model site. Chuck’s and Glenn Barlow’s Cheerful build logs are great “go-to’s”. You could also do well to look at Thukydides Alert.

- 714 replies

-

- lady nelson

- victory models

-

(and 1 more)

Tagged with:

-

You might also consider Cornwall Model Boats. Their shipping charges to US are surprisingly competitive with US shops, and their pricing on European kits are discounted considerably compared to US prices.

-

Well, they have a presence on the forum.. You could ask them. Artesania Latina - Model Ship World™ OcCre - Model Ship World™

-

Zero Clearance for Table Saws

Gregory replied to DelF's topic in Modeling tools and Workshop Equipment

Interesting. I posted a topic a while back about using tape for O clearance with my FET and drew some criticism. However, I have continued using it, and find it very effective. It’s'not like we are sawing 2x4’s on a 10” table saw.- 12 replies

-

- Zero clearance

- table saw

-

(and 1 more)

Tagged with:

-

Kit review 1/50 - HMS Supply - Artesania Latina - by Kevin

Gregory replied to Kevin's topic in REVIEWS: Model kits

With all the excellent work you are doing with Speedy, I have to believe some sail making is in your future. Take a look at what DrPr is doing with Albatros. -

I mainly use CA, so I don't think I have any innovative clamping ideas beyond what can be found here. The main challenge is clamping to a curved surface and not marking the wood. Once you solve your clamping challenge you might consider the Titebond Speedset glue. It only needs about 15 minutes clamping time. I have had good results with it.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.