-

Posts

654 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Jay 1

-

Tim, she's looking really good--nice to see some chips fly, too! You were sort of in my neck of the woods--Mesa Verde is a wonderful place, and this is a good time to visit (cooler weather). I'm glad you had a wonderful holiday! Jay

-

Sam, I didn't see it at 1st--was thinking of how I used to use them as intended for installing/removing circlips--but ones with long nose posts would be able to do what Stelios described...methinks I'll be digging my circlip pliers out and giving this a try! Jay

-

Thanks, Sam--yep, that makes sense. Just couldn't see circlip pliers working out... Jay

-

Your windlass looks really great, Gregor; likewise, I like your chimney and mast step--very nice! Silver soldering isn't as daunting as it may look/seem (Russ wrote a good tutorial in the downloads section)--the hardest thing sometimes is figuring out how to make a small, fiddly piece. Jay

- 210 replies

-

- Sherbourne

- Cutter

-

(and 5 more)

Tagged with:

-

Sounds like things are coming along well with the rigging, Kimberley--good to hear! Crochet hooks and other similar items make great rigging tools--your arts and crafts background is definitely paying off for you! Jay

-

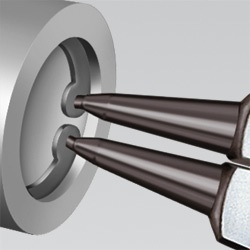

Stelios, I like your method--very nice! However, I'm a confused about the circlip pliers. Could you post a photo of the ones you're using, please? The type of circlip pliers I'm familiar with have 2 posts at their tips--like the picture below--so I'm having a hard time seeing how this type of pliers can make such nice ovals! Cheers, Jay

-

You're welcome. Your arts and crafts background will be a big help! There's a lot to learn with ship building--I'm also learning a ton, too. Plus, this is a great community of teachers--there are incredibly talented people with a wealth of knowledge here on the forum! I think that's one of the big reasons why I enjoy the hobby as much as I do. Jay

-

GS-hypo, watered down fabric glue, and etc. are good choices for your knots. CA (superglue) can create a number of problems, so most builders avoid using it. Also 100% synthetic string is a bear to work with--it slips, stretches, is hard to tie or make coils with, and so forth. DMC brand thread is one of many nice choices--you'll likely get some different input here. Chuck P., MSW admin and owner of the Syren Model Ship Co. (link on forum contents page), sells very nice rigging line--highly recommend it! Also before you rig, pre-stretch the line you plan to use. There are many ways you can do this (I tie heavy wrenches to both ends of the line I'm going to use and then drape it over a coat hook high on a door for a day or two). Also, a 3rd hand or two are also very helpful and worth the money (http://www.amazon.com/Third-Hand-Soldering-Tools-Magnifier-Loupes/dp/B000VB6HSM). Hope that helps, Kimberley! Jay

-

Hi Kimberly and welcome aboard! Here's a great animated knot tying web site--many are actually videos--that will show you exactly how to tie the knots... http://www.animatedknots.com/knotlist.php?LogoImage=LogoGrog.jpg&Website=www.animatedknots.com Good luck on your build! Jay

-

I very much enjoyed reading everyone's thoughts on the plans, hearing about your research, and trading ideas! My plans just arrived today from the NMM, so will study them closely in relation to everything we've been talking about. Gregor, I read the same about some of the Sherbourne plans recently--some may have been training ones; I just can't remember where I read that to cite the source (old age... ). I'll also be looking at some of those other 1763 plans a bit closer now that I'm ready to move forward with my build. I also agree that plans don't have to be followed with total faith. I'm sure the ship's look, fittings, and etc. were changed over the course of their active lives (I know many ship captains would change a ship's rigging to suit their tastes). I also suspect many beginner kits (at least the kits by good companies like Caldercraft, Amati, and etc.) get some modification by designers so that they are easier builds for new builders--sort of make sense. In the end, they're our builds, so we can do what makes us happy and makes a nice model! My only big complaint with kits is when they design them with bad mistakes and not fix those problems--it makes building them very difficult. I ran into this with an Artesania Latina kit--many things were just very messed up with the kit's basic design so that building it was very difficult, as a result I'll never build another one of their kits again. Sumner, that's a beautiful view you have! Guess I could deal with that altitude on beautiful days! Wow, 3 elevators...I won't complain about my ride times anymore..lol! Jay

- 57 replies

-

- caldercraft

- cutter

-

(and 4 more)

Tagged with:

-

Essex - Process and corrections to the new Model Expo Kit

Jay 1 replied to samueljr's topic in Wood ship model kits

Sam, I think we both feel the same about sails...in their non plural form they are a 4 letter word! LOL! Jay -

Essex - Process and corrections to the new Model Expo Kit

Jay 1 replied to samueljr's topic in Wood ship model kits

Sam I've been quietly following most of this about the Essex for a while now. Kudos to you and ME for seeking a positive resolution--it speaks volumes on both your and ME's commitment to, and integrity in, providing builders with quality products! Thank you for all of your diligent and conscientious work! And just to lighten things up a little, do you think you'll later do some sails for the Essex? Jay -

Wow, definitely can see the challenges with that limited space Sumner! And with little ones...yes, everything does need to be put away. Oi, didn't realize you were in HK--I was there a few times in passing when I was in the service. Don't think I'd like to be up that high but that's the nature of the island with its limited space! Hmm, the 4mm 2nd planking makes sense--my cogs are turning... About the gunport lids... There's a 2nd set of Sherbourne plans at the NMM (# 6764) online that has no port lids... Also, consider where the canon recoil tackles are located--about opposite where the hinges are. Every time a gun recoiled, the shock transfer from the recoil termination point would tend to induce lids that weren't well secured to swing shut. Even if well secured, the recoil would also place a lot of stress on side hinges (definitely not made from high grade steel or alloy). As another check, a search on the NMM plan site using "circa 1763" (quotes not required http://prints.rmg.co.uk/category/Ship-plans ) turns up quite number of 1763 cutter plans. Most, if not all (been awhile since I looked at the ones I downloaded), those plans don't have lids... While I think the lids will look great on a build, I'm just not sure if they were used on these ships in a sideways (90 degree) configuration. Hope you didn't mind my chiming in on the gun port lids... Again thanks for your updates, Sumner...and am not going to think about how high the altitude is on your 63rd floor! Cheers, Jay

- 57 replies

-

- caldercraft

- cutter

-

(and 4 more)

Tagged with:

-

Thanks, Sumner--am starting to feel better, so I think I may pull up a chair to my building board and do a little work this week. Looking forward to seeing your clinker planking and your counter--more importantly, I'm glad you've had some free time for some play! Jay

- 57 replies

-

- caldercraft

- cutter

-

(and 4 more)

Tagged with:

-

Kester, sorry for the delayed reply--been down ill for the past week plus, so haven't been as active or attentive here on MSW as I normally am. I do hope you post your BNII to the gallery--I'd love to see the work you did on her! I'm also fond of fishing schooners--a few are planned future builds! Jay

-

The wales and stern are looking good, Sumner! Kester's right, you should still be able to see some, if not all, of the plank directions on the stern after you paint, particularly if you airbrush. Keep up the nice work--looking forward to more when time permits for you! Jay

- 57 replies

-

- caldercraft

- cutter

-

(and 4 more)

Tagged with:

-

Kester, I really liked Captain Courageous as well, but my avatar is a photo by Wallace MacAskill. Some of his most famous photos are of the Bluenose; his photos of the Bluenose were the inspirations for Canada's famous .50 Bluenose stamp as well as .10 cent coin. Here's a link to his work if you'd like to see more of his photos: http://gov.ns.ca/nsarm/virtual/macaskill/ Jay

-

Silly question? Better Corel or other manufacters?

Jay 1 replied to maggsl_01's topic in Wood ship model kits

Max, in addition to Andy's excellent suggestions and advice, you might like to give some consideration to a few of Krick's (Krick is a German company) kits like the Alert: http://www.krickshop.de/Produkte/Standmodelle/Bausaetze/Schiffsmodelle/Alert-Zollkutter-Baukasten.htm?shop=krick&SessionId=2693xd0b22f40316454d97eb48f896f31f659&a=article&ProdNr=20240&t=35&c=85&p=85 Jay -

Titanic Sinking Mystry Solved: New Evidence Emerges

Jay 1 replied to Hank's topic in Nautical/Naval History

Stunning revelation, Hank--thank you for sharing this profoundly disturbing and eye-opening clip! Jay -

It's always a pleasure reading your retrospective log Kester. I really like how you did the furled sail--it came out beautifully, and using copper for the hoops was a wonderful idea! Your craftsmanship and and research are superb! I hope you don't mind my mentioning this in your log, but wanted to let Paddy know (since he's also a follower of you build, too) that he can purchase Caldercraft kits from Ages of Sail in the US. Also, having them shipped from Cornwall Boats in the UK to the Staes often is about the same total cost as Ages of Sail. I purchased my Sherbourne from Cornwall, as I also ordered a few extras that Ages didn't stock. Looking forward to your next installment! Jay

-

John and Wayne, thanks for info. for ordering plans! I agree with what everyone else has shared about making these types of resources known and more accessible. It's a pity all those models are where no one can see or appreciate them. At the very least, putting photos out to the public would be a nice start (the 360 type are great). On the flip side, it may simply cost too much money--if so, what a shame. Makes you wonder how many other treasures are sitting in storage vaults... Jay

- 2,250 replies

-

- model shipways

- Charles W Morgan

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.