rtropp

NRG Member-

Posts

936 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rtropp

-

Todd, I used Basswood. I decided that, since this is my first kit, I would not buy expensive woods but use the ones that came with it. My next build will probably use boxwood, pear and a few others. The width is a hair over two inches. You should be able to find 3" boxwood at hobbymill and probably at dlumberyard. Richard

-

Are there work gloves that would protect my hands from potential table saw damage? In the past, I have used protective gloves when sculpting with knives and chisels but I am not sure they would offer much protection on a table saw. I understand about using push sticks etc. but I wanted to check and see if anyone knew of more effective protection that would allow me to work without hindrance. My wife is buying me a mini table saw for my birthday and asked me to check. Richard,

-

Todd, I believe that is the 1/16" sheet that I mentioned in an earlier email about additional materials. The one I used is four inches wide but I was able to make two rails from the one piece. The beading is done on a second piece of 1/16x1/16" and is supplied with the kit. The pen comes pre-filled with stain that was good for touchups on the airbrushed black I used. Perhaps just lucky to get the match but pleased about it anyway. This company also makes a paint pen but it seemed more noticeable when touching up. Richard

-

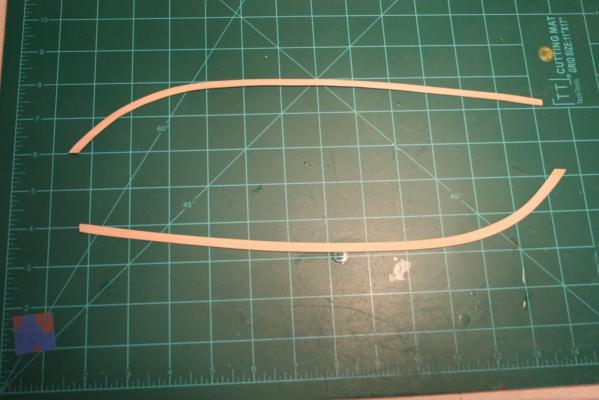

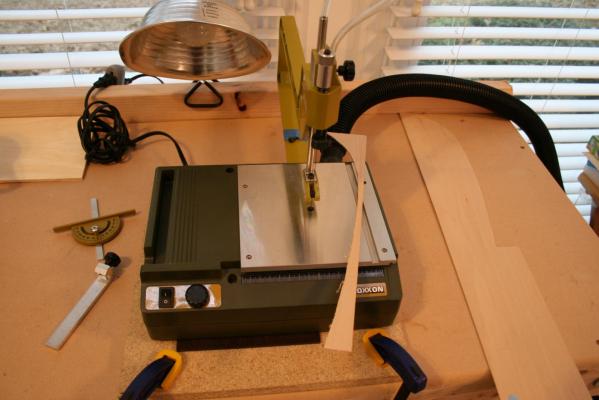

This update will cover the cap rail. I obtained a 1/16" sheet of basswood and copied one side from the plans. using a digital caliper to check the width I drafted the second line using a compass. I rough cut the shape using my scroll saw. final shaping used a table sander for the outer edge and the dremal sander for the inner curve. You can see my rigged vacuum. I try to be diligent about running a vacuum when sanding. First of all, I work in the sunroom and need to control that sort of thing since it is part of the house. Second, who wants to breath that stuff? finally ended up with: Now came the interesting part. I decided to attempt the 1/16 x 1/16 edge to the cap rail with a beaded finish per Chuck's note about advanced builders. ( I am not an advanced builder by any means but figured I should at least try.) After a couple of false starts I decided on a very simple approach that turned out to be surprising effective. I used a divider, opened at half the width of the piece to score the center of the wood going ... very... VERY gently. The I alternated between a dental pick and sanding stick. I went over the edges lightly to give them the outside curves and then use folded sandpaper that I kept slightly opened with my finger in the center of it, to model the inner curves from the scored line. I have to emphasize that I have never worked with so light a touch. I am amazed that my ham handed grip was able to accomplish it. This shot is before dusting and painting. Whenever possible I paint before adding to the ship. I use an airbrush which I think leaves the really fine details showing without paint build up obscuring it. Its just easier to do a little touch up later as required. anyway, I could not get the beading to show well once painted. It is noticeable when viewing the actual ship and I think it adds a really nice touch of realism. finally mounted on the ship with glue. One of the nice things about using wood laundry clips is that you can cut the tips to shape in order to clamp in some difficult spots. (and they are cheap.) Touching up black parts has become a lot easier once I have found this stain in a felt tip pen. It is almost unnoticeable once it dries. I am glad I tried the beading and believe that I will attempt most of Chuck's hints for advanced builders. Heck, how else will I learn? We'll see if I still feel that way after trying to joggle the deck planks A happy new year to all. Richard

-

I originally faced a similar skills problem with cutting and sanding and am still not as good as I need to be. I found that with time and practice I am getting much better at it. This is why I am considering my first build as pretty much a learning exercise. To add to Robbyns's comment, I read in one of my modeling books that they do not recommend using a chopping motion as it can squeeze the fibers or rip them at the bottom. They recommend that blades work best with a sawing, cutting motion. The article displayed a micro close up of a standard craft blade and you could see the tiny teeth. As I remember they said the best cut was on the pull. I also read, probably in the same place, that cutting pads should not be used because the downward pressure of the wood on the soft surface will distort the wood being cut causing squeezing and tearing. I wanted to test all this out so I start cutting on a piece of mdf and I did get a much cleaner cut. I have to change blades more frequently, but I started buying 100 packs so that is not too difficult. In my build of the Syren I show a couple of jigs I created early on to control the right angle cuts and right angle sanding I needed to perform. I used these until I got lucky at an estate sale and picked up a Proxxon disk sander and using it has helped a lot. Holding the piece with two hands and using the guide provides much more control of the part being sanded. Another possible best practice was, I believe, from Antscherl's first Swan book. He recommends gluing the sand paper to a board and moving the piece rather than the sandpaper to get even cuts. Although it feels weird at first, it is working for me on smaller parts. Again, I get to hold the piece with two hands for better control and when I sit straight (yes mom, good posture was a good idea) I get cleaner cuts at more accurate angles. Now, with all that said, I am still clumsy with my cutting and sanding. I am getting better but slowly. I find myself buying a lot of extra wood because I do throw away a lot of pieces. Right now I am planking the deck and my first jogging attempt may not pass muster and have to be reworked. As Augie said, sandpaper is your friend. It really does fix a lot of little blemishes. And so it goes.... Richard

-

Ed, I just received my Naiad book one. Great piece of work. I will be going through it in detail before beginning my build. I Still have to decide if I will buy a precut lumber package or invest in a table saw and go whole hog on the project. So, it will take me time before I am ready to start it but there are some tools and such that I will start building in the near future. I would like to ask if you can set up one message, perhaps at the beginning of this thread that would be an edited collection of updates so they would be all in one place and current. This one message could be continually updated with any corrections, while new, regular messages could continue to discuss them which would provide a prompt / message for those of us following the thread. Summarizing them as a collection in one place would, at least for me, make it easier to keep track of them. Wishing you a happy, healthy new year. Richard

-

The line of paints I use is the modelflex Marine. There are some equivalents in their railroad line but not many. The only place I found the paints for sale online from http://shop.webairbrushes.com. The colors I ordered were: Qty | Item # | Description | Price Each | Total Price ------------------------------------------------------------------------- 1 | 16-431 | 16-431 Deck Red | $3.40 | $3.40 1 | 16-457 | 16-457 Dull Coat | $3.40 | $3.40 1 | 16-410 | 16-410 Navy White | $3.40 | $3.40 1 | 16-412 | 16-412 Hull Black | $3.40 | $3.40 1 | 16-414 | 16-414 Bulwarks Red | $3.40 | $3.40 1 | 16-413 | 16-413 Wrought Iron Black | $3.40 | $3.40 ------------------------------------------------------------------------- hope this helps. Richard Tropp

-

Todd, I do use an airbrush. The paints are Modelflex Marine Airbrush Paints by Badger. I like the airbrush because I find it easier to do light coats and save the details in the item painted. I tried reducing the acrylic paints sold by Model Expo as well as others but it was difficult... a real pain getting just the right mix and I ended up with a lot of airbrush clogging. The Badger paints are already cut for the airbrush and I found them very easy to use. I selected them because they have a line of paint, the Modelflex Marine colors that are specific to marine models such as the ships we do. Being new, they can be hard to find as they do not seem to be widely used yet. Also, using acrylic, I do not worry a lot about ventilation and they are easy to clean without strong chemicals. Easy cleaning is important because my painting sessions are very short. Richard

-

Hi all, Happy holidays and a wishing you all a great new year. Time for my next update. I have completed the inner planking. I decided to try this a little differently after my frustrating experience trying to keep the ports squared on the outer planking. I thought I would try to pre-fabricate the planking sections and see if that went any better... it did. I first installed the 3/16" bulwark plank along the bottom. I now realize the importance of the first planking on the outer side and the level of the sills. I must have had it a little off because I did have to cut the bulwark a little to leave the proper space between that first inner plank and the gun port. I am not yet sure how that will impact the decking... but I guess I will find out pretty soon. It was only a little off so hopefully the camber will be ok without too much fiddling. Then I cut planks to fit between the portholes and held together with tape. you can see that the edges are still uneven at this point. I used my bench disk sander to reduce the edges to the proper fit. Doing the fitting this way allowed me to easily keep all the edges of all planks in the section even to fit squarely to the ports. The result was fairly even planking on the inward side of the bulkwarks. Finally I added the topmost plank to complete the inward planking. At his point I forgot to take pictures, so I am adding a picture of the work after it was painted and with the cap rail installed. I am now finishing working on the cap rail. I read Chuck's note about advanced modelers trying to create the beading on the 1/16" stip. I warn you all now that his adding that was a heinous act of sadism. I asked my wife to go through the practicum and blank out all paragraphs that began with "... advanced modelers might want to..." Don't tell Chuck, but I ordered two dozen pizzas and gave them his address for delivery. Hah!! Seriously, I will show how I finally worked it out in my next post. It wasn't really all that difficult and did not require any special jigs. It just required a very.. very soft touch. I don't think you can even see the beading in the photos I will post, but you can see it in the model itself... and its kinda nice. Richard

-

It was from the first entry in Mark F's Syren build. Basically he found that... "Wood not included with kit 15. 5/32 x 1/32 wood strips (at least 2 for upper whales) 16/ 12 x 6 x 1/16 Basswood sheet for bulwark rails. 17. Balsa for bulkhead filler blocks." By this he meant that it was not supplied at all. For instance, #16 is the sheet from which Chuck indicates the bulwark rails should be cut. As for other missing parts, a few of us have experienced this with various components. A really nice thing about Model Expo is that they will replace any parts from their own line of Kits. They replaced not only missing parts but parts that I have messed up. No Charge... very nice. Just find the part numbers in your inventory/parts list and send that to them. It take a while to receive but a friendly reminder now and then does wonders. As for the items 15, 16, and 17 above, they will need to be purchased. Not really too expensive so for me not a big deal. In fact, not sure if I ordered them or picked them up at my local Hobby Lobby. Richard Richard

-

I am using a Triple Duty Foam Cradle for Model Ships that I bought from MicroMark (Item #: 85819)... about $19. It is very flexible with two removable sections that allow it to fit most boats and use in many positions. I have found it very adaptable to most work from planking to painting. The only thing I used a vise for was the original framing of the bulkheads. There I wanted something that held the full length of the keel to help keep it straight. I tried the ship clamp sold at Model Expo, and it was ok, but found the vise on my workbench was even better for that. I also read from one of our members about using a sock filled with rice. Sounds like a much cheaper and more flexible answer. Richard

-

Hi Dan, Nice work, I just started following your build and am very impressed. I like the look of your tree nailing and wondered how you did it. Thanks, Richard

-

Hi all, In my last post I was ready for the cap rail. So I started with the cap rail and broke the cap rail, started and broke it... bought more wood, started and, ... you guessed it, broke it. This degree of bending has been tough and I tried a lot of different methods including soaking, then steaming, then soaking and steaming. I just could not get to the bend without something snapping. I tried doing it in two parts but was still unhappy with the bends. So I tried to make a jig that would help. my first attempt below did not work. While the rubber band around the posts helped a little but the plank still broke. What finally helped was using the jig pictured below. I put a fairly wide rubber band around the forming screws. It is hard to see, but I backed the plank to be bent with another plank that I had bent but previously broken. That backing plank seemed to give it the strength to bend without breaking. I Painted the cap rail before mounting. Good tip Larry. I use an airbrush so it makes life a lot easier to pre-paint. Then added the fashion pieces and painted those and voila... Now onto the section 7.

-

Weathering Deck Planks

rtropp replied to Glenn-UK's topic in Building, Framing, Planking and plating a ships hull and deck

Model Railway enthusiasts have methods for weathering wood on their layouts. You can find weathering solutions at MicroMark and probably some other model railroad sites. Richard -

Wacko, there is a great thread concerning milling at: Model Ship World > Ship Modeling Tips, Techniques and Research > Modeling tools and Workshop Equipment > Milling machine. The link is http://modelshipworld.com/index.php?/topic/4200-milling-machine/page-5 Lots of good discussion. I also have a number of pictures showing the unpacking of this MicroMark mini mill. They had a great sale recently so I went for it. One of our members started a great thread about using the mill to create jigs for modeling. I plan to add to it as well as its sister thread shown below as I learn more. Model Ship World > Ship Modeling Tips, Techniques and Research > Wooden Tips and Tricks and Making Jigs > Milling work and miniature jig making http://modelshipworld.com/index.php?/topic/4320-milling-work-and-miniature-jig-making/ There has been growing interest in Milling so Nigel and others are hoping to centralize information about milling in these sites so they are easily available. Richard

-

Hi Larry, painting ahead of time for some parts is easier. I figured that for the hull, I would have to paint across some of the planking at the water line so would need to be done after the fact anyway. Pre-painting the sheer strake would have been easier. I have pre painted the cap rail and will do that with the second layer of the fashion pieces. Boy did that cap rail take forever to bend without breaking the wood. I must have gone through 6 feet of wood strip before I came close. I will show that in the next post when I finish the second layer of fashion pieces. Why are those called fashion pieces anyway? Also was wondering if anyone knew full size ship's transom and second transom would have been like the model or if the original ship they would have been planked or some other construct? I am referring to the outboard side of the upper stern (counter?) Good night all Richard

-

Finally, an update to the build. I have been remiss in working on the build as I became preoccupied with buying and setting up my new mill. (I just love this hobby.) Anyway, In my last update I had stained the hull. Next was painting which, since I used an airbrush, I began by masking. The painting did not come out too badly. I still had some leak under the tape so I will have to burnish the edges a little more carefully next time around. I also picked up some Tamiya yellow masking tape to try the next time. Then I went to work on the fashion pieces. This required a number of reworks. So tiny... such big fingers. As I look at the work on the fashion pieces it looks crude but it should be covered up by a second layer so I will hold off judgment for now. Also, there will be a little... well maybe a lot, of paint touch up around the work area. By the way, Larry, you were right about holding off on protective finish for now. Next will be the cap rail Richard

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.