-

Posts

560 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Coyote_6

-

Congratulations! Grecian is a beauty. Wonderful work. Her and Harpy side by side is just fabulous. Thanks for sharing them together like that.

- 52 replies

-

- Grecian

- Vanguard Models

-

(and 1 more)

Tagged with:

-

'Tis always so. Looking good Phil. Still waiting for a small deadeye that took flight a couple days ago to return to me. Keep up the great work!

- 288 replies

-

- Card

- Pre-Dreadnought

-

(and 3 more)

Tagged with:

-

Phil - I love your sea stories - brings me back to my Marine Corps days, particularly 1986-1990. Simpler times for sure.

- 493 replies

-

- minesweeper

- Cape

-

(and 1 more)

Tagged with:

-

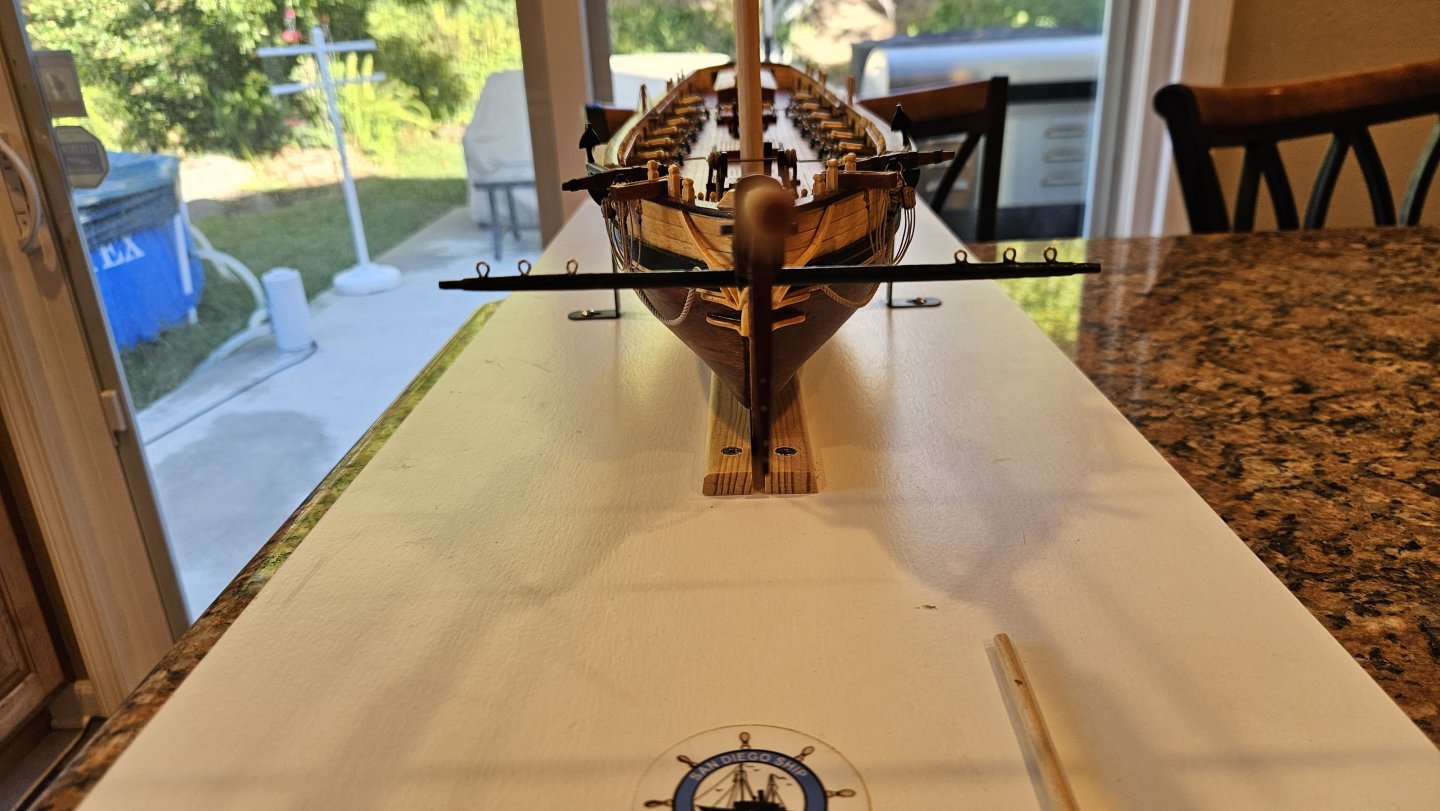

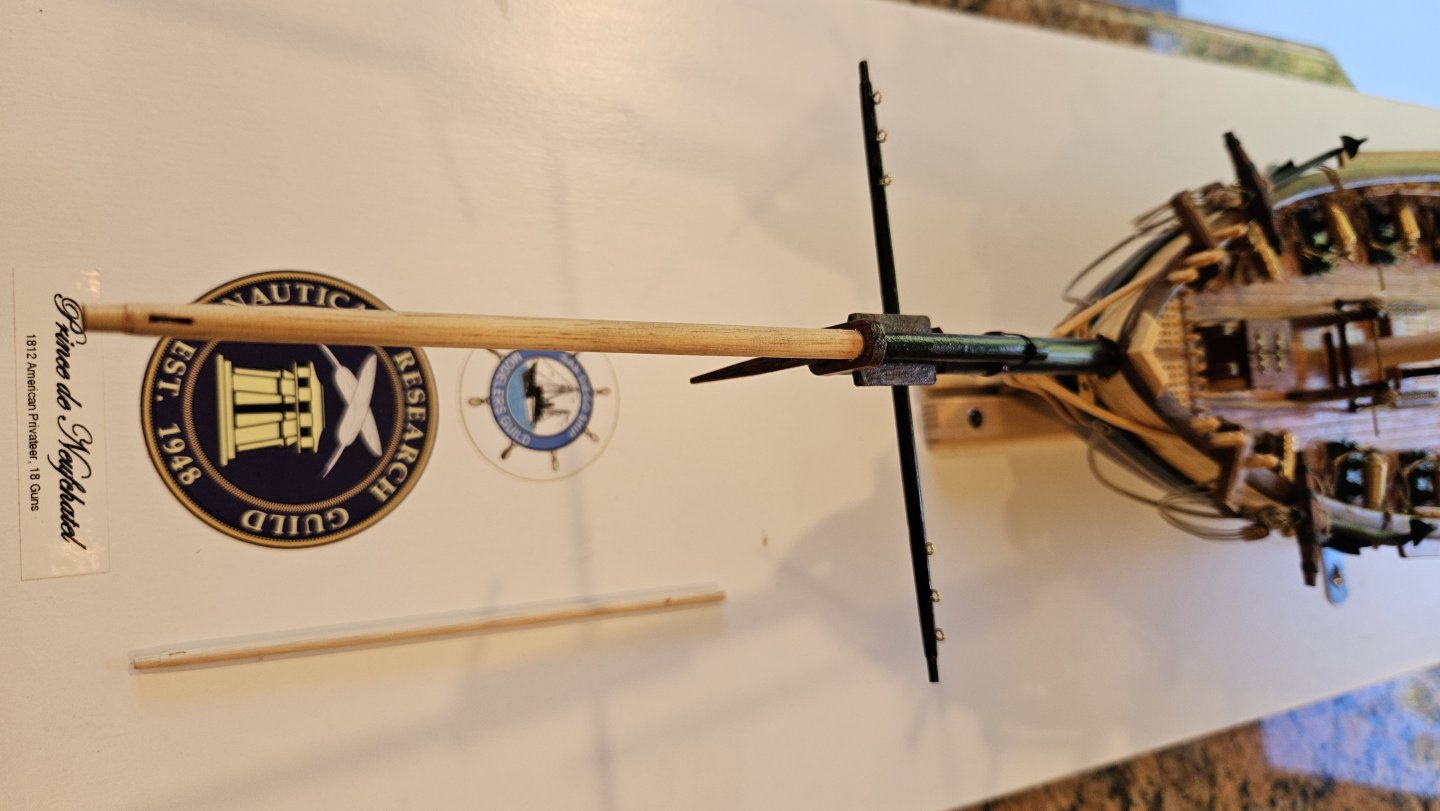

And finally closing the weekend with the bobstays. (Syren Ultra Brown 0.025", Syren Ultra Tan 0.012") I am thinking I might be needing some masts soon to continue rigging? Anyway, thanks for checking in and for any and all comments/advice. (Marquardt, Global Schooner, page 169, figure indexes 2 and 8, Petersson, Rigging Period Fore and Aft Craft, page 84, and Chapelle's rigging plans)

-

@Dr PR Thanks Phil. If I am being honest, I may be a bit overwhelmed with this new first-timer task!🤪 There's like 20 lines at the bowsprit, I'm referencing like 3 different books and Chapelle's sail plan, and just trying to get it right. I may be a bit tightly wound!! 🤣 Thankful for the help from you guys. Makes all the difference. I think it's the eating an elephant analogy. How do you eat an elephant? Focus on 1 bite (line) at a time. I am learning and having fun, so there is that!

-

Bowsprit gammoning and frapping turns per Lever. Let me know if I have issues friends - I think corrections will be more difficult the farther we proceed! Port: Starboard: Frapping turns: I think bobstays (bobstay and bobstay preventer???) are next on the list. Thanks for looking in and any comments in advance! (Lever, Sheet Anchor, Page 19)

-

@Dr PR Thanks Phil! I did not know that it was called a crupper - fun fact. Thanks on inhaul and outhaul. Unfortunately Albatros didn't have a spritsail yard so I am winging it so to speak. I think my biggest trouble is Lever or Marquardt will show something (spritsail yard footropes as topic of the day) - Chapelle's "plan" does not. Does that mean she didn't have spritsail yard footropes, or did Chapelle/RN know they were always there so did not note them? Slow and steady wins the race here. I'll be in touch 🤣🤣🤣!

-

I have to admit to being a bit lost at sea for the last 6 weeks. Spars and rigging are a far greater challenge then I expected. With no plans I am floundering. I have resolved to rig what I understand and hold off on what i don't. An example of an issue is the jibboom inhaul and outhaul. I know they exist and were used. Do they stay rigged or only when they are needed? Serving. So much is served. At 1/58 scale do I need to serve the lines for my first build, or is an appropriate diameter line 98% of the battle? Anyway, I have built out the bowsprit according to Lever. Spritsail yard according to Chapelle. So a little progress anyway. (Open to any thoughts here!) Gammoning the bowsprit and rigging the bobstays is coming next.

-

The railings and ladders are incredible Phil!

- 288 replies

-

- Card

- Pre-Dreadnought

-

(and 3 more)

Tagged with:

-

I am probably too late to the party, but if the bulkheads are planked inboard and outboard you can compensate somewhat for the deformed plywood with the planking. My experience is that the planks can be sanded down to smooth the bulge. (Especially true in the bow where you can use longer planks over the plywood.) The plywood can also be thinned (or even partially removed where it sticks out a bit much. That said, she's looking good. The first one is always a challenge. Keep up the great work. Examples: Rough structure issues with my plywood bulkhead core starboard side. Missing gunport "frames" in the plywood form, port side.

- 17 replies

-

- Swift

- Artesania Latina

-

(and 1 more)

Tagged with:

-

The only comment I can offer is that if the pellet is lead it may not be the best choice for a long lasting solution? I think lead is subject to oxidation/disintegration over long periods of time. https://www.navsea.navy.mil/Home/Warfare-Centers/NSWC-Carderock/Resources/Curator-of-Navy-Ship-Models/Lead-Corrosion-in-Exhibition-Ship-Models/ (Hat tip to user Bob Cleek who cited the above in the following MSW thread: )

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.