-

Posts

1,409 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by DelF

-

I have just found your log for the first time after seeing your completed model in the gallery. I wish I had found it sooner! I am very impressed by the beauty and precision of all your work - in particular your rigging and woodworking skills set a very high standard for the rest of us to aim for. Derek

- 231 replies

-

- model shipways

- armed virginia sloop

-

(and 1 more)

Tagged with:

-

The CA-related symptoms have calmed down a bit so I've had another go at coppering today. In the meantime I'd finished a bit more deck furniture: I've not used photo-etch before and I'm really impressed with the detail you get - particularly on the deck pumps. I'd struggle to scratch build work of this quality. The recommended AK 174 burnishing fluid leaves a nice finish. The fluid looks like Casey's Brass Black, which I normally use, and works in a similar fashion. I mentioned the importance of cleaning the brass in a previous post. I should add that, as with Brass Black, I find I get the best finish by dipping in the fluid until the brass is sufficiently black all over, taking it out and rinsing in cold water, rubbing all over with a cotton bud to remove any surface powder then repeating. This leads to a deeper and more consistent black. On with the copper. I'll just show one area that I struggled with initially - the bows. You'll see from the photos that I didn't get it right straight away and I'm going to replace at least one of the plates. This is the area I'm working on - I wasn't sure at first how the curved plates on the hull should meet the flat plates on the stem. This is the approach I developed.: I started with a strip of paper the same width as the copper plates and laid it on top of the last row of plates on the stem. Holding the strip flat I pushed the paper into the join between the hull and the stem, and marked the join with a pencil. The following photo shows that I cut the paper template just outside the pencil line - this is to allow a small strip to overlap the hull: Using the template I cut the plate with my Xuron scissors. These are very sharp and precise - great for cutting thin metal and planks. I'd tried using a small pair of tin snips but they tended to raise the edge of the copper plate. Next, I used a piece of scrap wood with a mitred end to crease the plate into the join, before gluing it: A simple matter then to complete the row with another small piece of plate. I then used the same paper template method to cut out the next plate on the hull. This time I cut the template exactly on the pencil line so that the copper plate overlapped the plate on stem: The next shot shows the area in close-up: Things never look as neat in close-up! I'll definitely replace the first of the curved plates, but the next two actually look OK from a normal viewing angle. I should add that I'm using surgical gloves every time I handle the copper. I was lucky enough to buy a box of 100 pairs well before CV-19 was heard of. They certainly help to keep the plates free of marks. As for the CA sensitivity, a fan and face mask certainly help. I'm still sneezing a bit, but nowhere near as bad. Ideally, I should have a vacuum pump exhausted to the outside to suck the fumes away. Anyway, I'll persevere - at this rate it'll take longer than the planking and I'll never catch up with Glenn and Vane (not that I'm competitive ). Stay safe everyone. Derek

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

Thanks Guys, much appreciated. HMS Speedy will keep me occupied for a while. Alongside that I'm currently torn between your Queen Anne's Barge (having read Meddo's log) and your 18th Century Longboat. I love your small vessels. I will also get back to HMS Winchelsea when I can get my act together. I started well on her but hit a block when I found the keel pieces didn't fit together well. Basically, I'd messed up copying the plans. I've had other projects to keep me occupied so I think I've been putting off getting back to Winchelsea. But I shall. Derek

- 77 replies

-

- model shipways

- pinnace

-

(and 1 more)

Tagged with:

-

Thanks Chuck. I decided to replace the base. There was nothing wrong with the kit-supplied material, I just felt the castello boxwood was a better match. Hardly surprising, as I milled the planks from the same sheet. I'm definitely marking the log as 'finished' now. Thanks again everyone for the likes and comments. This was my first build log and I really appreciated the support. In another sub-forum Chuck suggested supporting new loggers this way and he's absolutely right, it does make a difference. Derek 31 March 2020

- 77 replies

-

- model shipways

- pinnace

-

(and 1 more)

Tagged with:

-

Hi Glenn I think I'm just in the unlucky 5% that're susceptible 🤧. The good news is that proper ventilation seems to be the solution, which I'll try when the symptoms allow. If that doesn't work I'll dig out my old scuba gear and wear that. Come to think of it, that gear might be handy anyway in the current crisis. Derek

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

Hi Meddo I just found your log and I've enjoyed catching up with your latest build. I'm particularly impressed that you've had a go at carving your own decorations. Having recently enjoyed building one of Chuck's other designs, the English Pinnace, I'd planned to have a go at another small vessel, probably the 18th century longboat also by Chuck. However I'm now seriously tempted to get the QAB for my next project. She'll look stunning when she's finished (looks pretty good already!). Derek

- 221 replies

-

- queen anne barge

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

Thanks Sea Hoss. Glad to hear the fan works for you. That’s definitely the way I’ll go. Derek

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

Probably not long on each session. Like you I went fairly slowly - maybe two or three pairs of planks per day. However I was doing it almost every day until I got the second planking finished, and I think it was that prolonged stretch that brought on the adverse reaction. I would strongly advise playing safe by getting appropriate ventilation. Derek

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

I started coppering Speedy. Unfortunately I've had to put the work on hold for a while as I've developed an adverse reaction to CA. I started to notice a problem during second planking when I suffered a streaming nose and constant sneezing. I didn't think it could be an allergy as the symptoms persisted long after exposure, and I'd used CA plenty of times before. I just thought I had a seasonal cold. However the same symptoms started again almost as soon as I began using CA on the copper plates. I did a bit of research, and according to Wikipedia around 5% of people will develop sensitivity to CA after prolonged exposure, and will suffer flu-like symptoms. I think prolonged is the key word - I'd never used CA for extended periods until I did the second planking, and that seems to have triggered the sensitivity and now I seem to be stuck with it. Looking for alternatives I tried odourless CA but I couldn't find one up to the job, and other glues don't seem suitable either. So I've concluded I need to let the current symptoms settle down, then start using the CA gel again but this time wearing a mask and with a fan blowing the fumes away. Probably should have been doing that all along. In the meantime I'm tackling some of the deck furniture, starting with the capstan and pumps - small but satisfying mini projects. On the pumps, I tried the AK 174 burnishing fluid that Chris recommends in the manual. It works well, but I found that for good results it's best to rub the photo etch pieces with very fine (#0000) steel wool before assembly, then soak them in acetone or white vinegar for a few minutes before using the AK fluid. The result is much better than trying to paint such small and detailed parts. Derek

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

I'll add my congratulations to the richly deserved plaudits above. Some (few) others may equal your skills as a modeller but none match the care you take in detailing and explaining your research and your building techniques. Thanks as always for taking the rest of us along for the ride, and I await your next build with anticipation. Best wishes Derek

- 335 replies

-

- alert

- vanguard models

-

(and 1 more)

Tagged with:

-

Thanks Glenn, that's very helpful. I tried to get references for the waterline from the plans and photos in the manual. I've not drawn the line yet, but when I put a laser level on the three reference points I'd marked they lined up well. However I like your idea of using the rudder as the primary reference, and shall check my points against that. If the plans are accurate I shouldn't be too far off. Thanks also for explaining your technique in more detail - very useful for a newcomer to copper work. Derek

-

Good job on the copper. I've fallen further behind you as I've been concentrating on finishing my pinnace. Now that's done I want to get on with Speedy. I'll follow your lead and use a wood strip to define the upper edge of the copper, but as I've never done coppering before I'm not sure how smooth I need to get the second planking below the waterline. Is the copper relatively forgiving, or do you need to smooth out even the tiniest lumps and bumps? Derek

-

What happened to the video - any chance you can repost it? Thanks Derek

-

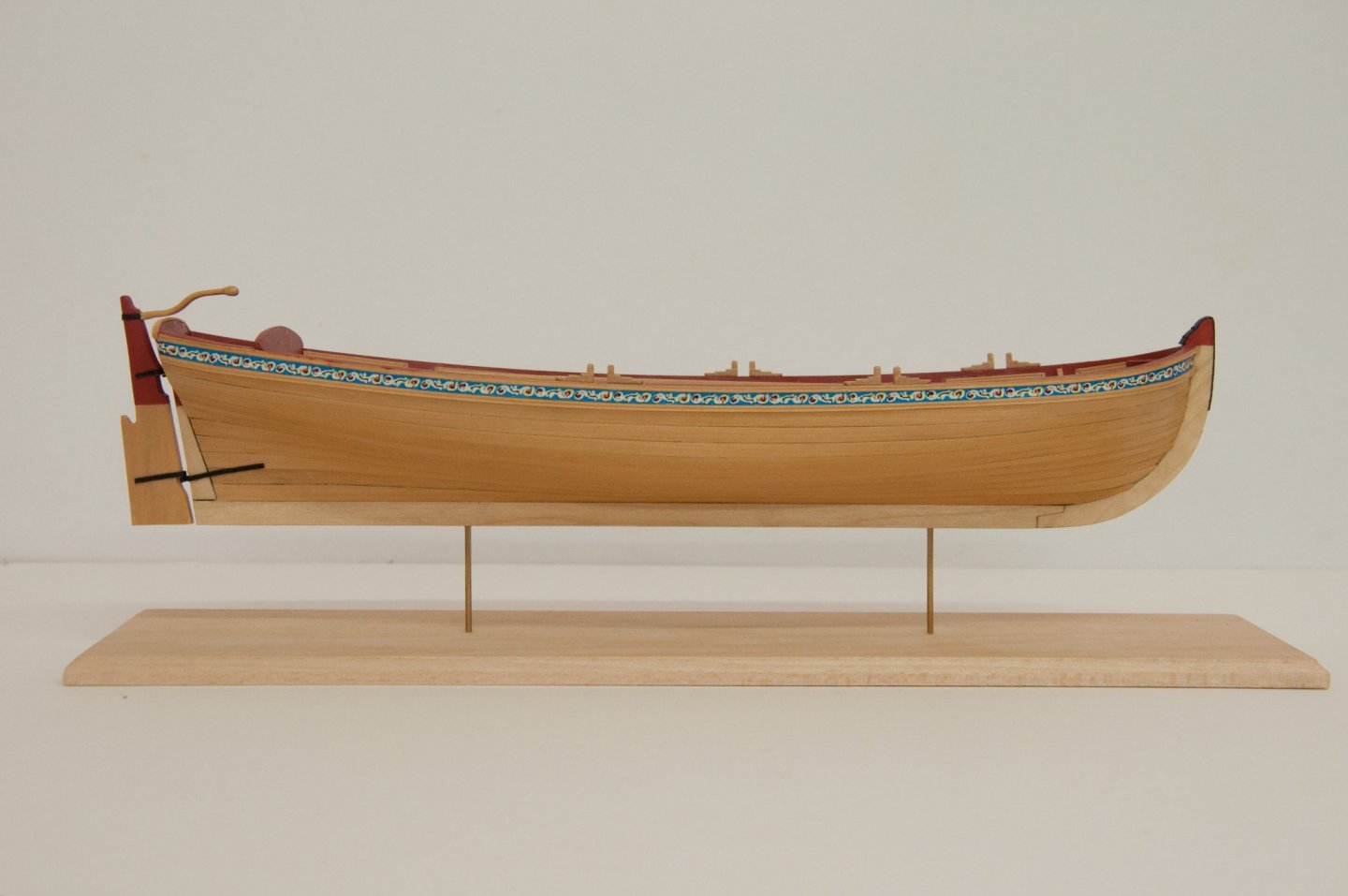

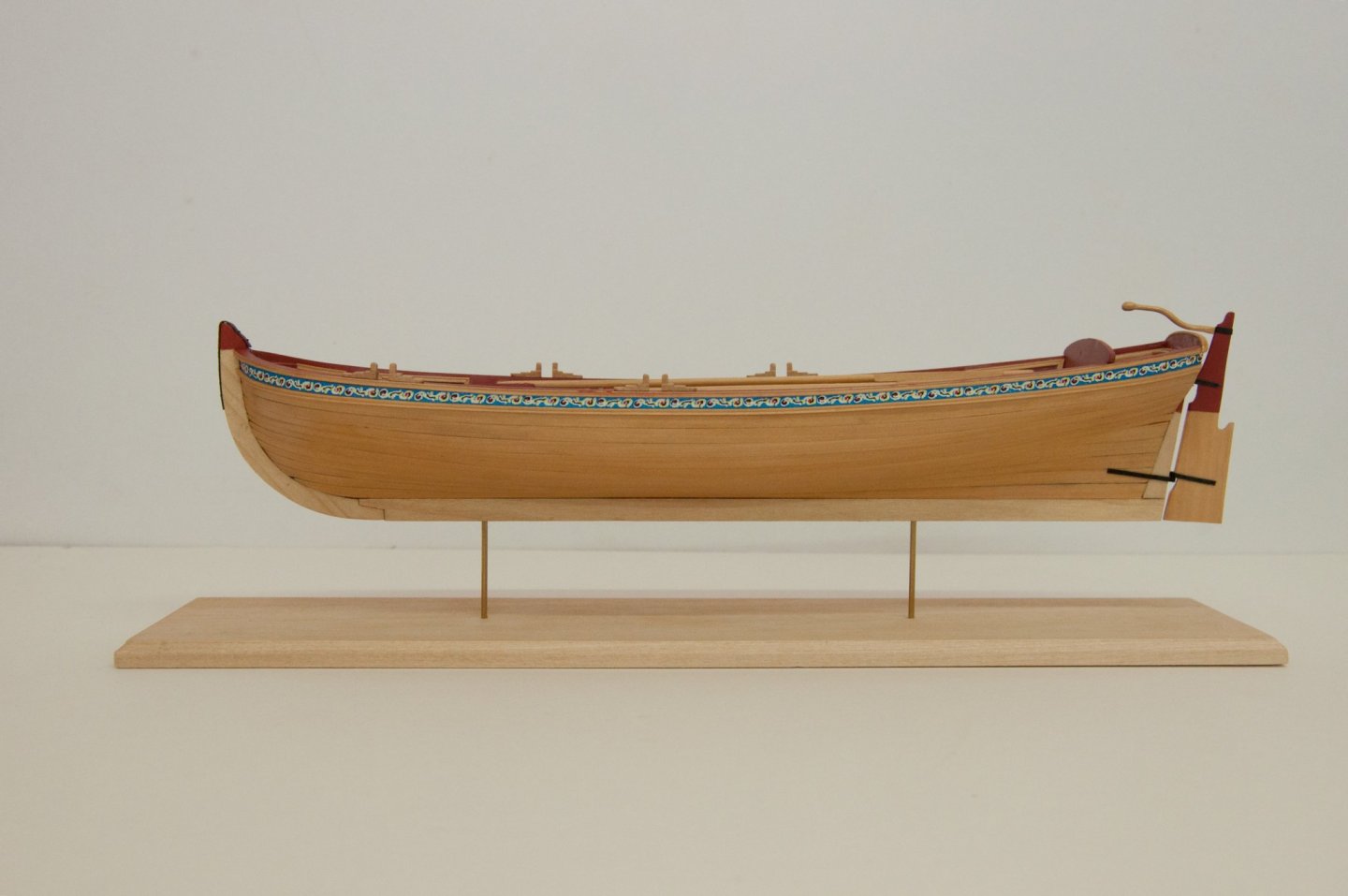

Much appreciated Chuck. Thank you for designing such a cracking model. You really do excel at these smaller boats (and the big stuff as well, of course 😀!). Just a couple more little jobs to finish off. The anchor was provided in the kit but the soft metal casting required a lot of fettling to make it presentable - not just flashing from the mould but the shaft was quite badly pitted. Fortunately there was enough meat in it to remove the pits and leave a decent result. I added a ring which I think would have been standard, and used some spare rope I made for Royal Caroline on my rope rocket. For authenticity I used a fisherman's bend with two half hitches and the end seized. All knots I'd done before but it's surprising how quickly I forget the techniques. As usual I fell back on the Ashley Book of Knots to remind me of the delights of riding turns and frapping. I had a barrel left over from my recent Victory cross-section so that was stowed down near the tiller, no doubt on it's way to top up the officers' supplies. I had previously drilled the keel for 1/16" brass tube supports, but I'm not sure what to do for the base. As an interim measure I've taken the kit base and shaped the edge with my Proxxon router table (a tool I ought to use more). Here's the result: And a few more views... As I've mentioned before, I only got this kit so I could scale it down to 1:48 for the Royal Caroline, and I started it for no better reason than it was there on my shelf. It turned out to be a most enjoyable build, taking just over four months which is Usain Bolt territory for me. I'm pleased with the result, and I may well be tempted to try more of the smaller vessels Chuck has designed. I particularly enjoyed the fact that I could work on the pinnace alongside HMS Speedy, with each providing a break from the other. I also enjoyed and appreciated the very good pinnace logs already on the forum, and the kind words and advice from several of the top builders. I'll ponder the base and whether or not I want a case, but for now I'll call this finished. I would highly recommend this kit to anyone looking for a relatively quick project with pleasing results. So long as you're prepared to have a go at single planking! Derek 24 March 2020

- 77 replies

-

- model shipways

- pinnace

-

(and 1 more)

Tagged with:

-

Looking really good. I agree about the sanding. I think I used to be afraid to sand too much because 1mm planking doesn't seem very thick, but it's surprising how much you can sand it without doing any harm. On Speedy I really attacked the first and second planking with coarse then medium sandpaper to smooth out the surface as much as possible and it looks like you've done the same. Derek

-

- 77 replies

-

- model shipways

- pinnace

-

(and 1 more)

Tagged with:

-

Many thanks Bob for a great recommendation. Ordered 12 March through your ebay link, delivered to the UK today (21st) very well packaged and no import duty to pay! Excellent service, particularly in the current situation. I'm looking forward to staying in and reading it - nothing else to do now all the pubs are shut 😟. Derek

-

Finished the oars today. Not much else to do as all pubs, cafes, restaurants etc are being obliged to close from tonight. Here's the steps I took in making the blades and attaching them to the shafts: : From the left: - sticking a photocopy of the blade (from the plan) on a strip of boxwood - filing the blade to shape - thinning the blade towards the tip - I also slightly bent the blade with a plank bender - filing a flat onto the end of the shaft - shaping the shaft end - gluing the two parts together Here's the final result: I haven't decided yet whether or not I'm going to paint the blades red as suggested by the kit instructions. I'm always reluctant to cover up boxwood. Feels like the home straight now. Derek

- 77 replies

-

- model shipways

- pinnace

-

(and 1 more)

Tagged with:

-

Many thanks for the likes. I hope everyone is well in these difficult times. I've been thinking about the oars. In his instructions Chuck suggests employing a Dremel or similar rotary tool as a 'poor man's lathe', using files and sandpaper to turn the handle and the round part of the shaft. I used my slightly less poor man's Proxxon lathe for my 1:48 scale scratch built version but doubted my ability to produce anything that would pass muster at the larger scale. Funnily enough I have no problems turning spars, but I think that's because they are tapered and I probably get away with results that don't match the 'proper' taper exactly, whereas an oar that is meant to be perfectly cylindrical along its whole length will show up any unevenness. Anyway, I decided to try a drawplate instead. I think its worth describing this method in some detail. I'm sure it's not original, and many forum members won't need to be told how to use a drawplate, but until fairly recently I was a novice at this and hopefully my description will help others new to the technique. Perhaps some more experienced people will also find this way of using a drawplate useful. Some time ago I wanted to buy Jim Byrne's drawplate until I saw that shipping and import duty would triple the cost, so I decided to make my own. I was surprised how easy this was. If you've got a piece of scrap steel and the necessary drill bits it will cost nothing. I made mine from a small square of 2mm steel off an old machine, but a steel ruler would work equally well. The DIY approach gives you total flexibility as you can just drill the holes you need for the job in hand. Using the drawplate I was able to produce treenails and to trim down commercial belaying pins to acceptable dimensions. For this job I started with a 6mm/1/4" hole drilled almost through the sheet... ...followed by a hole of the required size all the way through: When starting a new job you obviously need to decide what size stock you need to start with and what holes you need in the drawplate and how many. I start by looking at the final diameter I want to arrive at, and then get square stock whose sides are the same as that diameter or very slightly more - you don't want to remove more material than you need to. In effect, the drawplate will knock the corners off your square stock so it ends up round: However you won't be able to knock all this wood off in one go. In fact, as you get closer and closer to the final diameter, the drawplate is having to cut through wider and wider corners, making it progressively harder to get the wood through. In my case, the round part of the oars needed to be 2.4 mm - about 3/32". So if you start with 2.4 mm square stock Pythagoras tells you that the starting diagonal dimension of the wood is about 3.4mm - this will be the largest diameter hole the wood could pass through without cutting. With a little trial and effort I found the smallest hole the stock would pass through easily was 3.0 mm. Thereafter each pass needs to take off more wood, so to make them manageable I decreased the steps between successive holes. I ended up using four: 3.0 mm - removing 0.4 mm 2.7 mm - " 0.3 mm 2.5 mm - " 0.2 mm 2.4 mm - " 0.1 mm Most times a drawplate is used by pulling the wood through the plate, often with pliers to get sufficient grip. I've used this method successfully for treenails but it doesn't work for me at these larger diameters. Also the draw method works best if you are pulling the whole length of stock through the plate. It is harder if you have to work to a line as with these oars, where the round shaft connects to a square section which becomes a round handle. That's why I prefer the lathe for this sort of job, where I push the drawplate against the spinning stock, as I shall describe. I started by cutting 2.4 mm square stock from a castello boxwood sheet, and marked off the critical dimensions from the plan: As you can see, I left plenty of spare to give the lathe something to grip. I used my Proxxon wood lathe, which has the advantage of a hollow headstock to accommodate long work. Although I have a proper metal chuck for the lathe, I found the basic plastic collets more than adequate for this task. Here, I've set up the oar blank to prepare the handle. I've made sure the collet clamps on the part of the oar that will end up round, so marks on it at this stage will be removed. The section between the pencil marks will remain square and needs to be protected: I've tipped the drawplate slightly in the next photo to make it visible. In practice you keep it vertical to the lathe bed and square to the work. Note also that the work enters from the flat face of the hole, not the countersunk side. In drilling the holes you've created a cutting edge on the flat face of the steel. I've tried it the other way and it does work, but I find it harder to achieve a good finish. Of course the downside of starting without a countersink is that it is harder to get the drawplate started on the work. Normal practice for jobs like treenail making is to sharpen one end of the stock so you can get it started through the hole. I didn't want to do that here, but I found that pushing the plate gently against the end of the spinning stock was enough to get it started. I use the lathe at it's lowest revs, and (with due care and attention) find I can safely hold the end of the stock to guide it against the plate hole to get it started. Once going you just need to hold the plate firmly and push it gently towards the headstock, being careful to stop it exactly on the pencil mark. It only takes a couple of seconds to cover this short distance. As you progress down the holes you'll probably find wood shavings building up in front of the drawplate and obscuring the pencil mark. It just takes a moment to remove and restart: Once down to the required diameter it's on to files and sandpaper to achieve the final shape: My trusty Vallorbe barrette file which I've mentioned elsewhere was ideal for filing right next to the square section without straying on to it. However I chose to file the corners off the square section as I think that looks better than a straight transition from round to square. Next came the tricky bit - how to get the shaft round, given that I couldn't clamp the handle end of the oar without damaging it? Equally, I couldn't clamp the other end of the oar because then I wouldn't be able to pass the drawplate over the handle end. I decided the only option was to start the lathe with the drawplate already in position on the oar. To make this possible I started by rounding off the end opposite the handle. Again, it doesn't really matter where you clamp the oar at this stage as most of the remaining square section will be rounded. I've just made sure I've rounded enough of a length to fit in the collet for the nextstep: Once this end was drawn down to 2.4 mm I took the oar out of the lathe and passed the round end through the largest (3.0 mm) hole on the drawplate before remounting the round end in the collet. This end is excess so marking the surface does not matter. This is where three hands would be ideal! This time, the idea is to move the drawplate towards the tailstock, stopping at the pencil mark at the beginning of the section that will remain square. The obvious kink in the plan is that you have to dismount the work and remount it for each successive hole. However it doesn't take that long - I doubt if each oar took me more than three minutes to do all four holes on this section. Also, because revs are low and the work is small, you can support the handle end of the oar with your fingers with no discomfort at all: Incidentally, that isn't another drawplate in the photo above. It's a drill gauge which actually does work as a drawplate, but the hole sizes are too far apart and too large for most of my work. Here's the end result of a few minutes work - the oar trimmed to length and waiting for the blade to be fitted. It hasn't even been sanded at this stage. I hope folks found this helpful, and that it didn't come across as teaching granny to suck eggs. It's taken 10 times longer to write up the log than to make the oars so I'm going to have to knock off now and leave the blades 'til tomorrow. Derek

- 77 replies

-

- model shipways

- pinnace

-

(and 1 more)

Tagged with:

-

Hi again SpyGlass I've now got to my PC and found the set I bought a couple of years ago, from Eternal Tools - here. To be honest, I don't use all the files in the set, and could probably have done just as well with one of the sets of 6. Eternal also sell in the US and Europe. The following video gives a really good review of Vallorbe files, and might help answer some of the questions you and others have about the use of the different file types. Hope this helps. Derek

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

Hi SpyGlass On my mobile so can’t find record of set I bought - I’ll try tomorrow. However, if you just get one file I’d recommend a barrette for the reasons I’ve mentioned. See here. #4 cut is a good choice for very fine work; #2 cut is coarser and therefore removes material faster but still gives a very good finish. The site I’ve pointed to has a bewildering array of files. My set has 12 which is most of what I’ll ever need. The only additions I might possibly go for are slotting files - very fine files that jewellers use for cutting slots in small screws, and maybe some rifflers - the ones with curved ends for filing in awkward places. But I just like collecting tools! Derek

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

-

That’s great Richard. At this rate I’ll have to ask Vallorbe for commission. I got a mixed set of Their files, #2 and #4 cut, and that’s given me all the files I need (so far!). Derek Btw I think rifloir is the same as riffler

- 725 replies

-

- vanguard models

- speedy

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.