-

Posts

16,007 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by popeye the sailor

-

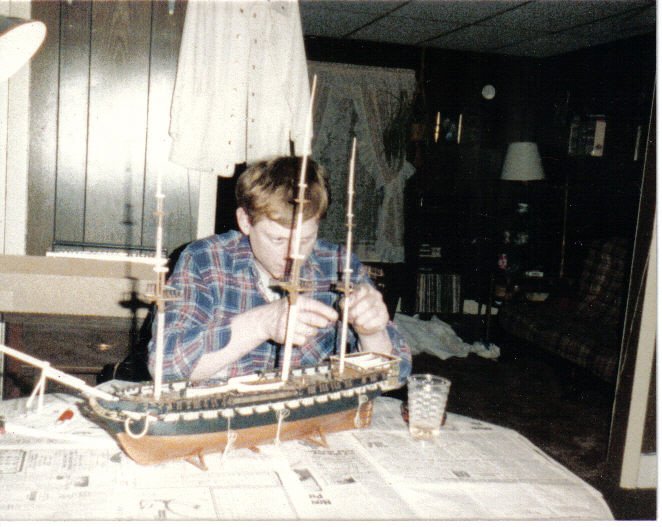

hi there! I was looking for your log. I quite agree.........it's good to see young blood flowing in this old hobby I was around 35 when I built the United States, and even younger when I built the Constitution for my mother. she's a grand vessel..........and not a bad kit either welcome to the forum!

-

back in the day, I was a Guillow's / Comet fan.........mainly rubber power. I got started by my English lit teacher. we were all assigned a book project to report on....our choice. about a week into it, he noticed I hadn't turned in a title, so he asked me about it. hearing that I didn't have one......and my feeble reason.......he told me not to worry and that he had just the thing. the next day, he gave me a paper bag.....in it was a Balsa flying Piper cub plane kit.......don't recall if it was Guillows or Comet.......it was blue and yellow. I was instructed to write on it......the building process.....what I did, what I used to build it, the flight afterwards...everything I did with the model. I built it, and it flew.........and I got a decent grade too. the plane was still intact..........I put it on his desk A few years ago, I built the Spitfire MK1....I have the Fokker Dr1 in the closet. it's in the sanding process.......I will get back to it one day look'in forward to your log..........

-

I hope your vaccinated........hoping for a speedy recovery too! I used to think that way........prepping an airbrush for a few small parts was too time consuming to me. when I got into wooden ships, I began to revive a new appreciation for the air brush ........rattle cans are nice, but the control isn't there. I still use a brush for small parts, but for areas where brush strokes would be an issue, I use the A.B. practical might not be a good description.........I love finding the masterpiece they hid in the box of shards

-

off on another gem for your collection.........all in to see the show late observation......if visibility is an issue, I first though you might simply paint the area you cut out in the color of the interior. but after seeing what your results are.......you've done an outstanding job. superb solution to your problem!

-

if they are to take the place of two of the screws, you can set the other two up as dummies........that's quite a set up!

-

....knew you were gonna say that guess I'd better start matching up the paints .....huh?!?!

-

it's not building them......the visual aides are good enough. I just like to know what the parts are called......helps when writing a log or blog. I know I can count on folks here...appreciate ya look'in

-

glad to see your getting better OC.......I take probiotics when I have to take antibiotics........last time had me runn'in to the lavi on a regular basis good it hasn't stopped you either...nice work on the current regiment. use the time to think about the trees........like what Miagi {spelling.....whatever}........think tree

-

I've built a number of these 1:96 scale kits and love them .........I've used the eye bolts on them all. the one thing that bugged me was the seam lines in the decks........so much, that after finding another United States kit, I made wooden decks for it. somewhere in the archives, there is a log, but currently it's in my closet and I haven't touched it. I really should get back to her........had to make a second set, since I procrastinated and the first set warped. I also acquired another Connie kit...up in the air as to what I want to do with it. I agree with the ratlines........they are like impervious to most glues....they always seemed to come loose for me.

-

I inherited a Tamiya U.S.S. New Jersey a few years ago from Lou. the owner passed away.........I would really like to continue where he left off, but it's still in my closet {one day Lou, I will get to it} from one model junkie to another.......I know your pain

-

you prompted me to try searching again........I even looked on Scalemates {I joined a few weeks ago}. the Hasegawa 1:450 Missouri, I'm not too worried about.......I can source a paint guide from other kits. the Nichimo 1:50 Shokaku is the one I'm most concerned about......basically for a paint guide, since I'm not sure with the INJ colors. I've had these since last Christmas.......or the one before that.......a bit of a blur

-

good job Lou I checked to see if they had instructions for the two I have........, but they don't. guess I'm still on the hunt

-

thanks all for the kind comments and the likes I glanced at the pantry calendar, and for the month of may, it showcases the 1948 Tucker Torpedo.....or commonly known as the Tucker 48. it was such a cool car, that it caused me to look and see if there was a model kit on it. alas.........there are plenty of die cast models out there, and if what I saw was an actual kit, the price tag is around $200.00! the Tucker 48 was just a flash in the pan....not too many were produced. Matchbox put out a replica of the car and there are places that sell preassembled die cast cars. it was a thought.............puffffffffffff*

-

AVRO Lancaster by Papa - FINISHED - Airfix - 1/72

popeye the sailor replied to Papa's topic in Non-ship/categorised builds

I've found that with some of the newer emerging companies.........Round 2 is a good example. in some cases, they forgot to remove the original mold stamps, but their method is ink stamping. it is hard to remove with thinners and such.....I've found the best way is sanding it off, if there is a threat of it showing through the paint. it's not to bad if it's a 'molded' stamp, since it's the same color as the plastic. it's not that uncommon either, to find the date stamp from another company, like Aurora, Pyro, etc. take the 1:72 scale Stuka I built a while ago.........this model was produced, using the same molds, by at least four other companies. there are many kits out there that have issues that your experiencing.....dry fitting {no matter how hap-hazard} usually helps in fitting everything together. as I build, I try and see what can be done as a sub assembly, especially if it is to be the same color. a lot of times one may have to jump around in the instructions, in order to head off problems. I decided to follow the instructions when I built the Christine model. when I got to putting the body on the chassis, I found that how they wanted me to assemble the firewall {and the fact that the inner fender wells are molded to the body} made the process difficult to do. I have another kit of the same model { same kit but different subject}......I might experiment and build it the way I really would have done it. no log though 'cuz I already built a similar model -

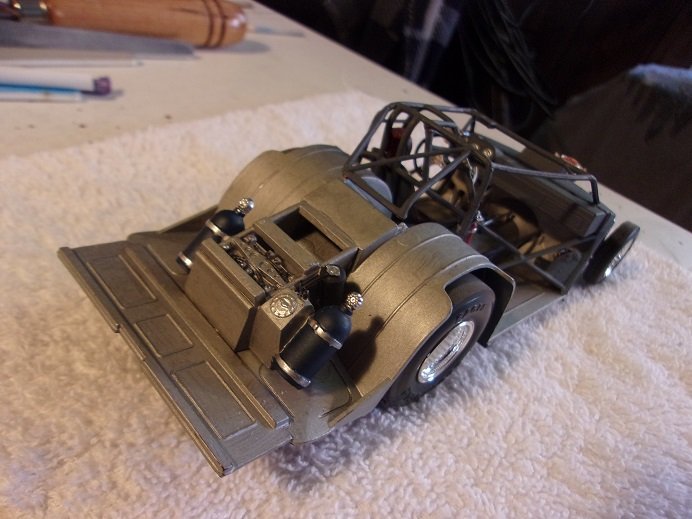

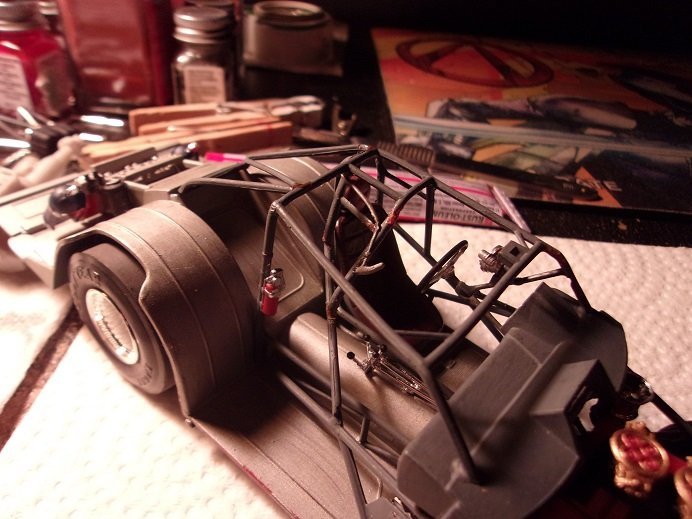

I'll tickle your memory a bit more Mark.....I'm across the finish line. I knew the roll cage would have troublesome areas, but the rest of the build went very well. even the decal issues didn't take away from it. I should have expected the cracking to happen, since the decals were dated '93. but piecing them together went well....the biggest concern was the arching decal that went along the sides. going from back to front was the best way to work it.......line it up to the contour of the fin, and the arch went as it should I probably should have given it a second coat of paint too, but it still came out with a nice shine. the Chute bracket and the spoiler braces weren't hard to do...we took off for the afternoon........we did early shopping. thanks for all the kind comments guys.......I really appreciate it when dry, there was a couple minor touch ups. since I had to do a lot of handling after the glass was in place, I was concerned that the window maker/cement wouldn't hold and they might come loose. I was surprised with how sturdy it was. I basically only used it to fill in small windows and canopies........I guess I'll be using it a lot more from now on the body just slides onto the chassis......it easily lifts off to display the chassis. makes me wonder why the hood isn't molded to the body........but I believe it's an alternative way to display it. so here is the model in it's entirety not too shabby from a used kit........had to fix a couple of things, but the rabbit came out of the hat at just the right time we might go to Hobby Lobby one day soon........I'm going to see if they carry the cases for model cars. it would be quite fitting for these two. I'm still up in the air about what to do with the other '58 I have. I've seen pictures of it in many colors......some I really like. since I got it in my head to do some mods to the body and such. I could go with a custom look. it would be the easiest....the whole look depends on a set of mags does anyone see the resemblance to the batmobile? I could go stock car.......one thing I do lack is bucket seats though. a lot of hometown dirt trackers didn't ditch the creature comforts. a class that ran at Barberville Fla. was called 'Thunder cars'.........women entered cars too! not too terribly tough either.......all one needs is a roll bar. ...or I could go all out and do a gasser or a top fuel I would have to see what I have in the spare parts box. I did a little visual research with the Chrysler 300. the wheel base is longer, as with the Belvedere/fury. we shall see.........

-

well.........getting near the end.. ....just gotta get the rest of the decals and rear parts on the body, and finish the roll cage on the chassis. the right side decals were a little worse........the long arching decal broke into more pieces, making it much worse. I got it though and managed to get the rest of the decals on. this isn't all the decals.........then the hood there are three areas left on the roll cage........the brace for the steering wheel, the back part, and the left side of the driver's compartment. the steering brace is too short, so it was cut off and a section added in. the left side of the driver's compartment was added.......and the back part of the cage was cut and repositioned everything is drying at the moment

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.