-

Posts

1,407 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Ferrus Manus

-

I love how the picture you took looks just like the historical photo.

- 282 replies

-

- Bluenose

- Model Shipways

-

(and 1 more)

Tagged with:

-

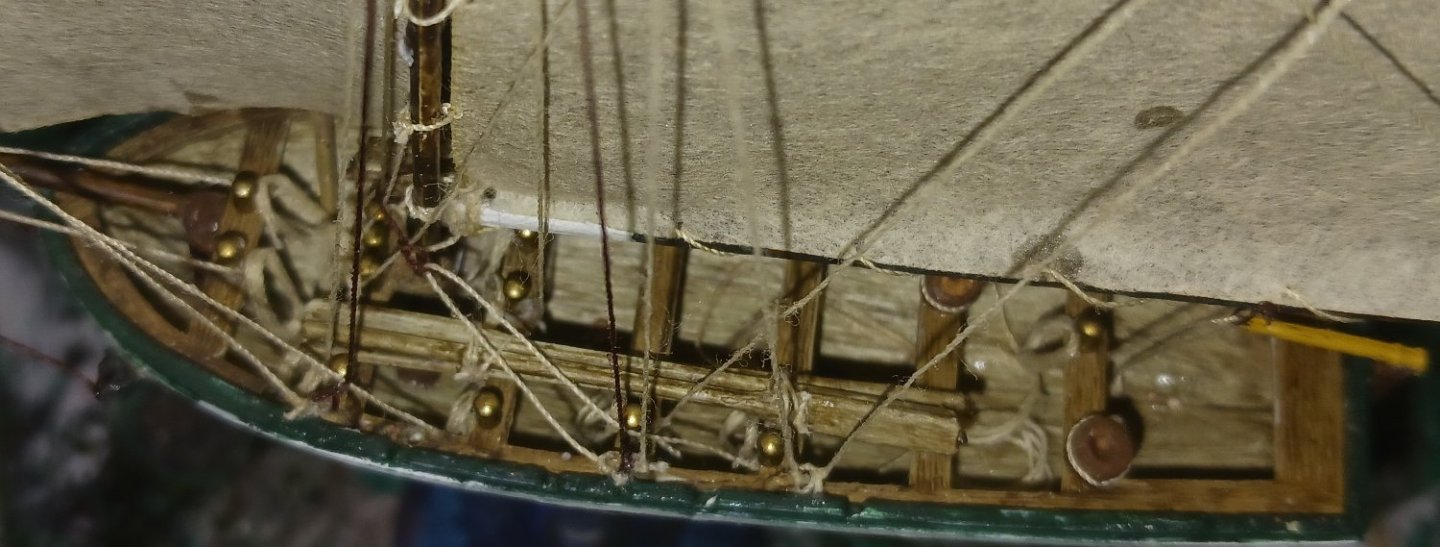

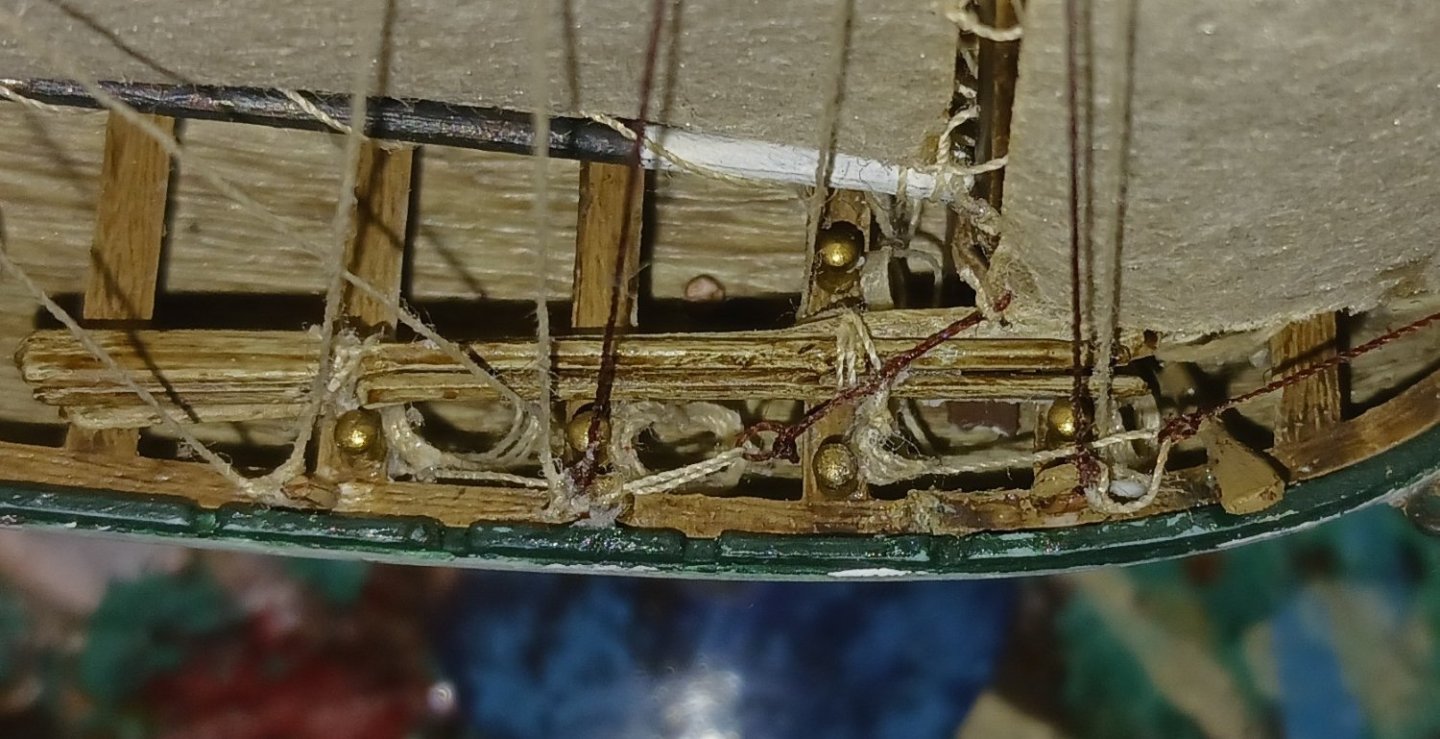

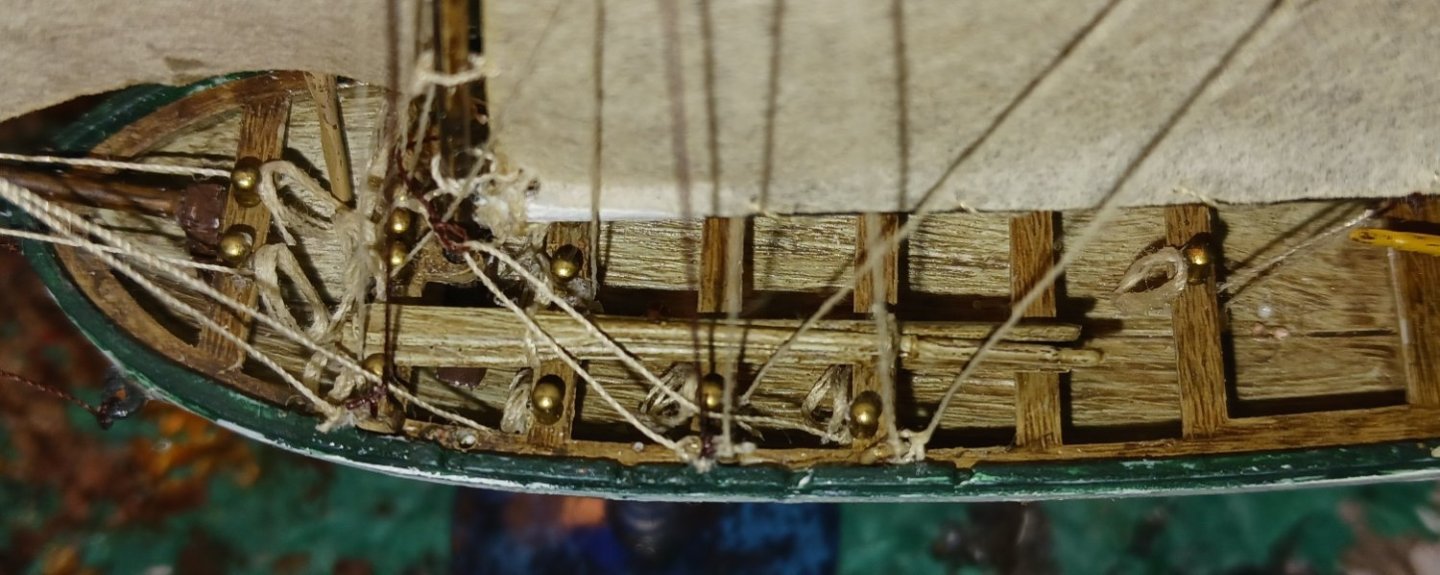

I haven't been doing much in the past week or so. This week I have had more time than usual, so I decided to work on the boat. I made all 16 rope coils and attached them to the boat last night. Then, today, I stained the bottom of the hull a clear gloss. Then comes the fun part. I painted the stand a little differently this time. It's a clear stand. On the bottom side, i painted some splotches of green, and covered that with brown. Then, on the top, i painted two shades of blue, intentionally making it not uniform, mostly so all the different colors could be seen. I quite like it.

-

To stain, i use the following paints: Citadel Nuln Oil, Citadel Agrax Earthshade, and Folk Arts Antiquing Medium. The latter works marvelously well, as can be seen on my Spanish Galleon.

-

The reason your weathering looked horrible, as you put it, was because you had the wrong paints for the job. I am assuming you were using Revell paints. Revell paints are generally of very poor quality and not suitable for weathering. To weather, you need a stain. Revell doesn't give you those.

-

It doesn't have to be. Most people who build with wood stain their ships in large swaths, with wide strokes of the brush. I am pretty bad at painting as well, but i manage. "I'm not artistic enough" was an excuse I gave for a long time before i made my second model. EVERYONE can get better, even you. I certainly did. Getting realistic weathering is a very simple, uncomplicated matter: basically, you smear a paint that looks like grime onto your model, and that's it. Simple as that. I have some paint recommendations for you.

-

Today is Columbus day, so ironically, it's a great time to work on your Santa Maria model. I assume you are using the Mataro Nave as a reference? It looks like you took a significant amount of features and replicated them on your model, which is probably a good decision.

- 38 replies

-

- Santa Maria

- Nao

-

(and 1 more)

Tagged with:

-

You're making real headway on this! I haven't seen many scratch nao's, so i will be following your build very closely.

- 38 replies

-

- Santa Maria

- Nao

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.