Bob Cleek

Members-

Posts

3,374 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Bob Cleek

-

Trix X acto history?

Bob Cleek replied to FlyingFish's topic in Modeling tools and Workshop Equipment

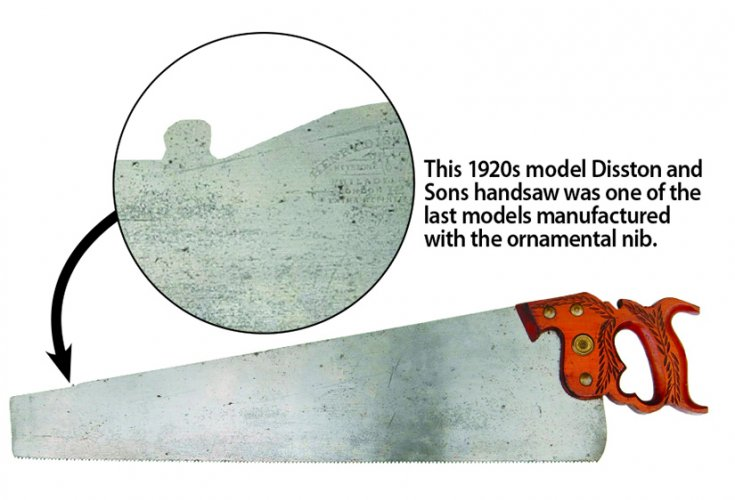

Good tool trivia question! That's the sort of question that drives me crazy. I couldn't find any thing on the internet about it. The "blister" on the heel appears in several of Stanley's smaller, simpler, cast-bodied planes. I can't think of any purpose it might serve other than to add some strength or rigidity to the casting in that place. Non-curved plane soles should be perfectly flat to work best, but a cast iron plane body such as the Stanley 101 series is slightly flexible, surprising as that sounds. (This deflection is often created when the screw holding the iron is tightened and it's for this reason that cast iron plane soles must be flattened with the irons mounted, and set above the mouth opening.) It would seem that the weakest part of the casting would have been right down the middle of the sole, were it not for the finger pad on the toe. The "blister" on the heel would complement the strengthening effect of the finger pad at the other end. These cast iron planes are susceptible to breaking if dropped on a hard surface, such as a concrete floor, so the "blister" may have been for the purpose of strengthening the edge of the heel. It may also serve some manufacturing purpose, such as perhaps simply being a vestage of a casting sprue. ... Or, like the nib on the tip of the pre-1920's Disston saws, it may just be a stylistic a trademark feature.) I'm definitely going to follow this thread and see if anybody's got a real answer and not just a lot of guesses! https://www.woodmagazine.com/tool-reviews/hand-saws/the-enigmatic-nib -

I think that he meant 1.5 times the length of the entire yard when both booms were run out, or 1.5 times half the length of the yard when only one boom was run out. In other words, the length of a stuns'l boom was approximately half the length of the boom and they were run out to extend half of their length with the inboard half of the stuns'l boom doubling the yard. I've never seen any that were otherwise. Since the purpose of the stuns'l booms was to expand the sail area, it makes sense that they would be made as large as possible, which would be half the length of the boom to which they were attached. I think the simplicity of the measurement practice was such that it's failure to be addressed in the contemporary literature is unremarkable.

-

Trix X acto history?

Bob Cleek replied to FlyingFish's topic in Modeling tools and Workshop Equipment

That's a nice little plane. It's a knock-off of a Stanley No. 101 modelmaker's plane. If kept sharpened and adjusted, it will give good service. I came by a 1970's X-acto boxed set very similar to the one pictured. It had a plastic-bodied plane that was useless. -

I suck ripping planks with my Byrnes saw

Bob Cleek replied to bigcreekdad's topic in Modeling tools and Workshop Equipment

Answer Jim Byrnes' questions above and, odds are, he will solve your problem in short order. I'm guessing you didn't realize "jimbyr" is the famous man himself. -

What were your first tools as a child?

Bob Cleek replied to FlyingFish's topic in Modeling tools and Workshop Equipment

This is the corollary to "If your mother says you might put your eye out doing it, then it's definitely going to be fun." -

What were your first tools as a child?

Bob Cleek replied to FlyingFish's topic in Modeling tools and Workshop Equipment

I got a Handy Andy boy's tool box with a selection of basic low-quality tools when I was about four or five. I think it was my dad's intention to keep me out of the drawers in his workshop. I still have the tool box and a few of the tools... a screwdriver, a hammer a square, and a (practically useless) plane. I also still have the scar on the back of my left hand that I gave myself using the handsaw sixty-seven years ago, too! -

What were your first tools as a child?

Bob Cleek replied to FlyingFish's topic in Modeling tools and Workshop Equipment

Me too! We took good care of our toys, didn't we? -

Lost Pirate Kingdom: New series on Netflix

Bob Cleek replied to Maury S's topic in Nautical/Naval History

I watched about an hour of it and gave up because it bored me to tears. I don't remember any "adult content." I guess I better watch the rest of it. That's about all that it seems might be considered "redeeming value." -

My comment about "wipe-on poly" was for the benefit of modelers outside of the US who repeatedly search for it to no avail as it is apparently not marketed in Europe. I didn't want them to think they were unfairly deprived of some magic elixir. I don't have any active build logs and don't anticipate starting any. I don't have anything to add to what the master modelers post nor do I have the time to maintain a build log in any event. Frustratingly, the impact of the pandemic on my business has left me with very little free time at all these days. I presently have four builds planned, a "generic" Connemara hooker, USS Boxer (1905), a scratch-built Charles W. Morgan "as launched" in 1841, and perhaps RMS Lucania (1893.) I'll post a few pictures of these in the "gallery" section if and when finished... if I live so long.

-

"Wipe on polyurethane" is nothing more than thinned polyurethane varnish. Only in America do people pay exorbitant prices for polyurethane varnish that is already diluted 50/50 with inexpensive thinner. It's the "instant everything" mentality. Minwax is laughing all the way to the bank. As barkeater wisely advises, always test any coating on scrap wood first to see how well it works. Always test and experiment before committing to coating the final work piece!

-

That's the beauty of modeling: You're never too old to have fun doing it!

- 2,215 replies

-

Yes, well, it may not matter if it won't be seen, but any drain located below the waterline which discharges through a through-hull fitting located below the waterline needs a vented loop between the fixture (usually a sink or head) which runs inside the vessel to a height sufficiently above the waterline to prevent the water from simply pouring into the boat up through the head or sink drain that is also below the waterline. Modernly, check valves are also employed, but reliance solely on a check valve which can fail simply by a some obstruction in the valve preventing its closing isn't considered prudent. Here's what it looks like on a head installation: The Bristol cutters and similar types are fairly deep drafted and it's not uncommon for their head and galley sink drains to be well below the heeled waterline. Head outlets are almost always below the waterline in small craft. The vented loop on your model's sink wouldn't necessarily be visible, being concealed behind the joinerwork, but any sink below the waterline at any angle of heel will require at least two pumps, one for the fresh water supply and one for emptying the sink, since the water isn't going to flow uphill. (On older well-found classic vessels, a third pump or faucet may have been present to supply salt water supply for washing dishes, etc.) Of course, modernly, where a pressurized electrical pump water system is installed, the sink faucet will look no different than a residential or recreational vehicle installation.

- 2,215 replies

-

At the risk of precipitating a complete nervous breakdown at this point... I'm just curious. Is that sink's drain well above the waterline at maximum heeling angle or no? If not, you'll have to equip the sink drain with a check valve, siphon breaking loop, and a pump to empty it out after use. Will the pump be manual or electric?

- 2,215 replies

-

The "metal spools" this chain comes on appear to be standard sewing machine bobbins. They're sort of like clamps... you can't have too many of them if you sew or have a planetary rope making machine. Handy little buggars. They make them in plastic and metal with the metal costing more than the plastic. For those who may have the need, I recently learned that chain like this be annealed and drawn through a hardwood draw plate to reduce its size somewhat within limits. I came across "wooden draw plates" in a commercial jewelers' supply house catalog and had never heard of them before, which sent me searching for what they are for. I learn something new every day on the internet! The wooden chain draw plates are used to make the links oval-shaped and of uniform size after round rings are formed on a mandrel, cut and joined to make round-link chain. Reducing the diameter can make the oval shape of chain links longer which may result in more realistic chain for certain periods.

-

I think the decision as to a stove is going in large measure to depend upon the date at which the model is portrayed. She's definitely going to be "finestkind" on all fittings and equipment, so you need to know the "when" of it all. If earlier, an iron solid fuel wood and coal stove would be called for. Later, an alcohol or kerosene stove might be appropriate. Modernly, a propane gas stove would be found on such a fine yacht. She would seem too small to carry a separate generator capable of powering an electric stove. Just my two cents' worth.

- 2,215 replies

-

Especially when working with powered drills and saws than can cause burning! Been there, done that, got the tee shirt!

- 95 replies

-

- POW

- Bone model

-

(and 2 more)

Tagged with:

-

Odd that somebody would only be selling a single volume. (The volumes each address a specific geographic area.) The seven volume set was printed in a very limited edition and originally was sold for around $3,500.00 for the set. I've recently seen an unopened set for sale at $1,2500. https://www.abebooks.com/9780881430066/Historic-American-Merchant-Marine-Survey-0881430064/plp

-

Proportional Dividers

Bob Cleek replied to Worldway's topic in Modeling tools and Workshop Equipment

Those options are also available. It's a matter of preference. I prefer a mechanical transfer of measurements because there is less opportunity for error and less thinking that has to go into it. With a mechanical measurement, any error is immediately apparent by a simple visual comparison, as well. At the end of the day, though, it boils down to what one is used to doing. Manual drafting is a skill I picked up when I was a kid in high school and, while I'm not anything near a professional draftsman, it's always been a quick and comfortable way to do the job for me. I've amassed a considerable collection of drafting instruments over the years just for the enjoyment of it. I have complete sets of Copenhagen ships curves, French curves, engineering curves, and "railroad" and "highway" curves (which have fixed radii.) I use the railroad curves for drawing deck and cabin top cambers conveniently, not often, but I've got them when I do. Similarly, I have an Omicron ellipsograph, which draws elipses to measured dimensions. I've only used it once or twice, but if I ever have to draw an elliptical stern, I'm good to go. https://americanhistory.si.edu/collections/search/object/nmah_904482 I have a couple of different "dotting pens," which will draw inked dotted and dashed lines in a variety of configurations. One can draw dots and dashes along a rule easily enough, but the elegance of the tools devised a century or more ago to do the job is fascinating. https://americanhistory.si.edu/collections/search/object/nmah_904301 I've also got a compensating polar planimeter which measures the area of irregular planes. A planimeter is used to calculate hull displacement, sail area, wetted surface, and things like that from lines drawings. Not something the average modeler would ever need to have, but it's another fun old instrument rendered obsolete by CAD these days which can be picked up for fifty bucks or less on eBay if one is so inclined. https://americanhistory.si.edu/collections/search/object/nmah_1214998 If one is a kit builder, or limits their scratch-building to plans drawn for modeling, most of this stuff is probably of little interest, but for anyone who finds it necessary to draw their own plans for modeling purposes, some of it can be very handy, albeit on rare occasions. For myself, it's mainly just an affordable outlet for my innate acquisitiveness... just another thing to collect. -

Proportional Dividers

Bob Cleek replied to Worldway's topic in Modeling tools and Workshop Equipment

No reason not to. There's more than one way to skin a cat. The handiest use I get out of proportional dividers is scaling drawings up and down. That, too, can be done with a copier, but often it's only small sections of a drawing that need to be redrawn which don't justify copying the often very large drawings encountered at 1:48 scale. -

Confusion with Halyards on stays

Bob Cleek replied to DaveBaxt's topic in Masting, rigging and sails

But then, in the contemporary model above, we see the hull planking is left bright, or, at best, newly tarred, and that would have appeared black at scale viewing distance in short order, owing to the build-up of tar and dirt and weathering. Moreover, the falls all coiled in gravity-defying perfect circles are not representative of anything existing in nature. So much for reliance on contemporary models to accurately portray contemporary subjects. They must be taken with a grain of salt because contemporary modelers seem to have exercised artistic license as freely as do many of today's modelers. This is particularly so with the so-called Admiralty Board models, which were generally not built to convey an artistic impression of reality in miniature, but rather to convey particular construction and design features which were often accentuated for such effect. At least, that's my conclusion and I'm sticking to it. I'm not sure why there is so much angst over the definitions of "running" and "standing rigging." If it "runs" through a block or a fairlead, in other words, when it's doing its work, it is intended to "run through something," it's "running rigging." If it generally just sits still, it's "standing rigging." In the days before metal cable, all rigging on a sailing vessel was made of cordage (excepting the obvious bit of chain here and there) and that cordage was made of natural hemp. The only difference in its color was the result of the amount of tar that it had on it. The color of cordage varies with its age. In the Age of Sail, cordage was generally made of natural hemp. Hemp can be bleached such that it appears quite white, but when unbleached, it is a darker, grey-er brown than the later "straw colored' "Manila" sisal cordage most people are familiar with these days and which is essentially useless for maritime rigging applications. Natural hemp will darken substantially when oiled and all cordage was oiled to preserve it. Anyone who has ever worked with real "tarred marline," which was available decades ago, will recall its color was a rather dark brown. Lanyards were made of real hemp cordage in olden times because it was the strongest cordage available and had little stretch, a quality appreciated when used for lashings and deadeye lanyards. While deadeyes permitted tightening the lanyards when they stretched, this was not, as some modelers mistakenly conclude, something that was done with any more frequency that absolutely necessary. Once a new lanyard had been stretched, it tended to stay stretched, so further adjustment was not necessary. (Keep in mind that the lee shrouds are always slack and the windward shrouds tight and that this condition is reversed each time the vessel tacks.) Lanyards would be tarred along with the rest of the standing rigging and so would end up as "black" as the rest of the standing rigging in short order. As for the presence of light-colored lanyards on some contemporary models, may I suggest that this is simply a result of the thread the modelers used for scale lanyards, which would have often been bleached linen thread, which is white or ecru and was not oiled. Now that industrial hemp growing has again become "legalized," we are seeing some "hemp" cordage coming back on the market. This newly available "hemp" cordage is apparently blended with flax and referred to as "hemp flax" or "flax hemp" cordage. For whatever reason, hemp has always been more expensive than flax (linen.) It is very difficult to tell the difference between hemp cordage fibers and flax cordage fibers, except that, upon drying, hemp fiber will twist counter-clockwise, while flax fibers will twist clockwise. (If you're wonky about such things, see: https://www.autexrj.com/cms/zalaczone_pliki/2-03-2.pdf ) Hemp twists in the right-handed direction and flax in the left. This "direction of the lay" is significant when making rope, which is made with either a "right handed" or "left handed" lay. In the marine environment, where cordage is subjected to repeated wetting and drying cycles, it is even more significant because flax swells quickly, while hemp swells slowly when wet. When rope gets wet and swells, the expansion of the strands causes the rope to shorten. (Yes, it's counter-intuitive, I know.) Hemp cordage is therefore more stable as to its length in the marine environment and thus was the preferred raw material for maritime applications, and particularly lanyards, which you wanted to stay tight once they were set up. -

Proportional Dividers

Bob Cleek replied to Worldway's topic in Modeling tools and Workshop Equipment

The procedure is very simple using a "tick strip." You take a strip of paper... (teletype "punch tape" or "ticker tape" used to be great for the purpose, but it's gone the way of the button hook these days) ... and lay it against the curved frame and mark ("make a tick") the lowest and highest points of the planking section on the tape. Then lay the tape flat and with your proportional dividers set to yield the number of plank seam divisions you require, you take up the overall length of the frame face from the tick strip with the "long legs" of your dividers. The opposite "short legs" of your dividers will yield the distance of equal plank widths on that frame length. Mark the frame lengths on your tick strip. Then take the tick strip and again position it on the frame face with the tick marks at the ends at the ends of the section of frame you want to lay out plank spacing for and transfer the rest of the tick marks to the frame face. Repeat for as many frames as you wish to divide. It's much faster than using a calculator and there's less opportunity for error because the proportional dividers require no calculation and the accuracy of the divisions yielded are easily checked by simply "walking" the points down the length of the distance to be divided. If the number of "steps" on the line ends with the point right on the last "tick" after taking the number of "steps" you desired, you know you haven't made any mistake in taking the original overall measurement. -

Thanks much, Dan. I was concerned about the strength of bone in small dimensions. It also seems to vary with respect to its porosity. It seems, as well, that the balls and sockets of the knuckle joints seem to be less porous than the long bones. One of these days I'll play around with the material and see how it works. Perhaps it might serve for blocks, but I'll have to see.

- 95 replies

-

- POW

- Bone model

-

(and 2 more)

Tagged with:

-

If you have a moment, Dan... I know this is "business, not pleasure" for you... Can you generally explain what is bone and what is ivory on this model? (I can't tell for sure from the photos.) Does it make any difference what is bone and what is ivory, and if so what difference? The reason I ask is because I've got a lot of bone handy and I've been musing about starting to use it for modeling. My wife breeds, trains, and shows champion basset hounds and we have a pack of anywhere from eight to a dozen living with us here at any one time. (We are AKC "Breeders of Merit" and ours is an AKC "Breed Preservation" kennel, not a for-profit commercial breeding kennel.) We buy sterilized beef bones wholesale in large quantities for the dogs. It seems to me it would be easy enough to cut some of these up to use for modeling purposes. (These bones are readily available at most pet stores, although large, straight leg bones may be a special order item in your local pet store.) With the diminishing availability of boxwood, not to mention its price, I'm thinking about alternatives.

- 95 replies

-

- POW

- Bone model

-

(and 2 more)

Tagged with:

-

Proportional Dividers

Bob Cleek replied to Worldway's topic in Modeling tools and Workshop Equipment

That's not a bad price at all for what's there. If you got them down to $100, you would be doing really well. The Paragon proportional dividers alone are worth that. "Anvil" was Keuffel and Esser's "second best" line out of a half dozen or so, surpassed only by their "Paragon" line. What is missing is a spring-adjustable large (6"?) dividers. These had an adjustment screw on the side of one leg which, when turned, provided extremely fine adjustment of the divider points to permit very exact measurements. There is a small dividers in the set of three "bow" instruments in the case, and the proportional dividers will serve as regular dividers comparable to the missing dividers in the Anvil set, so the absence of the large dividers doesn't limit the usefulness of the collection of instruments that are there. If one monitors eBay "drafting instruments" for any length of time, it should be easy to pick up a comparable replacement divider, though perhaps not an Anvil model, for a very reasonable price. "Stray" instruments from sets aren't worth anything near a complete cased set to the collectors' market. They show up on eBay often in "lots" of drafting instruments, which, if you are looking for a single item, can often be a very good deal. If you have any occasion to want a proportional divider, you shouldn't go wrong buying this one. They aren't making them anymore and are only going to become increasingly valuable as time goes on.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.