-

Posts

1,314 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by MrBlueJacket

-

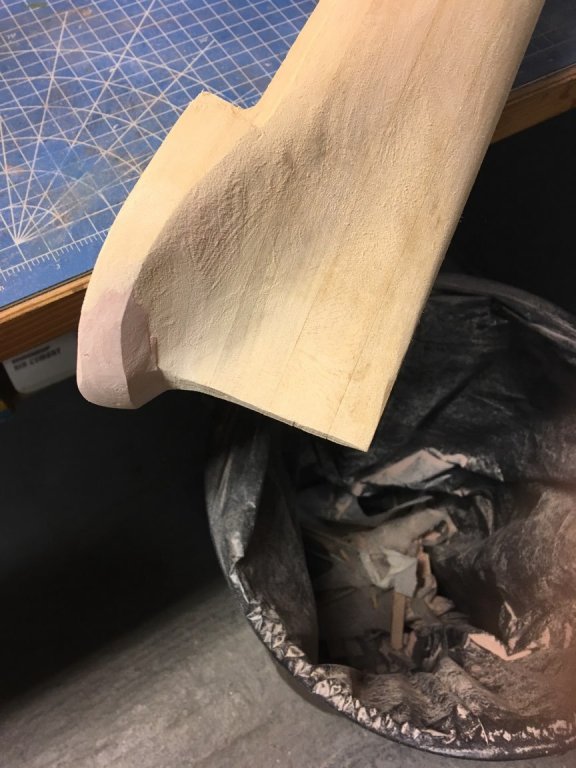

Here we are starting to sand down the Bondo And after it is sanded down, you can see where the knuckle rises up on the sides. It's not supposed to do that.

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

The stern has a pronounced "knuckle" which I lost during the sanding. So, I have to build it up with some Bondo.

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

I have used it before when fiber-glassing an R/C plane, and didn't have any problems. It seems to be sticking quite well here, too.

- 64 replies

-

- laughing whale

- trawler

-

(and 2 more)

Tagged with:

-

Although I tried to get out as many wrinkles as I can, it is not critical. When primed and sanded, the wrinkles will disappear. Any small irregularities will be puttied over.

- 64 replies

-

- laughing whale

- trawler

-

(and 2 more)

Tagged with:

-

So the bulwarks are on, and it is time to strengthen the soft balsa wood. I decided to use MinWax Polycrylic and silkspan. Here a section being applied.

- 64 replies

-

- laughing whale

- trawler

-

(and 2 more)

Tagged with:

-

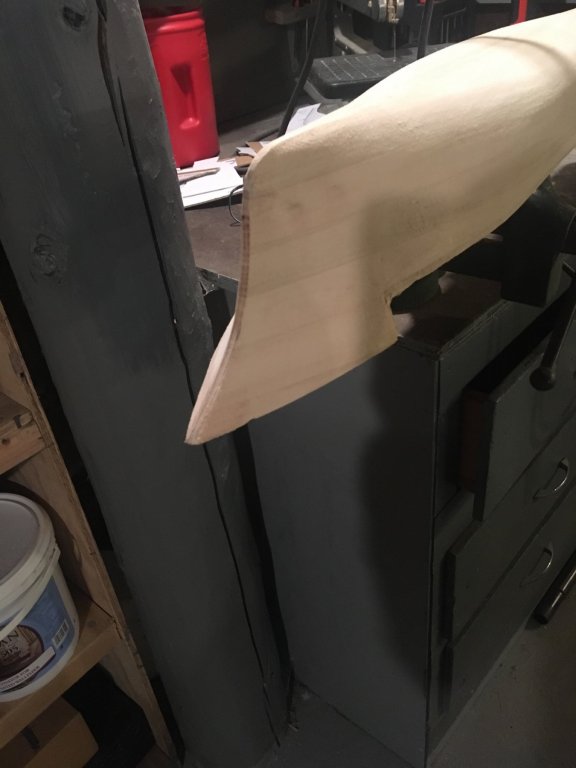

Looking good....like I said, the power tool helps a lot in the stern where the material of the carving tool mounting lug needs to be removed.

- 104 replies

-

- revenue cutter

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Need info on the BlueJacket kit "Spray"

MrBlueJacket replied to Moab's topic in Wood ship model kits

I have to chuckle a bit - older perceptions are sometimes different from reality. BlueJacket makes 78 model kits, and only 30 of them are solid hull, 12 are cast resin, 3 are plank on frame, and the rest are plank on bulkhead. -

That tool will be real handy when you attack the stern......

- 104 replies

-

- revenue cutter

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Al's grinder is a Craftsman as shown in the photo below. Also here's a link to a Makita one on Amazon. They run from about $60-$120 https://www.amazon.com/Makita-GA4030K-4-Inch-Angle-Grinder/dp/B002OTDIH2

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

Over the weekend I got the rest of the hull planked. Next will be adding the planked bulwarks, then covering the balsa with either polycrylic or polyester resin.

- 64 replies

-

- laughing whale

- trawler

-

(and 2 more)

Tagged with:

-

Al's advice is to " go gently and let the machine work." It takes the wood down in a hurry. Now I just need to finish sand to the templates and then do the bulkheads.

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

So Al let me borrow his 4" portable grinder - Boy, does that make short work out of shaping the hull! Unfortunately, I got a little to heavy-handed and it started to burn the wood.

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

- 64 replies

-

- laughing whale

- trawler

-

(and 2 more)

Tagged with:

-

And here's the dory, completed except for the seats, which will be mahogany. They will have to wait until I have painted the shell.

- 64 replies

-

- laughing whale

- trawler

-

(and 2 more)

Tagged with:

-

- 64 replies

-

- laughing whale

- trawler

-

(and 2 more)

Tagged with:

-

Starting to plank the hull - It's easy with the balsa supplied. I will coat the balsa with polyester resin and silkspan.

- 64 replies

-

- laughing whale

- trawler

-

(and 2 more)

Tagged with:

-

Actually, I have not heard anything. We actually talked about it but many are similar to our own offerings.

- 64 replies

-

- laughing whale

- trawler

-

(and 2 more)

Tagged with:

-

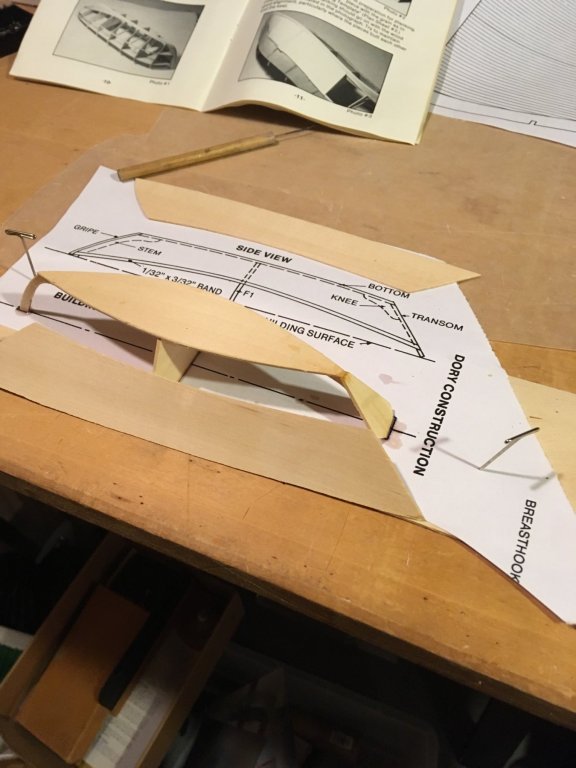

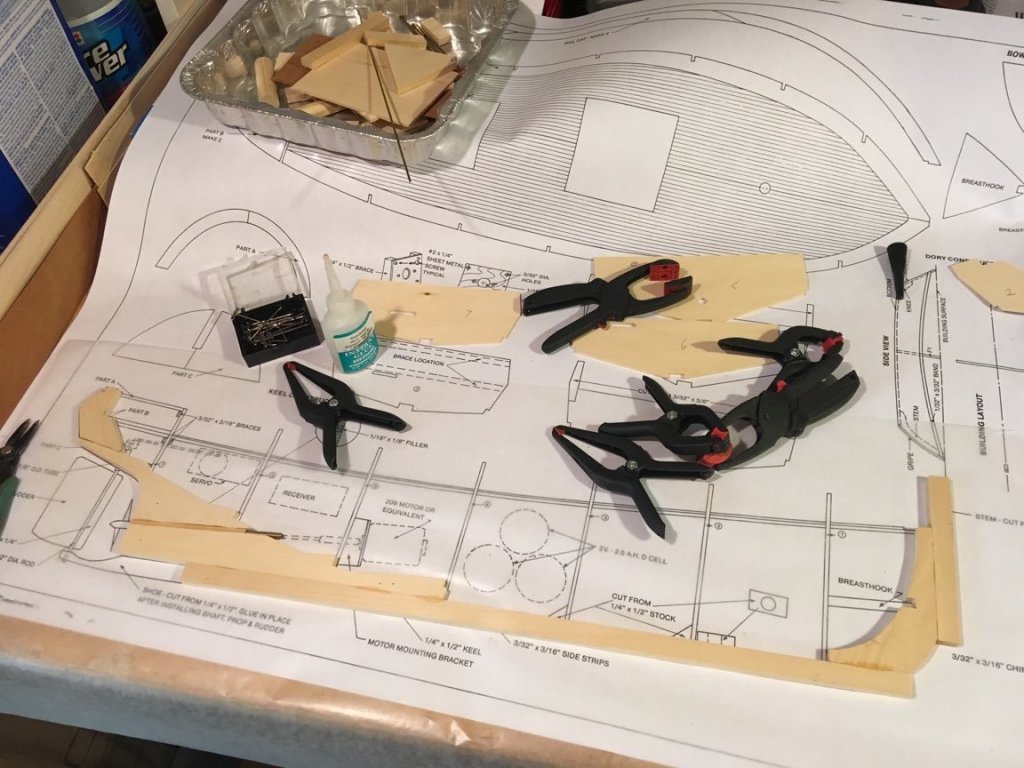

So now you can see all the bulkheads and decking in place. First photo is attaching the chine strips, second photo is the topsides, and the raised stern.

- 64 replies

-

- laughing whale

- trawler

-

(and 2 more)

Tagged with:

-

No-one will look at your model and say "you didn't overlap your plates" - instead they will say "wow what a smooth job of coppering you did" Modeling is part authenticity, but also part of the art of making it look good. Like I said in a past newsletter " putty and paint - makes it look like what it ain't" Keep up the VERY good work! Nic

- 104 replies

-

- constitution

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Jim, Looking very good. Remember, back to front, bottom to top. Of course, with butt joints it doesn't make a difference. Nic

- 104 replies

-

- constitution

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Looks like it's time to hoist the flags! Nice job......

- 43 replies

-

- virginia

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

You can see the rough hull in the first picture. I'll take some progress photos as I carve. Nic

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

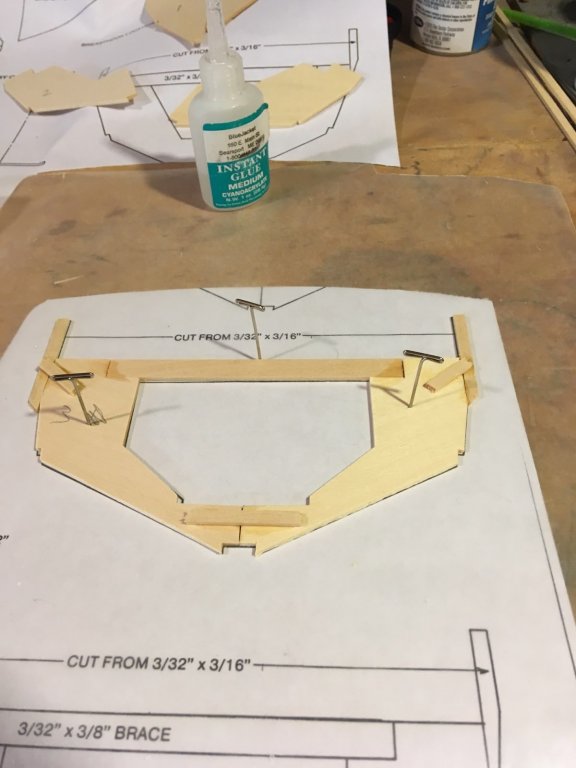

I took the previous photos on Fri. Saturday I actually started to do some assembly. Here's the keel: And one of the bulkheads. Experience has taught me that when butt gluing edge pieces, it is better to scarf a piece across the joint to strengthen it. Just be sure it won't be in the way of future assembly steps!

- 64 replies

-

- laughing whale

- trawler

-

(and 2 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.