marktiedens

NRG Member-

Posts

1,737 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by marktiedens

-

Thanks,Frank. Yes,this is not your ordinary run of the mill kit. Many parts have to be formed & shaped with the materials provided so it is a bit of a challenge. Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

Well,I decided to modify those stern pieces a little further. The upper piece should have a bit of a slant at the rear edge instead of perfectly vertical,so out with the belt sander & beveled the rear edge. Much better now I think. Thanks to keith w for the heads up on this. Now I have to modify the bottom piece to fit again,which means re-carving those grooves for the metal bands. Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

First,Thanks for all the nice comments. Pete - That sounds like it may be a good idea to pre-bend at least the lower wales. 2 by 7mm walnut is a real pain to bend. Keith - I was considering installing the wales before the transom,but did not want to try & chisel parts of it out while at the same time trying to fit the galleries. I also thought about just installing the lower wales first,but I didn`t know exactly where to end them under the transom. They appear to end in a curve to match the bottom decoration,which can`t be put on until the transom supports are i place. I am considering making the lower wales out of basswood - much easier to bend. Since they will be painted black it doesn`t really matter what kind of wood they are. The only trouble with using basswood for the wales is I would have to be careful not to ding them up - basswood is kind of soft. I may try to bend those walnut strips first to see how they come out. I remember when I built the Wappen Von Hamburg the lower wale was 3 by 8mm walnut - talk about hard to bend. Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

Hi all - moving forward on the transom. After studying the plans & Pete`s info I started with the upper transom support,which is the base for the entire stern assembly - it needs to be close to correct or everything will be off. First thing I did was attach some short planks in the position of the lower wale - that way I could slide the transom support in to the same place every time while fitting it to the sides of the hull. Then after fitting to the sides of the hull I installed a couple of dowels in the front edge so I could install it in the same place after removing the 2 short planks. The distance from the top of the upper support was 98mm - just what it should be to the upper quarter deck. Then I proceeded to shape the upper transom support. I used the metal bands that fit between the 2 support pieces as a guide to shaping the bottom.The profile of the top of this piece was not altered. Then I shaped the lower support both from the sides of the hull & the bottom of the upper support. Then the fun part - cutting the groove for the metal bands to sit in. Took most of a day with my little exacto chisel & files.Meanwhile, I installed 2 dowels to keep the 2 pieces in alignment. A dry fit of the 2 support pieces & metal bands came out pretty good. My hand held Proxxon belt sander was a BIG help in shaping these pieces. Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

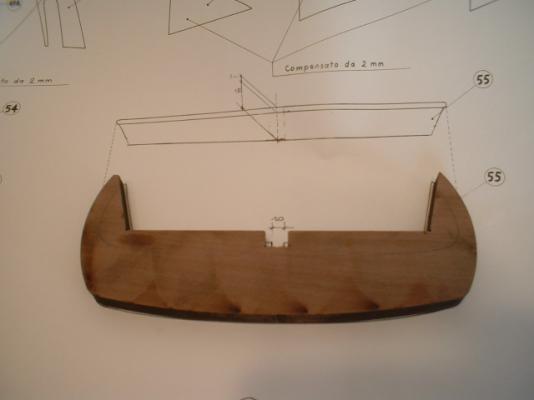

Update - started working on the transom & ran into a problem. After a lot of measuring & head scratching it seems the 2 main pieces that make up the transom support were made wrong. After contacting piratepete007 - the writer of the interpretive manuals - he contacted Euromodel & found out that a few years back the people doing the laser cutting cut a batch of these timbers the wrong thickness. I was going to contact them for some replacement parts but decided to just make new ones - not too difficult. In the first picture you can see the 2 parts sitting on top of each other,the thicker one on the bottom as it shows in the plans & Pete`s info. The problem is the thinner top piece should be wider than the bottom one. The second picture is of the new pieces I made. Finally,in the last picture I used one of the bulkhead knock-outs as a template to form the correct deck camber on them. Euromodel knew about the bad parts,but someone unknowingly put them into some kits. I guess I am a perfect example of Murphy`s law. Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

Keith - as far as the wales go,I laid the first strip of the second planking at the position of the top of the lower wale & with the same curvature so lining up the angle of the transom pieces should not be a problem. As far as shimming the 2 transom parts,Pete says that after beveling for the camber the parts should end up with thicknesses of 10.5 & 13.5mm along their entire width. Will the assembly of these 2 parts not be high enough if I don`t shim them? Mark

-

Hi Keith - that is my determination also. I have been in contact with Pete about this. He is going to contact Euromodel about this,but I am going forward & in the process of making new parts out of basswood. The basswood is a little easier to work with than that rock hard walnut anyway. Here are my nice new parts & thanks for your help & opinions Mark

-

Hi Keith - I took a couple of pics to show what I mean. The first pic has the thicker piece set on the plan sheet on top of the top profile,which matches perfectly. If you look at the side profile just above it,it appears that it should be the thinner piece. The second pic has the thinner piece set on top of the top profile of the plans & matches perfectly,but the side profile above it shows that it should be the thicker piece. In other words,the pieces are shaped correctly but the thicknesses are reversed. Also if I set the thinner piece on top of the thicker one,it is a bit narrower. Does this look correct to you? Mark

-

Hi Keith - I have a question for you - when matching up the pieces 54 & 55 with the plans piece 54 appears to be the 18mm thick piece,while 55 appears to be the 13mm thick piece. My issue is that Pete`s info seems to indicate that 55 is the thicker piece & 54 the thinner one . It also appears that way in a drawing on page 25 of manual 2 of his info. which is correct? I guess what I really need to know is which piece goes on the bottom? Also on plan sheet 7 the top profile of piece 54 matches the thicker piece but on the side profile it looks like the thinner piece. The top profile of piece 55 matches the shape of the thinner piece but the side profile looks like the thicker piece Mark

-

Thanks Ian - those gun ports were a bit fiddly to do,but I am happy with them. Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

A little more progress - planking all sanded down smooth & all gun ports that will be open are lined. I pre-painted the 1 by 5 mm strips for the linings before installing them - much easier than trying to paint them in place. No finish has been applied to the hull yet so it looks a little dull. Next up will be the stern galleries. Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

Thanks Michael - your thoughts are appreciated. Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

Hi Max - I recall the Wappen Von Hamburg by Corel also had square strips ti make the masts. They were already tapered so all that was needed was to round off the corners with a small plane & some sanding. Check your square bars for the masts - they may be pre-tapered also. Mark

-

Greg - thanks very much. Sanding is underway! Jason - thanks also. I really like that bow shot too. The bow is rather bluff,so a bit of edge bending was required but it came out ok. I did not need any drop planks. Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

Frank - thanks very much. Glad to get that part done. Janos - thanks very much. Actually I was just joking about needing a stealer - I originally thought I would need 2 or 3 . Ian - no offense taken. I am always open to suggestions or constructive criticism. Peter - thanks also for your nice comment.It is one big ship - I haven`t figured out where I`m going to put it when finished. I have scraped,sanded,scraped some more,& sanded some more,so it is looking pretty decent now. More pics when I have finished the gun port linings. Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

Thanks Ian - I know I can get it smoothed down ok,it`s just a lot of work .After building 20-some ships these are probably the roughest I have come across - they look like they were cut on a 10 inch table saw with a dull blade. Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

Thanks Nigel - I guess it is more than a little update . I wish I could have gotten better wood for the planking,but I would have had to spend 2 to 3 hundred USD for better wood like pear or boxwood .Anyway,I told myself when I started this build I would try to make the best of the kit parts.I don`t know why the planking strips were cut so poorly while the deck planks were very nice & smooth. Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

A little update - second planking complete! The wood for the second planking was not the best quality - the thickness & width was consistent but the surfaces were very rough on some planks. A lot of scraping & sanding will be needed. It looks a little splotchy now since I haven`t started any scraping or sanding yet. I was a little disappointed that I had to use one stealer on each side at the stern . Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

Hi Michael First let me say your seizings look pretty good to me. It is a bit difficult to explain exactly how I did mine ,but I will try. First i simply held the deadeye at the right distance from the lower one & wrapped the shroud around it,having both sides of the shroud held tightly around the deadeye with two fingers of one hand - in my case my left hand since I am right-handed. The trick I use to keep the shroud in place around the deadeye is a couple of drops of CA. I know it is nasty stuff but it really holds so I can continue to work without waiting an hour or two. With the shroud stuck to the deadeye I can them use both hands to install the seizings. I start with a simple overhand knot as close to the deadeye as I can get,then just wrap the line around any number of turns as I want to & apply a drop of glue to hold it. Same thing for the rest of the seizings. I almost forgot to mention at the beginning is when I am holding the shroud around the deadeye I keep some downward pressure on the deadeye so that when I tension the lanyards the distance between the deadeyes will not change. I hope you can understand my explanation. I will say it would be a lot easier if I had three hands! Also I should mention that each shroud pair should be looped around the mast & tied together before starting so you can put the downward pressure on the shroud without it slipping. Mark

-

Hi Greg - nothing special to space the pins. just dry fit them to see how it would look & then glued them in place. I was going to space them farther apart but after laying them out I liked the close together look better. Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.