-

Posts

1,297 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Bedford

-

Vaddoc, you know I admire your work so please don't take this as negative criticism, it isn't! I think we can make life hard for ourselves sometimes, like all the trouble you went to in order to get the deck profile printed. All I do is plot out the relevant points and draw it. You can use pins at all the mold stations and run a fairing batten (a length of thin section flexible wood strip) around them. This not only shows you any station points that are wrong but gives a guaranteed fair curve to the hull. I've just built a full sized sail boat this way and it's very accurate and symmetrical.

-

She's looking the goods John! If memory serves, when I sailed on Bark Endeavour in 2015 the manual showed 100 lines in the running rigging. She's an older style rig with fewer sails and hands aloft to do everything so I can imagine in this rig with more sails and lines to do most of it from deck level she's going to keep you quite busy!

-

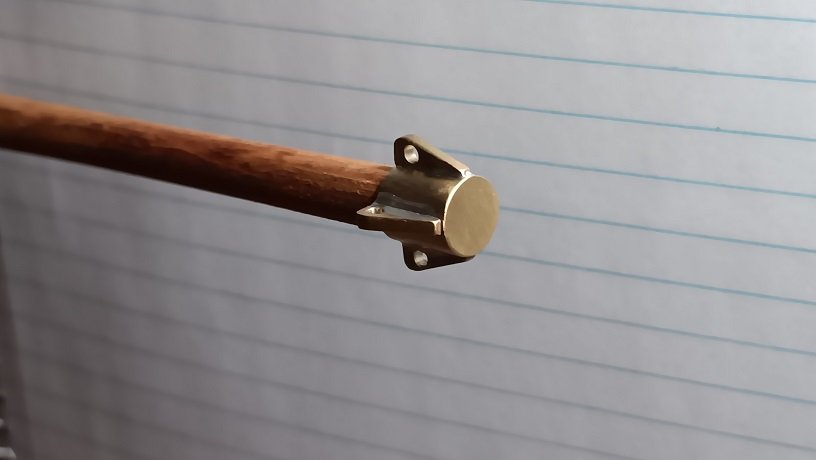

I've made some good progress on the pond yacht, thanks to Mark Pearse for sending me the rigging cord! I've made two travellers for the sheet horses from hard brass wire, now to try and work out how the sheets were originally set up, I'm trying to make sense of the pre-existing holes in the spars. There is a bloke I know through dinghy sailing that has mylar sail fabric suitable for pond yachts, he's coming through in the next couple of days and will drop it in for me. I think it'll be a whole lot easier than me trying to sew normal fabric nicely.

-

Thanks Keith, the existing mast and boom appear to be original and a second boat we've been given of similar age and size confirms that, she was most likely built as a Bermudan sloop. These are very simply rigged so it won't take much work in that regard but I think I'll need to build a nice display stand for it.

-

Hi John Thanks for the input, I'm pretty well convinced she had a Bermudan mains'l due to the height of the mast and the lack of wear or any other indication of a gaff on the mast. The rudder turns quite freely so that's still a bit of a mystery. I'm not too worried about it as it'll be fine for display purposes as is.

-

Mate, it's exquisite. In the second pic you can make out scroll work at the bow, it's duplicated at the stern and it has been suggested it could be 100 years old but I don't know about that as the finish is in beautiful condition. There appears to be no shrinkage in the deck either as there is absolutely no gap anywhere around the margin. Master craftsman built from excellent quality timber. It's a real pleasure/honour to be working on it.

-

I've been asked to restore a lovely old pond yacht for display in a local yacht club. It's beautifully made, the hull is carved from a solid piece of mahogany hollowed out and the deck is another piece of mahogany. Perfectly fitted and screwed down around the margins. I have no experience with pond yachts so I'm looking for some help with the details. Specs are:- L.O.D. 668mm - 26 1/4" Beam 160mm - 6 1/4" Mast 843mm - 33 3/16" with lower shroud mast band at 315mm - 12 3/8" high and upper shroud/stay mast band at 618mm - 24 5/16" high Boom 493mm - 19 3/8" Bowsprit is missing So the questions so far:- The rigging left in the mast suggests she was a fractional sloop but I'm not sure if she would have been gaff or Bermudan rigged. There are still two haly'ds at the top of the mast but it looks like there could have been three. How long should the bowsprit be, its heel, for want of a better word, is 114mm - 4.5" aft of the bow. There are two sheet horses, each running the width of the deck. 1 for the jib and one for the main. Might she have a club footed jib. There is no "comb" for setting the tiller and it has no holes in it or any indication it had things connected to it. How did it steer. I don't need to get her back to true sailing condition but I'd like her to look as close as possible to original and I'm hoping they don't want her stripped back and refinished because she's in gorgeous aged condition.

-

She's looking beautiful Mark I prefer the glue first paint later approach as it's easier to get them positioned properly as you said and easier to glue them on. Masking tape works well and can even be placed on the later painted surface to protect it from fine detail sanding of any paint that bleeds under the tape onto the sponson

-

As you know, I'm no expert in the field of quadrireme design or use so take this however you chose. I own a 15 foot Tammie Norrie, a beautiful rowing/sailing dinghy with a bit much freeboard for rowing in windy conditions so I deploy the rudder in such instances. My oars are 8 feet long so the motive force is at two points 16 feet apart in the water. That's a lot of leverage applied by each oar. To overcome that leverage with a rudder is not easy. I can tell you from experience that the boat can not follow the arc set by the rudder while being rowed. It goes straight and then when oars are lifted for the back sweep it takes the rudder a second or so to overcome the straight line momentum before imparting its influence on the direction of the boat. The boat traces an almost porpoising action but on the horizontal plane. This is with a full scale rudder in full scale conditions. Another way to look at it is as a drag car. Imagine a locked differential driving two tyres 4 feet wide and trying to steer with 4 inch front wheels. It ain't going to happen. The only way I can steer my boat in an arc is by altering the power I apply to the inboard oar and shortening the stroke. So as I see it you either reprogram to achieve this or make MUCH BIGGER rudders.

- 536 replies

-

- Quadrireme

- radio

-

(and 1 more)

Tagged with:

-

Keith, I don't think you'll have too much trouble making the ply conform as long as the curves aren't too great. We are building a 16 foot sailboat at the boatshed and it's got 6mm ply sheeting that has to bend two ways to meet the curve of the chine. The big thing is being able to pull it in and clamp it effectively and using the right glue. I suppose you've already considered the joint between the two lengths of ply but in case you haven't I'd be using a scarf joint rather than a butt joint to make the joint easier to hide.

-

Congratulations, a very long project with incredible attention to detail. A masterpiece! What's next I wonder...

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.