rtropp

NRG Member-

Posts

936 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rtropp

-

HMS Naiad 1797 by albert - FINISHED - 1/48

rtropp replied to albert's topic in - Build logs for subjects built 1751 - 1800

Albert, I will be following your excellent build with great interest. I appreciate all the detailed pictures. They greatly help in understanding how scratch building can be accomplished. Thanks for the effort you are making it presenting your work. Richard -

Ed, I have found a reference to Steel and wanted to check with you. They are listed as, The Elements and Practice of Rigging, Seamanship, and Naval Tactics (Cambridge Library Collection - Naval and Military History) (Volume 1) The Elements and Practice of Rigging, Seamanship, and Naval Tactics (Cambridge Library Collection - Naval and Military History) (Volume 2) The Elements and Practice of Rigging, Seamanship, and Naval Tactics (Cambridge Library Collection - Naval and Military History) (Volume 3) Are these the ones to which you are referring? All three? Thanks, Richard

-

Mark, they actually included one extra fuse, guess they figured that would happen. I will pick up some more. thanks for the tip. Once I figure where I want everything I will bolt it down. One of the links you listed had a great layout with tips on where to leave room for movement. Grant, As Mark says it may just be that the tables need to be used to smooth out a little. There is not much in the instructions about how to lock, unlock, loosen etc. Just a little paragraph and the advice to ask a friend for help if you have not done this before. The only folks I know with any experience are right here. I will call MM Thur afternoon just to see how helpful they might be. I think I expected a more detailed manual on the operation of the lathe, but perhaps that is just me. Richard

-

My MicroLux Micro Milling Machine, item number 84659, arrived today so I thought I would post some pictures of the unpacking. The packing was very good as you will be able to see. Also assembly was pretty much a snap. Only two parts for the main unit and a few handles for the compound table. The mill was shipped in one carton inside were two smaller cartons with the two parts to the mill The unit itself was well packed in rigid Styrofoam You can see the base unit with the compound table The second assembly was similarly packed in its carton Putting the two together was a snap... just fit and bolt. The only concern, and I am not sure if it is a problem is some red discoloration on the base. It does not look like rust, but I am no expert. I will call them in the morning. Also, the handwheels seem a little tight, hard to turn, but that may be me being too gentle with it. Overall it is a pretty solid machine. Now, until the tools arrive it is pretty much a paperweight. Richard

-

Hi, I appreciate your taking time out because this is not a ship question but for a project my wife requested. She has been so great about supporting my new hobby that I really want it to look nice. Below is picture of the frame to be painted. I am airbrushing to make sure it has a nice finish especially in the all the nooks and crannies. Also, because of the complex shapes I do not want to get into removing the old paint, just spray over it. I have a large bottle of white airbrush acrylic so should have enough paint. I appreciate your advice. Richard

-

Mark, I just visited the sites. Great information and well presented. They will be very helpful in acquiring a basic knowledge. I recommend them to anyone who wants to build some understanding of Milling and Mini machines like the Sherline, MicroMark and similar. Thanks for the links, Richard

-

Mark, I got the mini. I was ok with the MT1 vs R8. If I ever felt the need to upgrade to a machine like the Sherline 5400 I would be able to use the accessories I already had. My workshop is my sunroom so room is at a premium anyway. I was looking for some tutorials that would help but I could not find anything relating directly to MM machines. If you know of any, please let me know. Right now I have a couple of mini milling books coming. They are based on Sherline so I am hoping that they will be helpful. Once the MicroMark mill arrives and I have it set up I will post photos. Richard

-

Hi all, As you all will know from this thread, I was trying to decide which machine and was having a tough time of it comparing price vs. features. The Sherline, even with its price break, was just outside my price range. Also, I want to learn more about milling, both wood and metal, and learn some of the standard practices in milling. It seemed the Sherline is set up more like a standard mill than the Proxxon and would give me a better feel for standard milling as well as better capacity for milling metals, But as I mentioned, at the present time the Sherline is just outside my price range especially when you consider the accessories that will be required. Then MicroMark put their micro milling machine on holiday sale for $399. So, I pulled the switch and ordered it along with some accessories. (Oh yeah, accessories will end up more than the mill itself.) My rationale for the MM was that it is supposed to be similar to the Sherline in build and features. I will have to see about quality. The attachments should be, on the whole, compatible with Sherline. For instance, it uses an MT1 spindle which is same as Sherline, its hold down provision is 2 'T' slots, also similar to that on Sherline. Since accessories are a big part of the cost, it is my hope to not only have a wider range of suppliers ( i.e., EBay) but also be able to keep the investment in accessories should I need to upgrade. Also, there is a lot of information on the web about using Sherline and its attachments that might help in learning about the MM mill. Well, that's my story for now. I will update as I get the equipment and begin to use it. We have been hearing a lot about Proxxon and Sherline and this should give us another option to look at. Thanks, Richard

-

I have a questions about chucks. The Proxxon seems to have the type of chuck (collet??) you would find on a drill. The Sherline or MicroMark have a different chuck (end mill holder??). Is there an impact on performance or operation? Does it create any limitations? Thank You RT

-

Thanks Dirk, good to know. Mike, the only place I have found it so far is at http://shop.kremerpigments.com/en/search.html?page=search&page_action=query&desc=on&sdesc=on&keywords=ester Kramer's is a specialty producer of pigment and artist supplies. I have bought from them in the past and they are pretty good. They are located in New York City. RT

-

X-Y Attachment for Dremel

rtropp replied to Martin W's topic in Modeling tools and Workshop Equipment

I have cut proof gloves that I use in sculpting. They are made to allow control while protecting from cuts. I may be silly, but I'm not crazy... my mother had me tested! RT -

X-Y Attachment for Dremel

rtropp replied to Martin W's topic in Modeling tools and Workshop Equipment

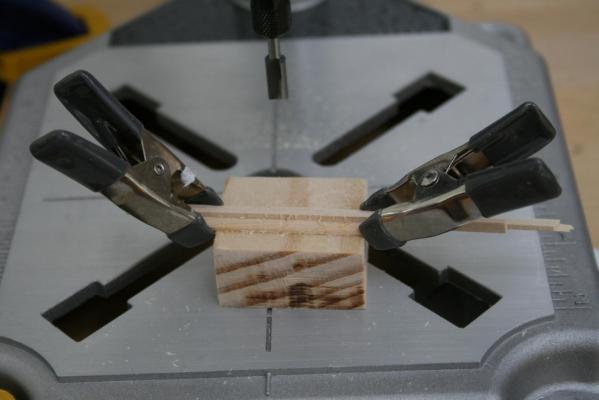

Thanks to all for the information. It looks pretty straightforward to attach the x-y to the Dremel, and if I need to I can upgrade to a better stand, such as the Vandalay or sell it and buy the proxxon or sherline if I really get into it. What's nice is that I feel I now have enough information from your experiences to go ahead and make a start of it. OK, I will embarrass myself and show you what I did just to try it out without a compound table. So, first thing I realized was that moving the jig with one hand while holding the head to the right height with the lever was not going to provide the best quality. But, it did provide decent cutouts for a plank that met a gun port. I think I am going to enjoy milling. RT -

Once again I have dipped into zu Mondfell's book. His advice on coppering is to... "clean them up very thoroughly with the fines grade of steel wool and a glass fiber brush and immediately apply a coat of protective lacquer (cellulose clear lacquer). ... unlacquered copper will show every fingerprint after a few hours due to oxidization. Do not try to age copper artificially - in 3 to 4 years it will acquired exactly the right patina, even under the lacquer." OK, so what is "cellulose clear lacquer?" Richard T

-

Placement of Treenails

rtropp replied to LFrankCPA's topic in Building, Framing, Planking and plating a ships hull and deck

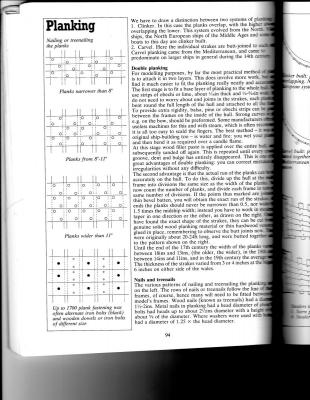

Larry, I hope the image below is readable. It is from "historic Ship Models" by Wolfram zu Mondfeld. I think the book is a must for any builder. there are some inexpensive used copies on Amazon. Only 5 -6 dollars. This is only a sample of the wealth of useful information it contains. Richard T -

Martin, I am not sure everyone is on the Proxxon wagon. I have read post by builders who have bought Micromark in the forum "Modeling Tools and Workshop Equipment //Milling Machine". Perhaps Proxxon is just a bigger company with wider distribution, especially worldwide, so there are more machines out there. Without hearing from other MM owners it's hard to say. Either way, I would not feel too bad. if nothing else, what I hear most is it is how you use it that makes the differences. All of them will do the job. Richard T

-

Theo, Thanks, exactly what I was looking for. Richard T

-

MIJ, I am researching various mills for purchase. I noticed your set up and was wondering what advantages, or disadvantages it might have when compared to the Proxxon MF70 Mill. It would seem to be more expensive than the MF70 once you acquire similar attachments. I would appreciate any thoughts you, or others, might have. Thanks, Richard T.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.