-

Posts

1,314 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by MrBlueJacket

-

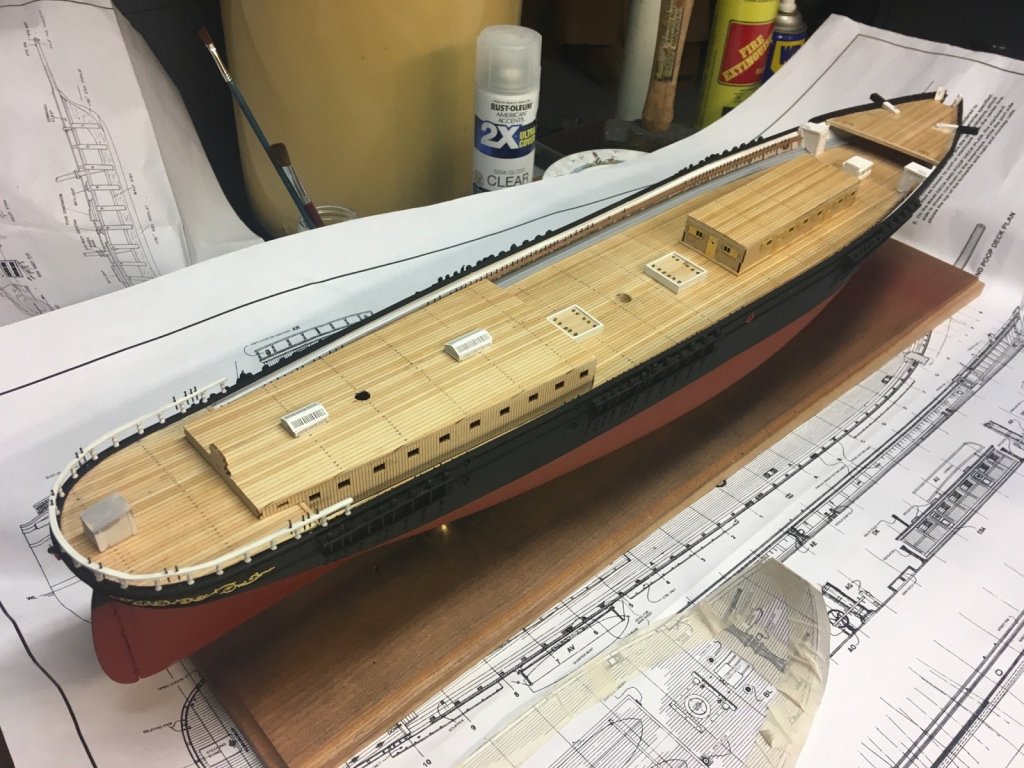

And, of course, what modeler cannot resist putting the sub-assemblies together to see what it will look like?

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

Legodude, when you finish this build, I will give you (or your designated buyer) 10% off your next BlueJacket kit. Thanks for posting! Nic

- 18 replies

-

- skiff

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

At the bow, the figurehead of "Red Jacket" (Sagoyewatha, Seneca Indian chief) was painted and mounted. His nickname is because a British soldier gave him a coat during the revolutionary war.

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

Today I put on the photo etched scrollwork at the stern. It took an hour of aligning and re-positioning and gluing to get it done. I am happy with the result!

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

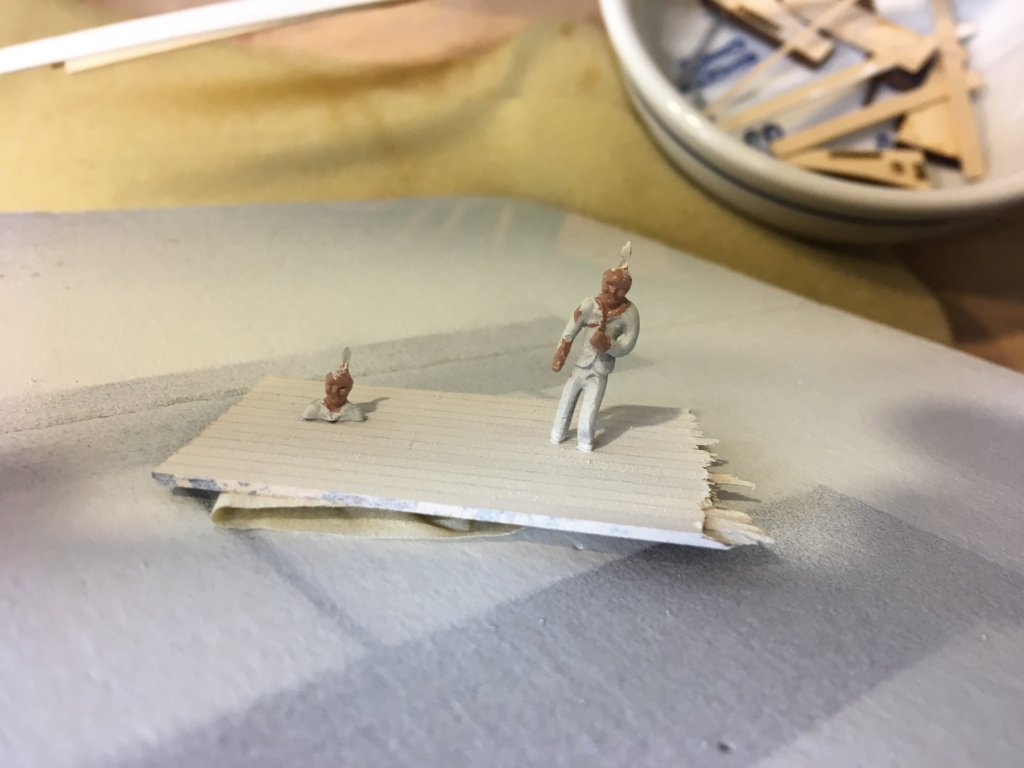

It's time to do the figurehead and stern carving. They are of Sagoyewatha, the Seneca chief of the Wolf clan. His nickname Red Jacket is because of the red coat a British army officer gave him during the American Revolution. One of the problems in painting is to mix the flesh color of an American Indian. A google search yielded plenty of advice from miniature figure painters, but they involved colors in acrylic and/or oil that I never head of. What I finally settled on is a mix of Burnt Sienna and cream. I think it came out OK.

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

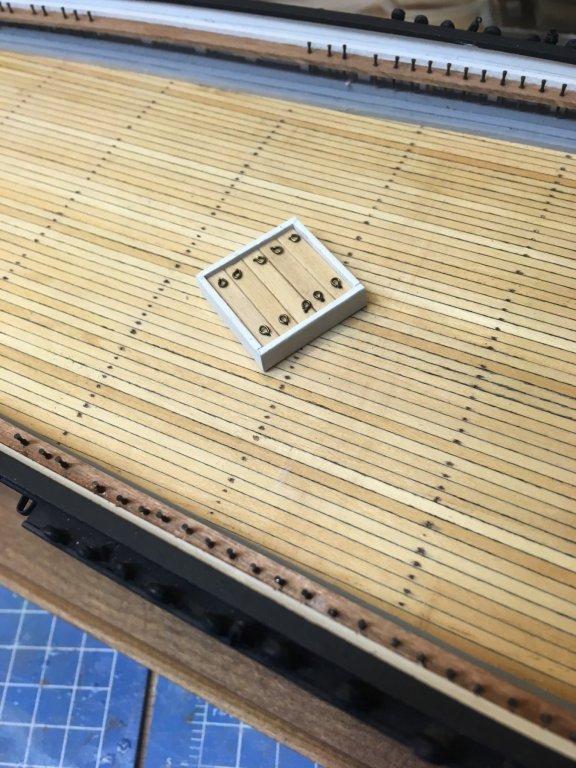

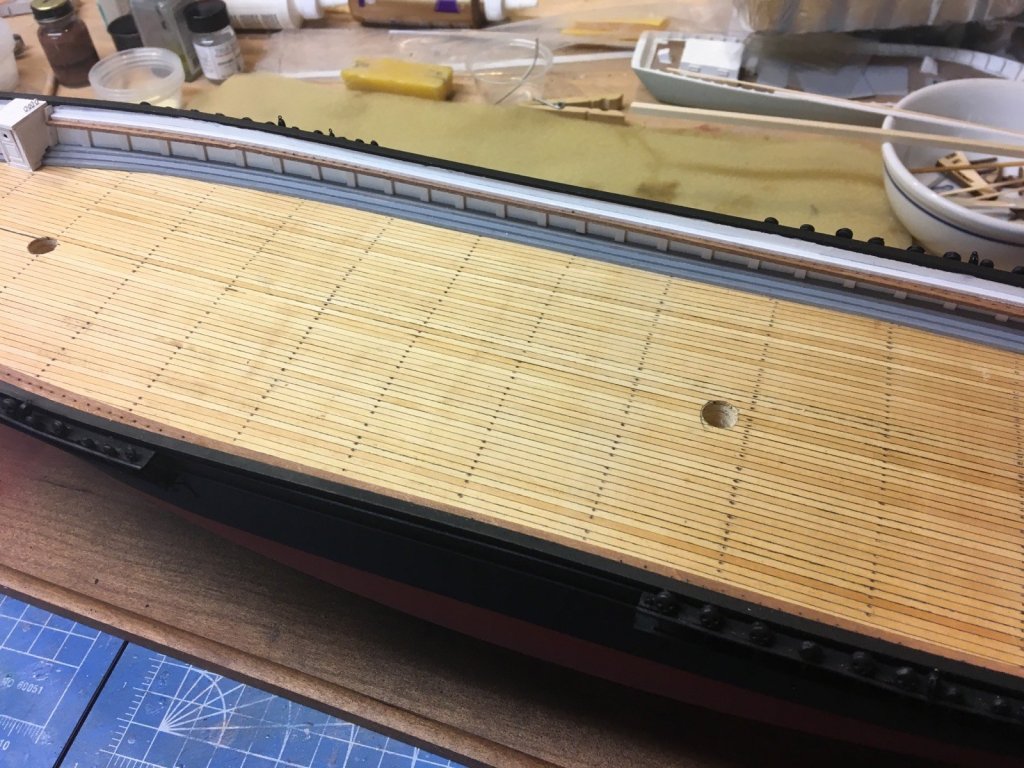

Last night I made one of the two hatches for the deck. I used eyebolts bent over for the hatch lifting rings.

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

Meanwhile, back at the pointy end............... We have installed the knightheads, catheads, hawse lips, spray rail, and some eyebolts.

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

And here's two of the 3 pieces glued down into their many little holes. There will be puttying to do to get a smooth railing at the transition point.

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

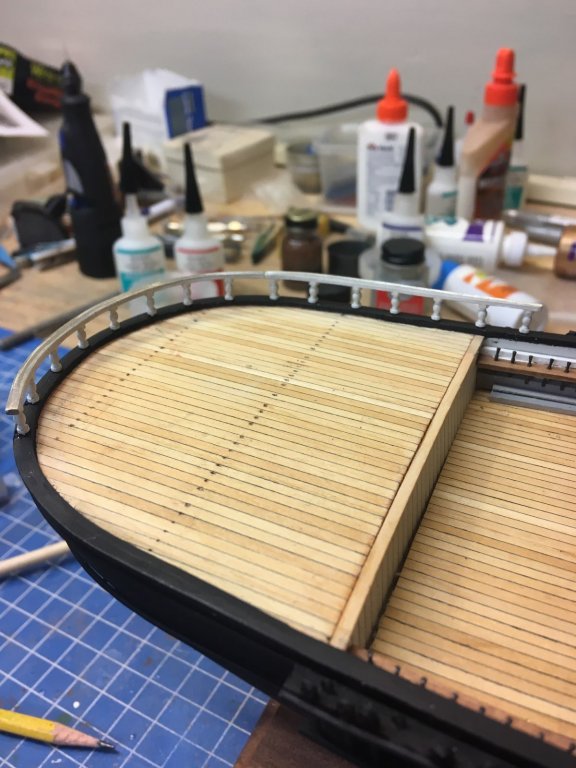

Over the w/e I started the poop deck railings. The kit provides several lengths of cast stanchions/railings. These have to be bent to fit the curvature of the stern I decided to bend them upside down, to get a more accurate curve. Then they will get painted and installed.

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

Pinrails - as promised. Now it occurs to me that I didn't have to be so precise about fitting the stanchions - the tops can't be seen!

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

To get each stanchion the correct height, the best way is to mark it in place. I use the Xacto blade to make a cut in the edge. Sometimes it needs a touch of sandpaper to fit, but mostly it goes right in. Then hold it with tweezers while you apply a drop of thin CA glue.

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

Last night I measured, trimmed and installed 34 stanchions on the port side. Each one is a slightly different length. It was a couple of hours of great fun.

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

Nice job finishing this, Jon. 10% off your next kit from BlueJacket has been added to your customer file. Thanks for the build thread. Nic

-

Take a deep breath, cross those fingers, and spray! OK it looks good, now the real test - pull off the masking tape........ HOORAY! Just a little touch-up needed on the inside of the bulwarks from the first spray job.

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

- 356 replies

-

- red jacket

- finished

-

(and 1 more)

Tagged with:

-

Further thought - where the stem separates from the hull, cut it at that point, then glue to the hull. The remaining wedge-shaped gap will be easier to fill, and the stem won't look elongated.

- 19 replies

-

- yankee hero

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.