-

Posts

3,254 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by NenadM

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Johnroy, thanks for nice words. Here on MSW is presented interesing line of learning you can notice following topics: A learn from B, B learn from. C, C learn from D. D learn from E, E pick something from B ... interesting brain network. As a spider net. About cooper ... in my place, I found cooper foil 0,5 mm in roll without adhesive, too rough for precise work and that was thinest I found Online - I have no idea, jusy I am not bying anything online- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Wonderfull work, Mark You are inspiring my imagination ... Have you read "Song of Ice and Fire" ... Nagga`s hill, temple of Ironborn, made of ribs of Nagga, dragon from ancient time Something like that

-

I carefully watch to your solution, because I plan to spread all possible sails on my Cutty

- 151 replies

-

- cutty sark

- billing boats

-

(and 1 more)

Tagged with:

-

Bob, you are in great trouble, but you succesfuly move forward. Lines in drawings are thicker than a blade ? Horror. Where to cut ? Left edge, right edge or somewhere in the middle. And it is easy to get mistake 1-2 mm left or right. Especialy in complex building as Victory Keep a good work my friend and dont forget poor CS And Niagara And Admiral

-

She is coming along nicely !!!

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Thank you Mark to your support and faight. It is very meanfull for my further work. Until you try, and try a bit more, and a little bit over that, you could not know what you are able to do Thank you Geof, I am sure that your hinges will be better, considering in mind that you are more dedicated than me Thank you David, yes, this is time for little break, forced by two day lassting bussines trip (today and tomorrow) Thank you Bob, I am waiting for your hinges. I poke you in ribs with my ideas, and you answer to this regulary with better job than I do. And not to forget - there are three rudders waiting for you !!!!! Thank you Brian, I wish I have your skils, things would be much easy Thank you Juleslucas. Main thing with choice of materials is - can it be soldered by my tools and my poor skils. At same time, material has to be thin enough to scale, but enough strong not to fall apart during drilling ( as cooper do in my hands). I found some nice brass metal parts of folders, but it just - do not work. Also trying with aluminium can, also did not work. One day when I enter to silver soldering, things will be different, I hope Thank you, CaptainSteve, I just posted in linked topic, and if you think that copy of link is not enough, let me know to edit post Hard working day, start with driving 170 km, 8 hours of meeting, and after return in hotel room, working until 20:00. It rains outside, so my planed walking is cuted off, so I ll probably go to sleep to rest for tomorrow- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

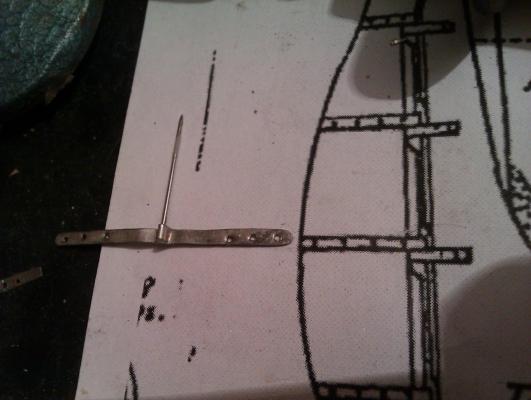

FOLDER MECHANISM - PART 2. Small contribution about use ordinary things that surround us There are hinges for rudder on line to be made ... but ... what materil to use ? And idea come Metal parts from folder mechanism http://modelshipworld.com/index.php/topic/2501-cutty-sark-by-nenad-m-started-on-tehnodidakta-19711983-plans-continued-on-campbell-plans/page-95#entry233671

- 396 replies

-

- Idea

- Bright Idea

-

(and 1 more)

Tagged with:

-

Nice work. Take care with putty. That openings are not for guns. These are water ports, with function to release excess of water to go out from deck on bad weather conditions. Cutty was a merchant, not a war ship, and has only one little signal gun on stern deck house

- 74 replies

-

- del prado

- cutty sark

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Shall I return to water ports to make 6 x 2 x 2 hinges ? NO ! This is dead end street with no exit full of many other "shell I ..."- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Bob, if you count experimenting, training and testing time until you find right method and material and line of moves - a lot. When things get clear and when finaly you know exactly what are you doing, it lasts a bit less than a hour per hinge, including taking photo process, changing tools on Dremell toy, looking for a fallen hinge on floor, and answering to Admiral's call "why you didn't do ..."- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

When you are begginer - yes. When you do this 30 years, you know this procedure better than many of judges (in Serbia). But still you can nor know all about civil procedure, criminal procedure, company procedure, tax procedure etc etc. Somewhere in life you must chose and specialize in some area. Similar as modeling - planes, cars, trains, dioramas, jewelery, dool houses, ships (plastic or wood), furniture, ... life is too short for everything. Same question about books, music, art, movies. Fortunately, this is not question about Admirals. You can try but you can not model Here, you must listen her music. see her movies and series, or simply run away in your shipyard

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

One of the most tricky question in future works for me is - how, to hell, to make metal fittings for masts. Making this litte hinges with success and satisfaction, and hope arise that I can/be able too make them also when time comes- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

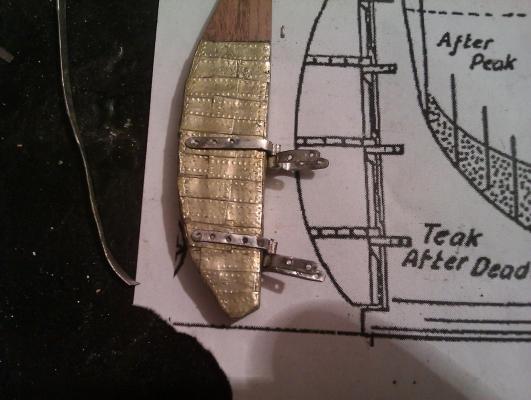

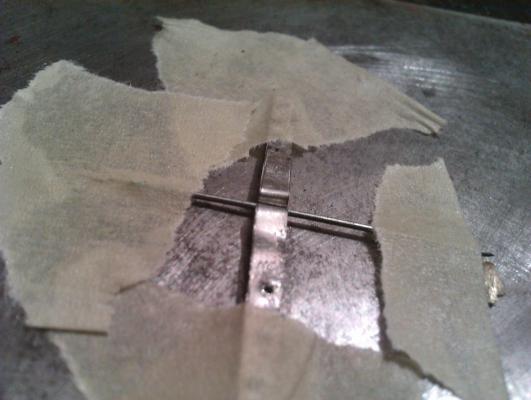

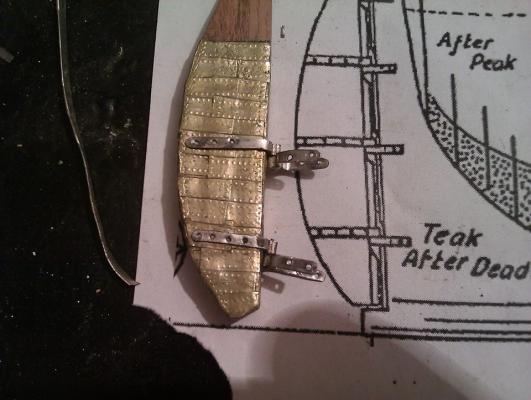

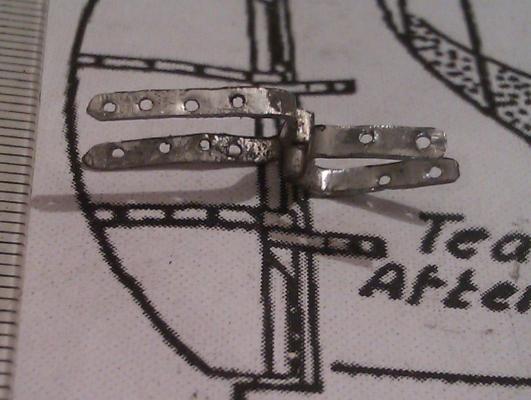

Still, I succeed to spent a hour in a workshop to make another hinge Here is process for dummies as I am You recognize this part of folder with mechanism ? New appedix for Captan Steve topic !!! Cut as much as possible to dimension you need to be in scale. You will correct later to the right dimension Shape around needle to get space reserved for soldering Shape whole thing to future look and test it to get right longitude Get holes for rivets on place. I use my 40 years old school divider - made of solid and good steel, and I saved this as tool I use more than 40 years Not align piece jet ! First clean another surface with Dremell tool of excess of material which appear after making holes on opposite side of piece Now align, and wide a little holes to the dimensions of future rivet you will use Solder needle to the prepared place. I use needle, it fits to my needs Cut needle on one side, and with Dremmel tool remove excess of needle and carefully and slowly, shape width of piece to the scale. Really slowly and carefully. This I found nice tip how to track your microscopic work: First, round corners. And when you star to thin piece, half of circle on corners start to change shape, and by this you can know you successfully thinned piece. Measure to the drawings as much often as you can Make another part using same method Solder another part, and take care about excess of heat, don't allow to un-solder first part And Ta - da - da - da !!!!! ( fanfare in background) At the end, hinges are between 1,5 and 2 mm wide, little more than in scale ( about 1/4 mm), and that is really much for me. From distance, this all look as it is 100% in scale- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

In a life, s***t never comes alone. Always one and another and another .... until only your nose stay under ... This are not pictures from document "Conservation plan" of Cutty Sark This are pictures of so called "carpenter ants" I found in my attic !!!!!!!!!!!!!!!!! And real war begins ... whole yesterday and today Hothead and me unmounted covering of roof wood ... and war will follow when I return from business trip tomorrow and next day ...- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

I do not understand, Bob, be more specific - rudder or rudders ...- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

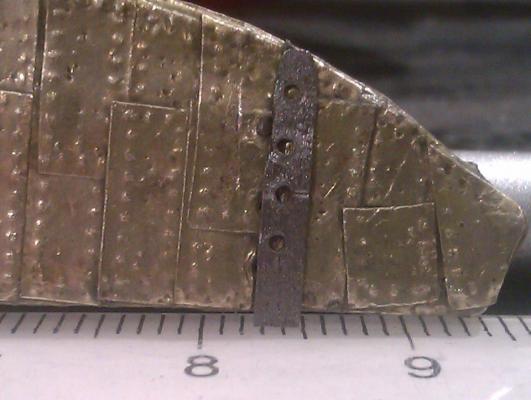

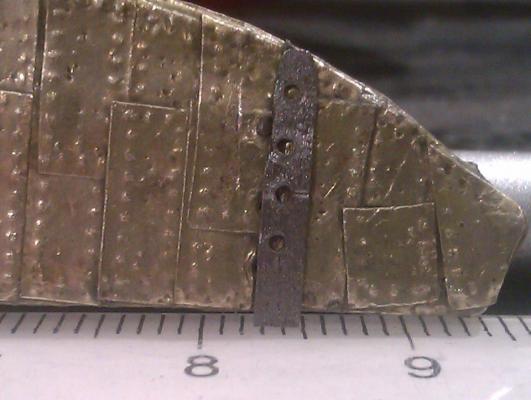

Right to scale !!!!! And rudder can move This is "dry" test before mounting. One of this days I ll explain whole process- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Bob, I mean folks This is democratic forum and everybody can read on his own way- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Nice head-breaking job you give to yourself. It is not complicated AT ALL ! Just keep following one drawings trying to match to other drawings. Nothing is easier, indead ! 1 REM "magic circle" 5 FOR bob = 1 TO 3 6 LET a=CS; b=VIC; c=NIA 7 PRINT bob,a 8 PRINT bob,b 9 PRINT bob,c 10 RND rib 20 POKE drawing 30 DEL woodpiece 40 NEXT bob 50 RETURN to magic circle I forgot syntax and comands, but you get a point?

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Some testing on way to make hinges ... obviously it can be smaller and thiner. Yesterday made - removed I am afraif I am not able to make them more smaller or more thiner. Maybe in next life And here I discover earlier wrong reverse turn of moves. It is impossible to glue hinges on rudder and to make imitation of rivets. Glue dont catch to varnish. So, there have to be real nails, and some more testings have to be done- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Mayflower by SawdustDave - Finished

NenadM replied to SawdustDave's topic in - Build logs for subjects built 1751 - 1800

I can see sailors pumping on panic ... -

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

Captain !!! I am already regular visitor to his clinic ... and it do not help, as you say... just another good reason to attach myself more and more to the MSW Bob, do you read this ? Always room for one more in clinic , particularly for folks with three models making simultaneously- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

-

Cutty Sark by NenadM

NenadM replied to NenadM's topic in - Build logs for subjects built 1851 - 1900

No, Bob, this little programs are not saved, even the magazine with following articles to that programs, and they are not saved in electric form Simply basic programs for positive law and judicial practice databases with possibility to input data and to save it ON TAPE, without machine code, without assembling And you are not alone which has somebody to poke in ribs ... My FB friend R.Vlahovic ( world champion in ship modeling this summer in Bulgaria) wrote me that fittings on ruder are to wide ( and he is right) and suggest me to remake them ... Cold shower ...- 4,152 replies

-

- cutty sark

- tehnodidakta

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.