-

Posts

540 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by shipaholic

-

Hi Ollie I built the exact same kit about 20 years ago (pics in the completed gallery here), the box artwork on mine was exactly the same so probably a similar vintage (I still have the box). When I built mine I did minimal painting because I wanted to produce more an ornamental piece rather than an exact scale model but I also did a few modifications to make it look more realistic and more like the Endeavour than it would have if I had just used the parts supplied and followed the AL instructions. I only used the wood supplied and the final outcome was pretty good, the deck planks and hull outer planking look okay. I mostly followed the instructions as there was no other reference material available to me at the time, so there a few things that are not quite right that annoy me now - the mast tops look too chunky, the line of the main wale isn't quite right and the stern doesn't look that good. The rigging blocks are fairly rough and chunky, so I individually sanded and lacquered each one which gave them a more accurate look. Every kit has its bad points but I'm sure you can make a good model from this one. Cheers Steve

-

HMB Endeavour 1768 3D Model

shipaholic replied to ODemuth's topic in CAD and 3D Modelling/Drafting Plans with Software

Fantastic work. It's great to see Marquardt's work translated to 3D. -

Today I fitted the heart and collar for the main preventer stay on the foremast. I have started making cleats, pretty fiddly because they are so small and I need about twenty four of them

-

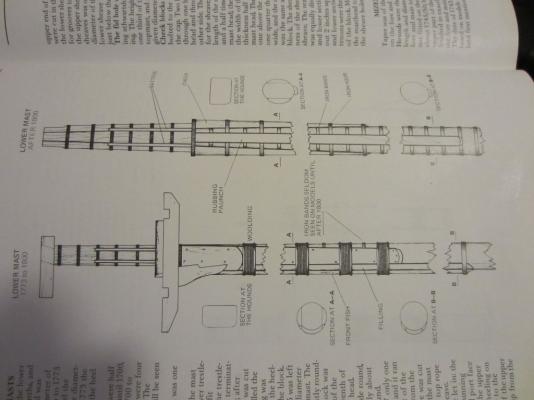

Fitting the woolding onto the masts, got the foremast top painted before running out of black paint.

-

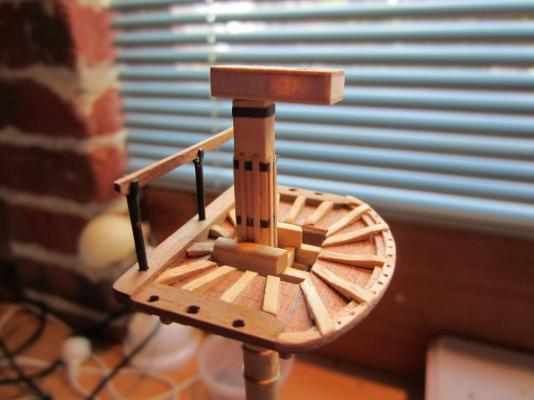

I finished the fore and main top rails today, just need to complete the mizzen top then I can paint/varnish the masts and put on the woolding rope

-

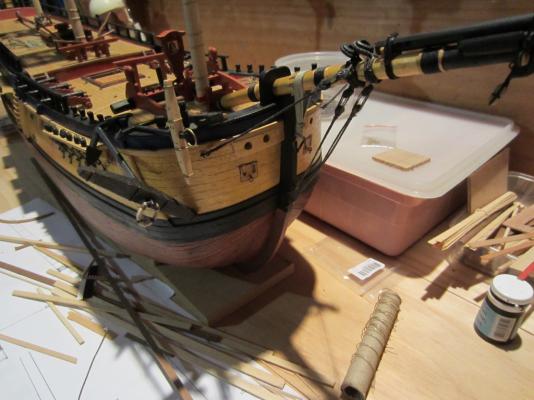

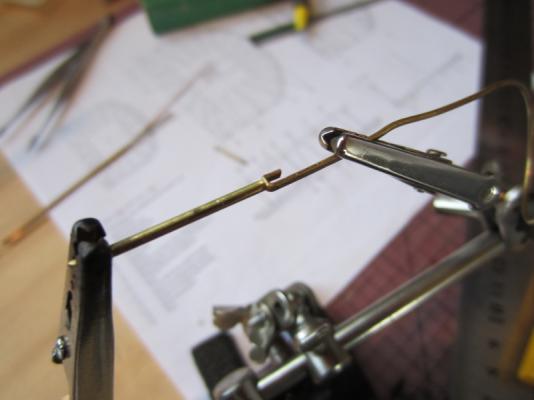

I've only been doing a few bits and pieces on the ship lately, Last week I made the jib boom, its just temporarily tied in place. Today I made the first set of four stanchions for the handrail on the fore top. I might need to make some sort of jig because they are a bit tricky to keep lined up properly during soldering using these alligator clips. I'm open to suggestions.

-

Oh no! That's terrible Greg. Bloody cats. Hope you can fix it. A cat knocked my AL Endeavour off the shelf, luckily the damage was easily fixed.

- 319 replies

-

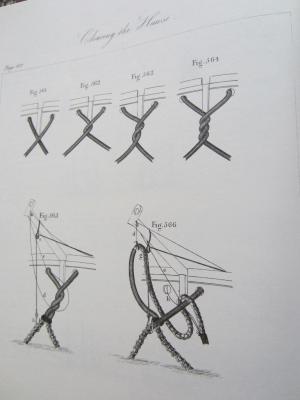

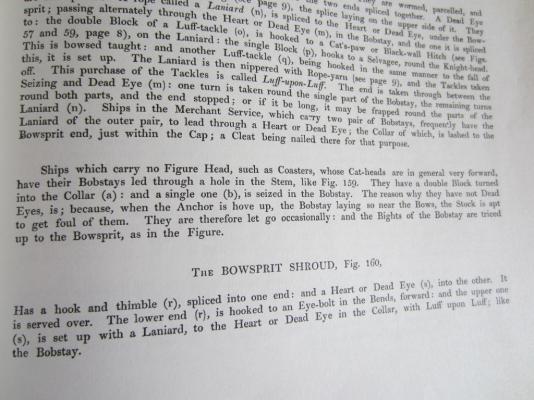

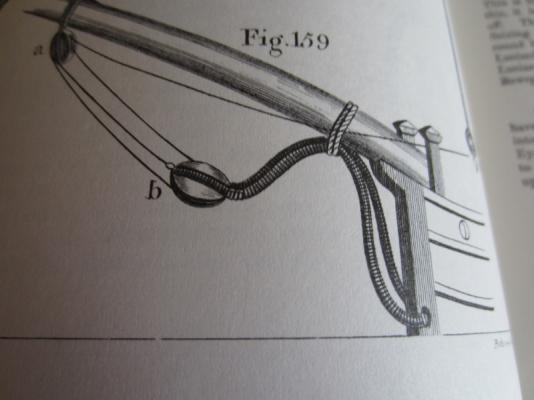

Hi Pat Can I weigh in on this one (excuse the pun) on the bumpkins Ships at anchor were very much at the mercy of the wind blowing the ship around, and it wasn't just a matter of dropping the anchor and then hauling it straight up again when weighing anchor. These diagrams from the book "The Young Sea Officer's Sheet Anchor" illustrate that fact. It seems anchor cables easily became tangled due to the ships moving around when at anchor, they even made the bobstay more adjustable on small ships like Endeavour that didn't have a figurehead so that it didn't foul the anchor cable. I cant imagine how the anchors on Endeavour would have been managed AT ALL with bumpkins fitted as shown in the AOTS. Cheers Steve

- 517 replies

-

- Endeavour

- Artesania Latina

-

(and 1 more)

Tagged with:

-

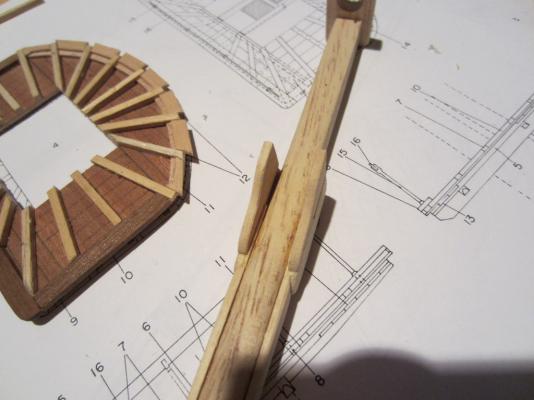

Hi Ron Do your instructions say to fit the main wales before the top layer of planks? the main wale should be fitted afer the second layer of planks. This is a pic of the first three top planks fitted where the main wale will go on my hull. Steve

-

Thanks Mike, yeah I saw the pics of your Victory, nice piece of work. I built a Corel Victory about 20 years ago but its nowhere near as good as yours.

-

Hi Slog The hoops on the masthead are made from plastic pinstriping for cars, just cut it to width and stick it on. The battens just sit on top, no notches. Cheers Steve

-

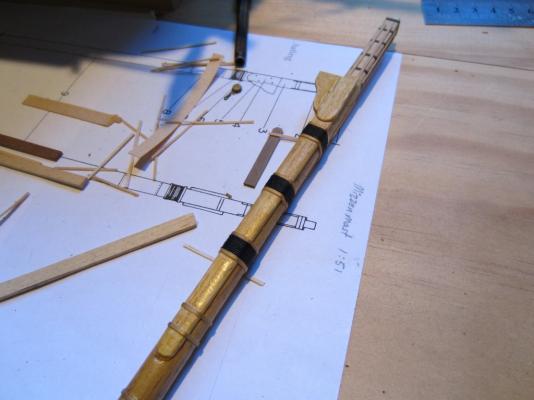

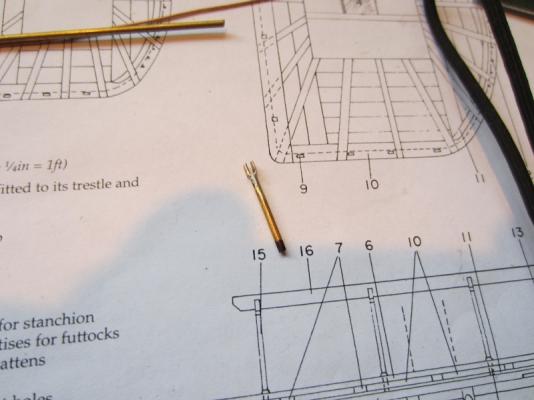

I've been working on the mainmast this weekend. For the masting I'm using the AOTS drawings which I enlarged to 1:51 scale

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.f4fa790b1fa2f0e00e3d149ed7bdd37c.jpg)