rtropp

NRG Member-

Posts

936 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rtropp

-

Deck planking

rtropp replied to latestarter's topic in Building, Framing, Planking and plating a ships hull and deck

I am doing off the ship but the reasons are a little different. It is the main deck and I messed up the bulkheads so would not get the lay required. I am using a sheet of 1/64 birch ply as the base. Once finished I will see how it looks. I could have tried to repair the lay of the bulkheads but that would probably be the next step if this doesn't help. Richard -

Tung Oil Finish?

rtropp replied to cdogg's topic in Painting, finishing and weathering products and techniques

I have been reading about using pure tung oil. I wonder if it is really a good idea on model ships. I suspect it would dry faster on the thin wood but not sure how long it would actually take to dry or how well other items would glue to it, for instance, deck structures on tung oiled deck. Richard -

Hi all, I have found a couple of suppliers of upscale parts on this site similar to the Syren Ship Model Company but would like to see many more options. I am considering a scratch build, and possibly some bashing of my current kit, so I am looking for a more comprehensive list so I can begin shopping around. Please provide me a link if the list already exists otherwise I will consolidate to make a list and post it. Again, I am looking for some of the upscale parts and accessories, wood, brass, etch, etc. rather than just kit replacement parts. Thanks, Richard

-

micro table saw stop

rtropp replied to michael mott's topic in Modeling tools and Workshop Equipment

ok, dumb question, why set up so that the cut requires this jig rather than just use the fence side of the blade for the cut off plank? I ask because when I look at the write up at hobby mill, he is set up for the cut off piece (thin piece) to be on the side with the fence and it seems to work for him. I appreciate the help. Richard -

concerning feather boards, They should not be too hard to make. Given the dimensions we work with (as thin as 1/16th" and 12 or 24 inches long), I wonder what the dimensions of the feather board could be. Also, with something that thin, what material could be cut thinner then 1/16 and still be functional? Richard

-

Thanks Floyd, appreciate the effort Richard

-

Floyd, you devil you could you show us a couple of pictures, perhaps with a ruler for scale. If I cant buy one, perhaps I can reproduce it. Just not sure how thick, long and wide it would be. Also, would help to see how you attach it to the table and fence? Thanks Richard

-

Greg, I would buy a byrnes featherboard also. Jim, that's a hint Richard

-

A slitting/routing fixture for the mini mill

rtropp replied to Modeler12's topic in Modeling tools and Workshop Equipment

Jay, Thanks for posting this. I am going to try to reproduce it. It would not only be a useful jig, but also work well as a project to increase my knowledge of using a mill to create jigs. Is it possible for you to post a few more pictures showing more angles, i.e. a top view of the back, and any other plans you might have developed. Also, could you put a ruler in the picture? I ask because being a newbie with a mill, I could use all the help possible. thanks, Richard -

Marsares and Charley, Glad the experience is helpful. I found that I do like the look of wood plugs vs, filler, and now it is not too difficult David, Not sure what you mean by the "other side." If you mean going into the concave depression side, that did not seem to work for me when I tried it so I use the opposite side, the side I am told is the correct one to use for drawing. I am able to get to the smallest hole on the draw plate without too much trouble, I believe it is 76 or perhaps 78. Since I do not try to thin the whole skewer, only a few mm at the end, it seems to go very quickly for me without all the preparation, soaking, splitting, etc. And without the breaking and tearing. Trying to draw the piece all the way through over and over again just did not work for me. Too clumsy I guess Richard Just edited this post. I noticed that I had used Charlie's name instead of David's. My apologies

-

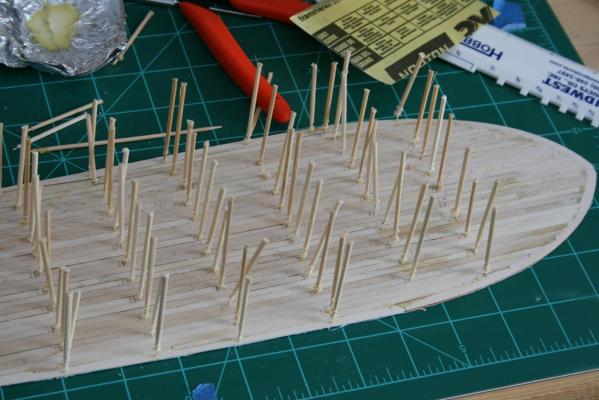

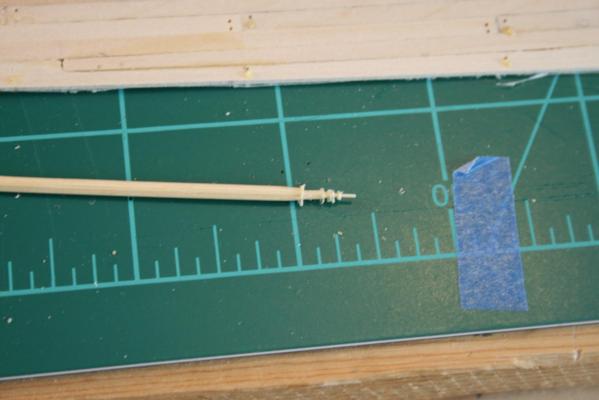

Well, I am still working on the contract in Houston each week so my build is slipping. Once I am in a routine I should be able to get some time in on weekends. Meanwhile, thought I would update on my battle with tree nailing. I just about decided that, after trying to follow the suggestions of half a dozen members, it was just not going to work for me. I was about to put the drawplate up on EBay and go back to using filler when I thought... one more time. So, here's what I did... and darned if it didn't work. I used 4" bamboo skewers. they are round and pointed on both sides. I had tried smaller toothpicks but they kept breaking... too weak. I took the skewers and cut them in half leaving about 2" per pointed end. I then clamped the drawplate to my worktable I gently... very gently hammered the pointed end of the skewer into the drawplate. When I reached the final hole size on the drawplate, I used so soft a touch that it almost felt as if nothing was happening. On that final hole I tapped from 15 - 25 times just to go that mm or two. Just a whisper... First, I was sure to use the correct side of the draw plate (which goes against all logic). I needed a thickness(... er thinness??) that was created on the smallest hole on the drawplate (MM's). After a lot of experimentation with going from the hole that was the size of the toothpick and working my way down, I found that I just needed to start at a hole about three sizes up from the final one I would use since I was not doing a complete draw, just the end and pull out the way it went in. Saved a lot of wasted time. On the first couple of passes I found it best to only go a tiny bit. If the end you thin is too long, it will break when you tap it in subsequent holes. In fact, if you tap and the pull out you will see a little ridge where the wood builds up. This seems to strengthen the toothpick for the next reductions. Remember, you are pushing (tapping) not pulling in creating the treenail so the dynamics are different in how the wood handles. You can see in the following picture how I stopped part way and left a "bulge" of wood at each reduction before continuing. And, that I only thinned a very small amount of the tooth pick. Note: if the thinned end starts to bend while tapping, just get rid of it and start another, once it starts to bend it will be a pain to finish and a bear to push in the predrilled tree nail hole. I continued on this way until I had a bunch. the picture below has about 10 minutes worth of work. Pushing them into the predrilled holes in the planks was fairly easy as long as you went straight down into the hole. I could actually feel it snap into place for most of them. I watered down the white glue just a little to get it to slide in better. Then let the glue dry and trim. I found this was a pretty quick and painless process. Of course 95% of the toothpick was waste, but they are cheap enough at the market that I didn't spend time re-sharpening and reusing them. My first try came out looking decent. I had prefabricated the deck as a way to get around some earlier construction mishaps. I think the ideas was good but the execution was bad. Should have measured a heck of a lot more before putting glue to wood. So I am doing it all over again. (the picture doesn't show the aft part of the deck where I screwed up...to painful to admit.) This is, in fact, where motion stopped about a month ago when I got talked into taking another assignment. I really forgot how work interferes with your personal time Anyway, since I have to do this again anyway, I am going to experiment using other types of wood, both darker and lighter than the planks, to see how they look once finished. It should be easy enough to use this method with almost any small diameter wood as long as it has a point. Even small square strips should work. I like using the natural color of wood but could stain the tree nails before gluing if that works out for a better look. Well, that's it for now. Monday I am back to the airport. Richard

-

Hi Ed, Its really a pleasure to follow along. I have your first book but want to continue building my skills on my kit before attempting it. I have a question about "washing glue", probably a silly one. How far into the glue drying cycle should you wash it off? Thanks, Richard

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Hi Ed, Its really a pleasure to follow along. I have your first book but want to continue building my skills on my kit before attempting it. I have a question about "washing glue", probably a silly one. How far into the glue drying cycle can you wash it off? Thanks, Richard

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Antony I have been following along in the background. Just wanted to let you know that I really enjoy watching your work. Nicely done. Richard

- 209 replies

-

Richard, Darn nice. I had to stop my build for the duration of a contract I took. It has me traveling to Houston weekly so not much time to get back into the groove. But, looking at your photos makes all the more eager to get back to it. Richard T

- 227 replies

-

- syren

- model shipways

-

(and 1 more)

Tagged with:

-

"Art Tape"?

rtropp replied to SGraham's topic in Building, Framing, Planking and plating a ships hull and deck

Just a thought, be carful which one you get. I had tried a thin colored tape from Hobby lobby but found if it stayed on too long some of the color transferred to the wood and had to be sanded to remove. It may have been left on too long, or pressed on with too much pressure but it did end up making more work. I suspect I may have bought the wrong type. I suggest testing it on scrap before using on the build. Richard. -

Wefalk, You are right, once it was cleaned off most of the stain went away. Richard

-

Fabius Do you use it as a "working" guide for your chisel while turning the cannon or as a measurement template while the spindle is stopped? Richard

-

Wood lathe templates or jigs

rtropp replied to rtropp's topic in Modeling tools and Workshop Equipment

jay, I see what you have done. I have a wood lathe, not a metal lathe, and not sure that would work... on the other had, without trying, I am not sure it would not work. I have to see how I would rig it up to the tool bar... Richard. -

grsjax, good site, I have it marked now. Thanks, Richard

-

Barry, I bought the smaller MM mill to create an compatibility path with the Sherline. It is MT1, as is the Sherline. Also the Sherline accessories pretty much fit on the beds of the MM Mini mill so if I do go the upgrade path I would not lose my investment in accessories. Many of my current accessories are Sherline and the mostly fit and work well. As for can I use it as is, I am a beginner with power tools, so it is all a learning experience. So far I have made a couple of simple jigs and also milled the parts for clamps similar to those in Ed Tosti's book. I am just touching on milling metal. Richard

-

Wood lathe templates or jigs

rtropp replied to rtropp's topic in Modeling tools and Workshop Equipment

Thanks all for your help, I have contacted vadalay and pennstate. I think the pennstate is made to work with wood lathes so hopefully they will respond with a unit that works with the proxxon wood lathe Richard

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.