-

Posts

380 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Boccherini

-

Paddy, all mine were turned on a lathe, whilst they are not exactley identical, you have to look closely to spot the differences. I did one first to work out an order to the process, then did four together. The idea is to do the same step on all four barrels, then move to the next step. This will help keep them similar, and is much faster than doing one barrel to completion at a time. Good to have you on board, look forward to seeing your progress. Regards, Grant.

-

Rusty, that is looking good. The mortices into the knees for the carlings are neat, I found them a little awkward to get right. Regards, Grant.

- 332 replies

-

- Triton

- cross-section

-

(and 1 more)

Tagged with:

-

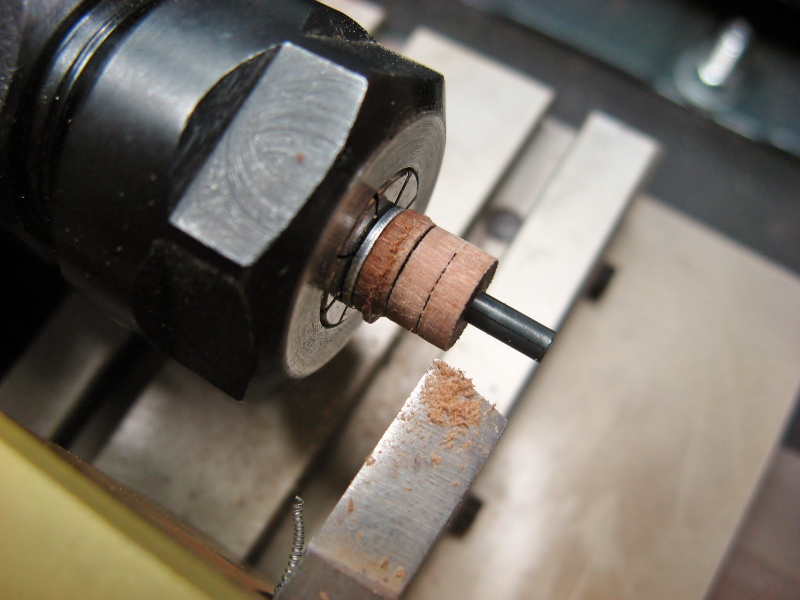

Harvey, thanks. The barrels were turned on my lathe. Fixing the trucks proved to be quick and painless, if only all stuff ups were this easy to repair. The trucks and keys were not glued in place, removing them was easy. I ended up using a dab of supa glue to tack the trucks to a drill shank in a collet on the lathe, then skimmed them down to size. The smooth surface of the drill shank prevented a permanent bond to the trucks. Grant.

-

US Brig Syren by Rustyj - FINISHED - 1:64

Boccherini replied to Rustyj's topic in - Build logs for subjects built 1801 - 1850

Rusty, looks really good, 'specially like the way you built the ships boat. Regards, Grant. -

Pete, 42 Rocker, Ron, thanks for the comments. Pete, the barrels were turned on a lathe. Ron, you'll do fine, just take your time. Rushing leads to errors and poor workmanship......see below . Mark & Russ, thanks for the comments, particularly picking up my error. As previously stated....haste makes waste. I had not noticed the different sizes of the trucks, mine are all the same . The remedy will possibly be relatively painless, I should be able to remove the offending trucks and replace them. Thanks again for picking that up. What's another week or so. Regards, Grant.

-

Daniel, glad to be of help to you. The gun assemblies are finally complete, time required:10 weeks. For a first attempt at this stuff, I'm satisfied with the result. This model was supposed to be finished for my sons last birthday, I'll be lucky to finish in time for the next one. Still, haste makes waste. Grant.

-

Bob, Pete has it right, there were only other build logs as references. Several were very good, but that is all past history. I see Joss (Matrim) has reposted his build log along with a couple of others. The Fully Framed Model books by David Antscherl are very helpful if you are looking for guidance on construction methods and extra detail. Regrads, Grant.

-

Bob, deck beam jig pictures (design from The Fully Framed Model by David Antscherl). Basic construction, this is a realy rough looking jig (built out of scrap lying around the workshop), but it works well. The height extension on the head of the jig is not neccessary, I put it on to sand the curve into my beam arms. Sand the curve into the underside of the beam as normal, then adjust the depth of the jig and feed the beam in from the left, against the drum rotation. You need to try and keep the curve of the beam at a right angle to the head of the jig whilst feeding it through, my apologies, this is badly described, but I think you will get it. Repeat, gradually screwing the jig toward the drum until you get to the required thickness. I was doing 2 passes through jig between adjustments. Do be aware that you are using a drill press for a job it is not really designed for (horizontal force), it's best not to sand too much at each pass. I hope I haven't offended you by highjacking your log. If you have any queries regarding this, please just ask. Regards, Grant.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.