-

Posts

653 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by jim_smits

-

The build is really coming together Stergios. I would recommend serving as it looks excellent and is well worth the time. I wish I had served all my shrouds on my Snake.

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Quick update on the Ballahoo. Onto my favourite task of tying ratlines..... Gone with the tan line and it interesting to see the contrast to the black shrouds. Only got as far as the port side so far but making progress. I draw a paper template for the shrouds and the spacing of the ratlines and used this to tie every fourth ratline. Double checked the spacing and then added every second and finally filled the gaps. Once the spacing was sorted I fixed in place with some diluted PVA, allowed to dry and trimmed of the ends. Still got a bit to do towards the top end and then onto the starboard side.

- 226 replies

-

- ballahoo

- caldercraft

-

(and 1 more)

Tagged with:

-

I give my snake a blast with my airbrush every so often to blow off the dust.

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

I used 1mm brass wire as it is a little more sturdy, you'll need to be careful on the topgallant spars as they are quite thin.

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Hi I did pins for all the yards on all of the masts. i suspect it would be easiest to do the pins now before you attach the masts in place but you'll need to be careful with alignment.

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

-

Mikeaidennh - only queried your post as this thread has been about caldercraft being poor and the only posts re CMB had been complimentary and therefore your comment didn't seem to fit. Apologies. CMB have always responded promptly to queries other than between Xmas and New Year which is understandable. In fact their delivery turnaround time has always astounded me but then I live in UK. Have ordered lunchtime and 80% of the time receive order next day in post I will again re-iterate, though, that the best way to deal with both CMB and Caldercraft is to call them. However Caldercrafts management do seem to need to go to a time management and organisation course.

-

I used Alexey Domanoff's excellent serving machine.

- 226 replies

-

- ballahoo

- caldercraft

-

(and 1 more)

Tagged with:

-

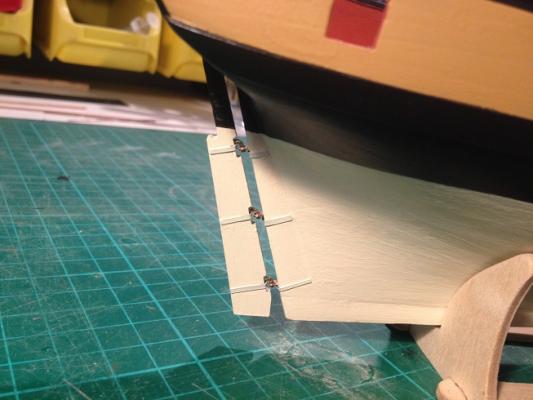

Progress is continuing. Moved onto rigging the ship. Got the shrouds on the foremast in place. I served a section of each shroud which was to be secured around the mast. The first two shrouds on each side were formed from one length which was seized to form a loop around the mast. Deadeyes were then attached to the bottom of the shrouds using a couple of lengths of brass wire to act as a spacer between the deadeye on the channel and the deadeye to be attached to the shroud. Then seized the deadeye in place and painted some dilute PVA into the seizings to fix all in place. I've added the lanyards but these are not fully tight as I will tweak the tension later. Also now painted over the rudder straps as per replies from everyone.

- 226 replies

-

- ballahoo

- caldercraft

-

(and 1 more)

Tagged with:

-

I suspect you mean Caldercraft / JoTiKa and not Cornwall model Boats as CMB have always been excellent when I have dealt with them. The key to dealing with Caldercraft is to give them a call but I agree that they really could do with working on their organisation when dealing with email enquiries.

-

Hi all, I've asked this in my build log but hopefully can generate a wider opinion here. I'm fitting rudder straps to my ballahoo model, using black paper to represent the straps. The hull is not copper plated but finished in 'white stuff'. My query is would the straps have been overpainted with 'white stuff' or would the metal have been left bare? I like the contrast of straps (black or cuprous) against the white hull but would prefer a more historically accurate finish if possible. Cheers guys

-

I know what you're saying Stergios. The straps look good against the white but my head says surely they would not have bothered paint round them....

- 226 replies

-

- ballahoo

- caldercraft

-

(and 1 more)

Tagged with:

-

A quick question for you guys as I can't seem to find a quick answer. I am about to add some rudder straps onto the ballahoo but I am unsure if the straps would be left as the bare metal or would they have been overpainted with white stuff? Answers on a postcard to......

- 226 replies

-

- ballahoo

- caldercraft

-

(and 1 more)

Tagged with:

-

Caldercrafts Snake - Register For Updates?

jim_smits replied to Kitzilla's topic in Wood ship model kits

I was exactly the same on the parts front when I started Snake as it was my first build. Get a log going and ask lots of questions. We will happily help out! -

Caldercrafts Snake - Register For Updates?

jim_smits replied to Kitzilla's topic in Wood ship model kits

Ive always had excellent service from Caldercraft. Usually only takes a quick phone call and they are very quick to help out. -

Caldercrafts Snake - Register For Updates?

jim_smits replied to Kitzilla's topic in Wood ship model kits

I've got the Snake kit but have to admit I havent registered it. Will echo Brian's advice and recommend a full check on the parts list and follow up with Caldercraft if anything is missing. They are very good in posting out any item required. Looking forward to your build log, there are a few Snake modellers out there, feel free to use our logs as inspiration. http://modelshipworld.com/index.php/topic/509-hms-snake-by-beef-wellington-caldercraft-scale-1-64-first-wooden-ship-build/ http://modelshipworld.com/index.php/topic/634-hms-snake-by-stergios/ And the Snake link in my signature. Good luck! -

Cheers Eamonn! I wouldn't say hard but I had to take it slow and steady. I marked two bands 6mm apart at a point on the dowel leaving about 5mm leeway at top and bottom. Scored these two bands with a scalpel down to the approx depth required, about 1mm. Then very carefully shaved flakes away to form the cone and taper the top. Finished off with sandpaper to smooth back to the circular cross section. As I say, not too hard just take your time and use a fresh blade with lots of small strokes.

- 226 replies

-

- ballahoo

- caldercraft

-

(and 1 more)

Tagged with:

-

Thanks for the likes everyone. Got an update of the last few days work. I have now finished the bowspirit and the two masts. Used a davids plane to taper the bowspirit and the sanded extensively with multiple grades to give a nice smooth tapered finish. The two masts were carved using a sharp scalpel to shape the top section and then careful planning to taper the main section towards the top, finishing with sandpaper again. Decided to follow the paint scheme of my Snake build and paint the masts and bowspirit in yellow ochre. Then spent a while drilling a variety of holes to fit the mast cleats and also to allow eyepins and blocks. For the eyepins with blocks I followed the same methodology I used for my carronade rigging and again was pleased with the results. The blocks on the bowspirit were attached in much the same way to simulate a strop. The bowspirit has been pinned into place, whilst the two masts have been inserted into the deck but not fixed or glued at all. Onto standing rigging....!

- 226 replies

-

- ballahoo

- caldercraft

-

(and 1 more)

Tagged with:

-

Hello Good looking build so far. Pickle was a build I considered before I settled on my current Ballahoo build. Planking, coppering and your deck look great and I will be following with interest. Keep it up! Jim

- 76 replies

-

- caldercraft

- finished

-

(and 1 more)

Tagged with:

-

Nice bit of progress in the last couple of days. Added belaying pins to the four pin rails, and added cleats to the various points across the hull and deck. Still need to add a few more eyelets to the deck and the hull but I want to confirm which of these require a block to be seized before fixing the eyelet in place. And then I shall be moving onto shaping the masts and bowspirit.

- 226 replies

-

- ballahoo

- caldercraft

-

(and 1 more)

Tagged with:

-

I have now managed to assemble the two deck pumps and add to the build. Always find putting these together a bit of a faff. Anyway, filed down all the white metal castings and ensured that all the hinge points met and would take a pin. I used a length of walnut dowel for the base of the pump and drilled a hole down the centre to take the deck pin and pump assembly. Also cut a notch in the side to make gluing the housing of the handle a little more solid. primed and painted the metal parts and reassembled with a touch of cyano in places. Had to touch up the paint in a couple of spots. Finally pinned to pre-drilled holes in the deck.

- 226 replies

-

- ballahoo

- caldercraft

-

(and 1 more)

Tagged with:

-

The 1.5mm dowel that is passed through the hole will rest on the trestletree assembly of the mast below and is in essense what 'holds' the mast in place. What you will want to do is ensure that the hole is at the correct hight so that the transition from square profile to round profile of the mast sits within the wooden brace that holds the two masts parallel. Thats probably about as badly explained is it could be but my brain seems to have gone on holiday today.....

- 1,144 replies

-

- snake

- caldercraft

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.