-

Posts

1,296 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by DocRob

-

There is indeed a lot of components crammed into the engine area and everywhere else as well. Handling the kit and test fitting becomes more and more difficult because of that. I will stay with my poco a poco (little by little) approach and prepare more sub assemblies and try to not build myself into a corner. Sometimes, I think, I should have chosen an easier MFH kit as my first car kit from them. I assume, their F1 cars are a bit easier to build up, there are no doors, no openable hatches and bonnets, but now it is to late to complain . Cheers Rob

-

I used the curing time of the body parts to prepare the firewall. I installed all the components except for some electrical wiring and tubing and test fitted the whole thing into the body as well as onto the chassis. I hope, joining everything together later will work out. It becomes harder and harder to test fit and every test results in color abrasion or in knocking off some parts. Cheers Rob

-

I envy your figure painting skills, Greg. The figures are not only well painted, but they also blend perfectly into the style of your setting. Cheers Rob

-

Thank you Alan, I have to admit, the whole painting and finishing process with car bodies is relatively new to me and I´m really nervous with each stage. As a security blanket, I have a tiny sprue of 1/32 bombs, where I apply exactly the same colors and decals step by step as a dummy for testing effects of colors, get a feeling, how hot they are, if it´s better to apply light or wet coats or if they affect decals. The nervousness stays nonetheless as it becomes more and more difficult to repair damages later on. The drop of goo on my airbrush had skipped my attention though. Cheers Rob

-

Phew, I think, I have saved the Cobra from binning for now. After carefully sanding the splatter dots. first with 1500 grit, then 4000, 6000 and finally 8000 grit, there was one culprit left, the most visible unfortunately. I carefully dotted heavily thinned Tamiya LP-2 gloss white with a fine brush into the tiny crevice, building up the spot, until the color looked right. After drying the same sanding treatment like the others. After all was wiped clean, I applied two coats of Zero Paints lacquer gloss with about 50% of added leveling thinner and an hour of drying time in between. I think, I have a 95% solution achieved and later, when everything is properly cured, I will sand very carefully and polish until it´s an absolute high shine finish. Cheers Rob

-

You wouldn´t like it with the splatter blobs, Gary . They are not huge, but they disrupt the look completely, somehow. Tomorrow, I will try to wet sand these blobs away with very fine grained sanding sponges. The last possibility would be a tactical one. If I can´t alter the situation, I need a good story. How about a barn find . Cheers Rob

-

Thank you Alan. Random accidents happen and it was clearly my fault, not checking the airbrush. That´s the other frustrating thing about it, I hate to make mistakes and prepare everything properly, to not let something like this happen. I worked for more than a month on body preparation, airbrushing, decaling and clear coating and had hoped to finish this stage yesterday. I did the at least to me very difficult thing and leaned back. Today, I jumped into the Atlantic and crawled hard for two kilometers, to let some steam off and maybe tomorrow, I will look for solutions. Cheers Rob

-

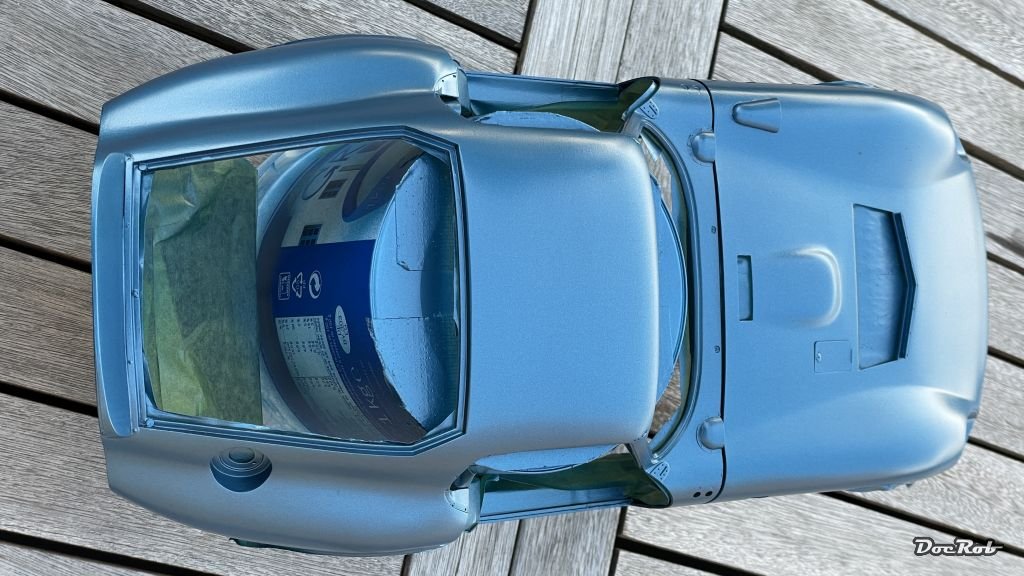

Have you ever had that modelling moment, where you wanted to rewind time for a minute? I had one today. After checking, if all the decals settled perfectly, I cleaned the body with soapy water, to get rid of any residues from the decaling phase. Then, I applied a first coat of Zero Paint clear gloss, with maybe 20% added leveling thinner. The first layer is only misted, to seal the decals in and due to rapid drying time (relatively high air pressure and low thinning ratio) reduce the risk of harming the decals with hot liquids. After about an hour, I applied the second layer of clear, this time more liberal with about a third of leveling thinner and after another hour, I applied the (planned) last layer thinned with ca. 50% of leveling thinner and sprayed on wet. So far so good, until, I took out the airbrush out of it´s holder, to blow the body color dry a bit and didn´t notice that some goo was on the front of the airbrush casing, which squirted onto my just finalized paintjob . Now, I´m really frustrated, as everything went well since days of prep work, until the final seconds. I was about to bin the kit instantly, as I absolutely hate these kind of mishaps. I usually prepare my work thoroughly, trying to think ahead of everything, but when something goes seriously wrong, I´m impatient, restless and uncompromising. I´m not sure what to do, leaving it as is or waiting (again) for the clear to dry completely and then carefully try to sand the dots away and re-clear, risking of ruining everything or finally binning the kit. Here are the pics, it looks not too bad, but it is not acceptable. The orange peel look is due to the lighting of some hundred LED´s, the paintjob itself is near perfect and will be perfect after polishing. The dots on the roof´s stripes are the worst, but there are some more. Cheers Rob

-

Thank you Yves and Craig, to be honest, the blue is the interpretation of my camera. Whatever setting I change, it just doesn´t show it correct or maybe the camera is right and my eyes are off . The color has a slight petrol tint, not that pure blue like on the pics. It nevertheless looks beautiful. Today, I checked the decalwork and added a few drops of Micro Sol here and there. Cheers Rob

-

I hesitated starting with the decaling, because something was nagging me. I didn´t like the oversprayed part of the body, where I dented the paintjob. Tiny marks were still visible and imperfections tend to sum up, specially with high shine car bodies. I wet sanded the area carefully and then resprayed again. And now, I felt, I´m ready for decaling. There is no makers branding on the decal sheet, but the decals were of perfect quality. They are glossy, very opaque, not at all brittle and easy to apply, which made the not so easy task a lot more comfortable. I aligned the stripes more by eyesight, than measuring. The decals are overlapping the borders on the ends and where cutouts are and with perfect placement and some scalpel corner cuts, you wrap the decals around the bonnet and body edges, which of course looks better in the end. Until now, I used only lukewarm water with a drop of detergent for application and the decals behaved perfect, contouring around the edges by themselves after a while of drying. Today, I will evaluate some critical areas and may use some decaling fluids there. And now the Cobra got it´s stripes Cheers Rob

-

I think, it´s too much splash for being so close to the harbor wall and seemingly no waves on the water. The figures are way too relaxed in their poses, not expecting a harsh maneuver so close to the wall. A boat this size should only glide with low speed in shallow water close to the bank. Cheers Rob

-

Time for some glosssss. I used Zero Paints lacquer clear gloss with about 40% leveling thinner added. Came out pretty decent and should be good enough for decaling. The very high gloss is difficult to capture on the photos. Before, I applied a fourth coat of Cobra Blue overall, to let the tiny blemishes on the bonnet disappear. Unfortunately, during photographing, I tried to hinder my cat, jumping onto the model, it hit a stone and I have another small mark in my paintjob . Cheers Rob

-

The paint indeed layed down beautifully and very smooth. Best thing is the extremely fine metallic pigment. I don´t like the un scale glitter look of many metallic paints. The color looks always different, even to the human eye. That way, there is not a lot of possibility to question historic adequacy . Cheers Rob

-

That is an interesting story, Jack. I have seen Miles Davis live with his later stuff in 1985 in Berlin. I liked the concert, but prefer earlier recordings. My favorite is the soundtrack of Elevator to the Gallows and I do like the movie as well. Another hobby of mine is collecting and foremost hearing vinyl records on my very decent turntable via a good amp and quality speakers. I have several Miles Davies albums, but my interest is wide spread from classic to punk, with some bias on jazz and world music, but never boring charts stuff. Muchas gracias Alan and Craig, the blue metallic paint is a strange one. It changes it´s looks dramatically with different lightings. My good camera, which I normally use for modelling pics, was not able to render it correct, equal, which parameters I altered. I had to use my IPhone, which did a slightly better job. So much about the objectivity of photography . Cheers Rob

-

After an intense masking madness session, to protect the interior, I started with the body color. I fear, there will be color lifts with the interior, despite cleaning the resin properly, thorough priming and airbrushing, but this needs to be addressed later. It´s also one of the reasons, why I didn´t mount some of the ready painted inner fairings, before painting the body. A Kind Of Blue from Miles Davis was my soundtrack for the paintjob I used Number Five´s Cobra Blue as the main color. Other than with classic plastic kits, I had not to fear reactions with the resin and could coat a bit more liberal. I airbrushed three medium coats with a drying time of about 20 minutes in between. Number Five colors are ready to spray, but I added about a third of leveling thinner after some testing. They spray very fine and even, with extremely fine metallic grain and dry semi matte and fast. At first, I thought, coverage would be not too good, as the black overspray shined through the first coat, but after some minutes, the paint leveled and became more opaque. Besides the horribile smell, (I always wear a respirator) I absolutely love my first experience with Number Five colors. Besides, I used only one 30ml jar of color for the big Cobra, which is great to my eye. After checking, I found some tiny dots on the bonnet and will lay on a fourth coat tomorrow. Cheers Rob

-

The painting stage has finally begun . I cleaned all the resin body parts in warm soapy water with a large brush and sponge first and then primed everything with Mr. Surfacer 1500 grey. After drying, I sprayed the white sections with Tamiya´s XF white (bonnet inside and firewall and small parts of the main body) These areas got masked then. Finally, I sprayed two jars of Tamiya´s excellent LP-5 semi gloss black onto the inside of the wheel wells... ... and the inside and window framing of the body. Some interior parts got also sprayed during that session. Next will be an intense masking session for the interior and a lot of praying, there are no paint lifts after. Cheers Rob

-

Hopefully these are the last preparations before entering the painting stage, but as often, there was one step back, before advancing. I had to remove the already installed internal framework and internal rear view mirror, because they would have interfered with masking the inside of the body later. I finalized cutting the transparent air scoop vac parts with a pair of fine scissors, sanded them to fit and dry fitted them for drilling holes for the rivets. The first side, I drilled with a 0,6 mm DSPIAE drill bit, which tended to lift up the clear part, when drilling through. I changed to a Tamiya 0,6 mm drill bit for side two and got much better results. No lifting and dramatically less burr, which is a pain to remove with these clear vac parts. When you compare the drill bits, the Tamiya is of the classic HSS style and angles, where the DSPIAE bit is like all the other PCB board drill bits and not good for drilling thin materials, as it "eats" into the material and leaves a lot of burr. Cheers Rob

-

Great work, Dave. Your rigging came out beautifully. I recommended using a 0,5 mm drill bit for getting rid of the burr and cutting a slight cone into the ends of the turnbuckle tubes for better fiddling in the monofilament especially for the second time. I also recommend to cut the micro tubes with a sharp blade rolling them onto a cutting mat. This produces a far cleaner cut, than sawing. Do you plan to blend the color border around the side fuselage Balkenkreuz and Bavarian lion a bit more? Cheers Rob

-

Thank you Alan, the Cobra Coupe build is indeed a complex affair, but that shouldn´t put you off, building these type of kits. The Crocker motorcycle, I built, was a thorough enjoyable project and very rewarding. The Cobra or similar full bodied cars with doors and bonnets are not the best choice for beginning with MFH kits. I learn so many new techniques through the builds, often collected from fellow modelers build logs, that I like to share my experiences as well. Cheers Rob

-

Today, I prepared all the parts, which will be added to the firewall. Again lots of cleanup work and naturally drilling holes for mounting the parts and adding tubes and hoses later. Besides, I added tiny magnets to the rear hatch and the doors. The magnets have a diameter of 2 mm and are 1 mm thick. The doors were pre-drilled with a 2 mm drill bit and cautiously finished with a 2 mm milling cutter, to not drill through the door with the drill bits front cone. You can see the magnet shine through in the doors side view, it was close. The magnets will definitely help, to keep the doors in aligned in good position when closed. Cheers Rob

-

Thank you Mark, I hope that solved the fit issues sufficiently, but even with all the test fitting, I can´t tell for sure, if everything is perfect, until the final assembly. With my backup idea of adding two tiny aluminum rivets, I feel save enough now, to continue with other areas, which need to be addressed before I take out the airbrush. Cheers Rob

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.