-

Posts

555 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Coyote_6

-

Well done! Quite the achievement Phil. Congrats - one to be proud of!

- 288 replies

-

- Card

- Pre-Dreadnought

-

(and 3 more)

Tagged with:

-

Lots of experience and good advice in this post! The ratlines look great. Keep that First Mate happy!

- 261 replies

-

- Victory Models

- Pegasus

-

(and 3 more)

Tagged with:

-

That has got to be the coolest thing!! Well done Glen!!!

- 156 replies

-

- Queen Annes Revenge

- bottle

-

(and 1 more)

Tagged with:

-

So glad for the favorable outcome. And so glad to have you back - prayers for the Admiral's continued good health going forward!

- 436 replies

-

- Syren

- Model Shipways

-

(and 1 more)

Tagged with:

-

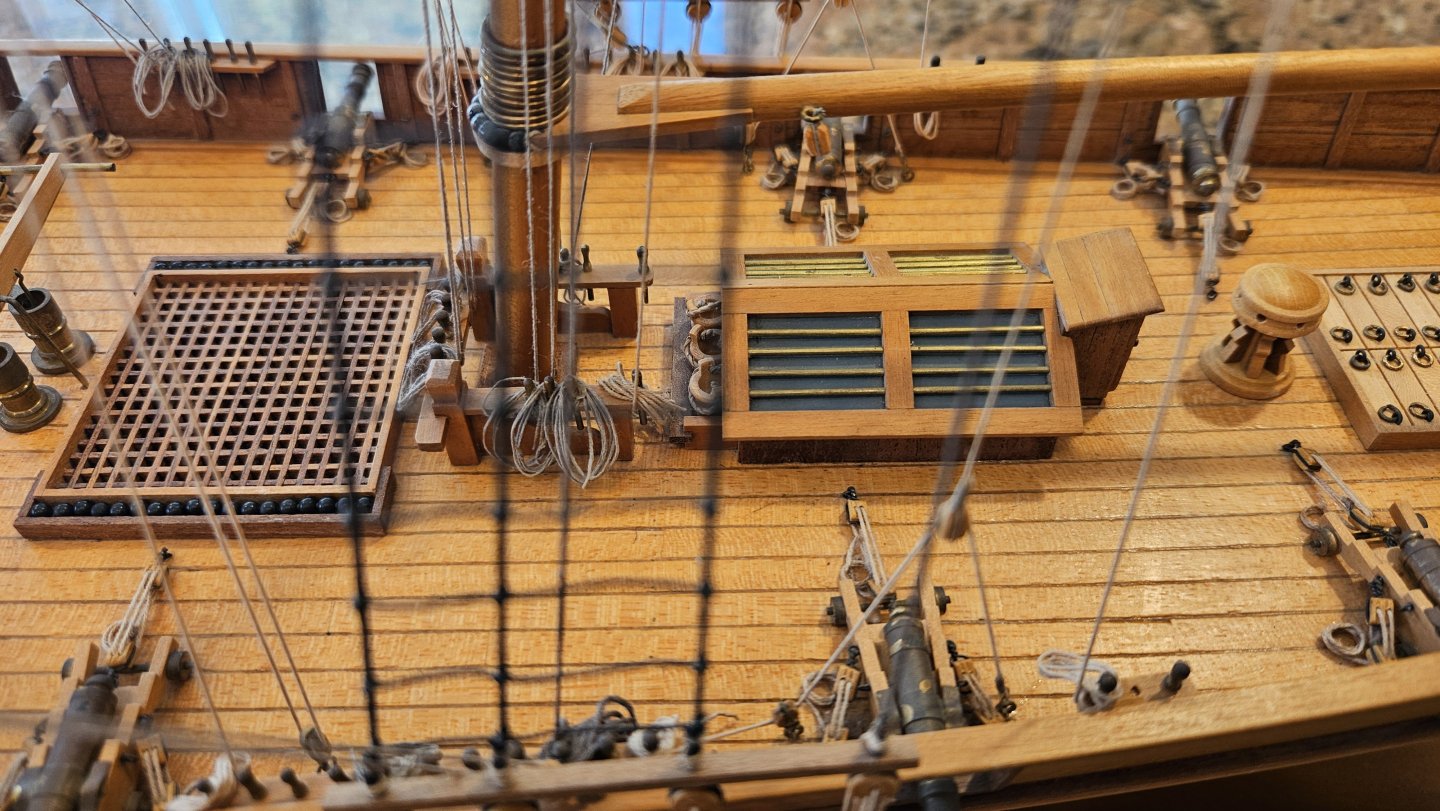

(No pics of Prince in this post. These are all of Harvey 1847 built by another San Diego builder.) A little side tracked the last 2 weeks. A local builder was retiring and donated an Artesania Latina Harvey 1847 build to our local school's history department. She needed a lot of cleaning, a couple finishing touches (capstan repair, cannonballs, and some diluted glue to secure her rope coils), and a name. Named her Grace and ordered an inexpensive builder's plaque with the builder's name on it... I made my first flag and I think it turned out ok. Used the inkjet printer on tissue paper approach (with Krylon Workable Fixatif) found here on MSW and it looks pretty good. Where else can you get a 1847 US flag in an appropriate size? 🤣 I will use this technique on the Prince for sure! I did add a block and a halyard for the ensign as well. She cleaned up well and will go to her new home this week, so it'll be back to the Prince - it was good practice!

-

Good to see you back at it. Praying for your continuing improvement! And nice work on the shrouds. That's where I'm at on my project.

- 261 replies

-

- Victory Models

- Pegasus

-

(and 3 more)

Tagged with:

-

That looks so darn cool! Wow! The torches look great - what detail!!

- 156 replies

-

- Queen Annes Revenge

- bottle

-

(and 1 more)

Tagged with:

-

Shame to have to paint those hose racks Phil - the silver and gold looks awesome on your finger there. Nice. Work soldering those up!

- 490 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

-

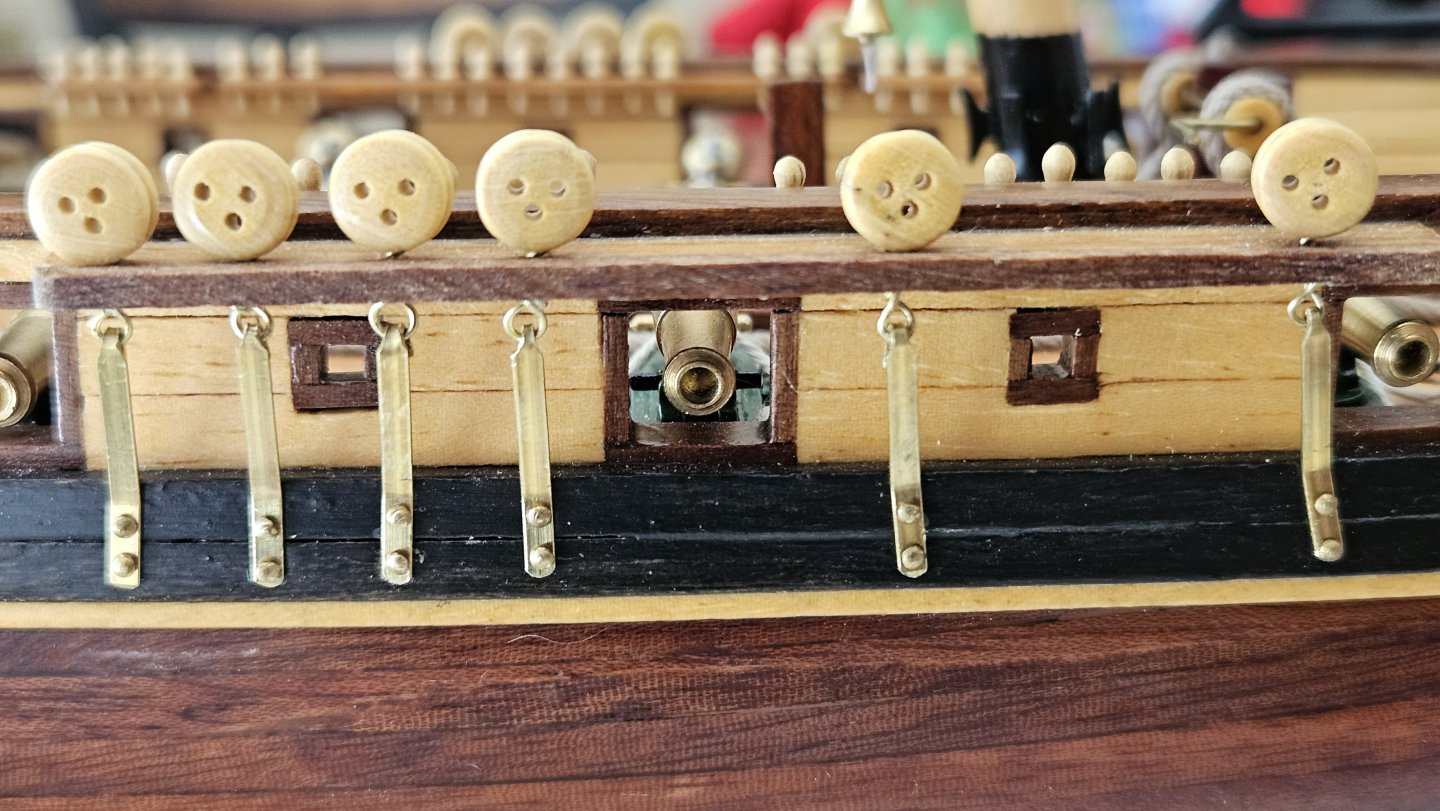

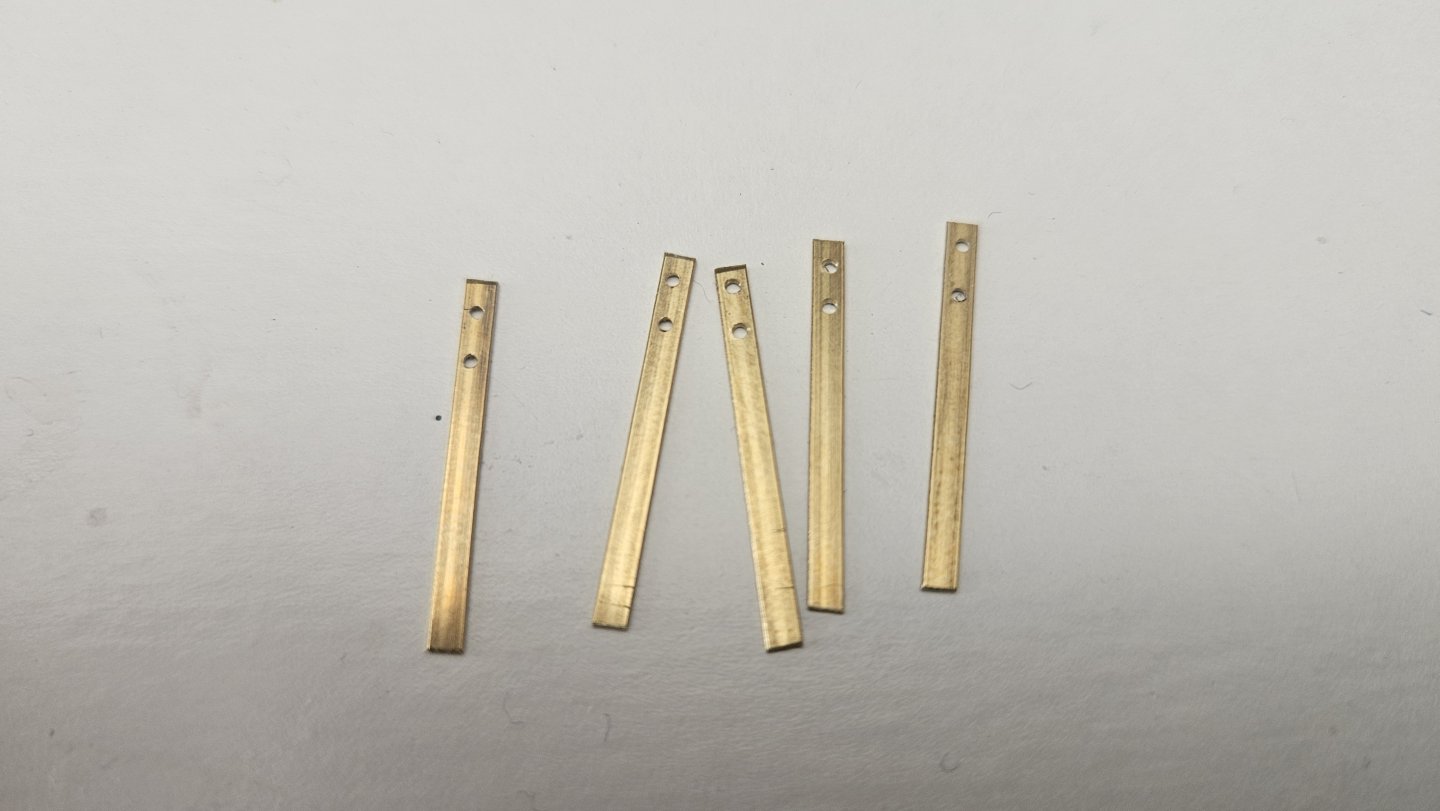

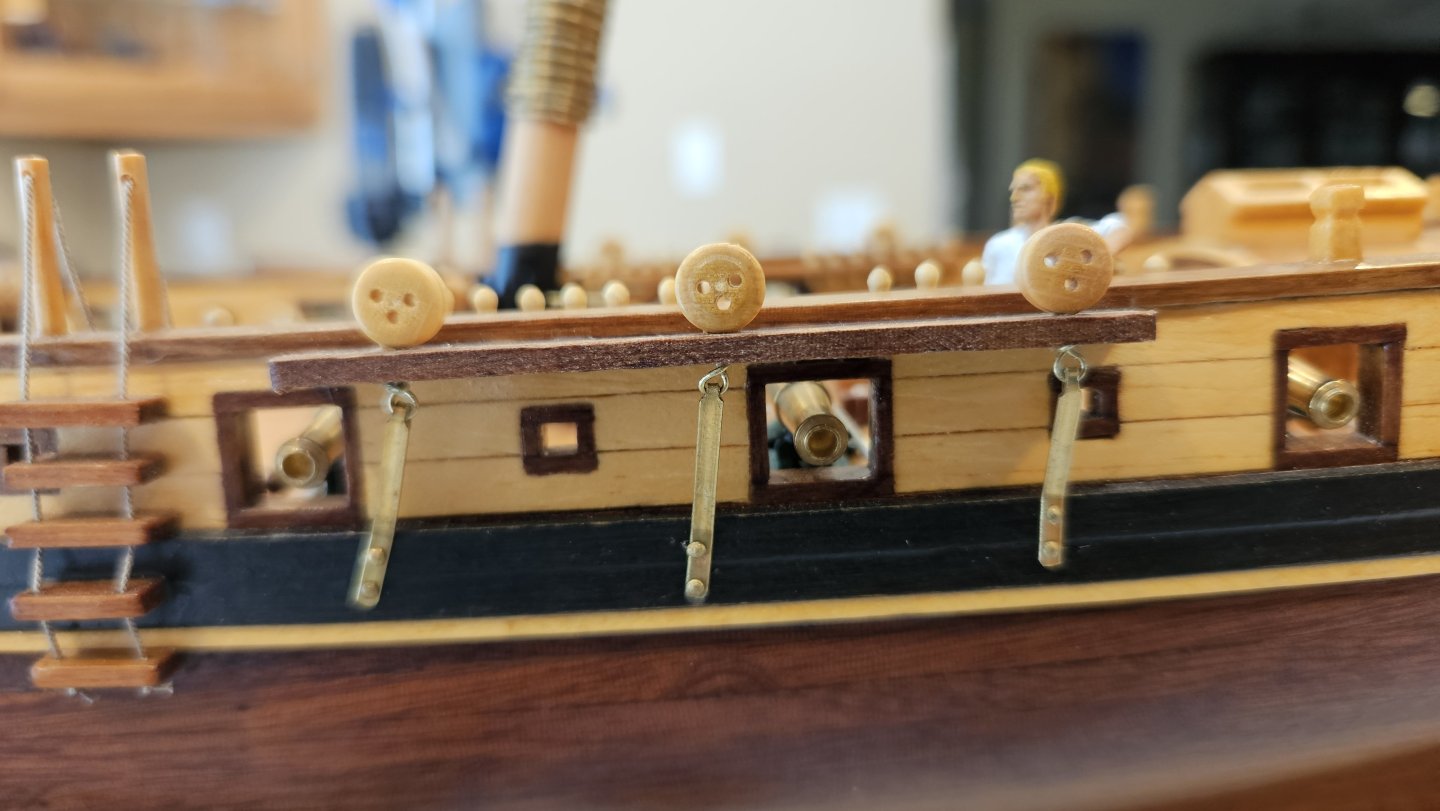

I have no excuse. But Mr. Nash (and the cooper?) has (have) completed all the chainplates!! Each chainplate custom sized, bent and ground. Each nail custom cut. Wow. *PRO TIP* Drill the holes in the stock first so you don't have to throw an almost finished piece away when the drill bit doesn't go where you intended. 🤣🤣🤣 Rough plates with holes. Cutting to approximate length only after holes came out acceptable. Bent and ground to fit through the deadeye strop. (First nail cut to length.) And the final bend...

-

Glen! The window screen grate is inspired!! Wow. And amazing work - end result was worth the troubles.

- 156 replies

-

- Queen Annes Revenge

- bottle

-

(and 1 more)

Tagged with:

-

Those ship's boats look really good in place! Nicely done Phil. Nicely done.

- 288 replies

-

- Card

- Pre-Dreadnought

-

(and 3 more)

Tagged with:

-

Very nice work to date Mark. And nice upgrades to the kit plywood. Beautiful work sir!

- 257 replies

-

That vent for the engine room is very very very nice! Wow. The slats are so uniform.

- 490 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

-

Those launches look great Phil! Wow. Very impressive and nice finishes.

- 288 replies

-

- Card

- Pre-Dreadnought

-

(and 3 more)

Tagged with:

-

Nice work Phil. Nice to watch someone who really knows what he's doing. Very very cool insight for us.

- 490 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

-

The deck and bowsprit look awesome Mark. I particularly like the look of the deck wood. Don't forget to check that bowsprit angle against a couple sources - it can cause big troubles! Ask me how I know. 🤣🤪🤣🤪🤣

- 257 replies

-

Mark, The book title is compelling. As long as it looks correct to the builder, at least the builder will be happy! Is it this guy? https://www.fishermensvoice.com/archives/201809CastinesJohnPGardnerAndHisShipModels.html Your nibbing looks very clean. Well done!

- 257 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.