-

Posts

438 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Q A's Revenge

-

-

-

Good point. I suppose it would increase the cost of the kit though and where should the manufacturer stop? Should they supply the paint as well for example or sandpaper?

- Canute, CaptainSteve and mtaylor

-

3

3

-

my only comment is it is very difficult to cut out a curved frame or any part with curves with a table saw. Personally i never owned a hobby table saw and never missed having one. my first purchase was a 10 inch band saw you can cut curves pieces as well as resaw with it. Multi tasking.

my very first planked hull i ripped the planking material down with a small bandsaw then planked up the hull. Yes some planks were thicker some thinner, they had saw makes on the surface. Step two i used a $2.98 pack of sand paper and sanded that hull smooth as glass. Could i have done any better with all the fancy power tools? nope only faster and to be honest i am in no hurry. I am an artisan not a machinist.

So do you need a table saw? not really

I'm given to understand that In years gone by the Bandsaw was regarded as the "king of saws" for the very reasons you've mentioned. I would have thought a modest bandsaw would be far more useful.

-

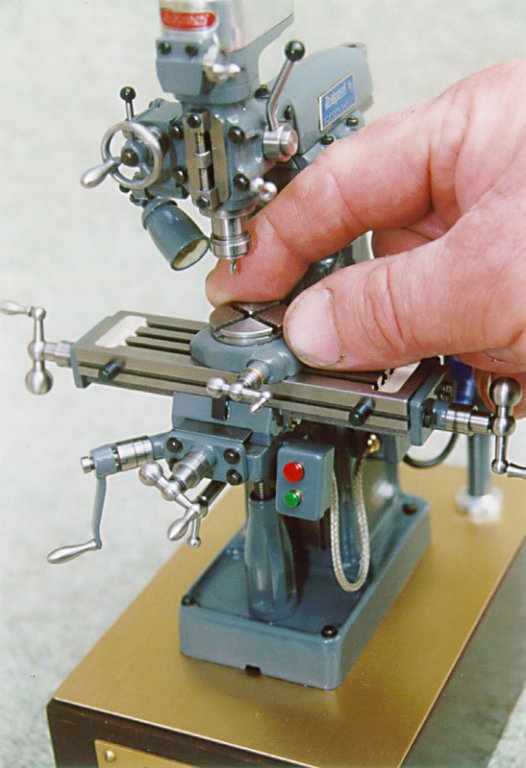

I'd like one of these, a fully functional miniature Bridgeport!

-

Some people don't know it these days, but scrapers used to be used rather than sandpaper for smoothing wood. And scrapers are much faster than sandpaper, if properly formed and burnished. And they leave a finish that is hard to describe, which sanding doesn't. In fact, I may choose to scrape the decks of my current model rather than sand it...

Matt

Agreed, scraping leaves an almost polished finish on many woods. The problem is most folks (me included!) don't know how to sharpen a scraper properly.

- mtaylor, thibaultron, Canute and 2 others

-

5

5

-

I sometimes grind down a (thick) nail to a razor sharp point and use it as a chisel.

Masonry nails are very hard steel. I once saw an article where a guy had made a complete set of miniature turning tools from them. If memory serves the nails were something over 1/8" diameter and 3 or 4 inches long.

- tkay11, thibaultron, michael mott and 2 others

-

5

5

-

-

-

I've cut softwood on my mill at its top speed of 2540 and it's doable with a slow feed but not ideal. There's a nice little Sieg X1 mill and clones out there that run at a speed of 100-5000 rpm which may be a better bet for those intending to cut a wide range of different materials.

-

I've got a 12" Bandsaw and ripped up some lime into nice 1.5 x 7mm strips the other day. Unlike a table saw bandsaws can cut both straight and curves. Full size drill presses often don't have a chuck that will take very small drill bits and don't run fast enough anyway. A 1" belt sander is great for small stuff and unlike a disc sander you can swap grits quickly.

-

-

-

-

Is it me or are these instructions pretty poor?

http://billingboats-direct.com/estore/instructions/billing/bb605.pdf

There is only one page of construction notes for the whole kit. Unless I've missed something some parts aren't pictured at all in the diagrams.

-

Although the most common size of bore is 1" which presumably would require an adaptor there are other sizes available which may fit directly.

-

I also bought the three piece fly cutter set. Waste of money as I only ever use the largest one I've got!

I couldn't afford a clamping set when I first got my mill which is just as well because I made/bought individual clamping elements as I needed them. It's worked out far cheaper.

Safety specs - prescription ones are good if you need them.

1-2-3 blocks are very handy

11/2" square to get into tight spaces setting stuff up on the mill.

1" paint brush painted bright red so you don't loose it - great for cleaning chips off the mill vice/table.

Make a stop for your milling vice. Handy for repeat placement of parts.

Long neck LED light with magnetic base.

-

-

In that case Google "slitting saws", lots of companies sell them or check out eBay.Thanks for the answer QAR. Having had a look on the site they don't seem to have the fine-kerf slitting blades I tend to wear out most often.

Best wishes

Rob

They also sell quite cheaply at model engineering shows, that's where I've bought all mine. Often only a couple of pounds each.

-

These folks may be able to help? They say they can bore the blade to the size required.Does anyone know of a UK supplier of blades suitable for the Byrnes table saw? Alternatively has anyone got an alternative adaptor bush to suit what is available this side of the pond?

Rob

I don't think 20mm is an uncommon bore for small blades so there should be plenty of others. Worth a Google.

-

This is a great looking compact table saw not much more than the cost of a Proxxon. I wonder if you can get thin blades to fit full size saws to make them a bit more suitable for model making? Fitting a smaller diameter blade isn't likely to present any problems.

Manual here if anyone is interested:

https://www.tooled-up.com/artwork/ProdPDF/Bosch%20gts-10-j_manual.pdf

-

I had a brief look at one of the Proxxon circular saws on a recent trip to Axminster and can't say I was over impressed with the quality. It seemed over priced to me but it does have valuable features that other mini saws don't have like the ability to tilt the blade like a full size table saw. There seem to be similar saws to the Proxxon out there at a better price point, at least in some parts of the world and I would not be overly concerned by things like a poor rip fences etc as these are easily replaced. Digital calipers or depth gauges are also relatively easy to add if required to provide accurate cutting. Many folks regard foreign machine tools as a "work in progress" that once fettled by the owner provide a good compromise of price and quality, if you have the skill to do the work!

-

Microcrystalline Wax has a myriad of uses and is great for most woodworking tools. Renaissance Wax is one of the top brands but there are others. It's not cheap but it does go a long way.

- mtaylor, druxey, thibaultron and 1 other

-

4

4

-

-

They have small Japanese saws with two interchangeable blades with 17 and 22 TPI at Lidl today for £7.99.

http://www.lidl.co.uk/en/our-offers-2491.htm?action=showDetail&id=28425&ar=12

SIEG SXO micro Milling Machine

in Modeling tools and Workshop Equipment

Posted

I've always like the look of this one. It has a handy 5000 rpm top speed.

http://littlemachineshop.com/products/product_view.php?ProductID=4700