rtropp

NRG Member-

Posts

936 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rtropp

-

I have some proxxon equipment including sander, scroll saw and wood lathe. . I also have the small micromark mill that is now discontued. They do a pretty good job especially for a beginner. I bought the byrnes table saw based on the comments on this site. I was not disappointed. The biggest differences are precision and durability. The components are designed to trovide a high degree if precision, higher than other hobby tools. The materials and their weight also add to the precision by providing a very stable work platform. The materials are high grade metals and I expect them to last longer than I will. I wouldn't necessarily get rid of my proxxon sander but if it bit the dust, I would replace it with Byrnes equipment Richard

-

Wood lathe templates or jigs

rtropp replied to rtropp's topic in Modeling tools and Workshop Equipment

Hmmm, guess not. I read about it in shop notes 2 from NRG and hoped someone could give me a lead Richard -

Hi all, Just a quick note. I did not like my second attempt at the deck so I started the third. Then I received a call to see if I would consider taking on a project with a client in houston. ( I live in atlanta). I ended up agreeing so I am taking a break from my retirement. I am commuting each week so have not been able to devote much time to my build. I did have some success using a draw plate while working on the second iteration of the deck and will post some pictures as I get time during the week. Richard

-

Does anyone use any type of template jig for producing and reproducing wood parts, like cannon, on a wood lathe such as the proxxon 250db or other micro wood lathe?

-

Hi all I have the db250 also and am just beginning to learn how to use it. I am interested in turning wood cannon. Does anyone have any pictures of their process for turning wood cannon? Does anyone use any template jigs for reproducing cannon and other parts? Thanks Richard

-

Hi Richard, Your build is looking great. I am considerably behind yours. I am reworking the deck for the third time. I just can't seem to get it the way I want. I have a picture of yours sitting on my workbench. Richard T

- 227 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

laser char management?

rtropp replied to justsayrow's topic in Building, Framing, Planking and plating a ships hull and deck

Many of us have similar problems, I'd be interested to see if there any new suggestions. Richard -

Mark Happy to see you move ahead. I believe I will emulate your wood choices when it's time for my scratch build. I am especially interested to see how you handle ebony with all you learned last time. Richard

-

Hi, I knew the basswood was too soft but since I had plenty around I figured I would use it for my first attempt, just to see how it went. I used the word "exotic" incorrectly. I meant woods like cherry or pear. But your point about the clamps being working tools is well taken. I have found the beech online but had not thought of Maple. I think, as long as I am ordering wood, I will try some. I will look into cast offs to convert for tooling. hadn't thought of that either. I had some oak trees cut down recently and have some choice pieces drying in the pole barn, but not sure I want to wait for them to get started. Things in my shop will be slowing down. Despite all my attempts to avoid interrupting my retirement, I received a contract offer I just could not refuse. I will be commuting to Houston weekly for the foreseeable future and I expect that to put a kink in my build for awhile. Strangely, I spied my wife dancing in kitchen when I wasn't looking. Hmmm... have I been home too long Richard

-

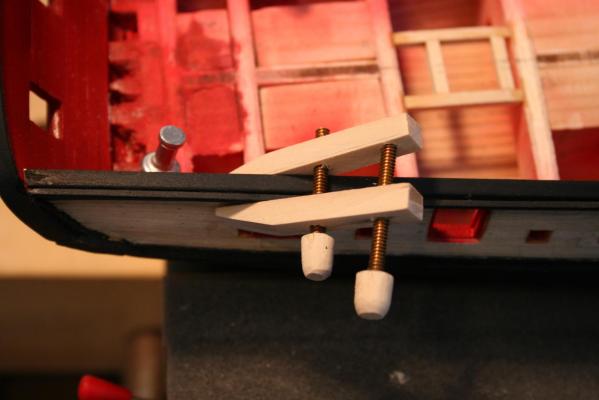

Well, I finally had a chance to work on the clamps. I used scrap basswood that I had around the shop. I will have to get some hard wood. Beech planks have not been easy to find online so I am trying to decide which other woods would be nice. Since do not have a thickness sander I am trying to find it 5/16" thick. Any suggestions for other wood types is welcome. I used pre threaded 6-32 brass Did not have dowels so used lathe to shape the caps. After a little more practice, perhaps building in the modifications suggested above, I will tackle the more complex 4-40. Thank you all for your help. Richard

-

casting metal parts including cannon

rtropp replied to rtropp's topic in Metal Work, Soldering and Metal Fittings

Resin, tin alloy, pewter, wood ... There are certainly a lot of options open to the home hobbyist that can be done without costly equipment. Chuck, unit I saw your photos of the resin cannon I had not realized they could looks that good and with such great detail. I wonder, what actually are the differences in the look of the finished products, say of the same cannons but of different materials? Could you pick out the brass from the resin from the others without touching them? Richard -

Salvatore, That does look good. I now that I have what I need for the 6-32, I will first make it as originally designed, to keep it simple while I am learning. Then I will try it with the washer, which should not be too difficult. If anyone tries the slot, please post the results. Right now I am focused on redoing my siren deck... again. Hopefully the third time is the charm. Thanks all Richard

-

Hi Belco, I was very interested in the article at the http://gabierschimeriques.free.fr/modelisme/canon.htm link. Problem is my French is ... well, nonexistent. I used Bing to translate and it came out understandable. There were some translations that were pretty funny, for instance "... A sleazy old made a makeshift cheap crucible..." But, still very understandable. I am interested to see that compared to a resin method for cannon to see what I might try next. Joe, that's a another hint On the other hand, I am not sure I could find any cannons better than Chuck's. That's 16 carronades. Not sure if Chuck also has the long guns, I did not see them on his site. Chuck.. What size carronades would I be using for the Syren? Richard

-

casting metal parts including cannon

rtropp replied to rtropp's topic in Metal Work, Soldering and Metal Fittings

Hi Joe, I would be very interested. It would be really helpful if you could use cannon or other ship fittings as your example. Just sayin'... Richard -

casting metal parts including cannon

rtropp replied to rtropp's topic in Metal Work, Soldering and Metal Fittings

Thanks all, We found out that the kiln would not work. There are many suggestions here and I will studying them. appreciate all your help Richard. -

Hi, I just received a 6" length of 6-32 threaded rod from eBay. Also have received a set of the 6-32 tap and die, and the right and left 4-40 sets from Victornet. Victornet is very reasonable. So I will be working on the simpler clamp (as soon as I finish the deck planking I am working on. I just checked MSCDirect and there prices look good. I will probably use them once I am ready for larger length rods. Thanks for the links, very helpful. Richard

-

QA, That is an excellent link... very helpful. I have gone around this a number of times and believe I am beginning to understand. I have ordered various size brass rods, sized both as inches and mm that would seem appropriate for the 6-32 and 4-40 taps and dies as well as the taps and dies themselves that are described in Ed Tosti's book. In order to use those these I will have to reduce the diameter of the rods when they arrive. Not having a metal lathe I will experiment with using my wood lathe, hand drill or mill with a hand held metal file to size the rods for use as 4-40 or 6-32. If that is too arduous an experience I will continue my experiments by searching for taps and dies that fit standard available stock without having to rework (file) them. It will have some cost but that will be the cost of the education. If this research becomes necessary, I should end up with brass rod samples in a range of sizes both inches and MM. Also a set of taps and dies in the range I think I will use (certainly not more than 1/2" or so. Then find a reasonably priced Tap/Die set to experiment with. Anyway, that's the plan today. I will post the results of my first efforts with 6-32 and 4-40 when completed. Richard

-

casting metal parts including cannon

rtropp replied to rtropp's topic in Metal Work, Soldering and Metal Fittings

I was thinking about brass because I have a neighbor who has a clay kiln and I believe it gets to pretty high temperatures so I thought I might give it a try. He thinks it might be possible to set up a jig that will melt the metal above the mold and allow it to pour down via gravity. Colin, the white metal looks a lot easier but I did not think you could get really detailed quality using white metal. I have looked at the links you provided and, maybe its me, I do not see really clean, defined edges on the castings. Is that incorrect? Richard

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.