-

Posts

1,298 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Bedford

-

On the subject of rudders, I wonder if they were, in reality, more trim tabs than actual rudders, as is the case in tall ships in which the set of the sails does most of the heading work. Having had the helm on a 4 man row boat I can tell you the rudder only has any real effect when the oars are out of the water so you end up with a segmented turn.

- 536 replies

-

- Quadrireme

- radio

-

(and 1 more)

Tagged with:

-

I was thinking the same as Grant, once you get the second tier of oars it should speed up, yes it's slow off the mark but then it should be. Before worrying about oar size I'd suggest you work out the theoretical hull speed "Hull speed can be expressed as a simple mathematical formula 1.34 X the square root of the length of the waterline (HS = 1.34 x √LWL). For instance, if a cruising sailboat has a waterline length of 36 feet, she should be able to sail 1.34 x 6, or approximately eight knots." Then work out the scale speed of the boat and take it from there, mind you it's doubtful such a big rowing boat would have ever attained hull speed. As for the amount of ballast, I'd leave that as is too for now because water doesn't behave in a scale fashion so if you make it lighter it might get tossed around like a cork. The ballast helps her ride in a more scale manner.

- 536 replies

-

- Quadrireme

- radio

-

(and 1 more)

Tagged with:

-

I'm glad the float test went well and it's good that you're thinking ahead and painted that prop, could avoid a disastrous encounter.

- 72 replies

-

- Seguin

- BlueJacket Shipcrafters

-

(and 2 more)

Tagged with:

-

Nice project! I've come to the party a bit late but I have a few epoxy/fiberglass tips that may be useful later or to others. I'm currently building a 17' sail boat, yes, full size and I've made wooden RC boats. On the real thing I fibreglassed the bottom for mechanical protection and I worked a sheet of "peel ply" over it, this gives a uniform finish like a fine fabric weave one you pull it off after curing. You could use it on model ships if you really needed to 'glass the hull as it greatly reduces the need for sanding. However on the subject of sanding, the topsides of my current build are merely sealed in epoxy and will be painted and an old shipwright gave me the best tip ever. Use a cabinet scraper rather than sanding! It's so much quicker and easier and you can control what and how much you take off. I've been to the boatshed this morning and scraped the whole topside of the boat in about 2 hours leaving just a quick sand to go. Yes the frames are a long way apart on this model and you have found an issue with that. In that case I think I would have cut patches of light fibreglass to fit between the frames and epoxied them in on the inside. Hopefully the thickened epoxy you've added will do the job but a sanding filler in epoxy makes it thicker but weaker. You can buy other fillers that will retain the strength. I hope I haven't worried you with that but if I were you I'd be floating it again with enough ballast to bring it to its lines and leave it for a few hours. Better you find a failure in the tub than on a lake.

- 72 replies

-

- Seguin

- BlueJacket Shipcrafters

-

(and 2 more)

Tagged with:

-

Keith, I mentioned a while back that I had to find a new place to live and a big deciding factor in moving here was the Lake Macquarie Classic Boat Association. A "Mens Shed" type arrangement, we are a group of like minded retirees that like messing around with small boats and we can build boats for ourselves with the help of many hands including a couple of shipwrights. It's a great environment and there's always something new to learn be it boat related or not.

-

I doubt they used rowlocks in those days or those ships, more likely thole pins or similar which don't allow feathering.

- 536 replies

-

- Quadrireme

- radio

-

(and 1 more)

Tagged with:

-

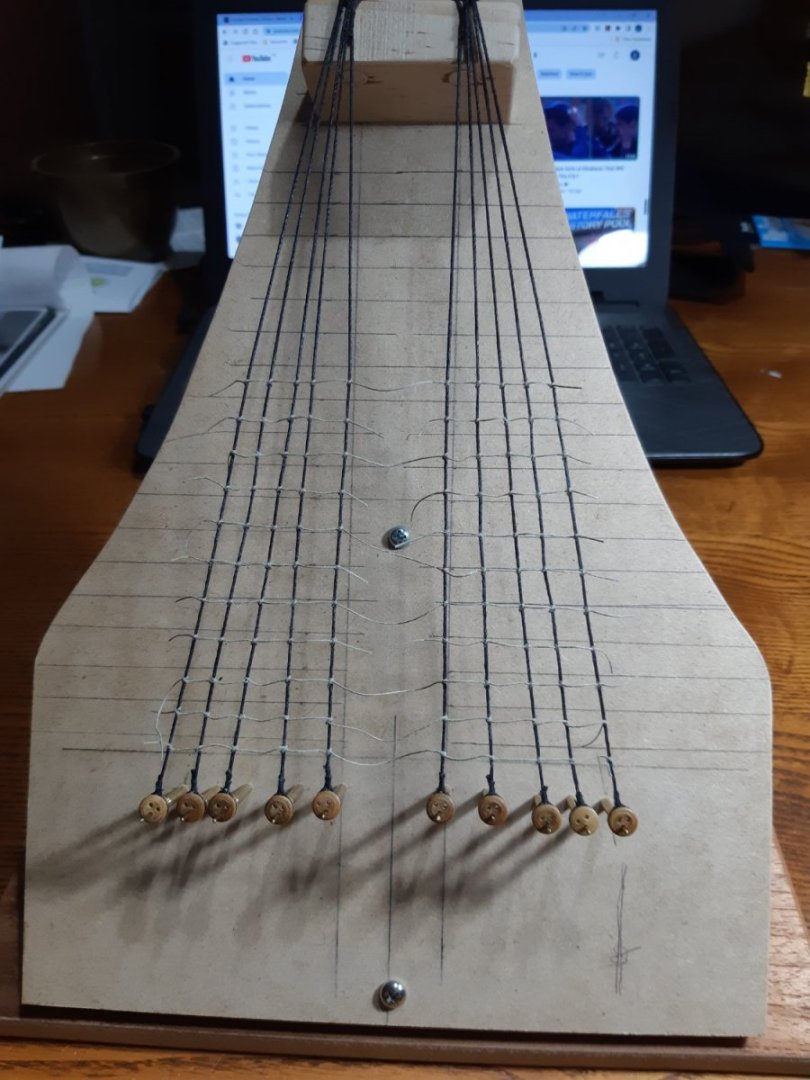

Well it's been quite a while between drinks on this build, mainly because I just haven't been happy with the chain plates and couldn't see a solution so I walked away. I have also been somewhat engrossed in a slightly bigger project..... I found a viable solution to the chain plate issue and was given an Amati shroud rigging jig which I promptly threw away but kept the pins. It didn't suit the lay of the shrouds on this ship and what's the use of a jig that doesn't let you mount the dead eyes until it's off the jig. I centre drilled each pin and inserted a length of 1mm brass wire so I could measure up the shrouds, drill holes in a jig for the pins and fully create the shroud including dead eyes before the rat lines. It's a lot easier than doing them in situ.

-

Just another thought on the lead shot ballast, if you pour it in loose and spread it around to where it works best you can then pour a little epoxy over it to secure and seal it.

- 536 replies

-

- Quadrireme

- radio

-

(and 1 more)

Tagged with:

-

Sorry to hear of the heart attack but very happy you've recovered and are back on deck. You've been missed as have you amazing skills!

- 2,215 replies

-

Shame about the planks but as you suggested, it's not a real concern, The rest of what you've been up to is beautiful, and I love a good pic of the symmetry of frames.

-

Well done, she looks great. Inspires me to get on with my R.C.

- 124 replies

-

- panart

- royal caroline

-

(and 1 more)

Tagged with:

-

Well done, she looks great. Inspires me to get on with my R.C.

- 124 replies

-

- panart

- royal caroline

-

(and 1 more)

Tagged with:

-

More nice progress! As for filling/sealing, I reckon you can't go past epoxy. You don't want to be paying a fortune for it but you should be able to get small trial packs. You can get really thin epoxy like everdure which goes on thinner than varnish and is easy to sand the furry first coat before doing a few more. If you get some normal epoxy you can thicken it with "Q cells" or similar. This makes an excellent easy sanding filler. I know Boatcraft in Aus do trial packs of the above with their Bote Cote epoxy system.

- 536 replies

-

- Quadrireme

- radio

-

(and 1 more)

Tagged with:

-

You've come up with a very clever solution and it does look very much like chain. Well done, as usual.

-

That could have been devastating, glad you were able to salvage it. Perhaps it's worthwhile moving incomplete models inside during long pauses in the cold months? Now you're doing some very fiddly stuff fitting that deck.

-

Absolutely beautiful, are you planning some kind of cap to hide the socket head screw. A polished brass plug perhaps?

-

This is a build from which I will suffer some degree of withdrawal, every time I open the site I do so with great anticipation that Valeriy has a new post on this magnificent build.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.