marktiedens

NRG Member-

Posts

1,737 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by marktiedens

-

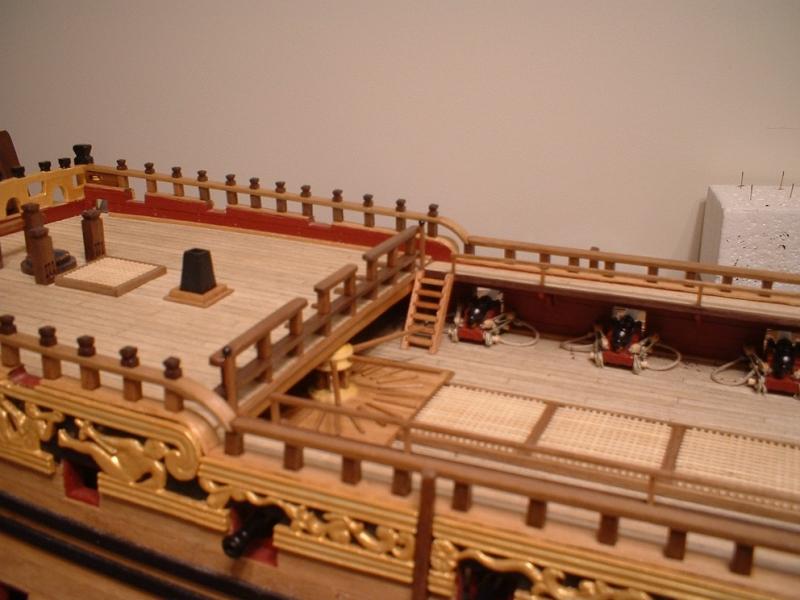

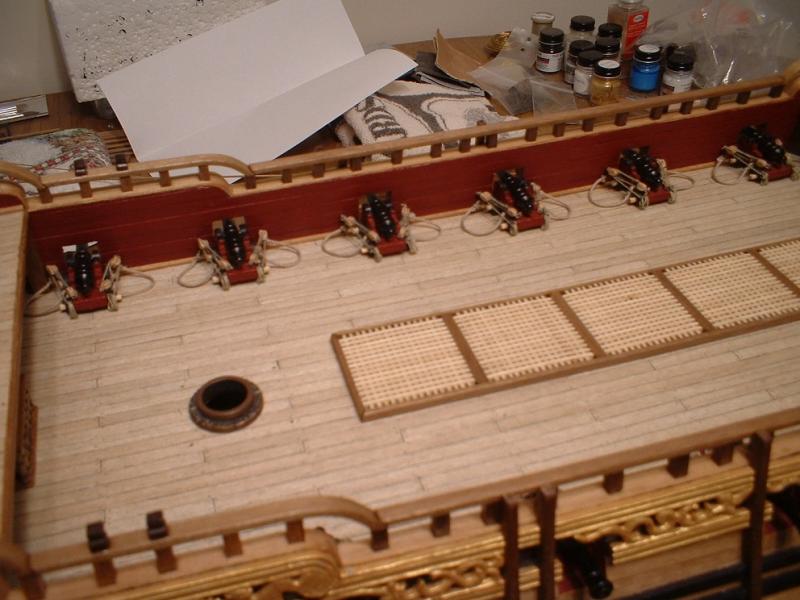

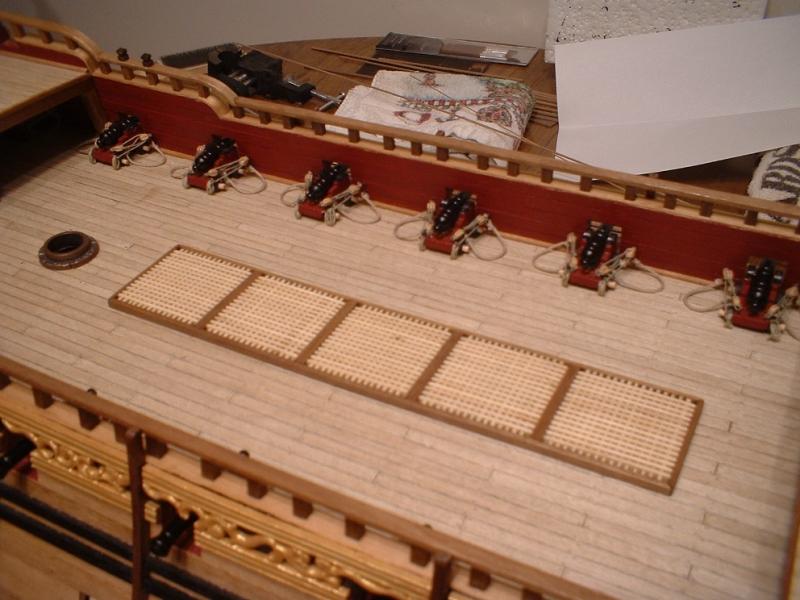

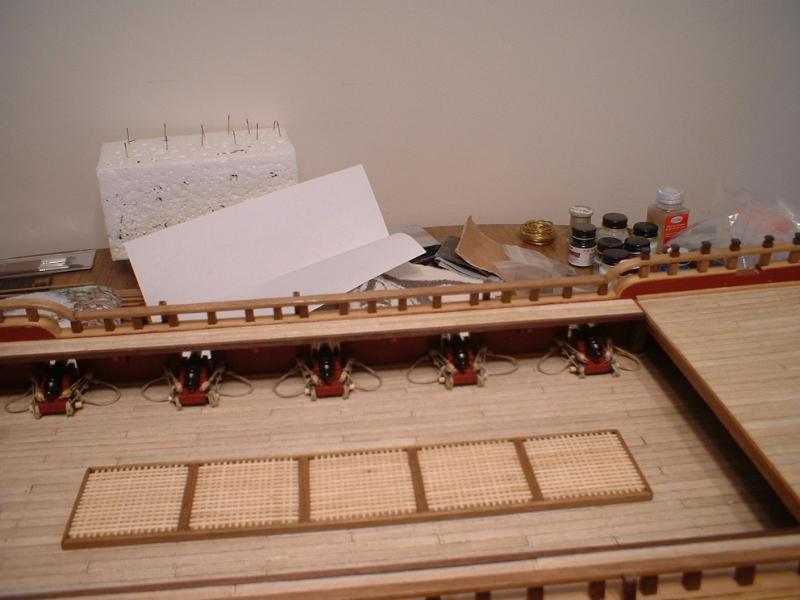

Another update - all the cannons with carriages are now in place & rigged. Very fiddly work - the blocks are only 2.5mm long & difficult to work with. Also the curved ladders are now in place & a curved handrail added up to the upper quarter deck breast rail. Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

Another small update - made up the skid beams for the ship`s boat using 2x2 & 2x3mm lumber,& added gussets at the corners,& glued in place. After that I drilled & filed the holes in the catheads & glued them in place. Still waiting for some small blocks to arrive so I can get the rest of the guns in place on those upper decks. Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

I believe they are called "crows feet" - have done a few myself. Awesome looking ship! Mark

- 962 replies

-

- sovereign of the seas

- ship of the line

-

(and 1 more)

Tagged with:

-

Thank you very much Greg & Don and also for all the likes . Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

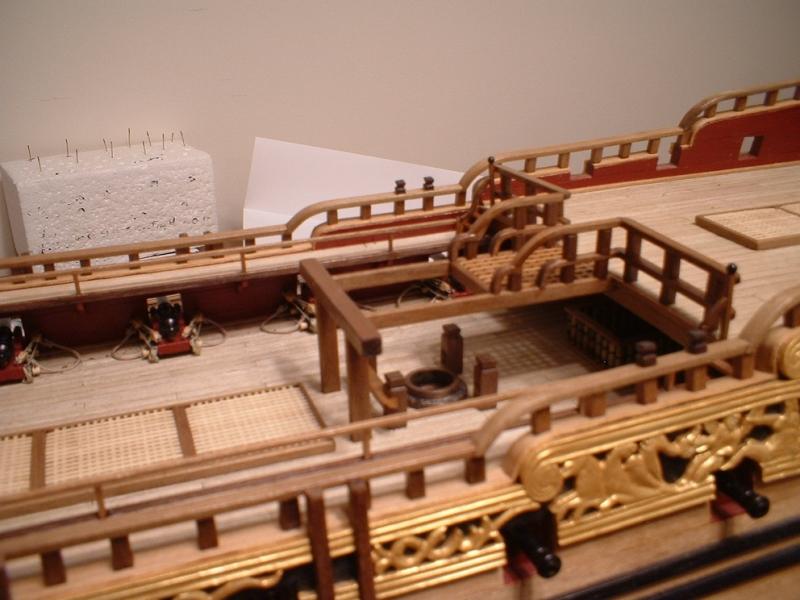

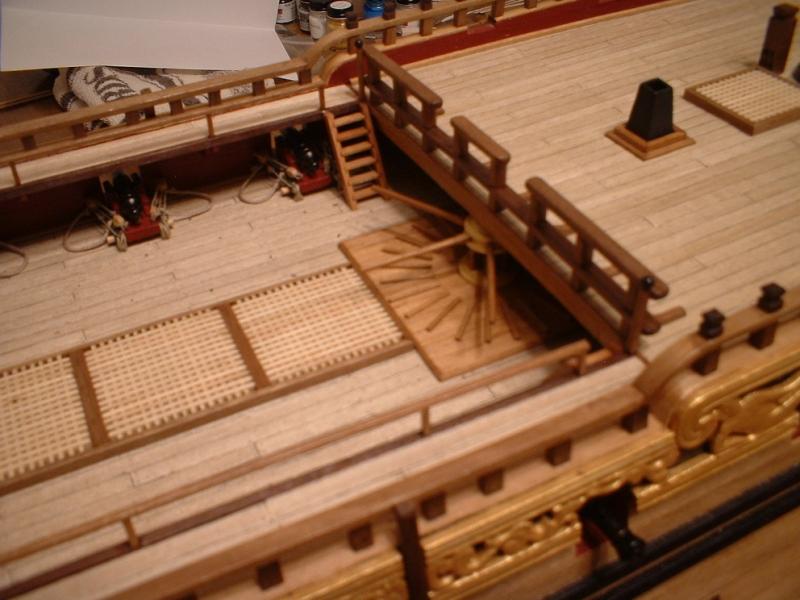

Thanks Keith & Lawrence. One thing I forgot to add to my last post is the bottom of the staircase was narrowed down to 10mm & the top steps ended up at 13mm wide. It looks just the opposite in the last picture,but it`s just the camera angle. Also forgot to add that stringers were added to the sides of the steps - I had to curve & add a twist in them to fit right - that was the hardest part. I have been conversing with Pete as to whether their should be an inner balustrade or not & am leaning toward leaving it on. The plans show an inner balustrade, but it seems to be absent on contemporary models. Have to think about that for awhile. Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

Hi all - another update. Figured I may as well do the curved stairs. First thing I did was cut the steps from some 3x5mm strip. Then I glued them up into a curve. Then I added a landing at the top plus one more step. I made the hand rail stanchions by putting a round wood toothpick in my Dremel & cut some grooves with a file. After staining & gluing in place,I formed the handrail with my plank bender & glued them in place. This last picture shows the curved stairs in place. They are not glued down yet - the quarter deck guns need to be mounted first as access will be limited after the stairs are permanently in place. As always,thanks for looking in. Also the hand rail will be finished after the stairs are permanently in place. Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

Thanks Greg for your generous comments . Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

Hi Keith - got them from Ages of Sail - they are much nicer than I could ever make. They are made by Amati,I think. If you go to their web site,click on "fittings". They have a lot of fittings,so you may need to go through numerous pages to find them. Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

hss vs carbon steel drill bits

marktiedens replied to Kurt Johnson's topic in Modeling tools and Workshop Equipment

Or you can go another step up with titanium bits,although they are generally not available in micro sizes that I know of. Mark -

Another update - upper quarter deck breast rail completed. first I cut 11 3X3X5MM posts for the rail. They were then glued onto a 3mm wide strip - spaced 6mm apart according to the plans. I happened to have a 6mm wide half round file which I used to create the arches,then a 2x4mm strip was bent to the curve of the deck camber & glued on top of the arches. Then the assembly was glued to the deck. I may work on the curved staircases next - have to think a while on those. Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

Thanks Don - being retired it`s party time all the time for me Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

Thanks very much,Nils & a late happy birthday to you as well Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

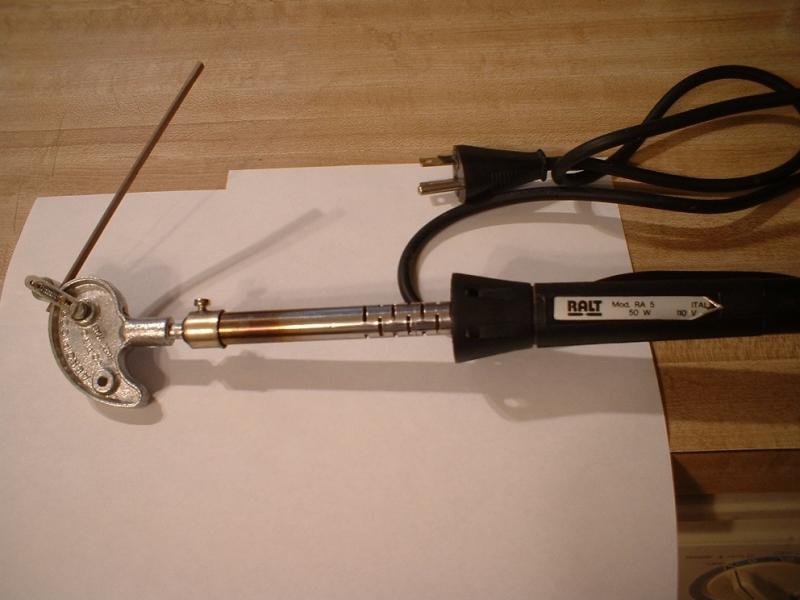

Yes,Don- that is the one tool in my arsenal I wouldn`t give up. By the way,the head is an aluminum casting. Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

Thanks Michael . In case anyone was wondering how I bent all those railings,here is what I use - a plank bender I bought many years ago when Aeropiccola was still in business. It`s simply a 50 watt soldering iron with a comma shaped head in it. It has an adjustable spring loaded roller to hold the plank down & you just plug it in & it will heat up. After soaking the plank in some plain water,I slip the plank under the roller,let the iron heat up,& start applying some pressure on the plank & it will start bending. Softer woods need only a few minutes to soak,while harder wood may need up to an hour depending on the thickness of the wood. This is the most useful tool I have - if you ever find one for sale -BUY IT. Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

Thanks Don - sorry about some of the poor photos. All I have is a point & shoot camera - difficult to get some things in proper focus. Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

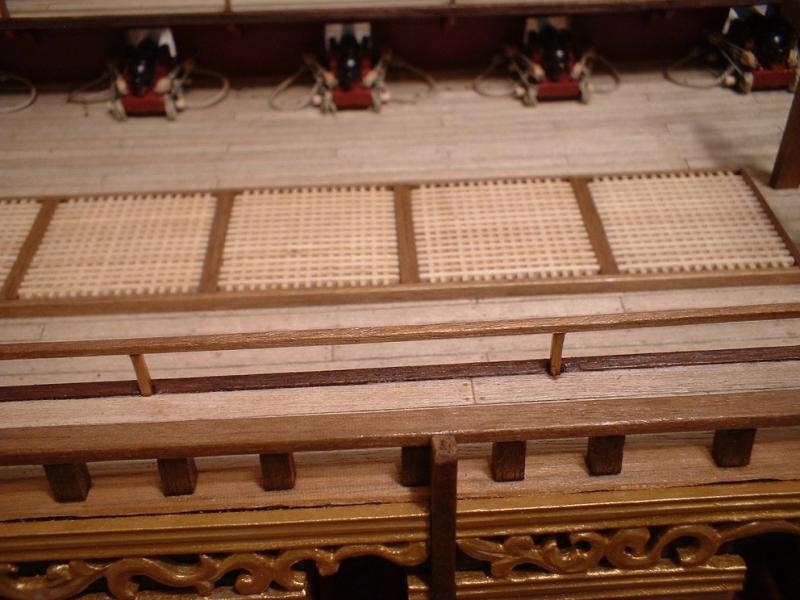

More progress in the shipyard - First thing I did was assemble all the ladders & glued them in place. Next I built a base for the capstan from 1x5mm strips edge glued together & added the small timbers around the base. One small problem I had was when I built the capstan I shortened it to fit under the forecastle deck beam but forgot to take into account the thickness of the base. So I just cut a hole in the base just big enough for the capstan to fit into. After fitting the base in place,I could just slide the capstan into place . Then I fitted all the bitts in place - all were pinned & glued. Next up were the forecastle & quarter deck railings. Their construction was pretty straightforward - just a matter of cutting a bunch of short timbers & gluing them together. Bending some of those 2x3mm timbers was a bit tricky,but I got `em done. The railing on the gangway was a bit fiddly due to the timbers were only 1.5mm square. The S shaped piece of railing joining the gangway railing to the quarter deck railing kept splitting or kinking when I tried to bend it,so I ended up just carving it from a larger timber. Also the plans showed that the grating between the quarter deck railings appears to have larger openings than the gratings on the decks,so I used a little larger spaced grating from my stash. Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

Hi all - More progress - I figured it was as good a time as any to get the 12 guns at the waist mounted as the rigging would be difficult to do after mounting the gangways. I won`t go into a lot of detail on the building of the guns,but I did modify the carriages a little by thinning them down a bit & putting a slant on the front to match the slant of the inner planking. The gun barrels were simply painted semi-gloss black & the trunnion caps were made from some copper strip & painted black also. The blocks I used were from Syren - very nice blocks. They are slightly larger than I would have liked,but smaller ones are a bit difficult for me to work with. After fixing the guns in place,the previously built gangways were installed. The front edge is level with the forecastle deck,& the rear edge is 2 steps lower than the quarter deck. Next up is some ladders & railings. Thanks everyone for looking in. Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

Hi E.J. - one thing you can do to simulate pulleys is to use a deadeye. Just file it flat on the sides so it fits snugly in the sheave. If you want it to look like metal you can paint it with brass paint or whatever color you like. They come in many sizes,although probably not small enough to fit in a small block. Mark

- 608 replies

-

- la couronne

- corel

-

(and 1 more)

Tagged with:

-

Thanks Vince. I am retired,so I have lots of spare time. You are doing a fine job with your ship as well. Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

-

Thanks David. I don`t recall doing any real carving. which parts are you referring to? If you mean the decorative scroll work,they are the castings from the kit - nice aren`t they. I did go a step further & opened up the stern windows & some of the scroll work on the stern & side galleries which were cast as solid pieces. I first drilled a hole in the section of the casting that I wanted to remove. Then I opened up the holes with a #11 exacto knife & really small files. The metal is just soft enough that it can be cut with a sharp blade. Not too difficult - just time consuming. The castings are made of a soft metal because many of them need to be bent & trimmed to fit. Mark

- 652 replies

-

- royal william

- euromodel

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.