-

Posts

2,530 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Rustyj

-

Ouch. Tough way to start the day but I know you'll get it all sorted out!

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thank you for the kind words Don!

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Very well done Don. That is a fine looking model and congratulations on the twin grandchildren!

- 144 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hi B.E. I just spent a very pleasant time catching up on your build log. Very well done!

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

I all. Well, we made it back without any serious issues driving though the Admiral nearly ripped the door handle off a time or two! We had a wonderful time and as astonishing as it might seem two weeks in England, Scotland and Wales and NO RAIN! Umbrellas and raincoats stayed tucked away. I must say that though she's undergoing an overhaul, touring the Victory was simply fabulous! Thank you Frank for your kind words. Thanks Ben. Yep sound advice but that look right first thing either pulling out or crossing the road almost got me a couple of times.😲 Thank you Dusan, I look forward to continuing to following your build. Thank you JJ. Again I'll continue to enjoy your build and also your new project! Again thank you to all of you who have followed along, supported and liked throughout this thoroughly enjoyable project.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Beautiful work on chapter 5 Glenn.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thank you Greg. Your kind words are very appreciated. Also thank you so much Dave, Steve20, Steve, John and Jim. Chris your work with pear was an inspiration to me. Thank you all for stopping by and the likes. On a side note I spent the last couple of days doing a deep cleaning of all the cabinets, drawers and counters here in the shop. Rediscovering items I forgot I had and items I wondered why I still had. I also will be out of touch for a couple of weeks. Going on a two week journey across the pond to England, Scotland and Wales with the Admiral. For all of my friends in the UK, watch out for the crazy American trying to drive on the wrong side of the road! 🤣 🚑 See you later!

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Chris. The great design really helped produce the finished product. Thanks Adam. It was a lot of fun working in pear and cherry. Thanks Chuck, Mike and Matt. The display location and method are yet to be determined. For now she'll just be covered and stashed safely away. Thanks Valdimir, Grant and Jean-Paul. Thanks Matthias, Its been a pleasure watching your build too. Hey Glenn I feel the same about yours! Thank you Steve and Ryland. Much appreciated. Thanks Peter, It's always fun to try some different colors. I'm glad it worked. Thank you everyone for the kind words and likes.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Matt and Glenn. Also thanks for all the likes and advice throughout this wonderful build. A special thanks goes out to Chuck for putting together such fantastic model! I started this adventure back on September 30, 2019. It has been a great learning experience. I got to watch some very nice Winnies being built. Enjoyed the comradery and friendship from so many of you who have the same passion as I do. Well, the lantern has been completed and added to the stern and with that my version of the Winchelsea is finished. Again, thank you for stopping by and most of all for your support, guidance and friendship!

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

I've finished the stern lantern now. Just have to make the mounting bracket. I will make it out of brass rod instead of the supplied wood bracket. Nothing wrong with the wood I just have the rod. After that I'll mount it and then other than some cleaning, sigh, she's done.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Work continues on the lantern. And yes I am dragging the end out just a little bit. 🤣 Thanks to you all for stopping by.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Hi B.E. Another thing I found out using pear is that to the eye pieces looked similar when untreated. But when a finish such as wipe on poly, like I used, the planks still took on a different appearance. If I were to do it again and were looking for a uniform look I would apply one light coat of finish then compare planks prior to planking.

- 648 replies

-

- Indefatigable

- Vanguard Models

-

(and 1 more)

Tagged with:

-

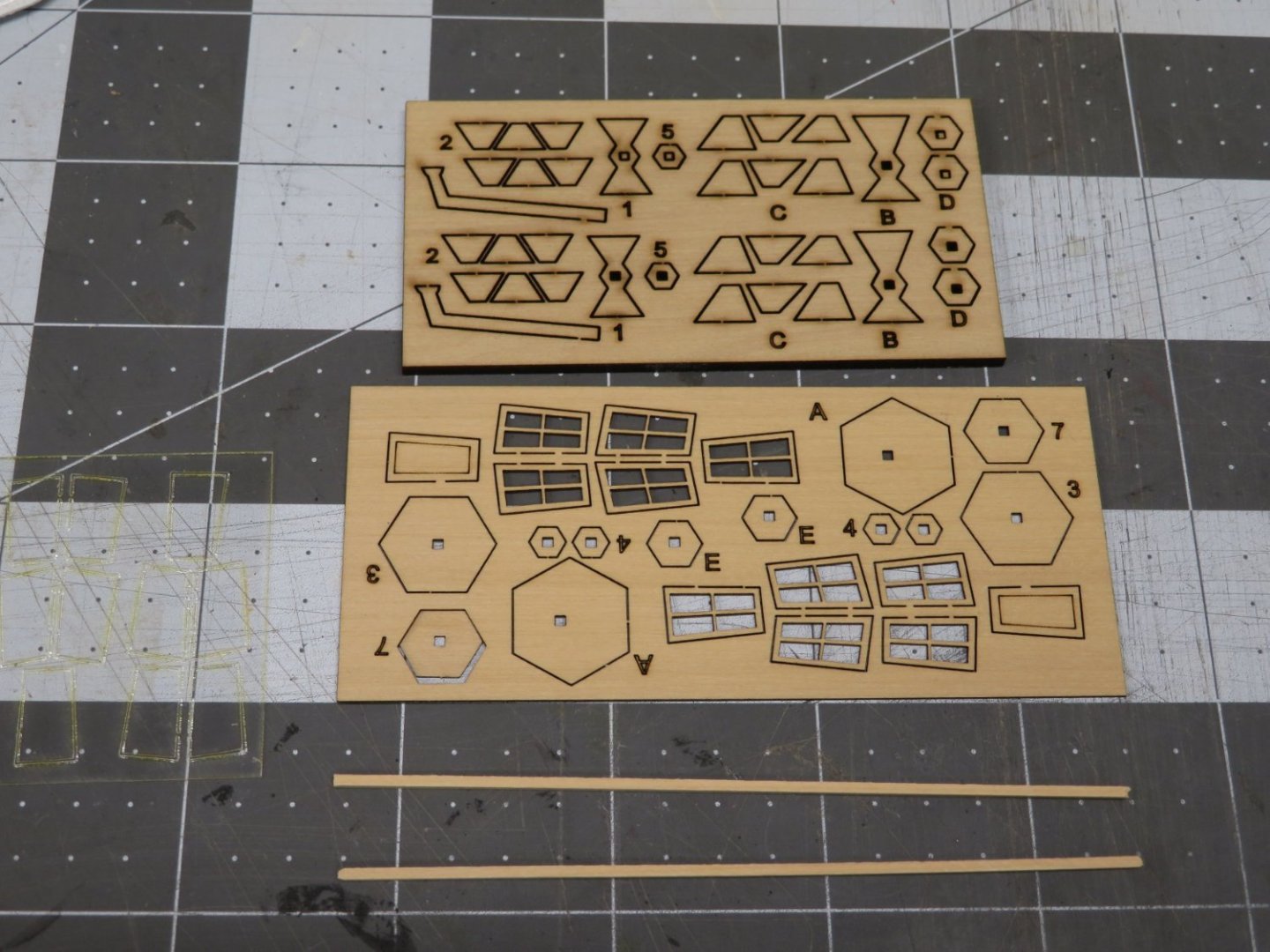

I've been slowly working on the stern lantern. The laser cutting is very sharp and the pieces are small and delicate. I started by assembling the top and bottom of the lantern. No sanding of the joints as they fit perfectly. The edges were the rounded off. Spring is in full bloom here. We have a male pheasant who for the last three years shows up looking for a mate. He was in the yard a couple of days ago honking away.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.