-

Posts

2,334 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by chris watton

-

Trumpeter Scharnhorst Battlecruiser 1/200 is coming soon.

chris watton replied to yvesvidal's topic in Plastic model kits

Maybe! Unfortunately, Yamato was sold in the early '90's, don't even remember who to. -

Cheers Right now, I make sure that every penny goes back into the business, hence the reason we both still have day jobs. I believe it is important to get the business up and running and be self sustaining, with all equipment bought before I take any money from it. I need another laser machine (larger bed and more powerful, for the larger kits I have in mind), and this also means I need to turn our garage into a fully fledged work unit, to house both machines and kit boxes. Before I can think about taking money from the business for ourselves, these things need to happen first. By the way, orders are not delayed, we are now fully up to date!

-

Trumpeter Scharnhorst Battlecruiser 1/200 is coming soon.

chris watton replied to yvesvidal's topic in Plastic model kits

I couldn't help myself, I ordered the kit! Although I know I will never have the time to build it, but Scharnhorst is one of my favourite battlecruisers, looks-wise. Told my wife it was only £55, and quite small a scale.... Years ago, I did buy and build for RC the Nichimo 200th scale Yamato, that was quite a monster! -

You can even leave off the pre cut decks and plank as much or as little of the deck you like - although no extra deck planking will be included, there will be an alternative 0.8mm ply deck pattern for the forecastle and quarterdeck.

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

Yeah, you would need to make a new figurehead, as Sphinx is the only one of this class I will be developing. Am hoping this will be ready for around July.

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

Just a little update. I ordered a few books that, for the most part, I have read and inspired some of the previous (and many future) model kit choices: Books – VANGUARD MODELS It was suggested to me from a MSW member that perhaps the brand new (just published) book on the life of the Duchess of Kingston may be a nice option for when purchasing the Duchess kit, so I ordered some of these too. The first book to inspire me was Frigates, Sloops and Brigs, although I had the original separate books, Sloops and Brigs and The frigates, but the new book combines both. It was this book (that I read and re-read) during my lunch hours at work that first introduced me to the Speedy. Still working on Sphinx, but I have also started laser cutting some sheets that are final. There are so many sheets that I felt I need to get started as soon as I knew the sheets are OK and final.. Oh, forgot to say, I have had my Master-Korabel kits order delivered, so they are all back in stock, with blocks and deadeyes arriving in a week or so, I hope...

-

Absolutely superb! Looks so good, well done.

- 222 replies

-

- First Build

- Lady Isabella

-

(and 2 more)

Tagged with:

-

Just to add, I will be providing enough pear strip second planking to go up to the upper laser cut planking pattern. The upper half of the patterns are to be painted and has markings for all channels, quarter hammock crane stanchions etc. The lower half of the laser cut pattern is not so essential, so that area can be planked in the normal manner if desired. The lower side rail/planksheer parts that intersect the gun ports will cover the join between the upper and lower pattern. So a standard planking option below that level is an option. I am doing the CAD drawing for plan sheets whilst Jim makes the prototype model from the production parts. For me, that's about another 6 weeks work...

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

No need for any flattening. The slight bend is likely temporary due to being in the box. When the hull assembly is built up, all will be straight and true anyway.

- 160 replies

-

- Alert

- vanguard models

-

(and 1 more)

Tagged with:

-

Hello Gregory. I do plan to once I have a few sizes done. As the photo etch parts cost quite a lot of money, and I prefer to wait until I have at least three versions to fit on a single production sheet. Ideally, I need another a size below the one shown, and two or three larger, for frigates and line of battle ships. Same applies to hand pumps, but I do currently offer some capstans and other fittings.

-

Yep, InDesign for putting the manual together, along with box art. I also used it to put the plan sheet together, but now use CorelDraw instead, as it's much easier to import my CAD drawings with text into this software.

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

Now, I hate to disagree with anyone on these forums, but I have built literally dozens of models using MDF for the past 13 years, and have never once experienced what you describe. I too have laid soaking wet limewood first planking to the MDF frames without the slightest issue. I had the first prototype Sphinx MDF skeleton outside by the bins for a couple of weeks, where is suffered rain, sleet and snow. No signs of swelling at all, although the 2mm ply deck did warp. All of my MDF is bought from he same place, and is the highest grade I can buy. You must have been very determined to get your MDF to react like that.

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

If you are building her as commissioned by the Royal Navy, Bounty would be coppered for such a voyage. It is an unfortunate fact (for those who hate copper plating), that the vast majority of English vessels (and a little later, French vessels) would have copper bottoms from the 1780's onwards. Blame Charles Middleton...

-

Always a compromise. I could do most in wood, but to keep to scale, they would be way too fragile. The alternative would be to increase widths/thicknesses, and end up with those way out of scale chubby parts like ships wheels. Took a while to decide about the topmast cross trees, as I would have liked them in wood. However, again, the scale widths were too small, and many would have had problems. Nothing worse than having such a part snap/break when you've already started the rigging process, and they were always painted anyway...

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

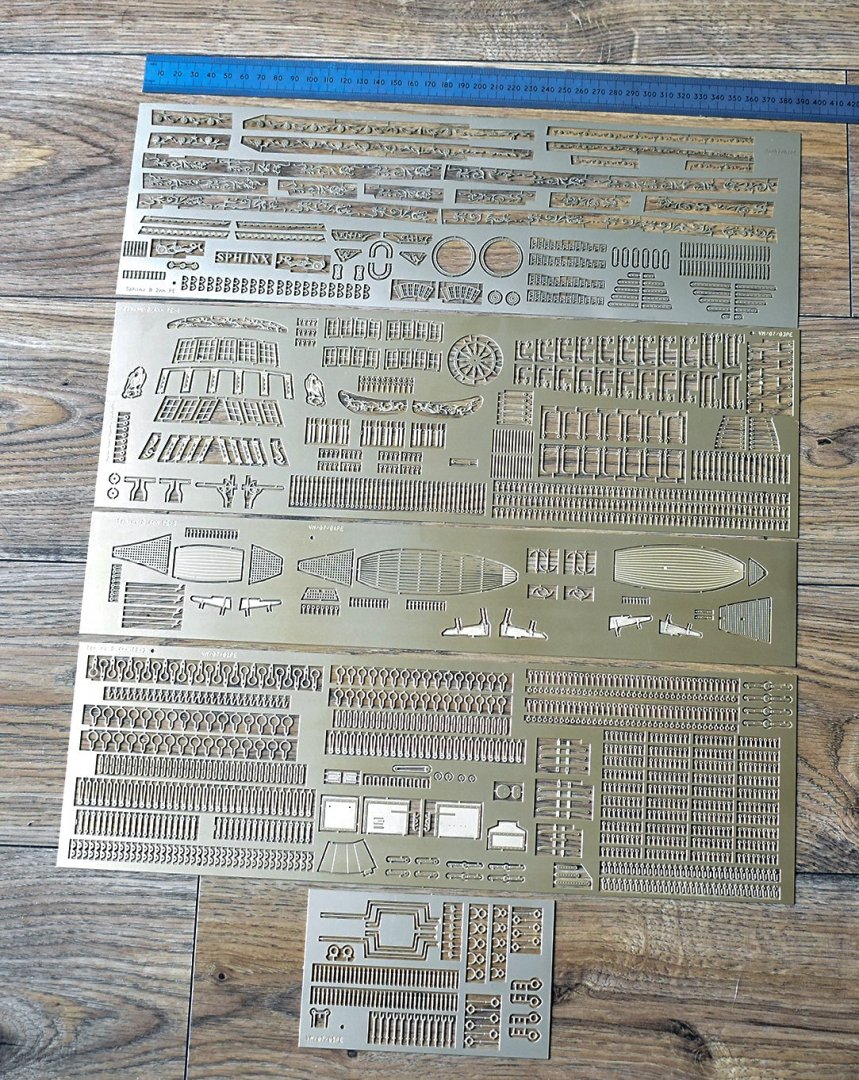

Just had the test sheets arrive for the five sheets of photo etched brass for Sphinx, which I shall get shipped to Jim. these are quite big...

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

Hi Alex, Your model is certainly inspirational. However, the vast majority of detail that isn't shown on the original Admiralty plans for Sphinx Class was gleaned from the AOTS Pandora, as this seems to be the closest match for the slightly smaller Sphinx.

- 355 replies

-

- vanguard models

- Sphinx

-

(and 1 more)

Tagged with:

-

Very nice, and very well executed. I will always have a fond affection for this kit, as it was my very first wooden boat kit I bought and made.

- 83 replies

-

- finished

- billing boats

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.